Method for preparing phosphate and iron oxide red by utilizing phosphated residue

A technology of iron oxide red and phosphate, applied in the field of phosphating slag treatment, can solve the problems of zinc phosphate precipitation, secondary pollution, waste of resources, etc., and achieve the effects of saving phosphorus resources, enriching economic benefits, and huge market capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

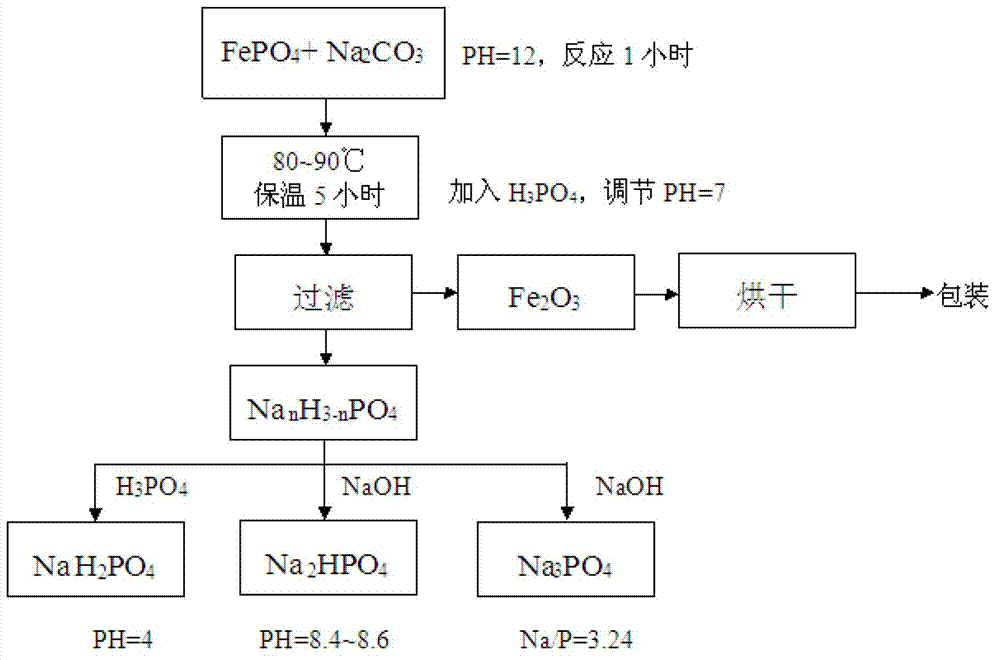

[0021] Such as figure 1 Shown, a kind of processing of invention utilizes phosphating slag to become the method for phosphate and iron oxide red, and the main component of phosphating slag is FePO 4 , the specific processing and utilization steps are as follows:

[0022] a.Na 2 CO 3 with FePO 4 reaction

[0023] to FePO 4 Na 2 CO 3 To PH=12, react for 1 hour to make the raw materials react completely, the reaction chemical reaction equation is:

[0024] 2FePO 4 + 3Na 2 CO 3 + 3H 2 O = 2Fe(OH) 3 + 2Na 3 PO 4 + 3CO 2

[0025] b.Fe(OH) 3 converted to Fe 2 o 3

[0026] Above-mentioned reaction product is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap