Heat radiation device and assembling method thereof

A heat sink and heat sink technology, applied in the direction of indirect heat exchangers, heat exchange equipment, heat exchanger fixation, etc., can solve the problems of the heat dissipation efficiency of the heat sink and the high manufacturing cost of the heat sink, and achieve low cost and high heat dissipation efficiency , The effect of low thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

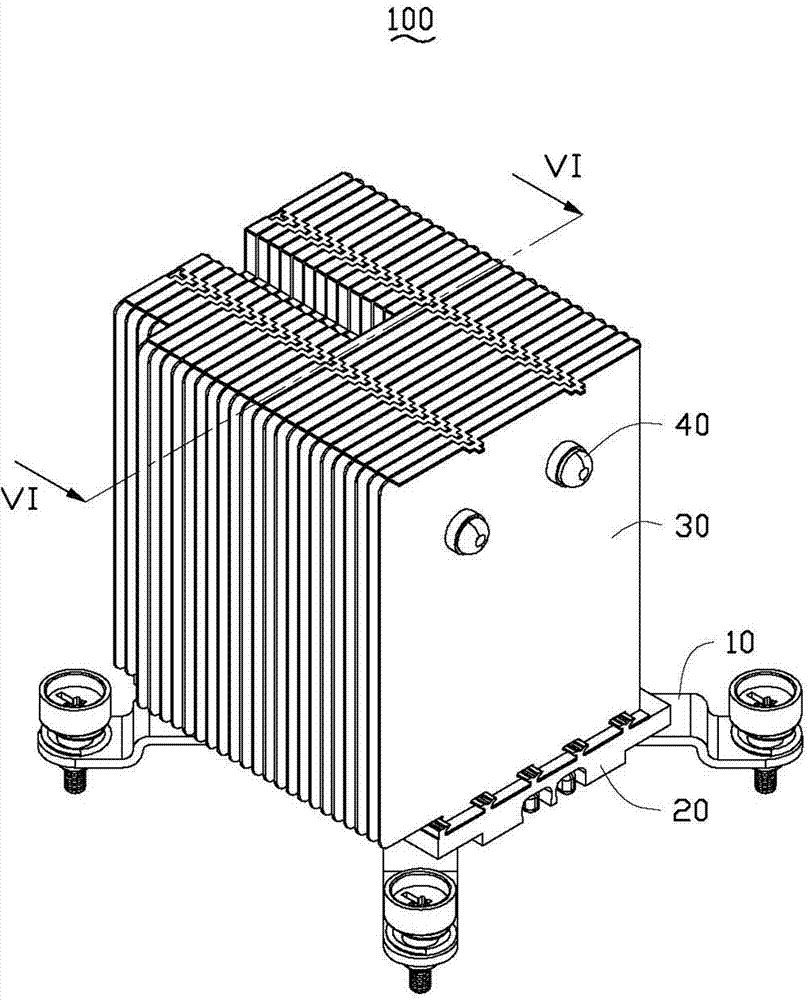

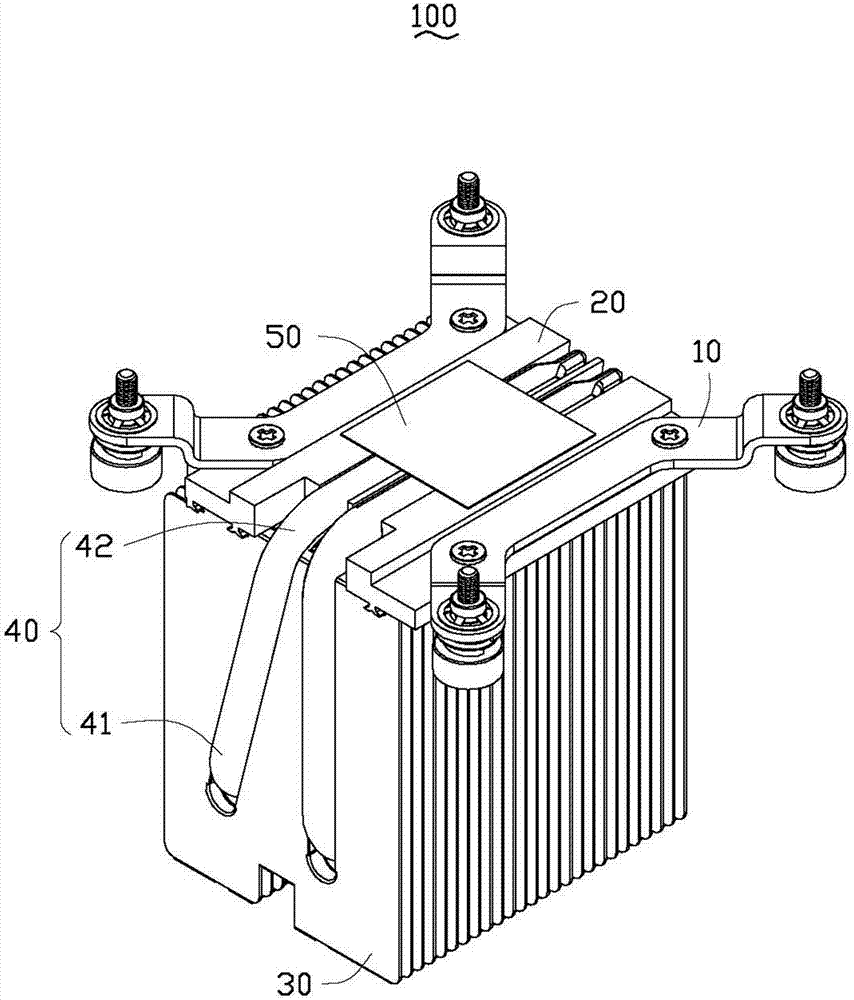

[0018] figure 1 Shown is the three-dimensional structure of the heat sink 100 provided by the embodiment of the present invention.

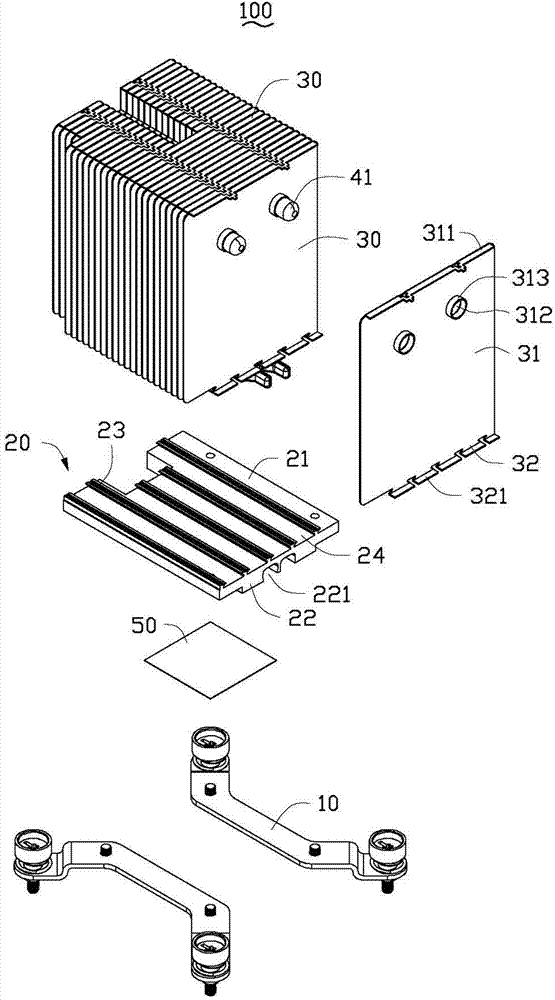

[0019] Please also see figure 2 and image 3 , the heat dissipation device 100 includes a bracket 10 , a base 20 , a heat sink set 30 and two U-shaped heat pipes 40 connecting the base 20 and the heat sink set 30 .

[0020] The bracket 10 cooperates with the base 20 for fixing the heat sink 100 on an external device to dissipate heat from the heat-generating electronic components.

[0021] See also Figure 4 , the base 20 is roughly rectangular and made of metal with good thermal conductivity, such as copper, aluminum and other materials. The base 20 has a top surface 21 and a bottom surface 22 corresponding thereto. A plurality of engaging parts 23 extending along the length direction of the base 20 are disposed on the top surface 21 of the base 20 . Each engaging member 23 includes an engaging end 231 and a supporting end 232 connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com