Drive system for a ball mill and method for operating a ball mill

A drive system, ball mill technology, applied in the field of ball mill drive system and running ball mill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

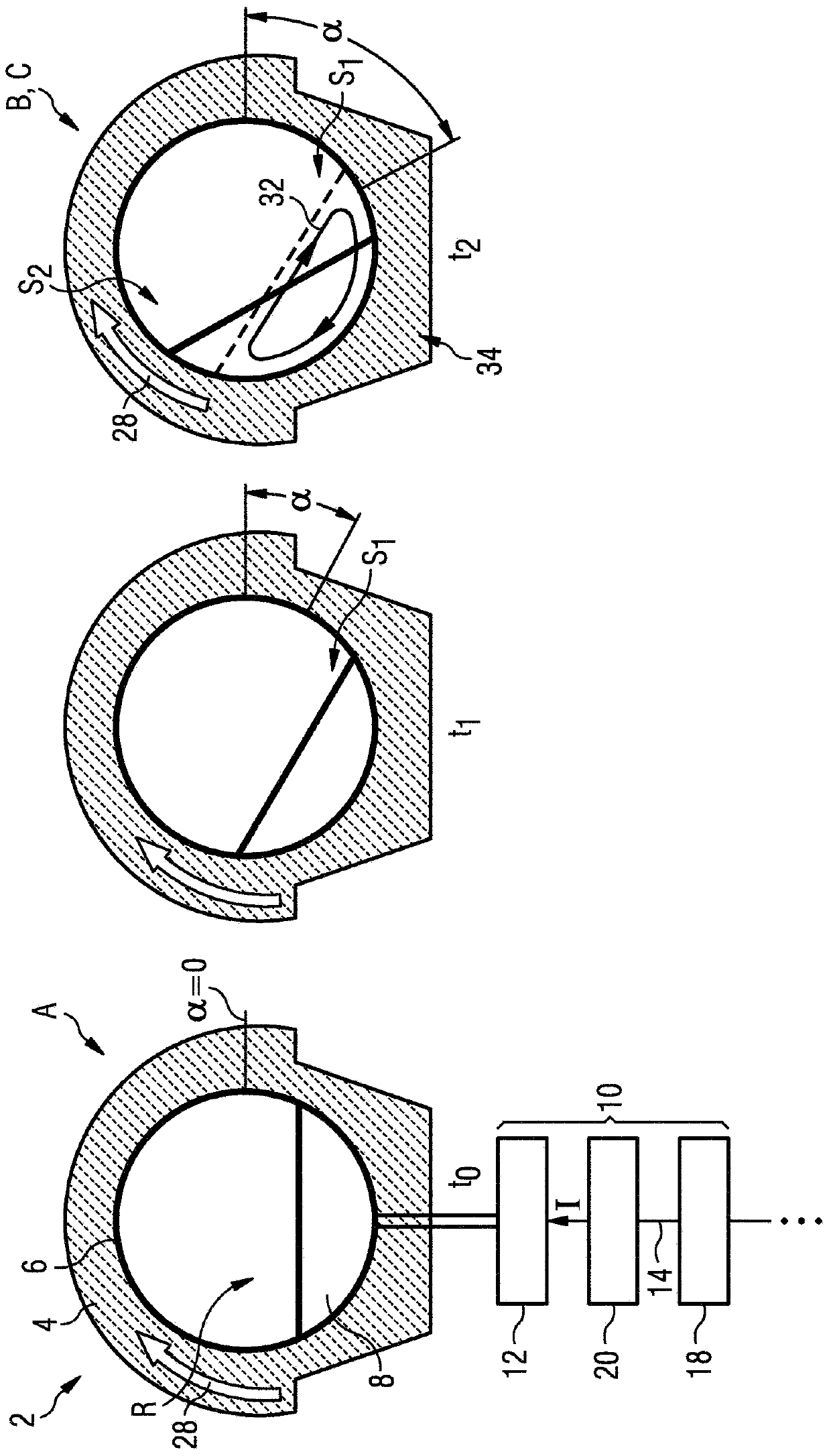

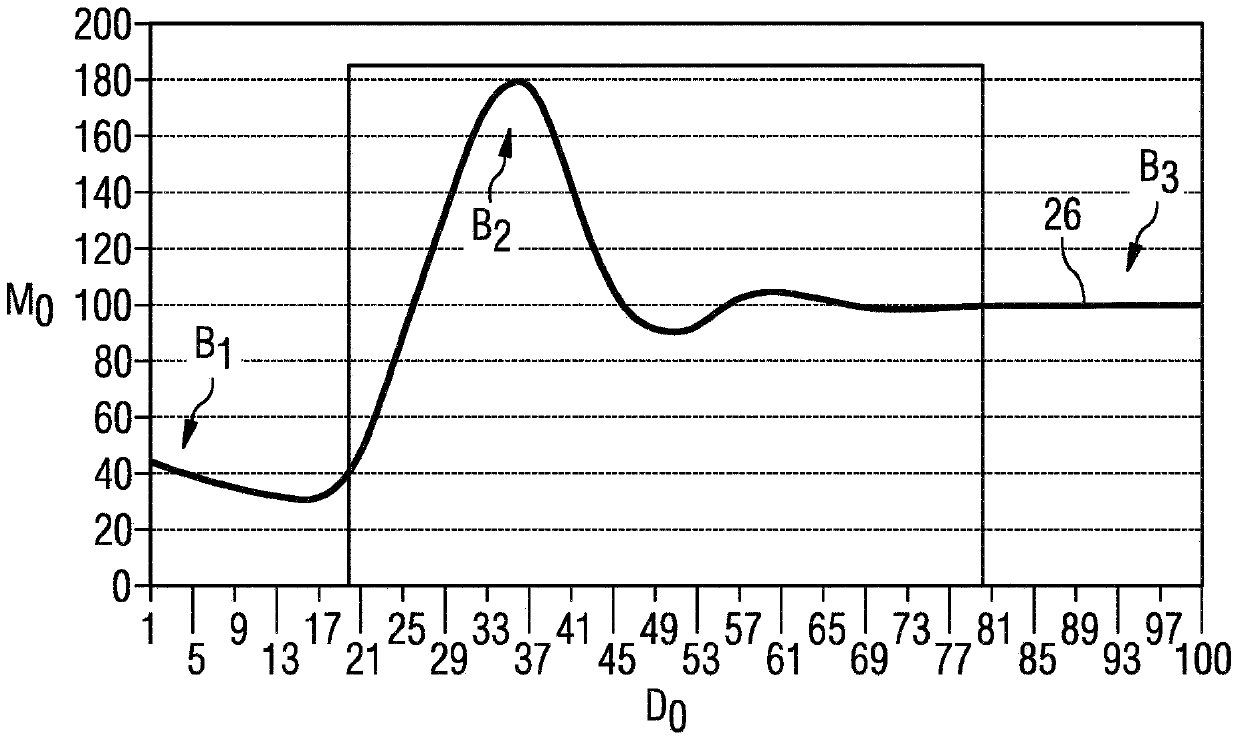

[0030] figure 1 A ball mill 2 is shown which essentially has a housing 4 and a drum 6 arranged rotatably therein. Inside the drum 6 there is the material to be ground, here in the form of ore 8 . Grinding bodies are usually included in the grinding mass, but are not shown separately here. Thus, existing grinding bodies are theoretically included when the concept of ore is used. The ball mill 2 has a drive system 10 comprising an electric motor 12 which drives the drum 6 . The motor is connected to a power supply device 16 through a feeder 14 (see figure 2 ) are connected. The drive current I of the motor 12 flows through the feeder. Drive system 10 additionally includes a resistor 18 in the form of a starting resistor, which is connected into feeder line 14 , and a switching element 20 connected in series with this resistor, which is connected into feeder line 14 .

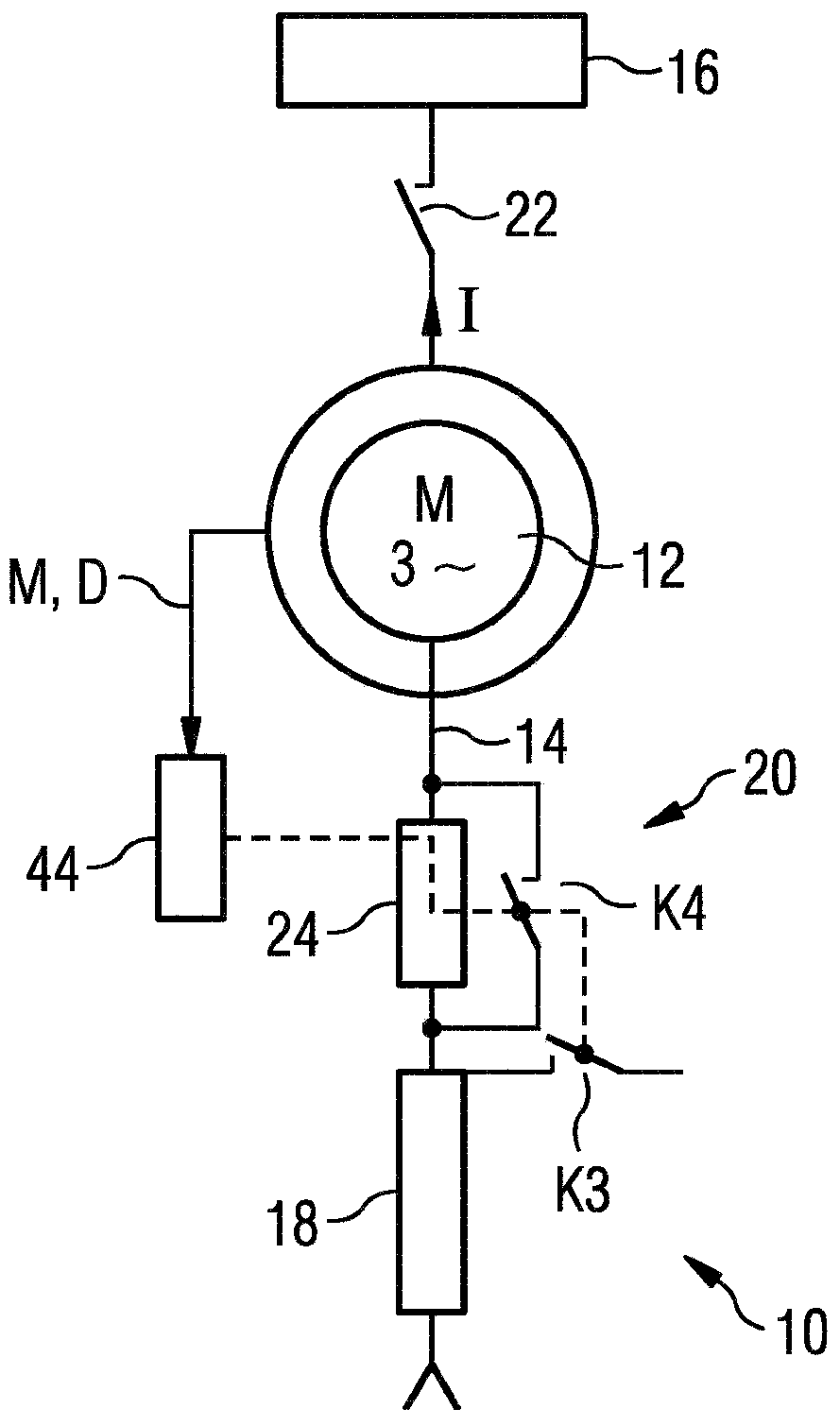

[0031] figure 2 supplementary shows figure 1 Details of a drive system 10 with a motor 12 and a resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com