Combined special-shape steel plate stiffened-core cement foundation pit support structure and construction method thereof

A special-shaped steel plate and foundation pit enclosure technology, which is applied in the direction of foundation structure engineering, excavation, construction, etc., can solve the problem that the bending and torsional performance of concrete core cement-soil composite piles is difficult to guarantee, and the internal support enclosure structure is difficult to reuse , Gravity support structure poor bending resistance and other problems, to achieve the effect of outstanding technical and economic benefits, convenient structure combination, and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

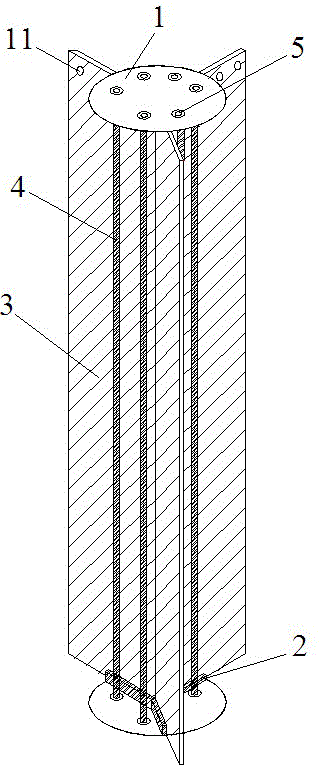

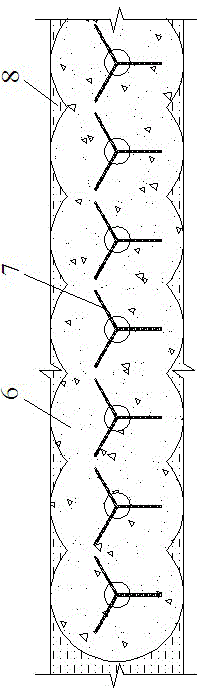

[0042] refer to Figure 1 to Figure 6 shown. The combined special-shaped steel plate stiff core cement-soil foundation pit enclosure structure includes combined special-shaped steel plates 7 and cement-soil mixing piles 6 .

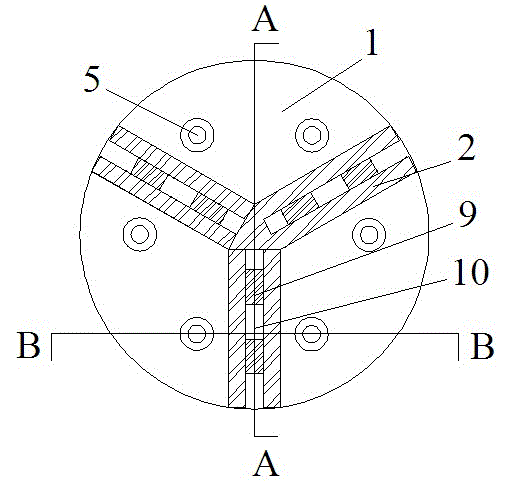

[0043] The combined special-shaped steel plate 7 is surrounded by 3 vertical steel plates 3 with similar or identical specifications, combined connectors 15 and steel strands 4.

[0044]Three vertical steel plates 3 are combined to form a Y shape, and the combined section is a Y shape. The angle between two adjacent vertical steel plates 3 is 120°. The vertical steel plates 3 are 8000mm long, 200mm wide, and 15mm thick. They are made of hot-rolled steel plates with a strength grade of Q345E. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com