Sorting device of spun yarn pipes

A sorting device and spun yarn bobbin technology, applied in the field of textile machinery automation, can solve the problems of waste of human resources, high labor intensity, extra investment in equipment, etc., and achieve the effects of realizing automatic operation, reducing waste and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

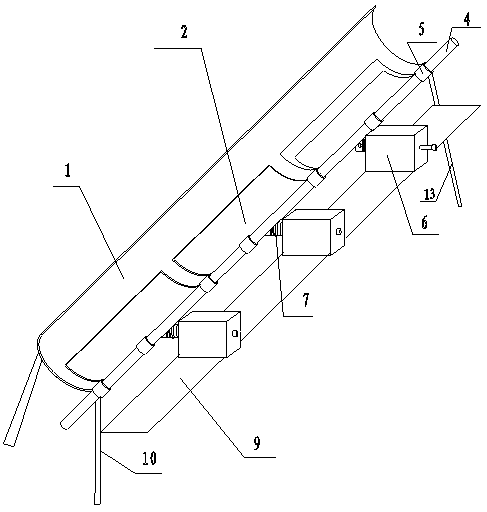

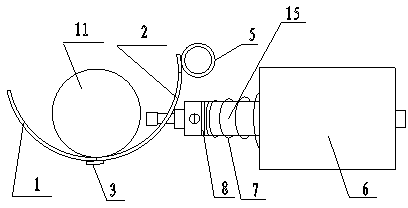

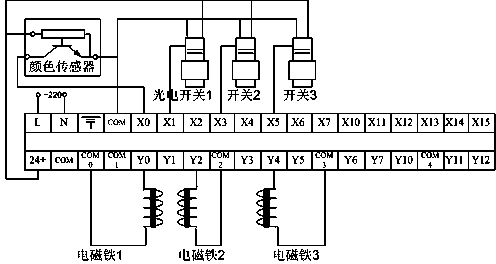

[0011] Such as figure 1 with figure 2 As shown, the quantity of movable arc-shaped plates 2 corresponds to the quantity of spinning tubes 11 of different colors, and each movable arc-shaped plate 2 is equipped with a rotating shaft 4, a metal pull rod 15, an electromagnet 6 and a tower spring 7, and the slide rail is high-supported. 13 is located at the bottom of the front end of the fixed arc-shaped plate 1, and the low bracket 10 of the slideway is located at the bottom of the rear end of the fixed arc-shaped plate 1, so that the fixed arc-shaped plate 1 is high at the front and low at the rear, and can maintain a clamping angle of 30° with the horizontal ground. There is a gap from top to bottom on the right side wall of the fixed curved plate 1, the shape, quantity and position of the gap are consistent with the movable curved plate 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com