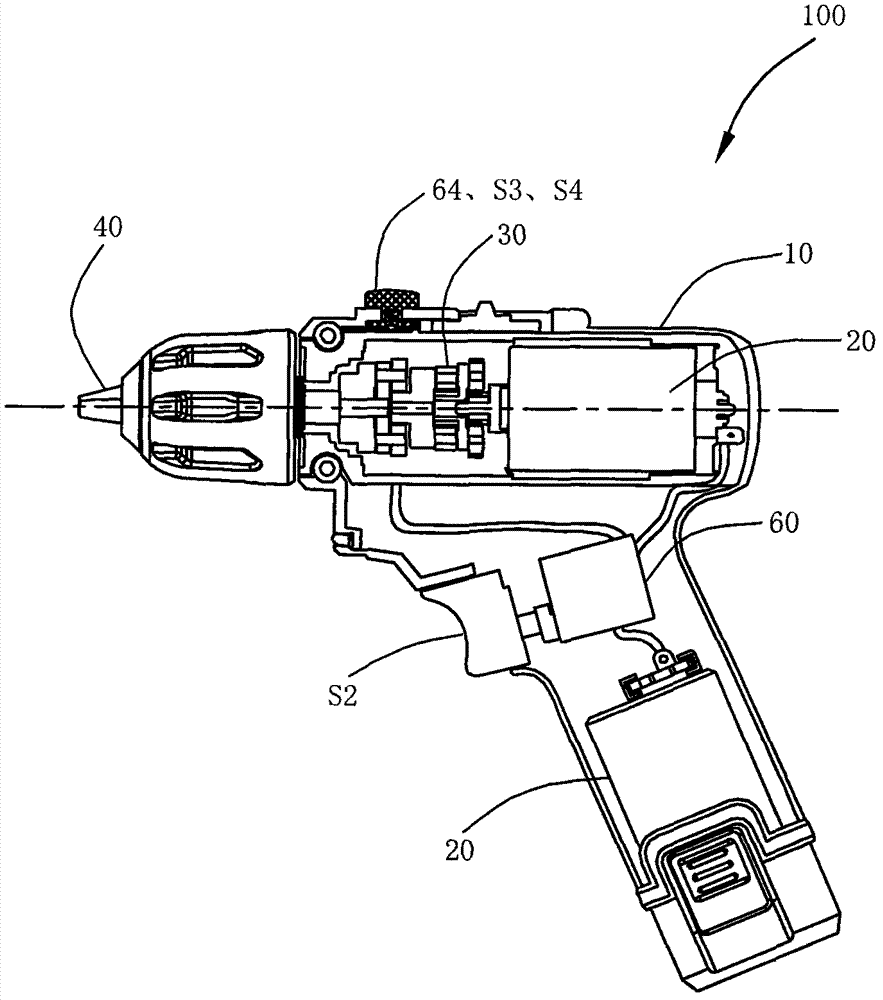

Handheld electric-driven tool and control method thereof

A hand-held power tool and control method technology, applied in the direction of DC motor speed/torque control, excitation or armature current control, control system, etc., can solve the problem of low accuracy and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

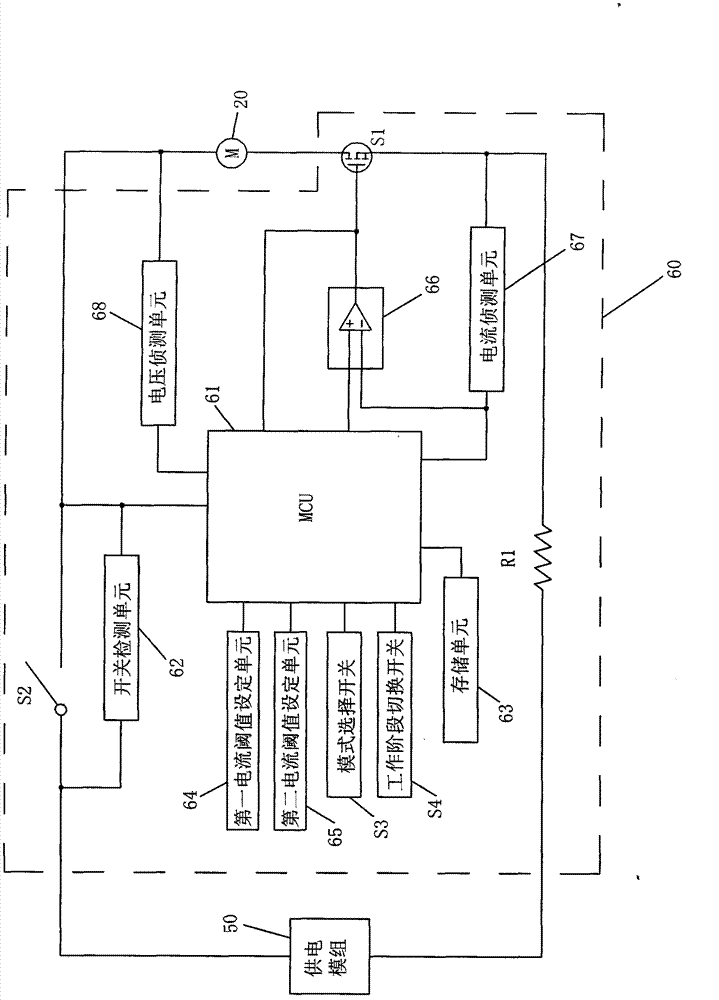

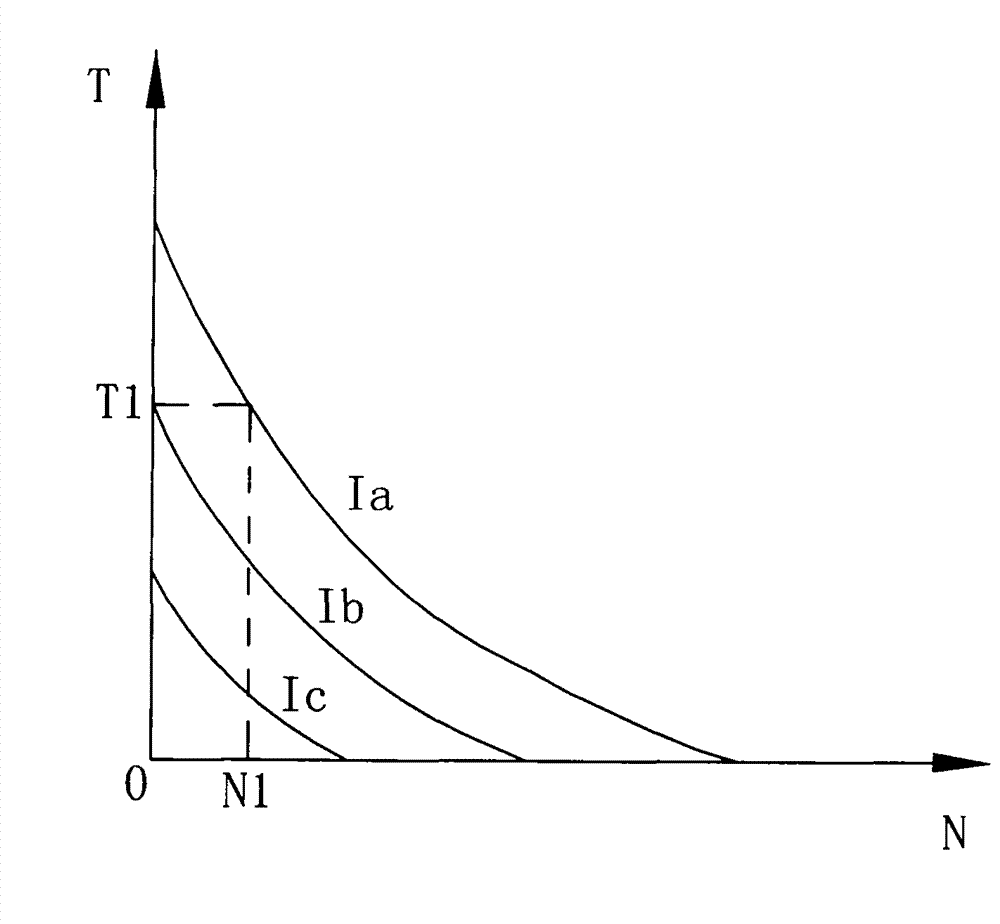

[0093] Please refer to Figure 10 , in the second preferred implementation of the manual mode, the second current threshold I2 is used as the reference threshold, and the current threshold is maintained for a period of time, and then the motor speed is maintained to complete the fastening of the workpiece. In this way, the sudden change of the motor current is prevented before the workpiece is fastened, and the motor 20 is effectively protected. Specifically, the second preferred implementation of the manual mode includes the following steps:

[0094] Step S1: Manually setting the first current threshold I1.

[0095] Step S2: manually set or automatically calculate the second current threshold I2, and the second current threshold I2 is lower than the first current threshold I1, and the first current threshold I1 is equal to the sum of the second current threshold I2 and a predetermined constant.

[0096] Step S3: The user presses the trigger of the hand-held electric tool 10...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap