Telescopic roller conveyor and frame

A conveyor, telescopic technology, used in transportation and packaging, roller tables, roller columns, etc., can solve the problems of waste of roller conveyors, difficult to reuse, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, embodiments will be described with reference to the drawings. It should be noted that the figures are only for illustrating the embodiments and should not be considered as limiting the scope of protection. Directional illustrations should only be considered as directional illustrations in the drawings.

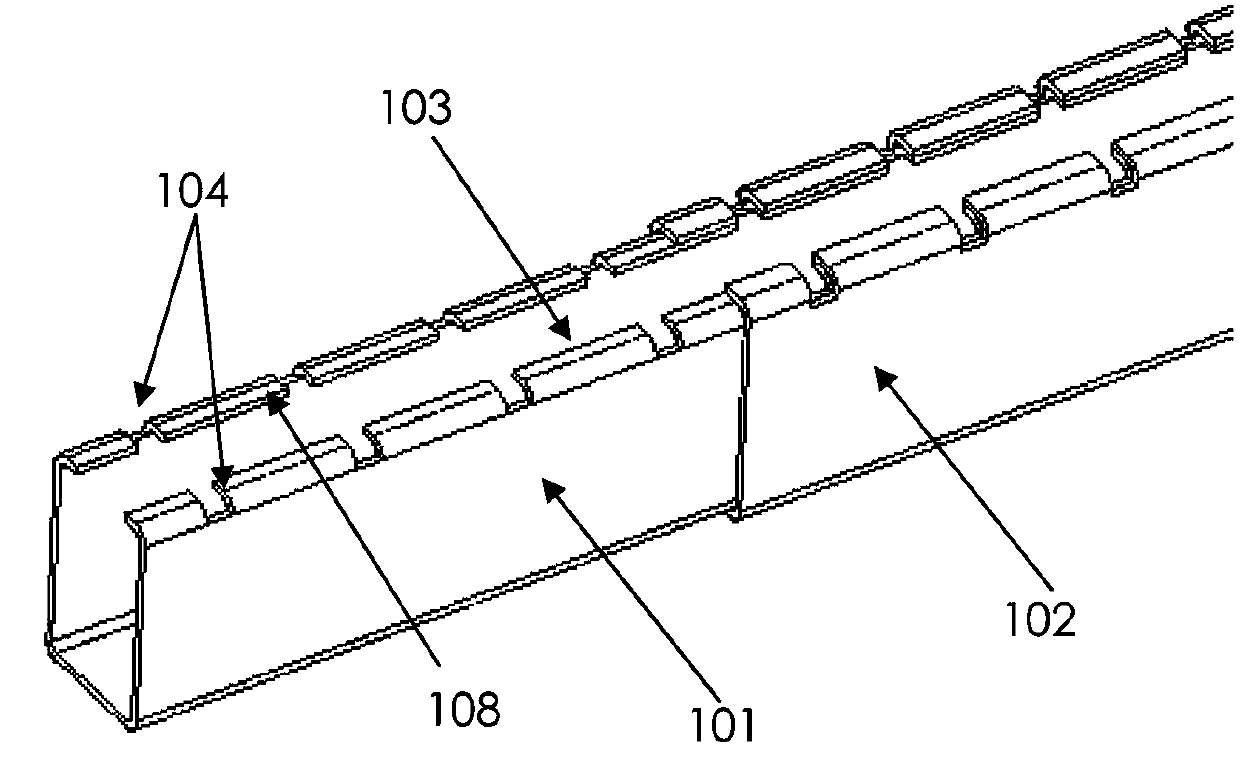

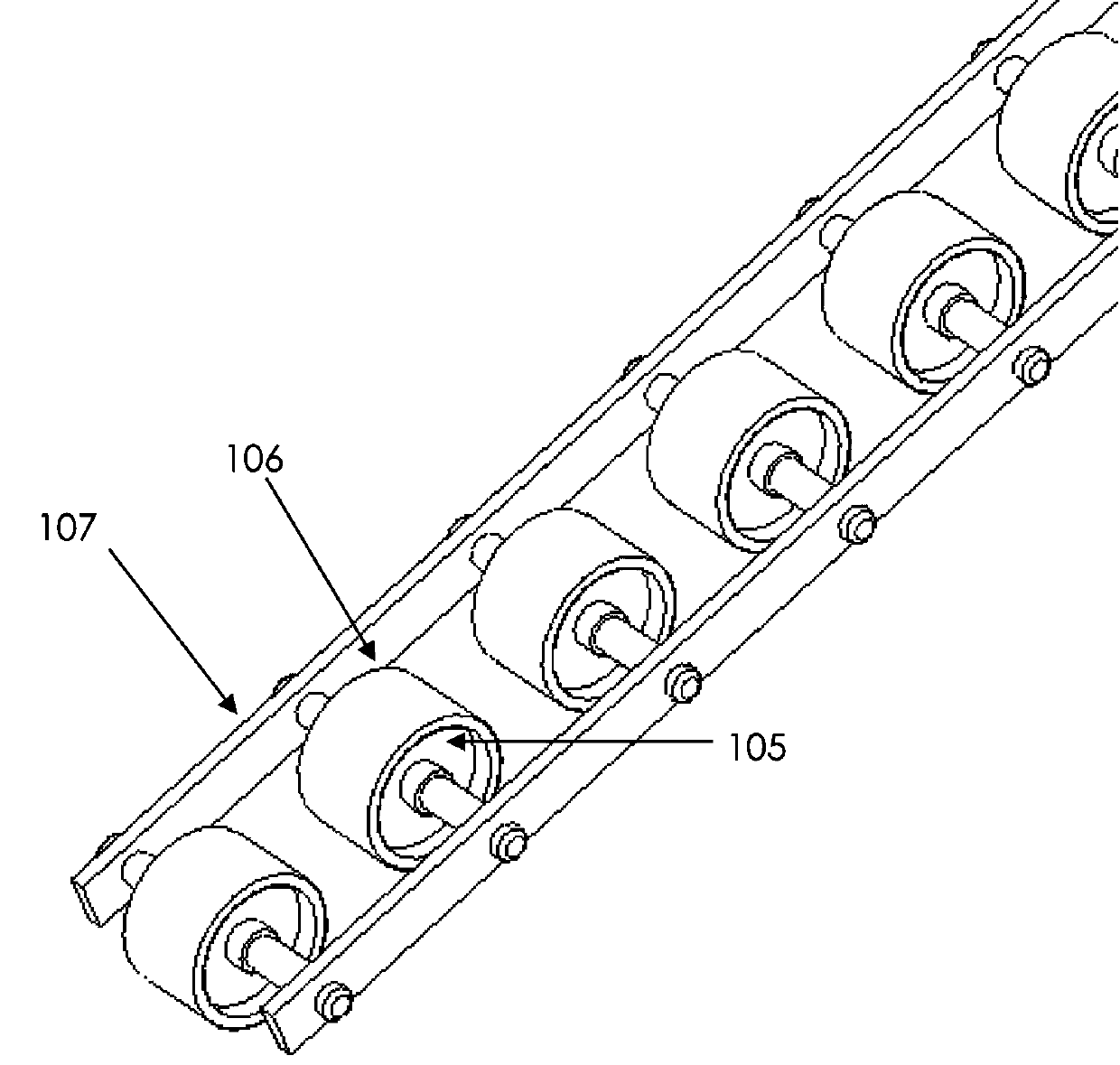

[0026] With telescoping roller conveyors, the profile to which the roller mechanism is fitted includes a telescoping function, enabling the production of roller conveyors of different lengths. The modular based design allows very easy rebuilding of for example a stand and enables the roller conveyor to be reused even if the size of the stand is changed.

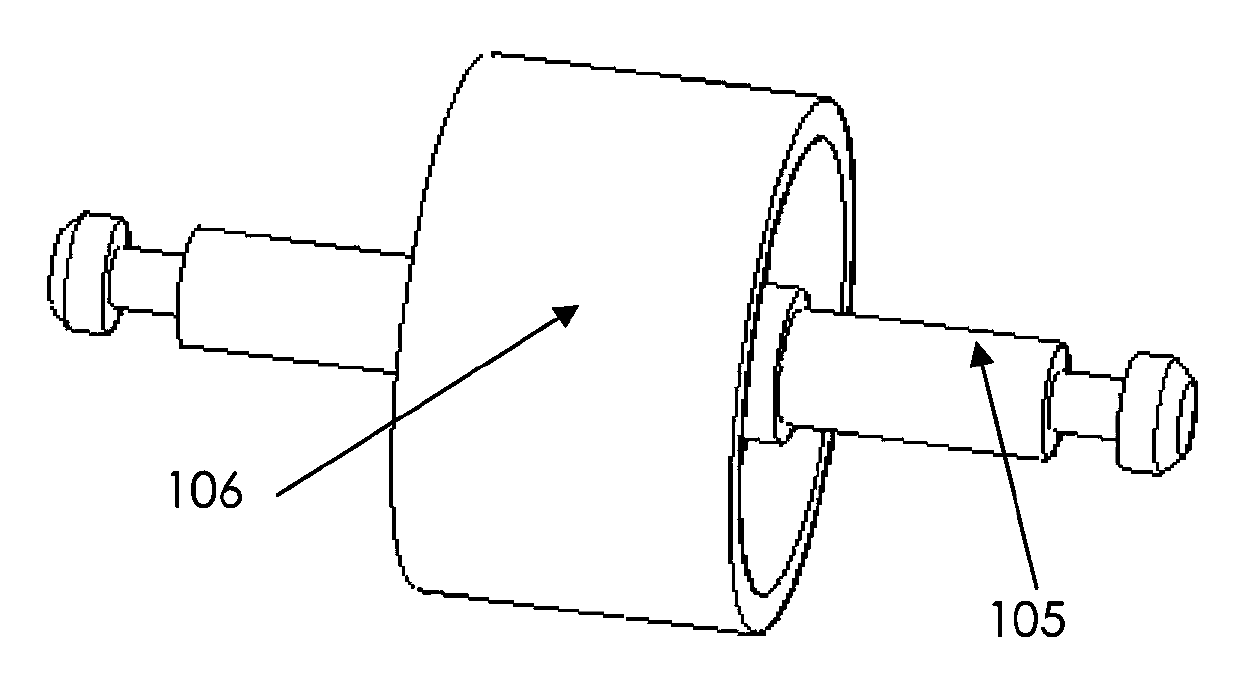

[0027] According to one embodiment, the telescopic roller conveyor comprises three different modules: an inner profile, an outer profile and a connection mechanism with a roller mechanism.

[0028] The combination with the connection means with roller means and the inner and outer contours results in a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com