lighting equipment

A technology for light-emitting equipment and light-emitting elements, which is applied to lighting and heating equipment, light sources, semiconductor devices of light-emitting elements, etc. Effects of reduced uniformity, simplified structure, large light distribution angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

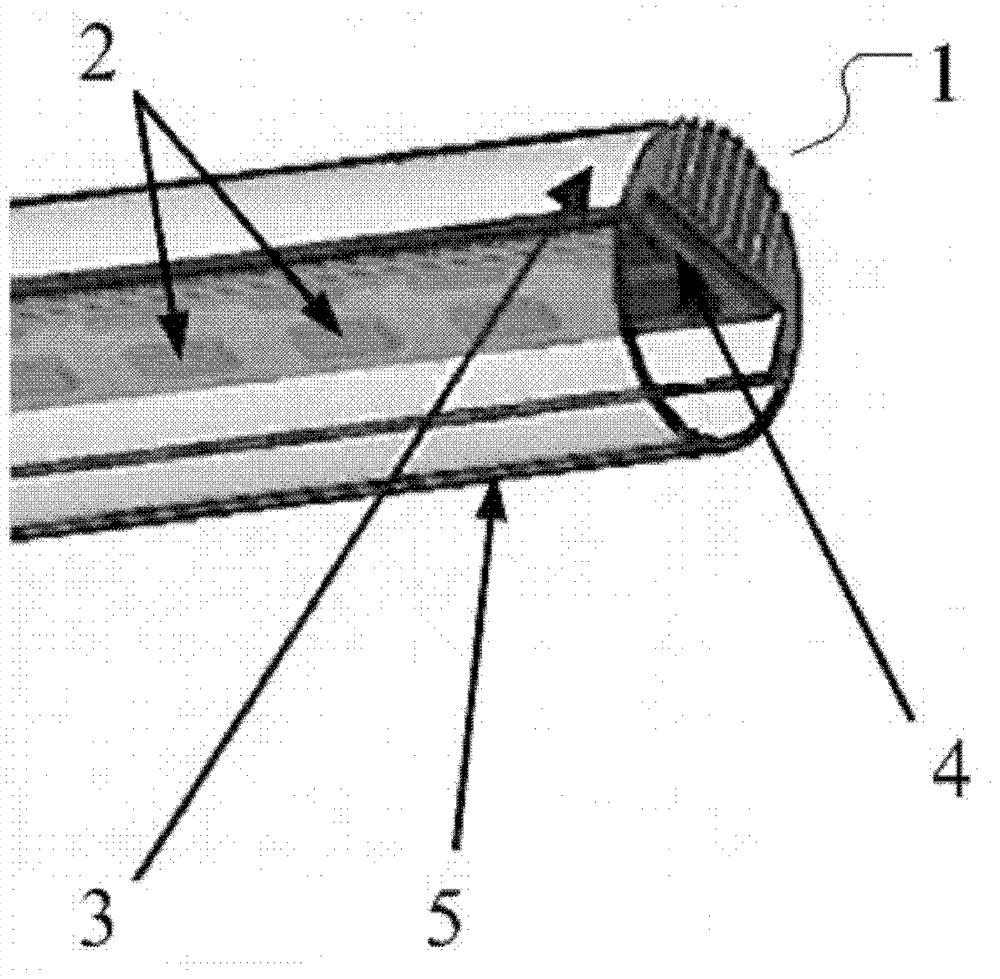

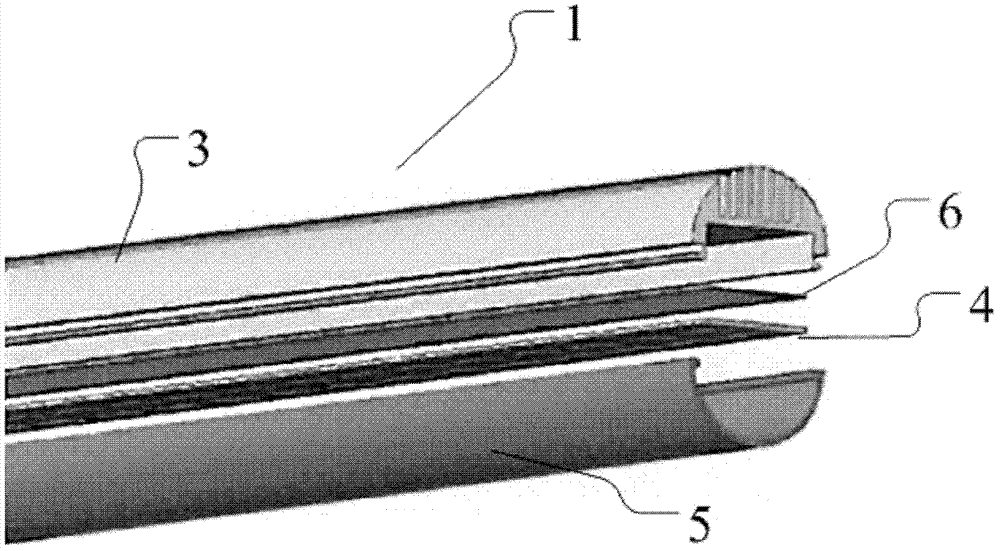

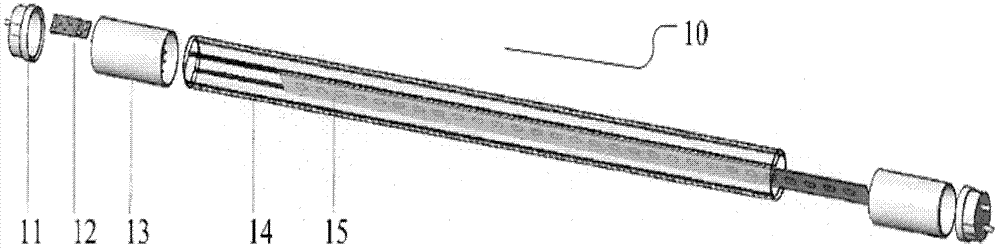

[0033] According to an embodiment of the present disclosure, there is provided a light emitting device, which includes: a light emitting element, which emits light with different intensities in different directions; a mounting part, on which the light emitting element is mounted; and a housing, which is used to accommodate the light emitting element. components and mounting parts. Wherein, at least a part of the housing is formed as a light-transmitting area, so that the light emitted from the light-emitting element can pass through the light-transmitting area and be emitted to the outside of the light-emitting device; the thickness of the light-transmitting area at each position is the same as the light emitted by the light-emitting element. The intensity in the direction pointing to the position is negatively correlated; and the thickness of the light-transmitting region at each position is gradually changed. Various embodiments and modifications of the present disclosure wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com