Shaft neck measurement device

A measuring device and journal technology, which is applied in the field of journal measuring devices, can solve the problems of measuring equipment purchase, high maintenance cost, measurement position and clamping method constraints, etc., and achieve fast measurement problems, good results, and low manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

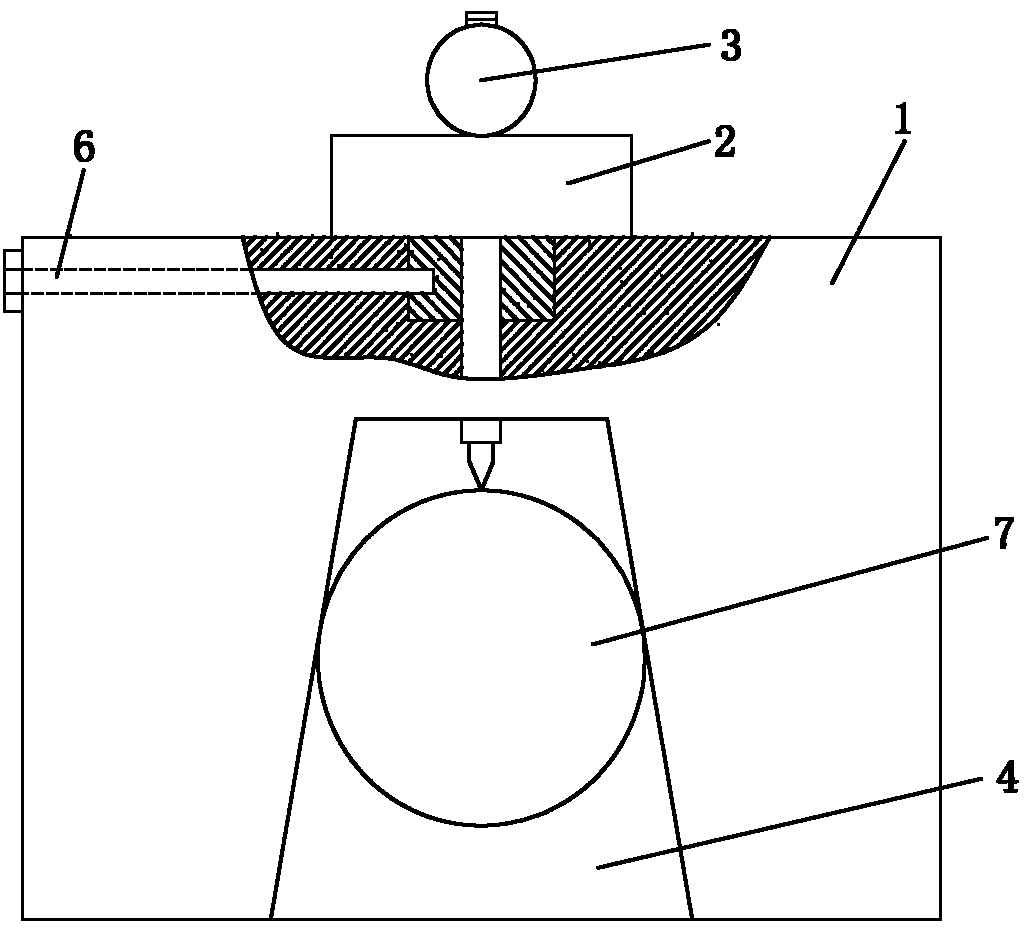

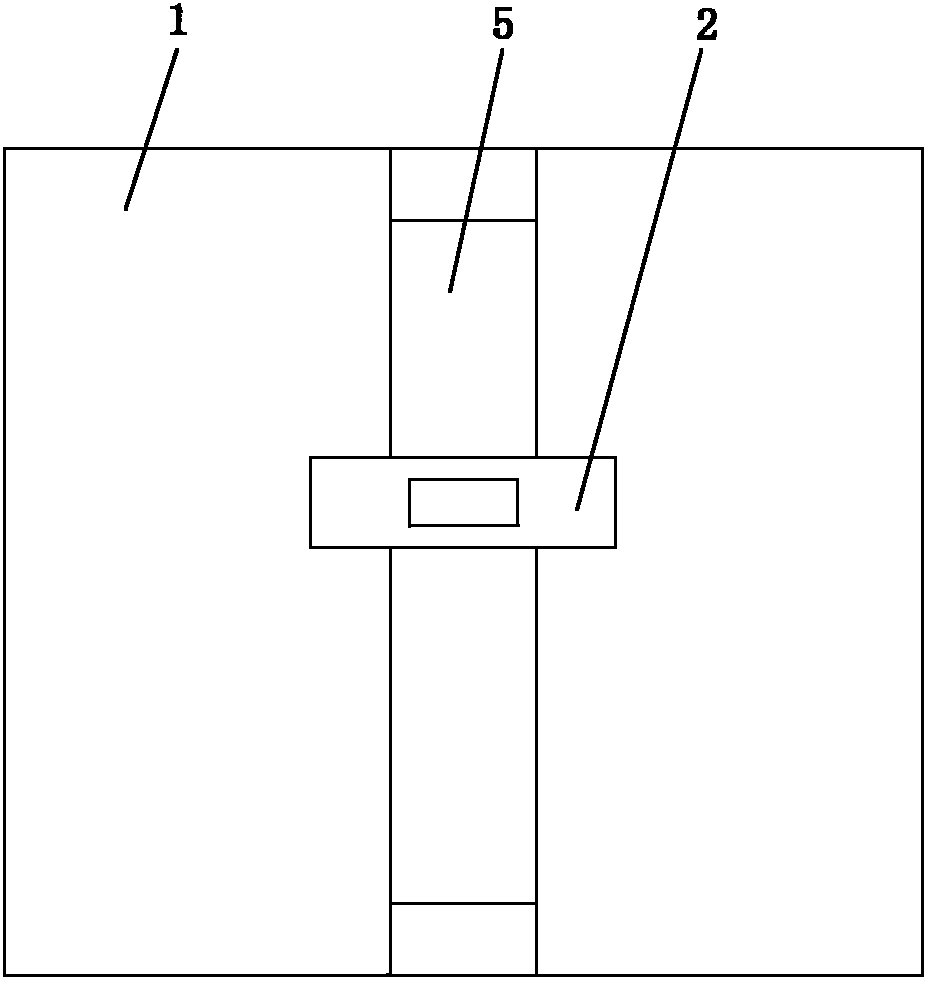

[0014] Reference figure 1 with figure 2 , A journal measuring device of the present invention includes a supporting seat 1, a watch cover 2, a dial indicator 3. The support base 1 is provided with a trapezoidal groove 4 extending from the lower end to the upper end of the support base 1, and the crankshaft 7 is clamped in the trapezoidal groove. The upper end surface of the support 1 is provided with a through hole 5 communicating with the trapezoidal groove, one end of the watch cover 2 is inserted into the through hole, the dial gauge 3 is fixed on the watch cover, and the probe of the dial gauge 3 penetrates Extend the watch cover into the trapezoidal groove 4. The through hole 5 is a strip hole, and the watch cover 2 is slidably fitted in the strip hole. A rectangular hole is provided on the side of the support base 1. The rectangular hole communicates with the through hole, and a set screw 6 penetrates The over-rectangular hole is threaded to the watch sleeve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com