Punching device for bookbinding machine

A technology of punching device and binding machine, which is applied in the direction of metal processing, etc., can solve the problems of disassembly and installation trouble, disassembly and installation speed, etc., and achieve the effect of smooth chip removal, quick disassembly and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

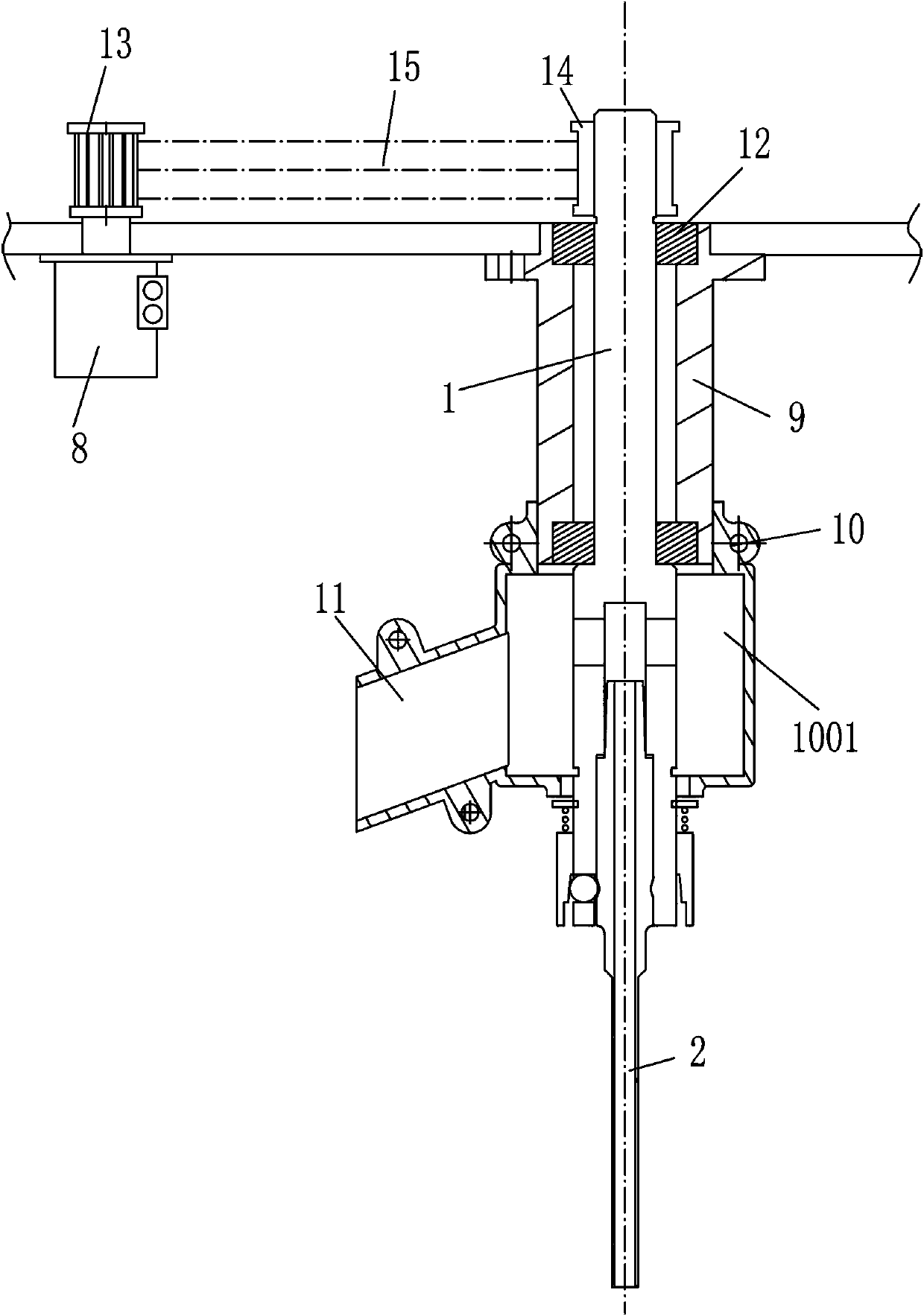

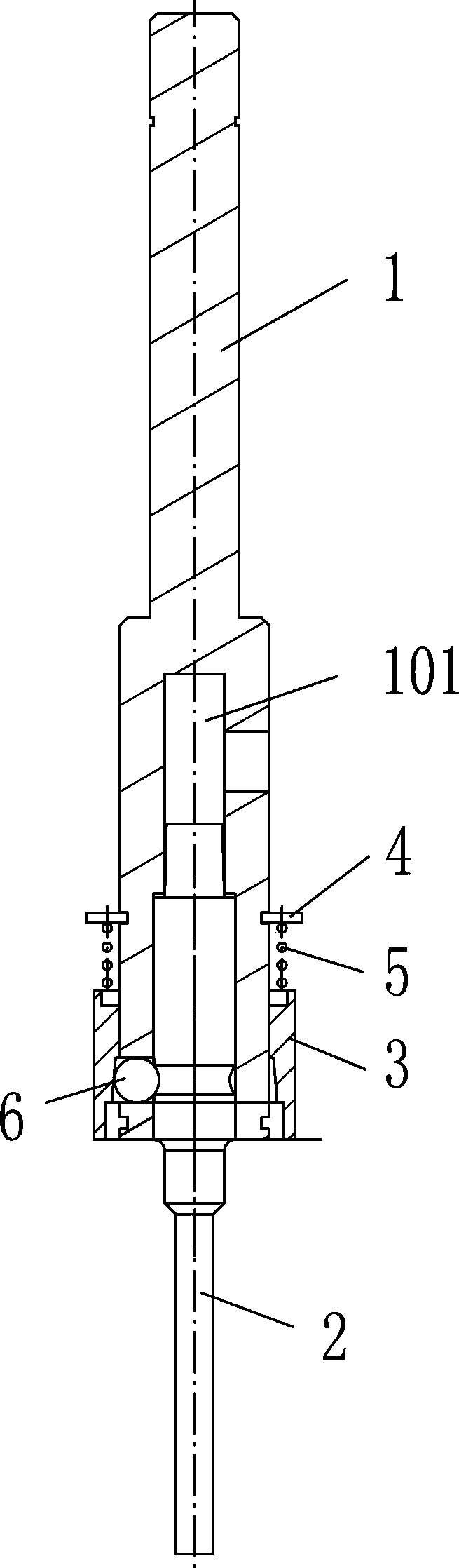

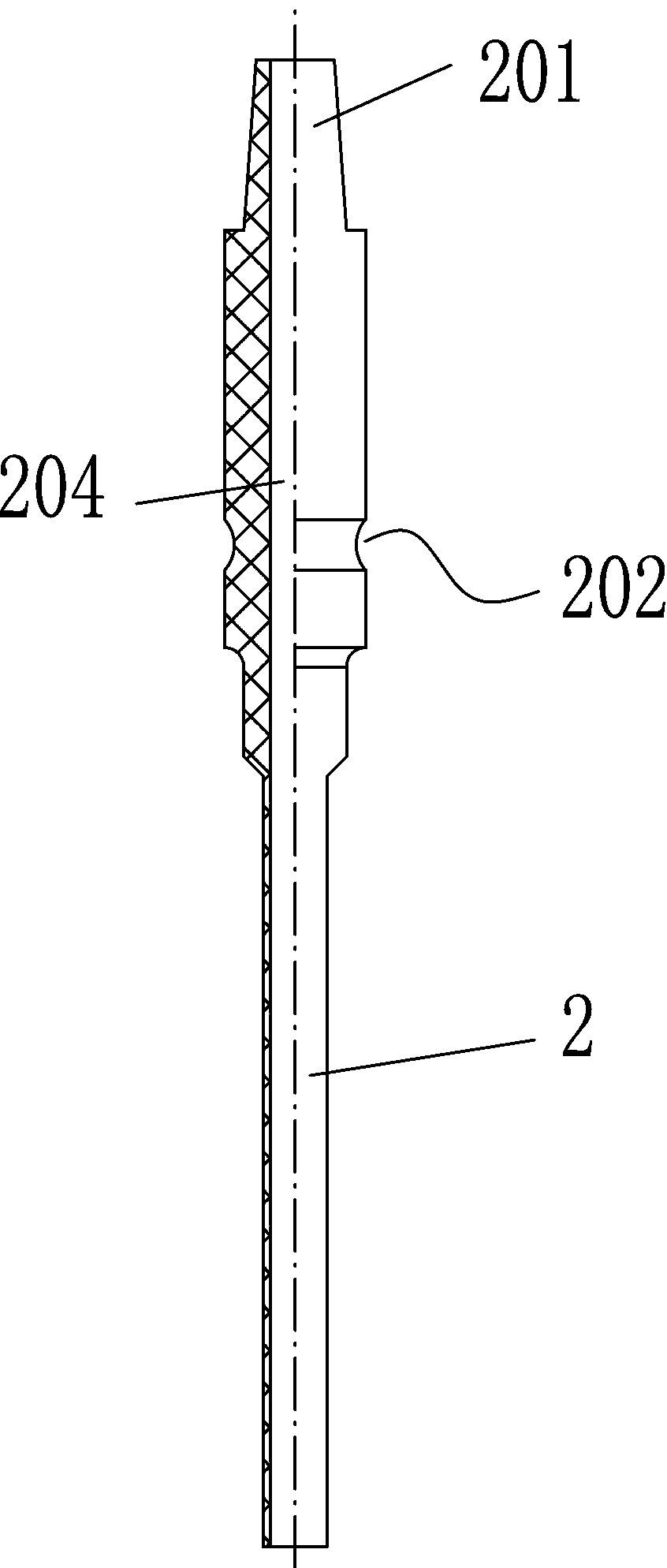

[0024] Embodiment 1, see attached figure 1 , 2 , 3, 4, 5, a punching device for a bookbinding machine, including a main shaft 1 with a connection cavity 101, a motor 8 for driving the main shaft to rotate, a cutter 2 with an inner hole 204 and an axle seat 9 for installing the main shaft , a bearing 12 is provided in the shaft seat 9, the inner ring of the bearing is connected to the main shaft, and the outer ring is fixedly connected to the shaft seat. There are two bearings 12, which are arranged at the upper and lower ends of the shaft seat. A driving wheel 13 is provided, and a driven wheel 14 is arranged on the main shaft, and the driving wheel 13 and the driven wheel 14 are connected by a transmission belt 15, of course, the driving wheel and the driven wheel can adopt mutually meshing gears. The upper end of the tool 2 is provided with a connecting block 201 fixedly connected to the connecting cavity 101, the inner hole 204 communicates with the connecting cavity 101, ...

Embodiment 2

[0027] Embodiment 2, see attached Image 6 , in this embodiment, the anti-disengagement connection mechanism includes a ball plunger 7 installed on the main shaft, and the tool is provided with a clamping hole 203 that matches the spherical plunger. Similarly, the clamping hole It is an annular groove extending along the entire outer peripheral surface of the tool. The number of clamping holes and ball plungers is determined according to the actual situation, generally 3, and the ball plungers are installed in the through hole 103 of the main shaft. The rest are the same as in Embodiment 1. Compared with Embodiment 1, the structure of this embodiment is simpler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com