Robotic auto-handling combined gripping system

An automatic loading and unloading and robot technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of increased equipment cost, high equipment failure rate, and equipment installation limitations, so as to reduce the failure rate, compact equipment layout, and reduce equipment investment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

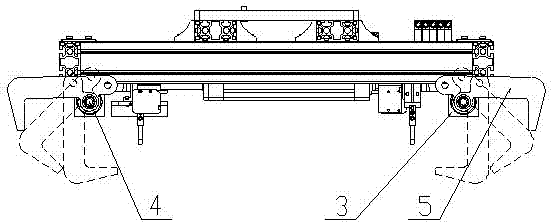

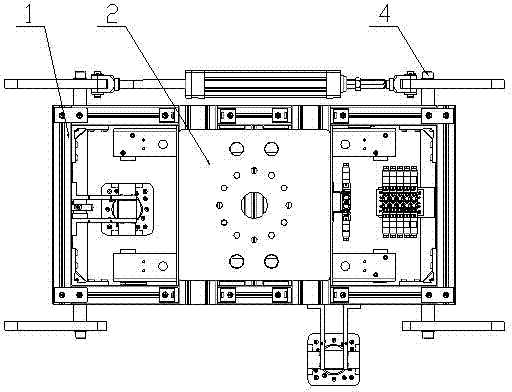

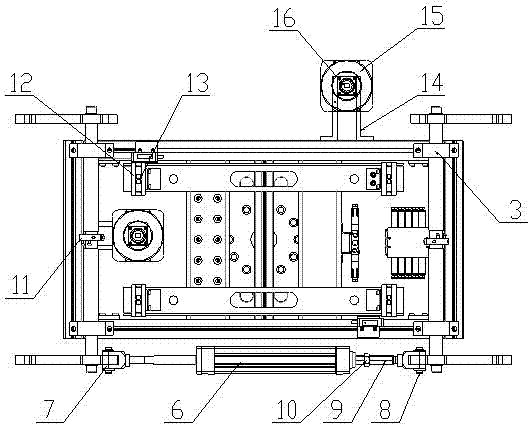

[0035] see Figure 1~Figure 5 , a compound clamping system for robot automatic loading and unloading according to the present invention, which includes an overall frame 1, a flange plate 2 is arranged at the center of the top of the overall frame 1, and a group of bearings with seats are arranged on the left and right sides of the bottom of the overall frame 1 3. Each group of bearings 3 with seats is equipped with a rotating shaft 4, and the left and right ends of the rotating shaft 4 are provided with hooks 5, the middle part of the rotating shaft 4 is provided with a limit adjustment block 11, and one side of the overall frame 1 is provided There is a cylinder 6, the tail of the cylinder 6 is provided with a connecting rod 9, and the end of the piston rod of the cylinder 6 and the end of the connecting rod 9 are respectively connected with the claws on the left and right sides through the Y-shaped double elbow joint 7 and the matching pin 8 of the double elbow joint. 5 uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com