High-temperature mineral powder cooling device

A technology of cooling device and slag powder, which is applied in the field of iron and steel metallurgy, can solve the problems that waste heat cannot be recycled and waste circulating cooling water, etc., and achieve the effects of avoiding evaporation loss, wide application range, and wide selection types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

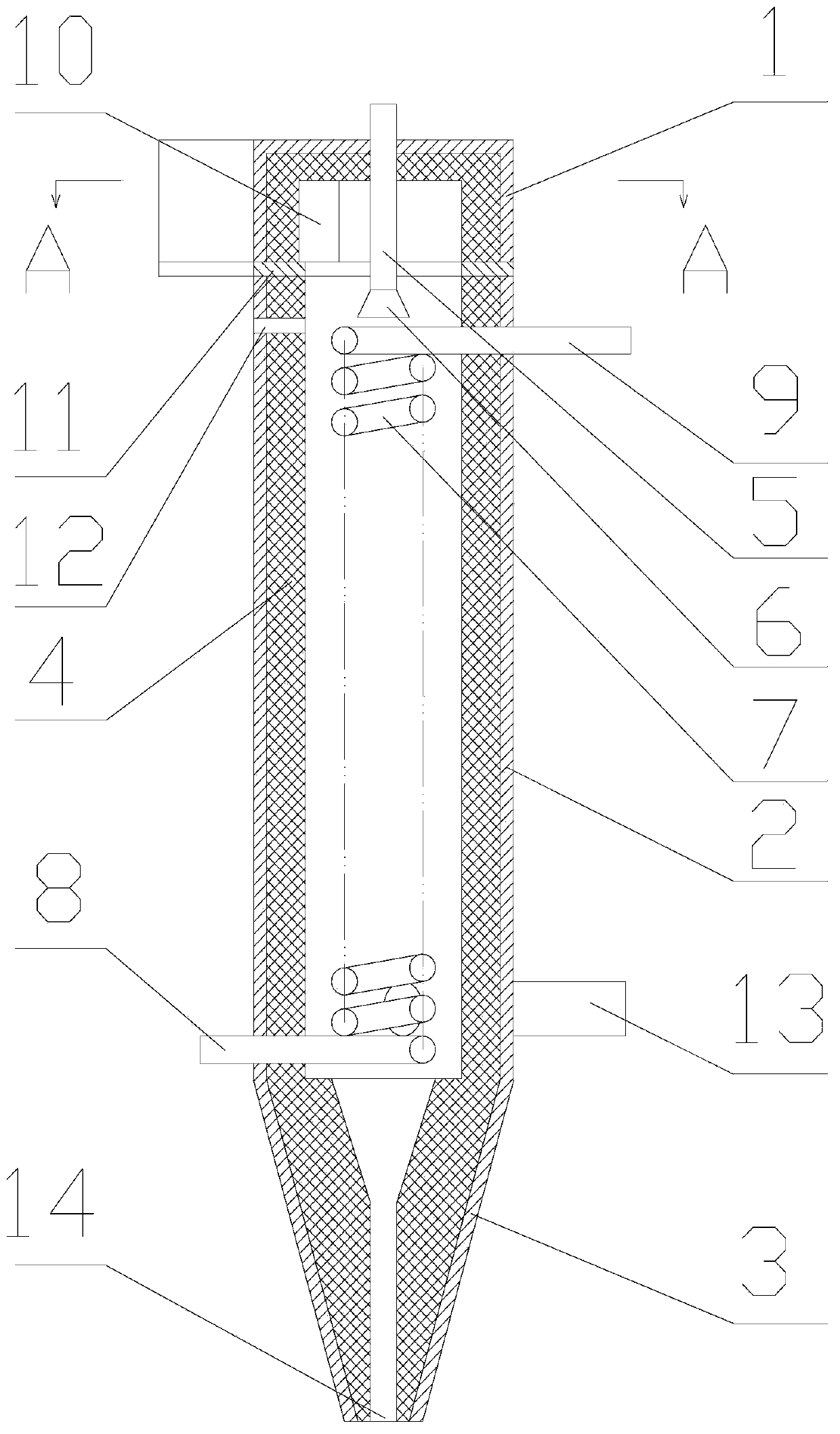

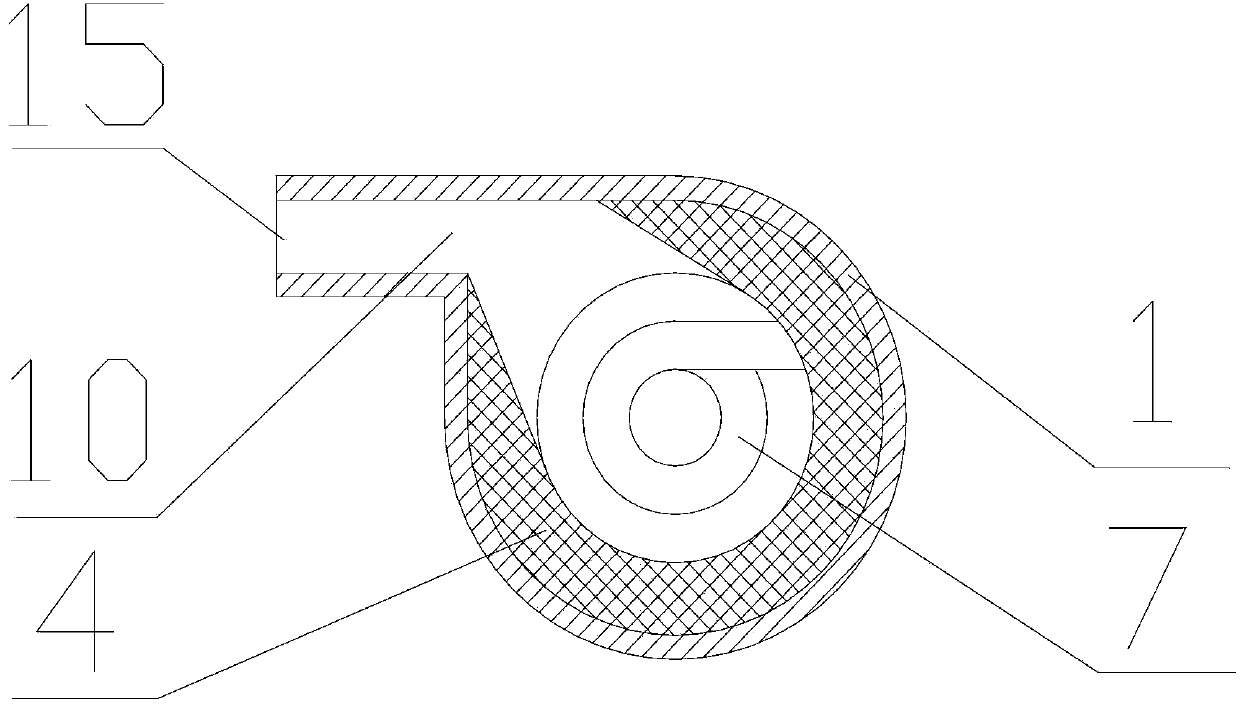

[0019] like figure 1 , 2 As shown, a high-temperature mineral powder cooling device includes a volute case 1 and a cooling center cylinder 2, the volute case 1 is arranged on the upper end of the cooling center cylinder 2, and the two are sealed and fixed; the volute case 1 includes a volute Mouth 10 and center casing, the center casing of volute casing 1 is the cylindrical cylindrical structure that has opening at the lower end, and feed pipe 5 is installed at the top center of volute casing 1; 10 is air outlet 15;

[0020] The cooling central cylinder 2 is a cylindrical structure with a through hole in the center, and a cooling spiral water pipe 7 is arranged in the central through hole of the cooling central cylinder 2, and the discharge end of the feeding pipe 5 is located at the cooling spiral water pipe 7 above; the upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com