Selector shaft with an open sleeve

A sleeve and switching lever technology, applied in the direction of elements with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problems of expensive manufacturing process, high material cost, high quality of stop sleeve, etc., to save Material and weight, flexible manufacturing process, effect of reducing scrap rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

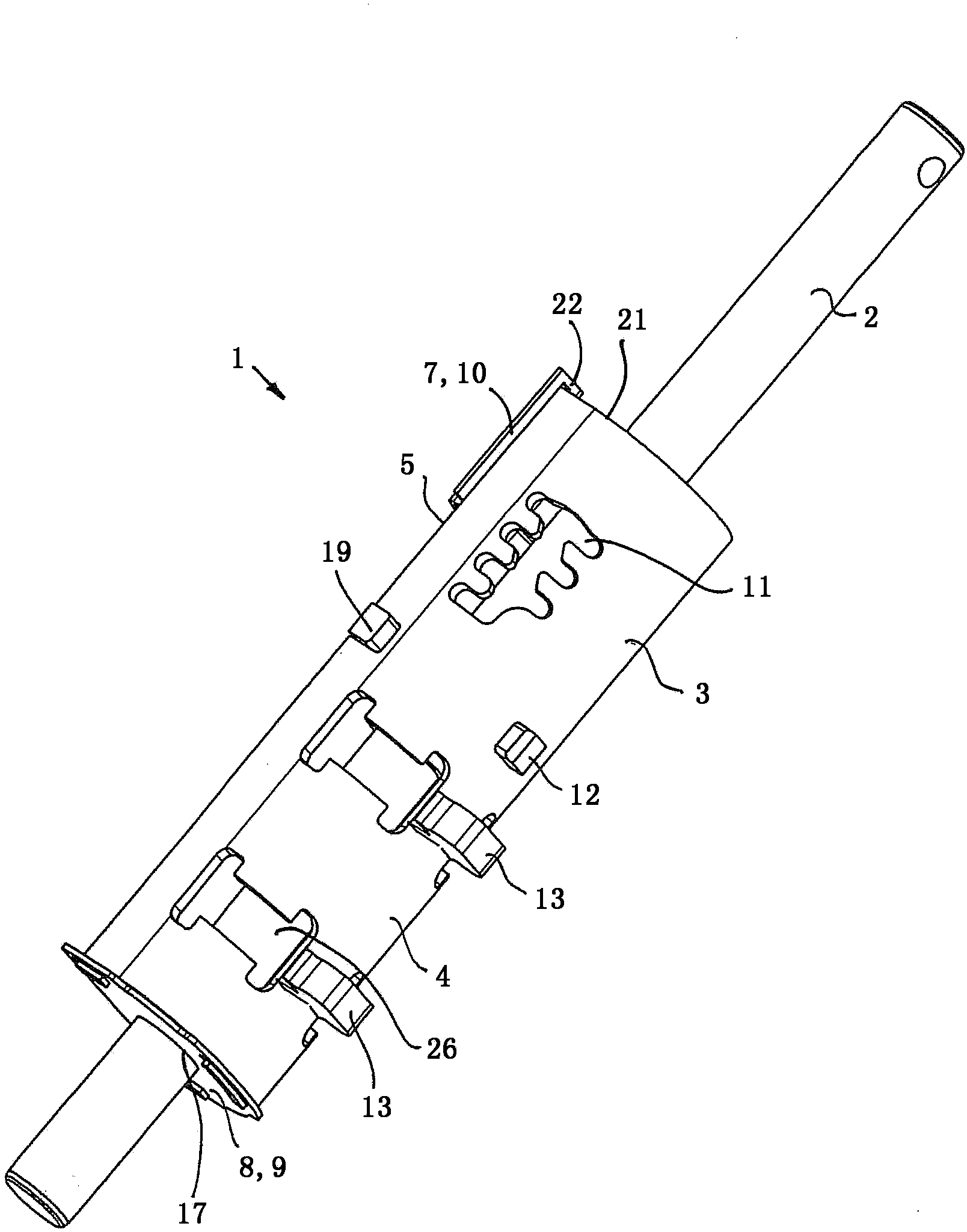

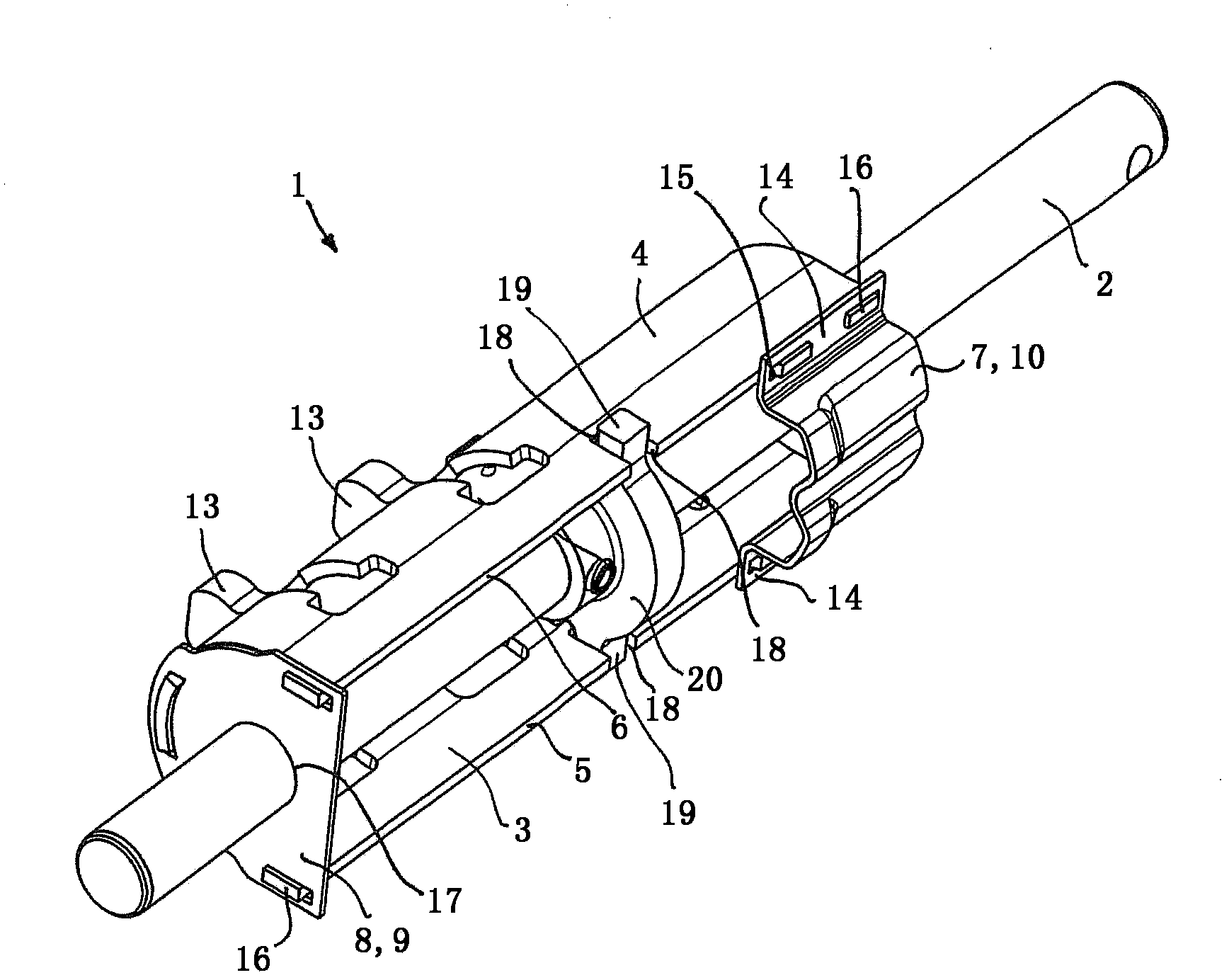

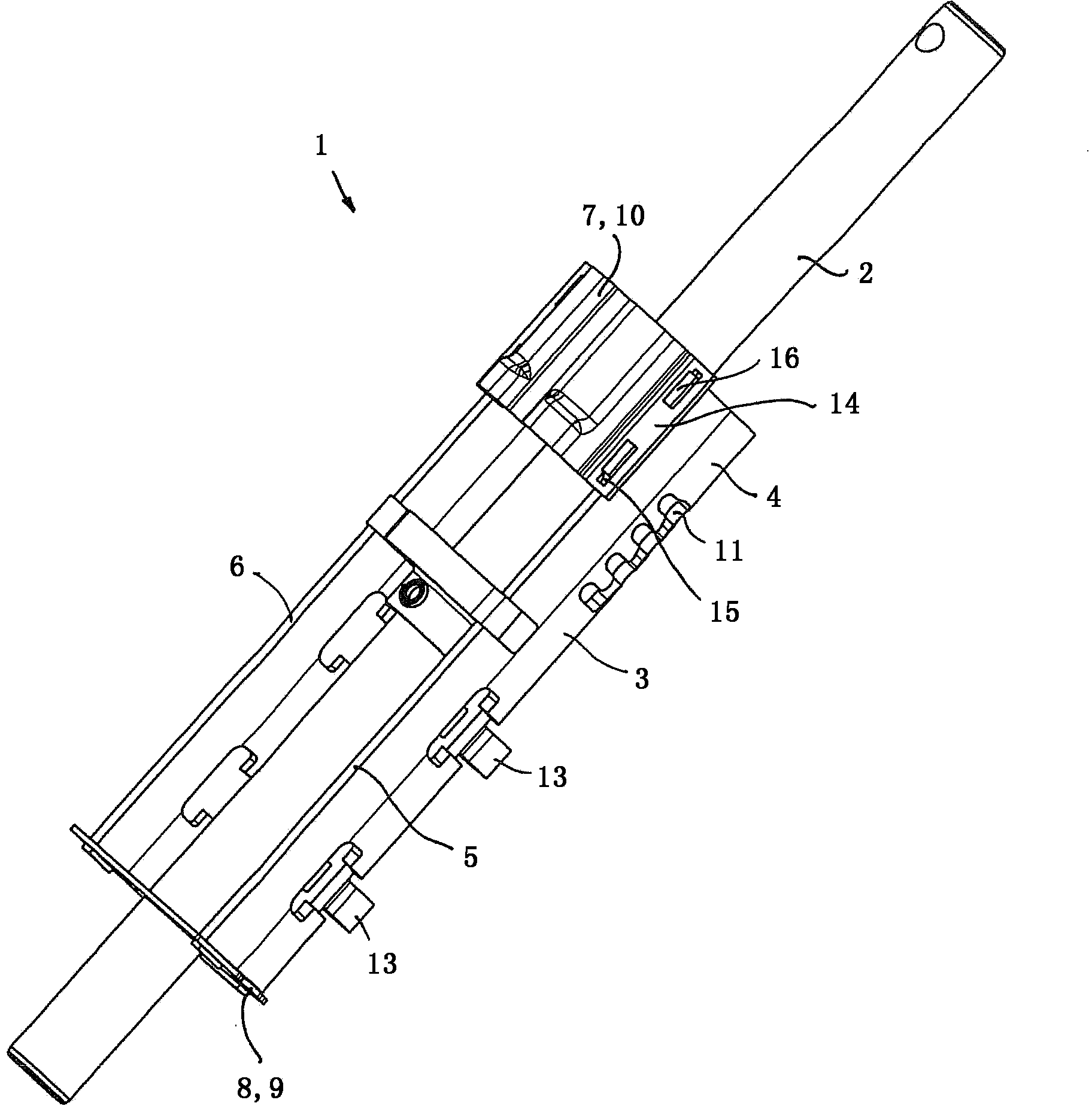

[0029] Figure 1 to Figure 3 A switching device 1 is shown which comprises a solid switching lever 2 and a sleeve 3 with a circular cross section. The sleeve 3 is assembled from a half shell 4 and two connecting parts 7 , 8 . The half shells 4 are produced from sheet steel parts cut to length from a strip. The desired outer contour with possibly required projections 16 or other projecting elements can be stamped into the sheet metal immediately after cutting to length. Alternatively, the corresponding sheet metal parts are stamped together from the strip. While still in the flat state, recesses, such as switching guides 11 for engaging pins (not shown), are punched into the sheet metal, and shapings, such as stops 12 , are introduced into the sheet metal. Subsequently, the sheet metal part is cold deformed to form the half shell 4 . The outer contour of the half shell 4 is U-shaped with two sides 5 and 6 , which are oriented parallel to one another. Switching fingers 13 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com