Metal pipe having an elastomeric coating, a coupling device and a system for transporting material in mineral processing plants

A connection device and metal pipe technology, which is applied in the field of metal pipes, can solve the problems of expensive metal pipes and difficult transportation of metal pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

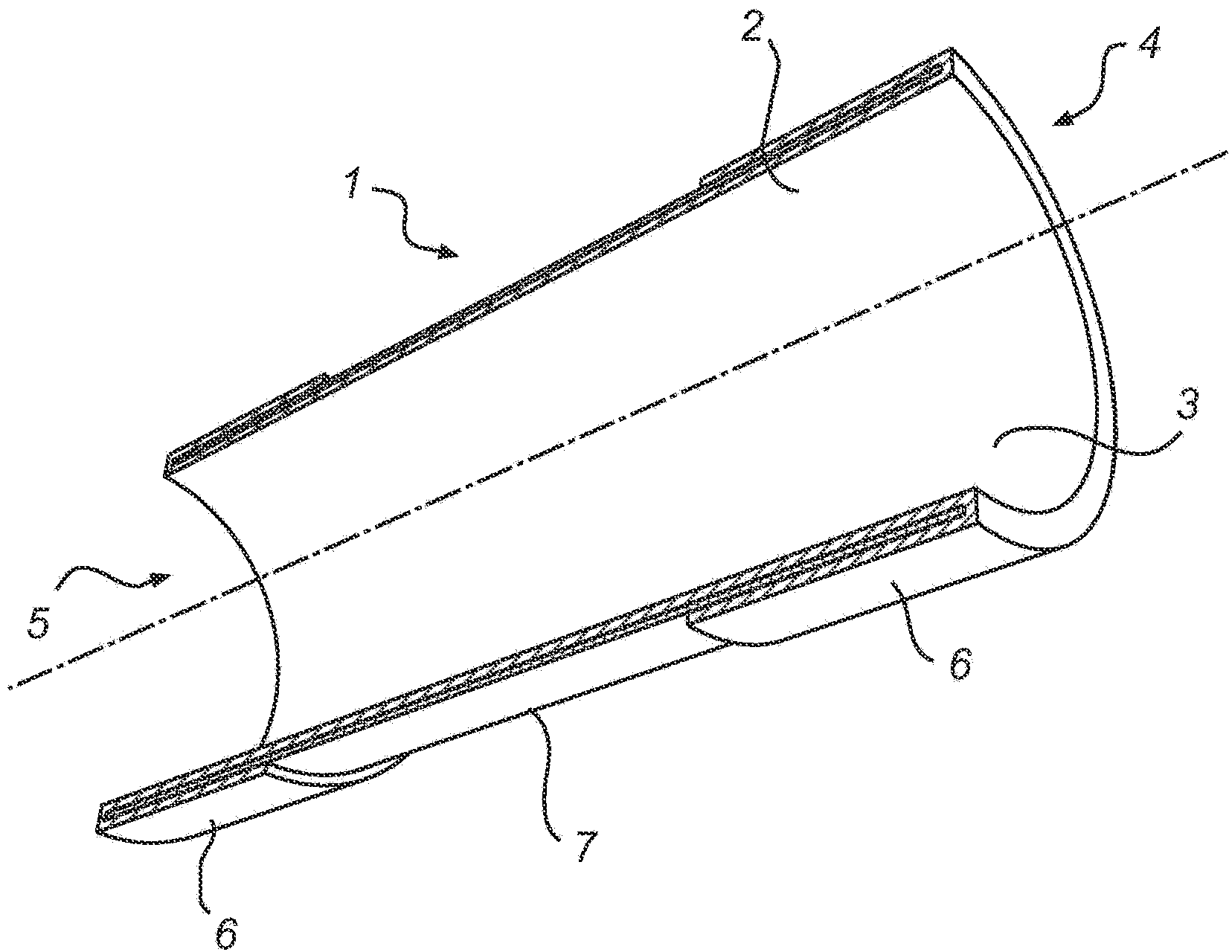

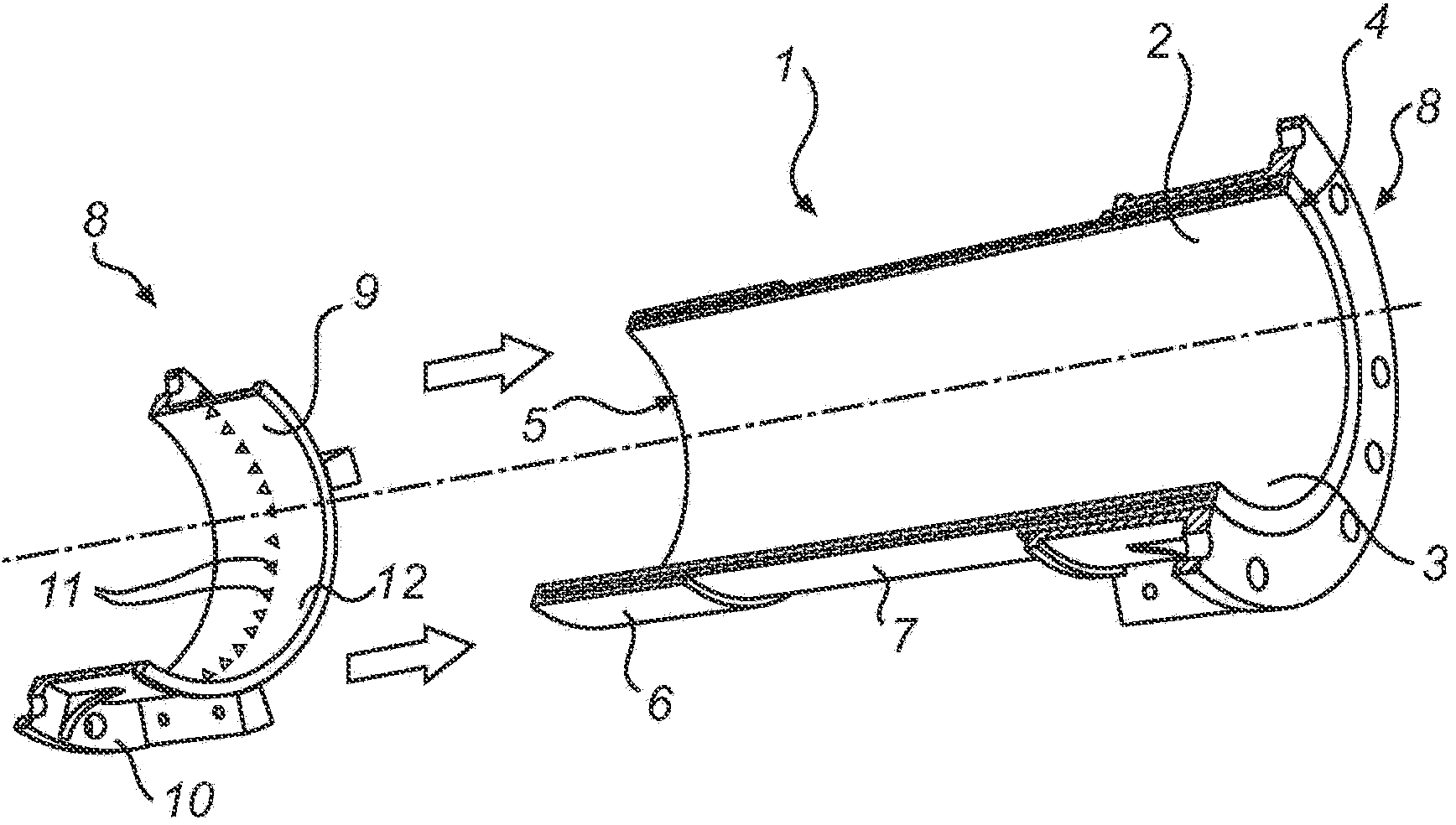

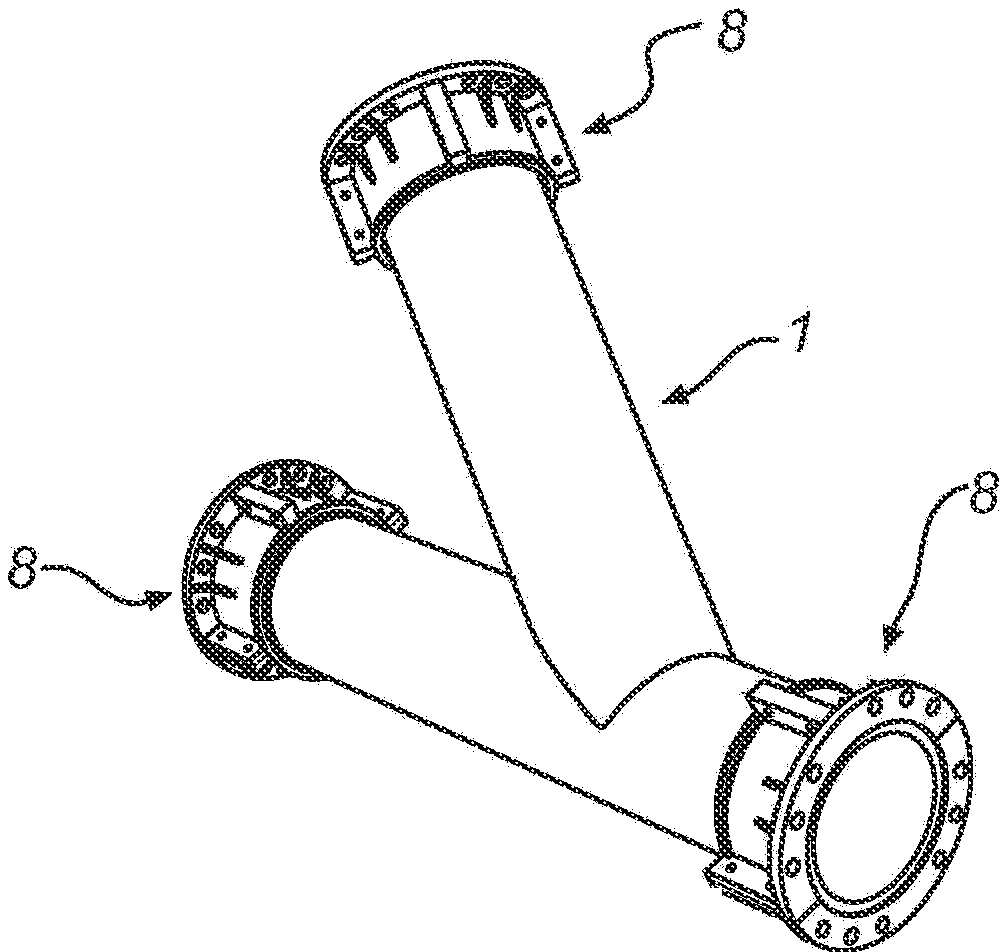

[0024] figure 1 An embodiment of a metal pipe 1 for transporting material in a mineral processing plant is shown according to the first aspect of the invention. The metal tube 1 is hollow and cylindrical. The metal pipe 1 is made of high-strength steel and has a rubber coating 3 on its inner peripheral surface 2 . The rubber coating 3 provides good wear resistance when transporting abrasive materials. The metal tube 1 has a first end 4 and a second end 5 . The outer peripheral surfaces 7 of the first end 4 and the second end 5 of the metal pipe 1 are coated with an elastomeric coating 6 . The elastomeric coating 6 consists of rubber and is vulcanized onto the peripheral surface 7 . The preferred hardness of the rubber is preferably about 70° Shore A. However, the elastomeric coating 6 may naturally be any other elastomeric material with the same or different suitable hardness. Also, the metal pipe 1 may be made of other materials than high strength steel which are more s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap