Liquid-immersed spent fuel storage system

A spent fuel and submerged technology, applied in the field of submerged spent fuel storage system, can solve the problems of poor reliability of the cooling system, achieve high reliability, eliminate the dependence of power supply and operators, and achieve the effect of efficient heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

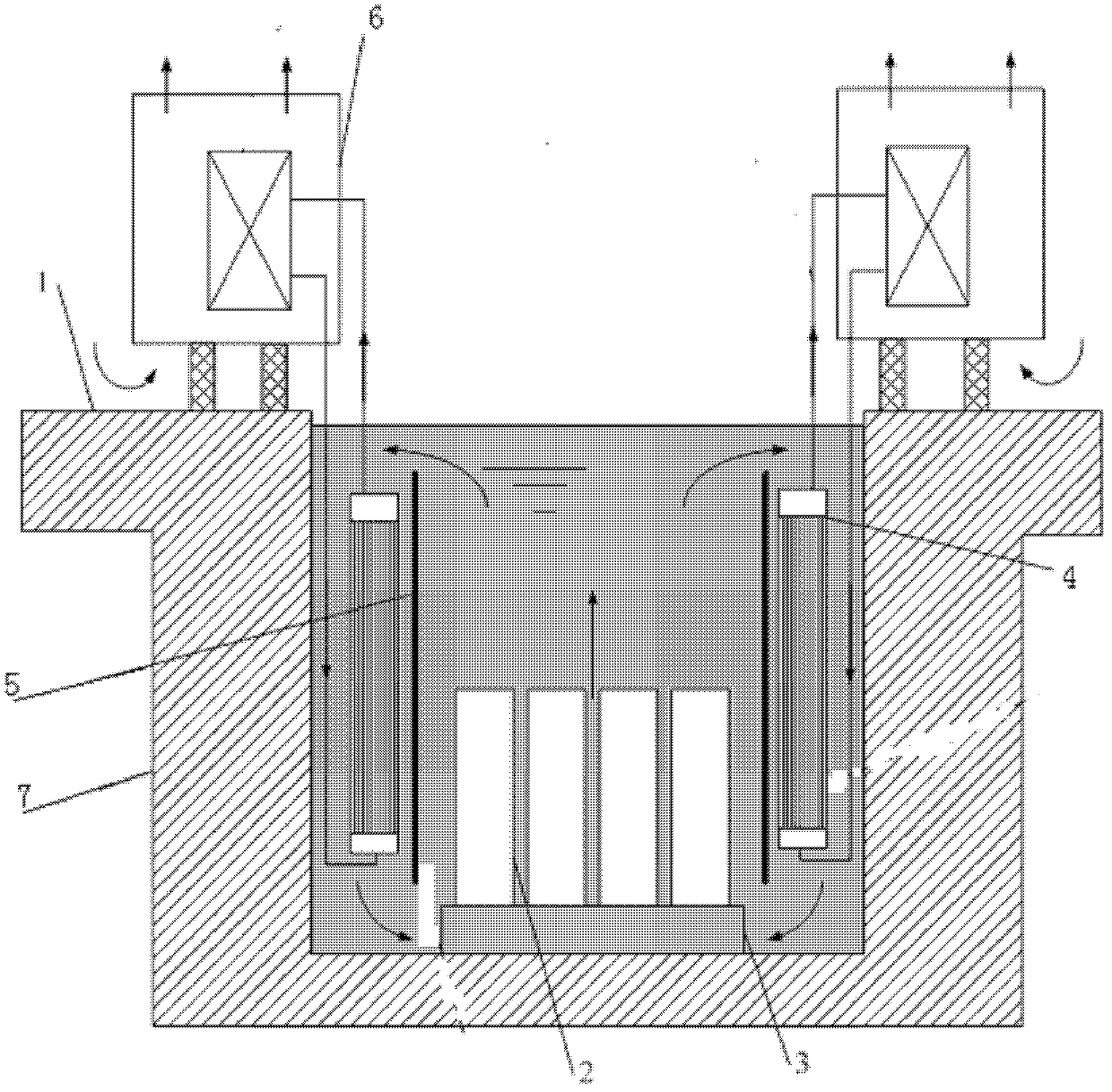

[0016] Such as figure 1 As shown, a liquid-submerged spent fuel storage system includes a closed spent fuel container 2, a spent fuel storage grid 3, a separate cooling device 4, a partition 5, an air cooling tower 6 and a spent fuel storage pool 7, on the ground 1 The cement pool is made below the spent fuel storage pool 7, and the spent fuel storage pool 7 is filled with cooling liquid. The cooling liquid is low-cost water or lithium bromide liquid that is difficult to volatilize and has a very high boiling point. The partition 5 is made of metal material with good heat insulation, such as stainless steel plate. The height of the part is 0.5 ~ 10m, which can be 0.5m, 2m or 10m, providing a passage for the flow of cooling liquid. The separator 5 is placed on the bottom of the spent fuel storage pool 7, and the separator 5 is immersed in the cooling liquid....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com