Lead-acid battery medium-density automatic packing machine anti-partition tilting and pole group overturning device

A lead-acid battery and plate-cladding machine technology, which is applied in lead-acid batteries, lead-acid battery construction, sustainable manufacturing/processing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

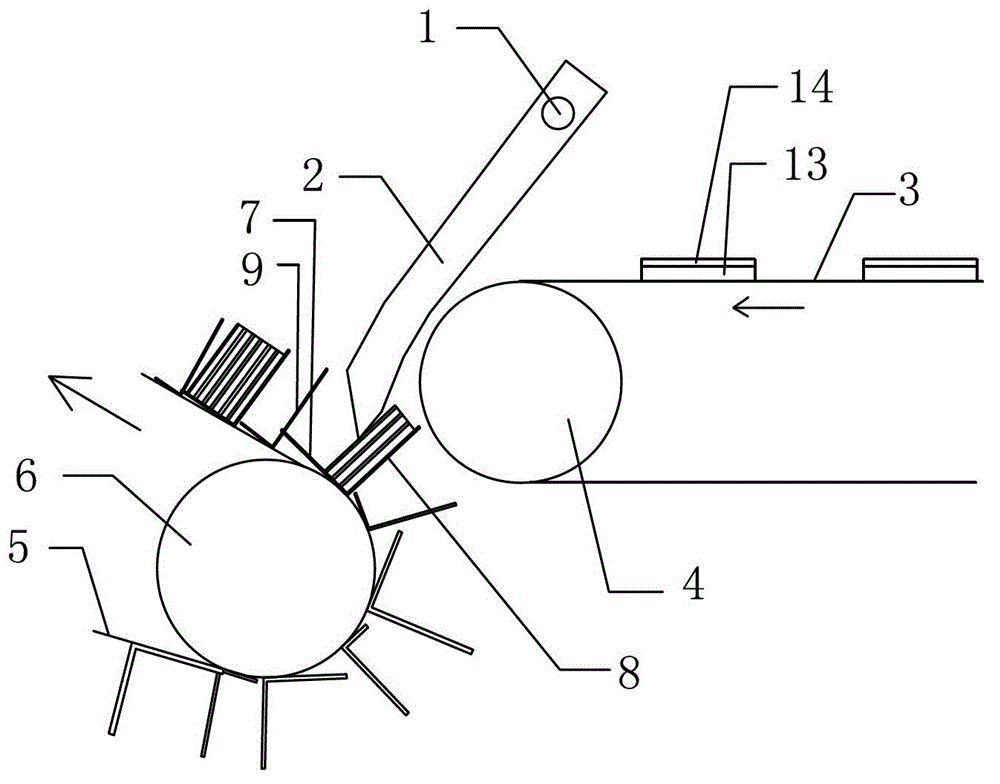

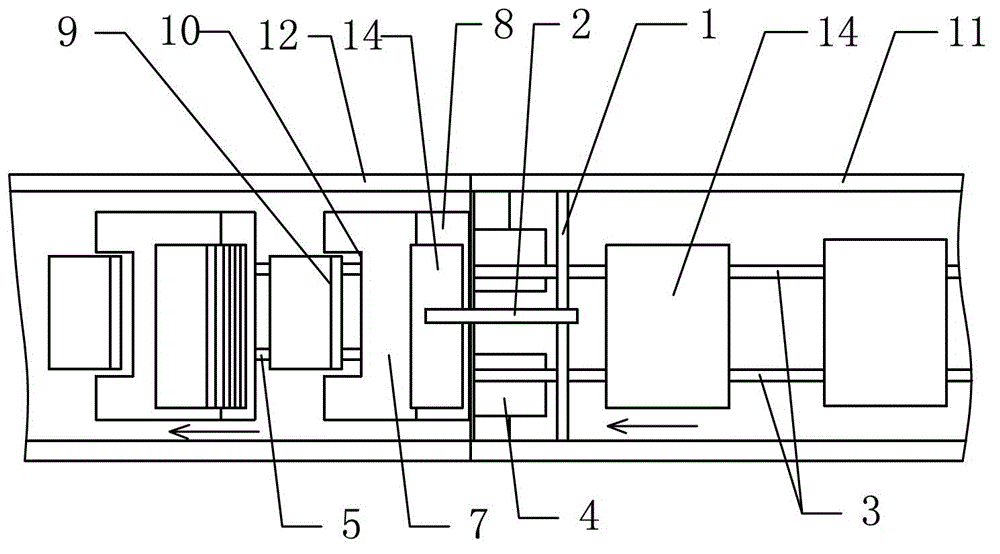

[0014] Such as figure 1 and 2 As shown, the anti-separator tilting and electrode group overturning device of the medium-density automatic packing machine for lead-acid batteries includes an output mechanism for outputting polar plates and separators and a device for receiving the output polar plates and separators of the output mechanism. The receiving mechanism is provided with a rotatable rotating plate 2 above the output mechanism, and the rotating plate 2 extends obliquely downward to the receiving mechanism. One end facing the receiving mechanism is located above the receiving part or directly abuts against the receiving part. When the pole plate and separator output by the output mechanism fall obliquely under the action of gravity and inertia, the rotating plate 2 will be lifted up during the falling process until it falls on the receiving part of the receiving mechanism, and the rotating plate 2 will touch the receiving part under the action of gravity. When the next...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com