Height adjustment device for car body

A car body and body height technology, applied in vehicle springs, vehicle parts, transportation and packaging, etc., can solve the problems of expensive horizontal adjustment devices, large structural space, heavy weight, etc., and achieve simple structure, energy saving, and low energy requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

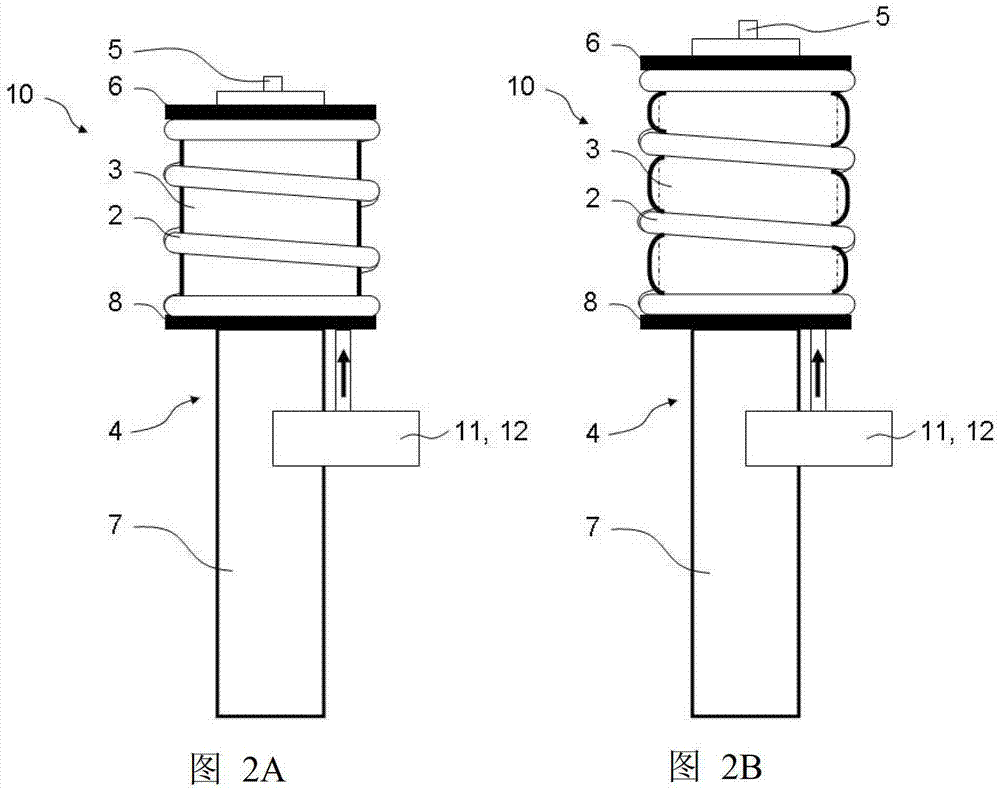

[0045] The same parts are always assigned the same reference numerals in the different figures, so that they are generally only described once.

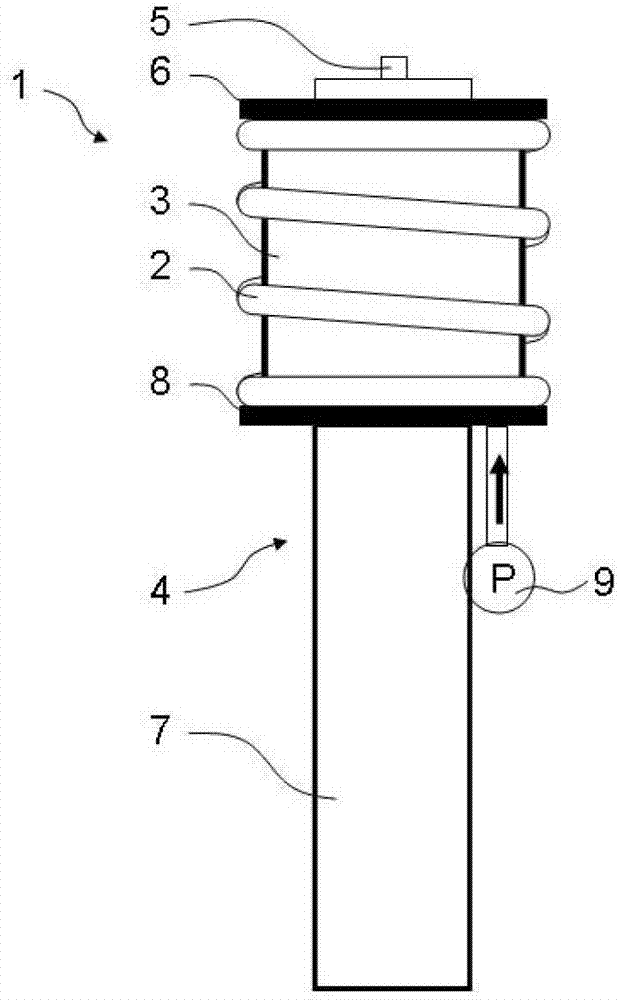

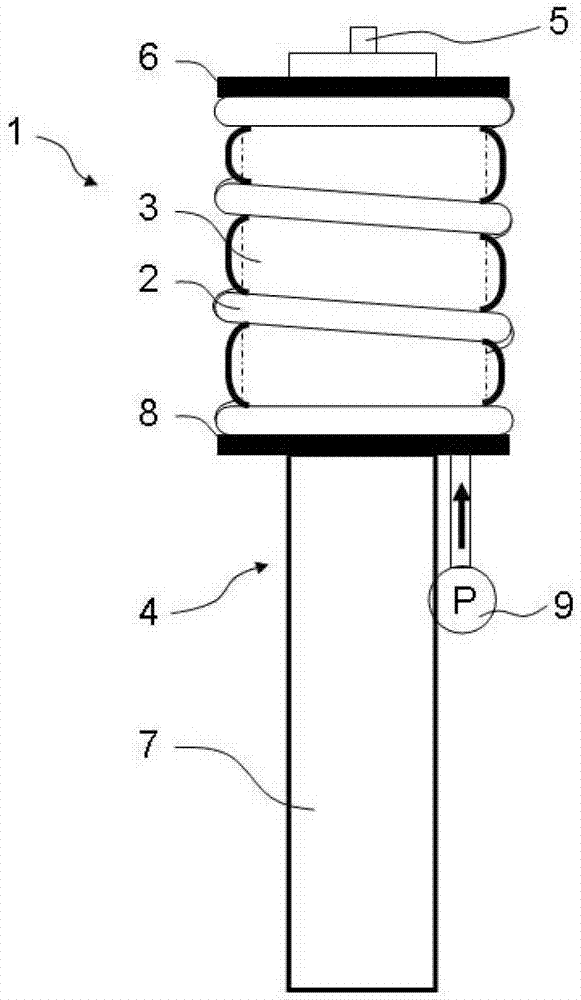

[0046] 1A and 1B are schematic side views of a device for adjusting the height of a motor vehicle according to the background art in a first low ( FIG. 1A ) operating state or a second high ( FIG. 1B ) operating state. For the body of a vehicle, in particular a motor vehicle, the device 1 has a helical spring 2 for supporting suspension parts that are movable relative to the motor vehicle body, such as wheel carriers, wheel control arms and the like. The vehicle body and suspension or suspension parts are not shown in FIGS. 1A and 1B .

[0047] As shown in FIGS. 1A and 1B , an air-tight, air-filled air hose 3 made of an extensible material is installed inside the coil spring 2 .

[0048] Furthermore, the device 1 comprises a buffer 4, for example a single-tube buffer or a double-tube buffer. The buffer 4 is connected parallel to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com