Light steel keel and construction wall body made of same

A light steel keel and building wall technology, which is applied in the directions of buildings, building components, building structures, etc., can solve the problems of poor sound insulation, affecting the living quality of the public, building quality, and low compressive strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

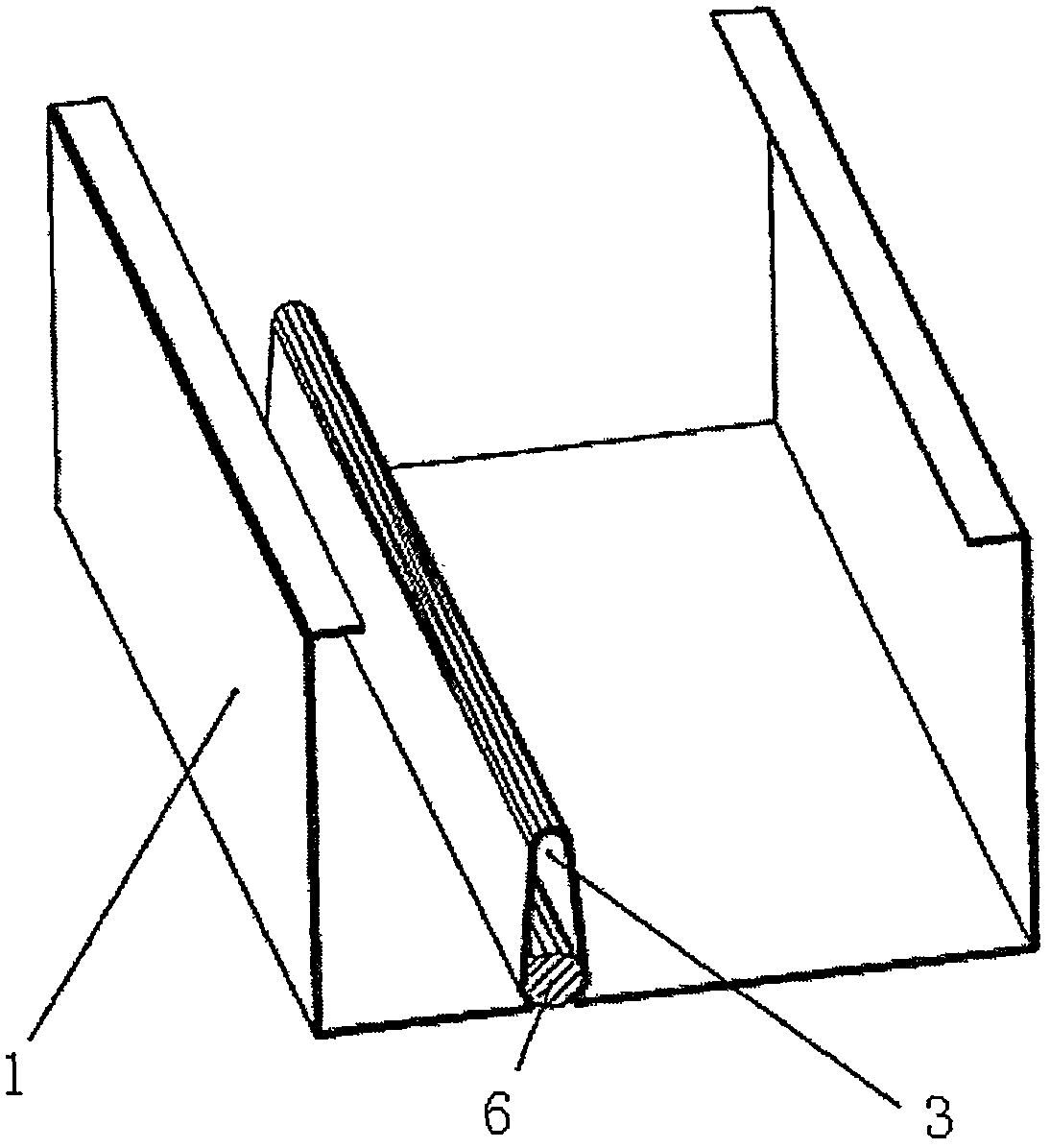

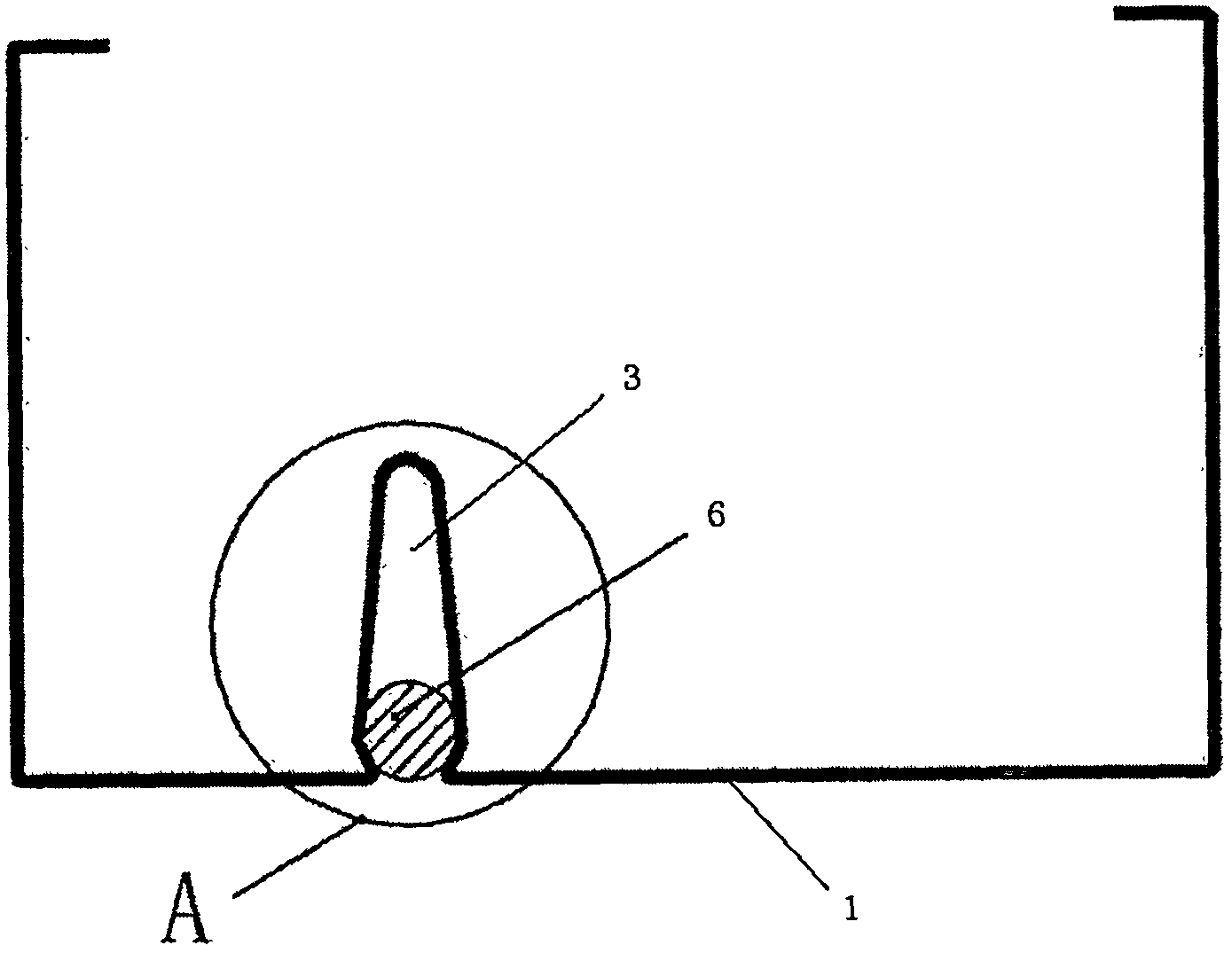

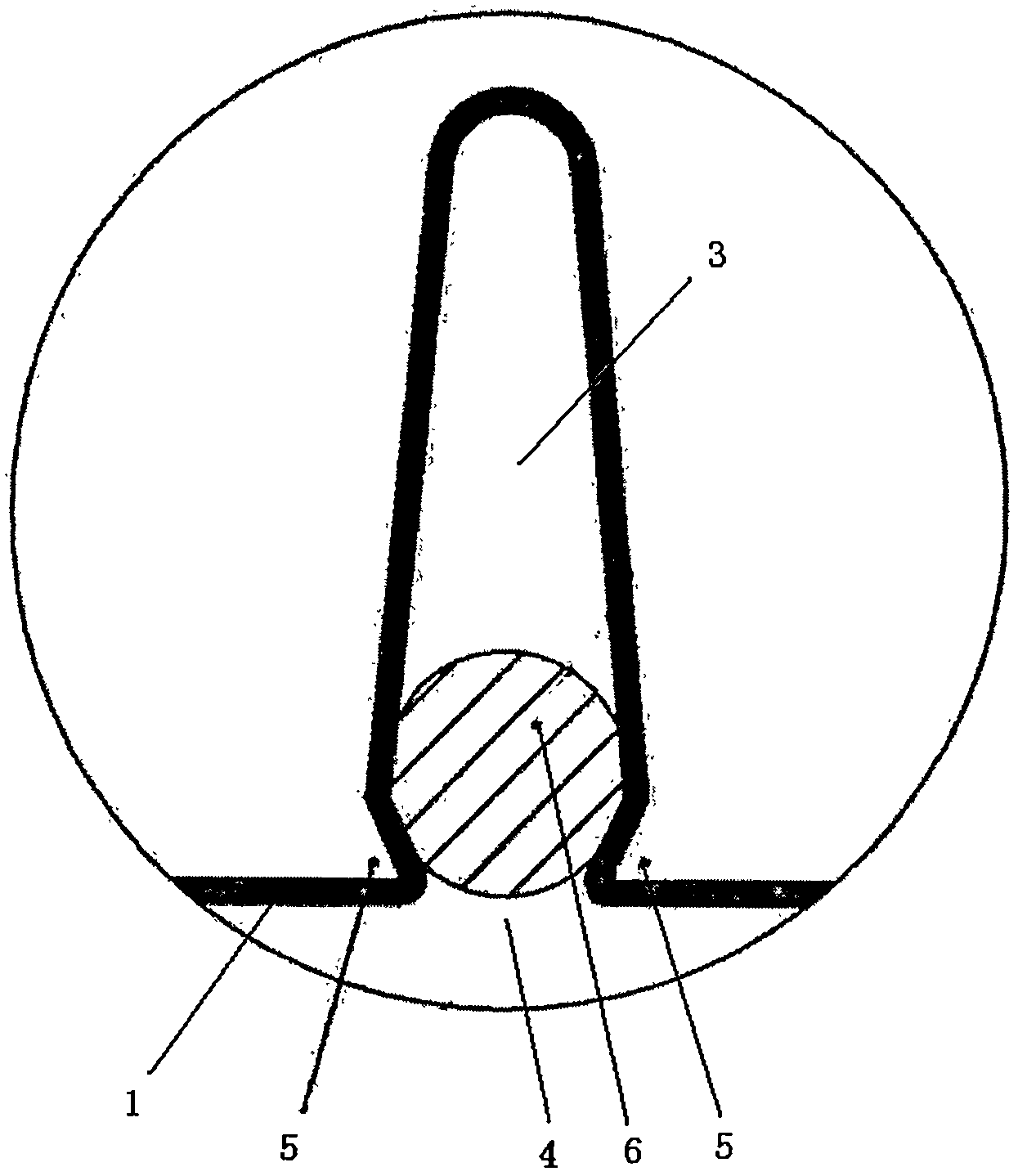

[0010] Embodiment 1: refer to figure 1 , figure 2 , image 3 , In this embodiment, a groove parallel to the length direction of the skeleton is provided on the skeleton of the light steel keel. Because of the specific structure of the groove, the impact resistance and compressive strength of the present invention can be improved.

Embodiment 2

[0011] Embodiment 2: refer to figure 1 , figure 2 , image 3 In this embodiment, on the basis of Embodiment 1, the cross-section of the groove is designed as a trapezoid, and two chamfers are respectively made at the two corners of the lower bottom of the trapezoid, and the chamfers are located at the notch of the groove. A rubber strip is provided, and the recess of the groove is provided with a restrained closing (chamfer) so that the rubber strip does not fall off from the trapezoidal groove, and at the same time increases the contact area between the rubber strip and the keel, so as to improve the sound insulation effect and Impact and compressive strength.

Embodiment 3

[0012] Embodiment 3: refer to figure 1 , figure 2 , image 3 , Figure 4 In this embodiment, a light steel keel frame with rubber strips inlaid in the trapezoidal groove at the inward constriction is selected, and at least two light steel keel frames are pasted with decorative panels as non-load-bearing walls in the building, so that the building wall has Better sound insulation effect and impact resistance, compressive strength, but also improve the overall firmness and stability of the building wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com