A kind of ultra-soft halogen-free flame-retardant thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer, ultra-flexible technology, applied in the field of thermoplastic elastomer and its preparation, thermoplastic elastomer materials, can solve the problems of large amount of flame retardant addition, large loss of material mechanical properties, elastic damage to elastic body, etc., to achieve Excellent flame retardant performance, economical processing, recyclable, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

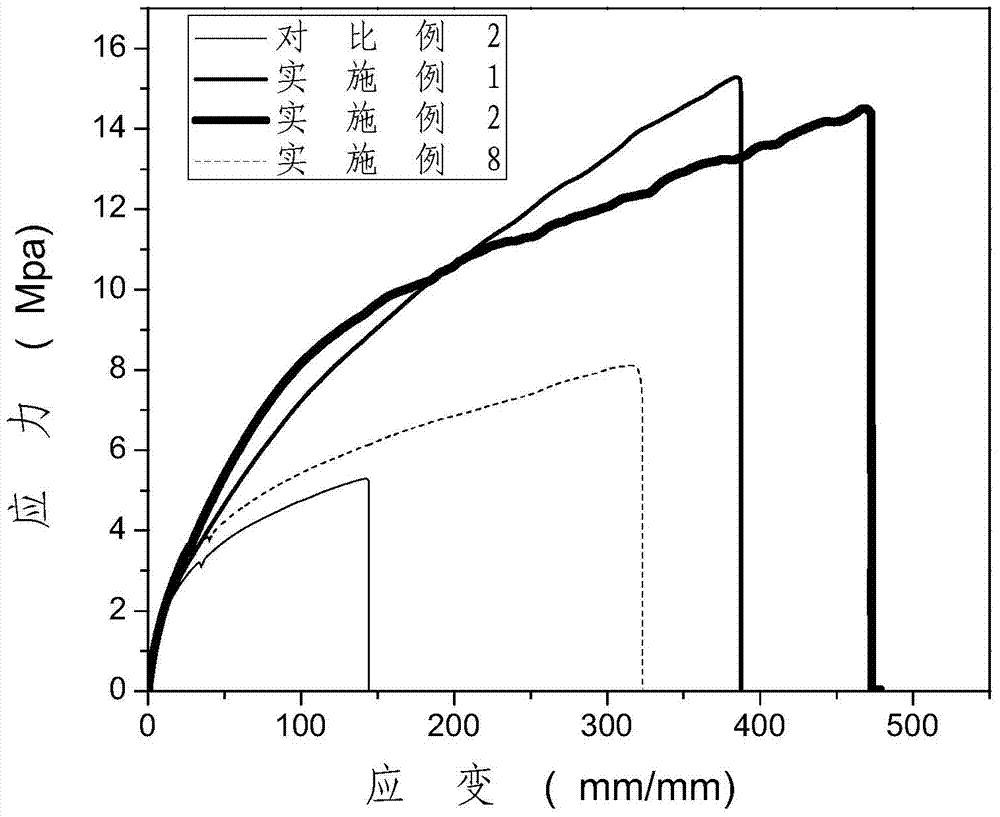

Embodiment 1

[0043] Step (1). Add 50g of ethylene vinyl acetate EVM, 50g of ethylene vinyl acetate EVA and 0.01g of dicumyl peroxide DCP to an internal mixer with a rotor speed of 80r / min at 160°C for dynamic vulcanization for 5 minutes After drying, the base material is obtained.

[0044] Step (2). At 160°C, 25g of the base material and 25g of aluminum hydroxide were added to an internal mixer with a rotor speed of 80r / min to melt and blend for 5 minutes, and the material was discharged to obtain a super-soft halogen-free flame-retardant thermoplastic elastomer;

[0045] The mass ratio of ethylene vinyl acetate cross-linked product, ethylene vinyl acetate EVA, dicumyl peroxide DCP, and flame retardant in the ultra-soft halogen-free flame-retardant thermoplastic elastomer obtained in Example 1 is 50:50:0.01 : 100; the flame retardant is aluminum hydroxide.

Embodiment 2

[0047] Step (1). Same as the experimental conditions of Example 1, the base material is obtained;

[0048] Step (2). At 160°C, 25g of base material and 25g of magnesium hydroxide were added to an internal mixer with a rotor speed of 80r / min to melt and blend for 5 minutes, and the material was discharged to obtain a super-soft halogen-free flame-retardant thermoplastic elastomer;

[0049] The mass ratio of ethylene vinyl acetate cross-linked product, ethylene vinyl acetate EVA, dicumyl peroxide DCP, and flame retardant in the ultra-soft halogen-free flame-retardant thermoplastic elastomer obtained in Example 2 is 50:50:0.01 : 100. The flame retardant is magnesium hydroxide.

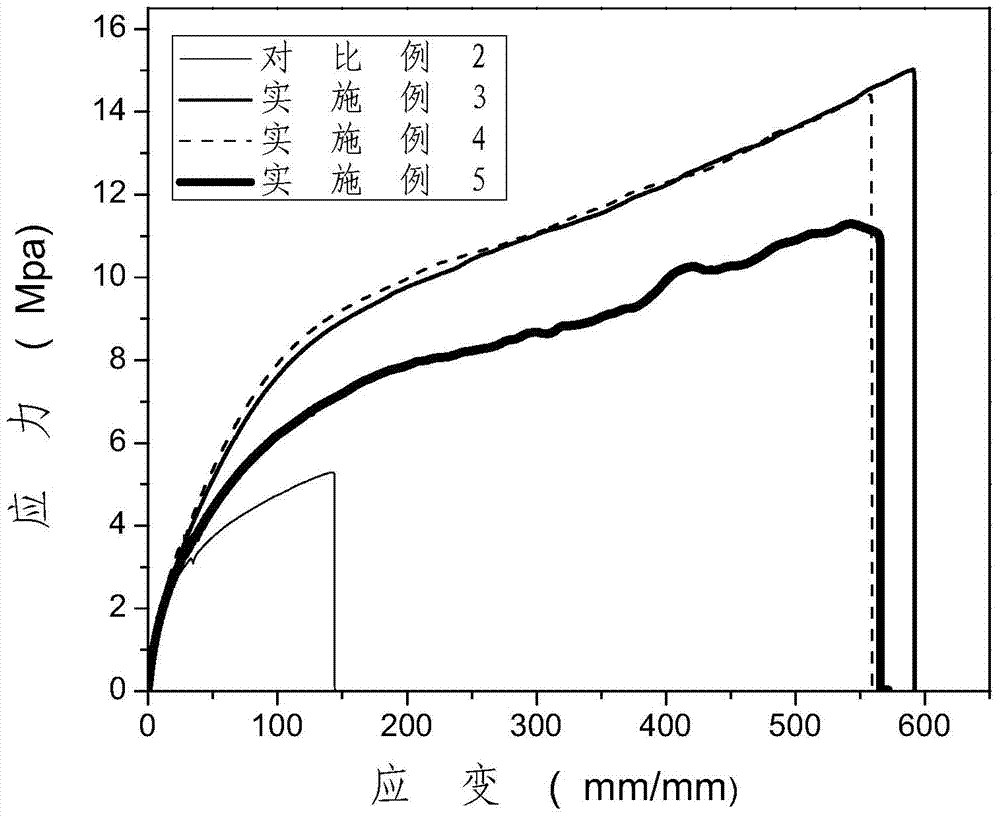

Embodiment 3

[0051] Step (1). Same as the experimental conditions of Example 1, the base material is obtained;

[0052] Step (2). At 160°C, add 25g of base material, 24g of magnesium hydroxide, and 1g of nitrogen-phosphorus expansion flame retardant NP-P20X to an internal mixer with a rotor speed of 80r / min to melt and blend for 5 minutes, and discharge to obtain Super soft halogen-free flame retardant thermoplastic elastomer;

[0053] The mass ratio of ethylene vinyl acetate cross-linked product, ethylene vinyl acetate EVA, dicumyl peroxide DCP, and flame retardant in the ultra-soft halogen-free flame-retardant thermoplastic elastomer obtained in Example 3 is 50:50:0.01 : 100; the flame retardant is magnesium hydroxide, nitrogen phosphorus expansion flame retardant NP-P20X.

PUM

| Property | Measurement | Unit |

|---|---|---|

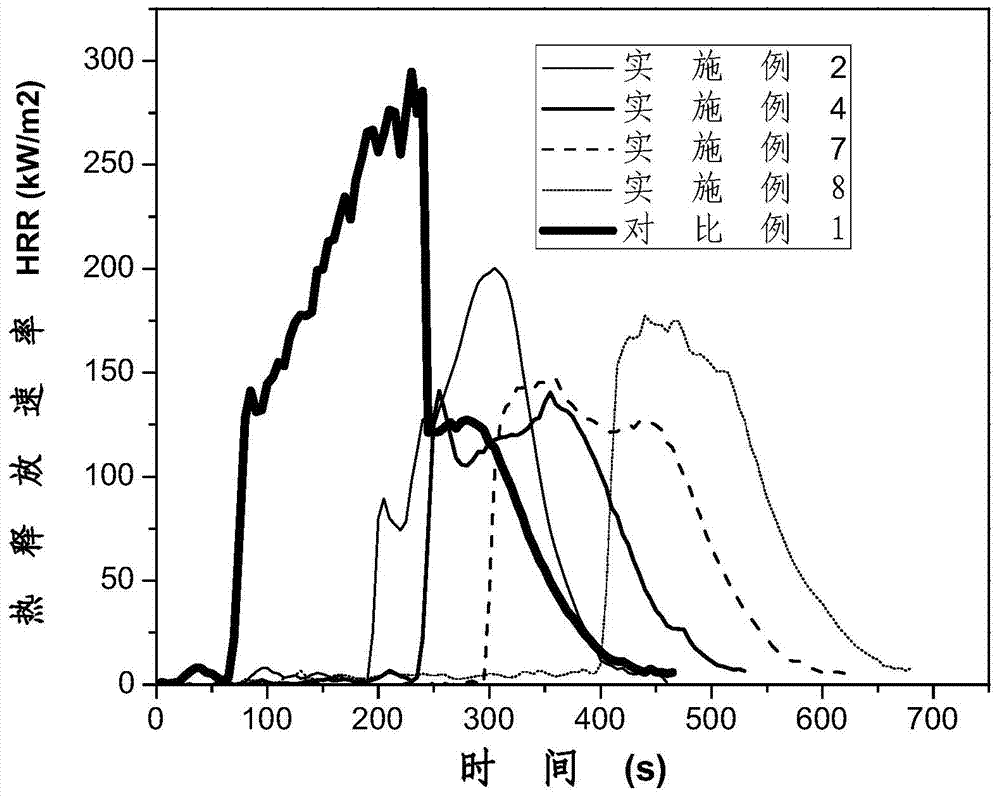

| peak heat release rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com