Cutting apparatus

A support surface and fixed blade technology, which is applied in the cutting of textile materials, textiles and papermaking, metal processing, etc., can solve the problems of cloth 106 damage, fixed blade 104 damage, sharpness reduction cloth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Hereinafter, embodiments of the present invention will be described in detail with reference to the attached drawings.

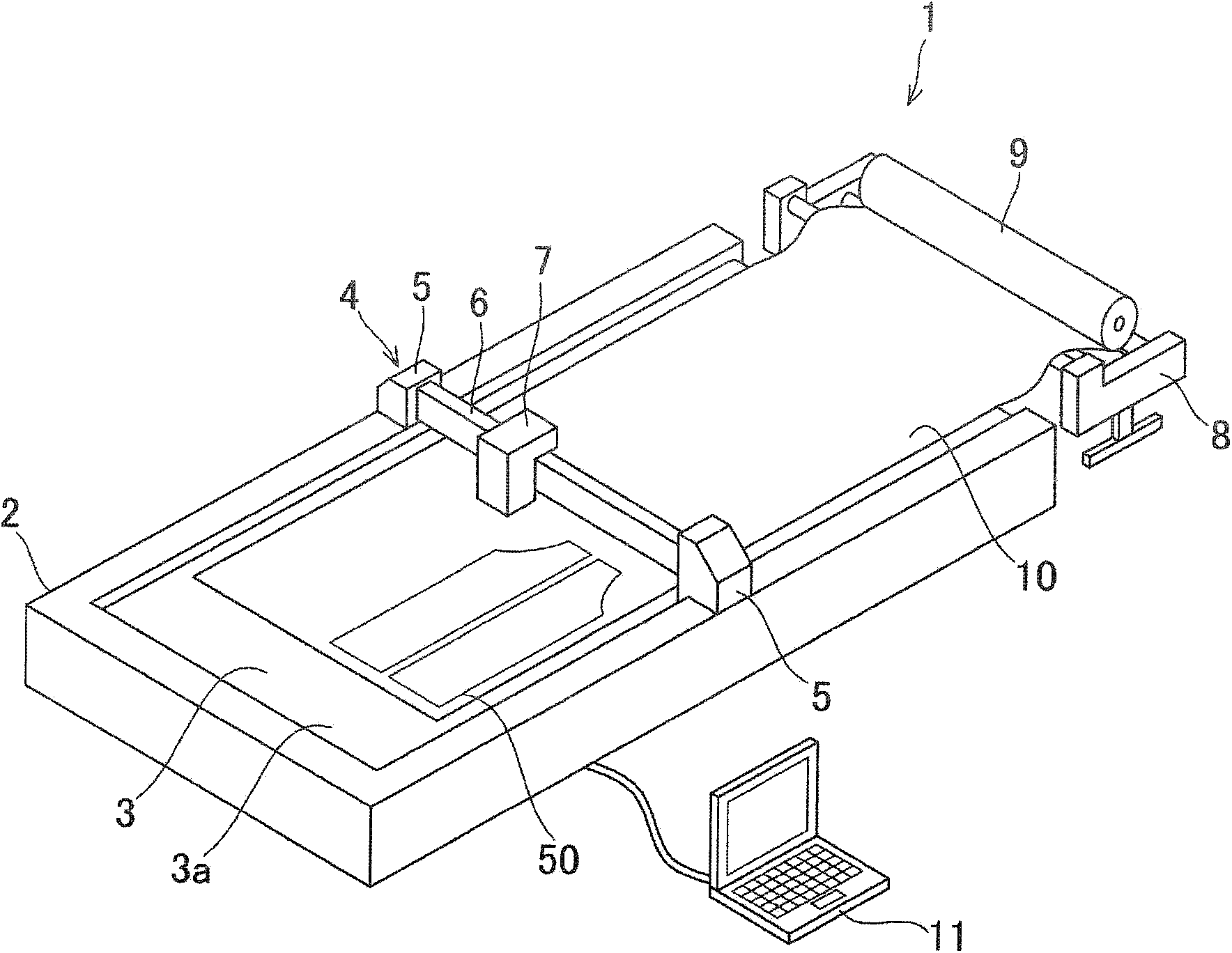

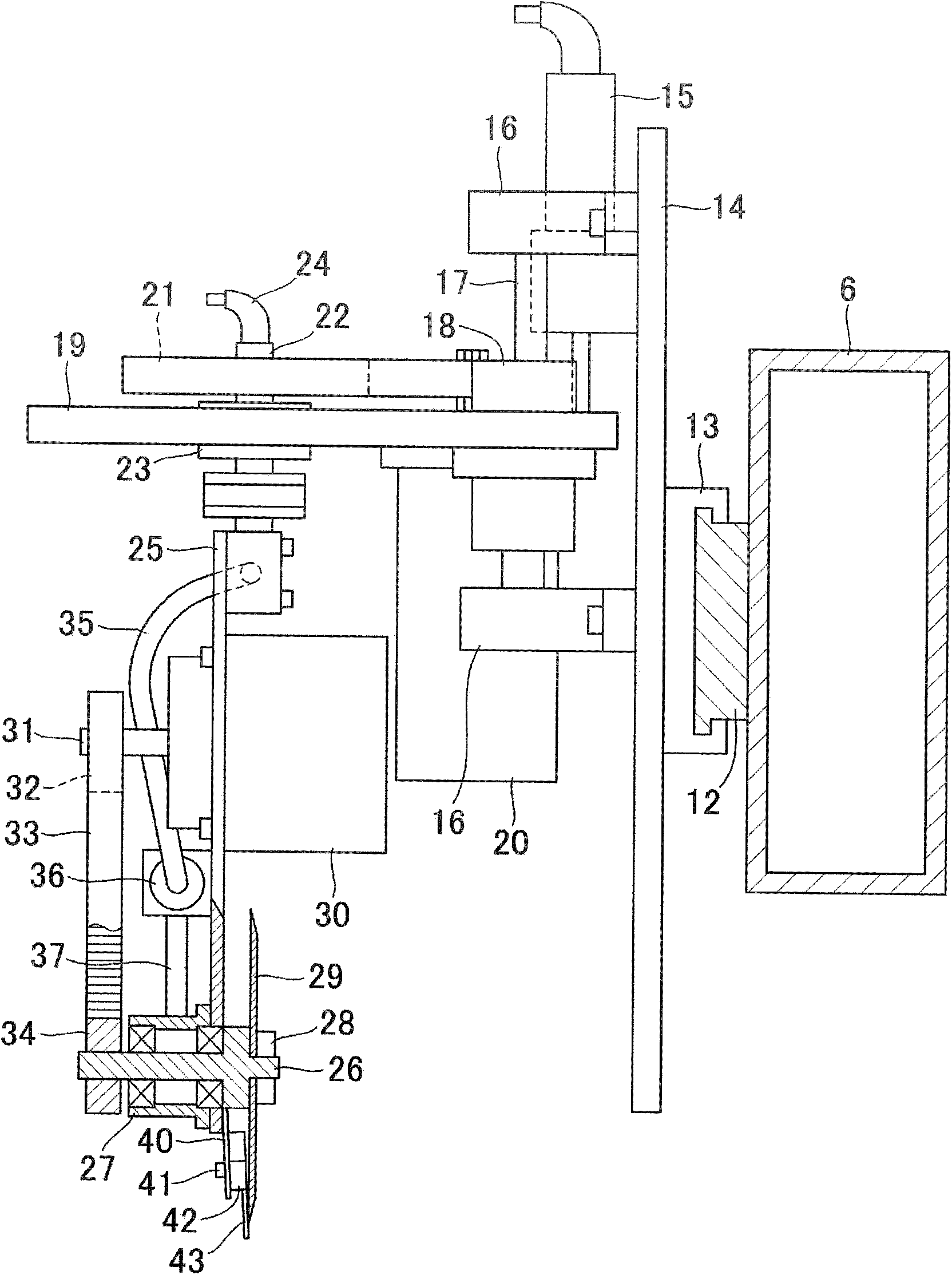

[0054] The cutting device according to the embodiment of the present invention is a plotter-type cutting device that cuts cloth as a sheet to create a pattern piece for clothing. The cutting device 1 such as figure 1 As shown, it roughly consists of a cutting table 2, a cutter unit 4, a fabric spreader 8, and a control device 11 as a control unit and a rotary blade control unit.

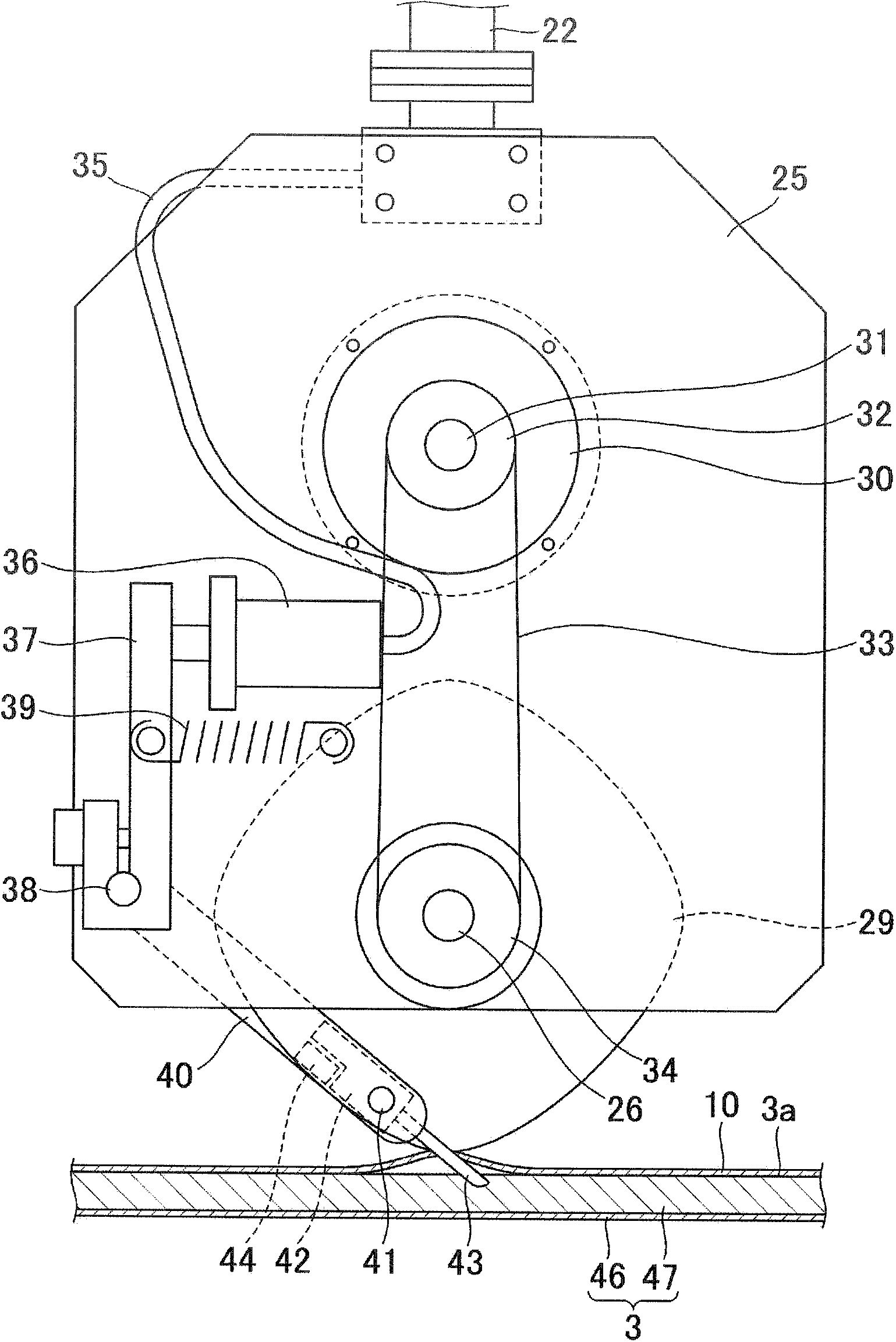

[0055] The cutting table 2 has a built-in belt conveyor that conveys the cloth 10 from the cloth opener 8 and supports the cloth 10 during cutting. The belt conveyor mechanism is built in both ends of the cutting table 2 in the longitudinal direction, and the conveyor belt 3 as a support portion is spanned between unillustrated pulleys extending in the lateral direction. The upper surface of the conveyor belt 3 constituting the belt conveyor is exposed on the upper side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com