Main electrical connection of double-bus disconnecting link section

A technology of busbar knife and double busbar, applied in the direction of busbar/line layout, etc., can solve the problems of full stop of two sections of busbar, complicated secondary protection, large investment increase, etc., to ensure normal operation, improve power supply reliability, and reduce power outages range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

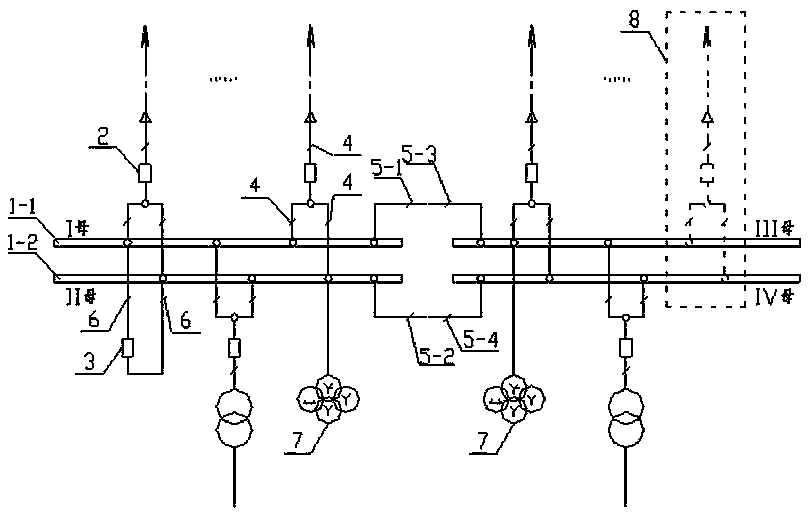

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings. figure 1 As shown, the present invention at least includes double busbars 1-1~1-2 composed of two sections of busbars, outgoing line circuit breaker 2, bus tie circuit breaker 3, outgoing line isolating switch 4, segmental isolating switch 5-1~5-4 , bus tie isolating switch 6, bus bar equipment 7, is characterized in that: double bus bar 1-1~1-2 respectively adopts two subsection isolating switches 5-1~5-4 to carry out segmentation, and in described double bus bar 1 -1~1-2 is provided with only one bus tie circuit breaker 3 and the corresponding bus tie isolating switch 6, and the section isolating switches 5-1~5-4 on the double busbar 1-1~1-2 are divided A set of bus equipment 7 is arranged on both sides of the section.

[0010] As shown in the figure, there is also an outgoing line interval 8 to be expanded on the double bus as an illustrative example.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com