Intelligent automobile glass and preparation method thereof

A kind of automotive glass, intelligent technology, applied in the direction of coating, etc., can solve the problems of time-consuming and laborious, defrosting of automotive glass, etc., and achieve the effect of excellent light transmission, good heat insulation and weather resistance, ensuring comfort and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

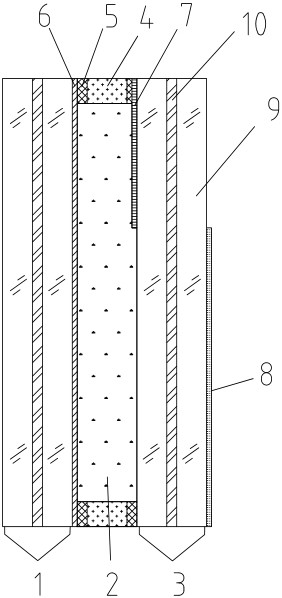

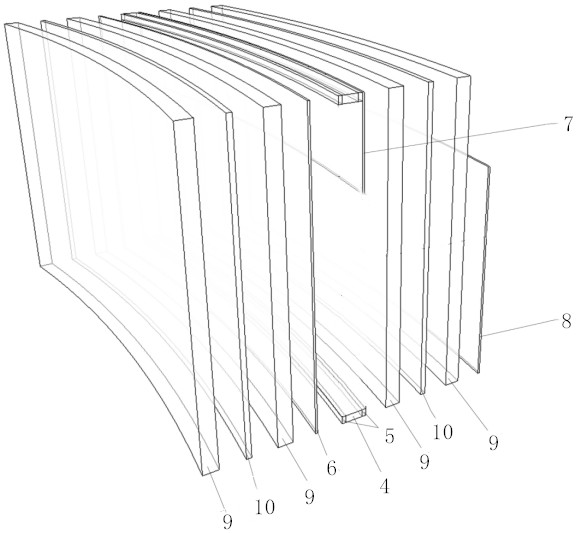

[0038] A kind of preparation method of described intelligent automobile glass, comprises the following steps:

[0039] a. Melt and mix polyvinyl butyral, 2-(2'-hydroxy-5'-tert-octylphenyl) benzotriazole light stabilizer, tobermullite whiskers and extrude to obtain organic layer; the organic layer is placed between the two glass layers and thermocompressed to obtain the first laminated glass layer and the second laminated glass layer;

[0040] b. Paste a transparent graphene electric heating film on one side of the first laminated glass layer; paste a photochromic film on the upper third of one side of the second laminated glass layer, and pass through the magnetron in the lower two-thirds of the other side. MgF plating by sputtering process 2 Film, HfxTiO 2-x (x=0.1-0.15) film, Si 3 N 4 membrane;

[0041] c. Use sealant to bond the first laminated glass layer with the transparent graphene electric heating film surface, the second laminated glass layer with the photochromi...

Embodiment 1

[0046] A kind of preparation method of described intelligent automobile glass, comprises the following steps:

[0047] a. Polyvinyl butyral, 2-(2'-hydroxy-5'-tert-octylphenyl) benzotriazole light stabilizer, and tobermullite whiskers are mixed in a mass ratio of 1:0.002:0.08 The organic layer was obtained by melt mixing and extrusion, the melting temperature was 165°C, the melt mixing time was 15min, and the extrusion temperature was 165°C; the organic layer was placed between two glass layers for thermocompression molding, and the thermocompression molding temperature was 145 ℃, the glass layer is tempered glass with a curved surface area, and its thickness is 2mm, that is, the first laminated glass layer and the second laminated glass layer are obtained;

[0048] b. paste a transparent graphene electrothermal film with a thickness of 0.5mm on one side of the first laminated glass layer; paste a photochromic film in the upper third area of one side of the second laminated g...

Embodiment 2

[0053] A kind of preparation method of described intelligent automobile glass, comprises the following steps:

[0054] a. Add polyvinyl butyral, 2-(2'-hydroxy-5'-tert-octylphenyl) benzotriazole light stabilizer, and tobermullite whiskers in a mass ratio of 1:0.002:0.02 The organic layer was prepared by melt mixing and extrusion, the melting temperature was 175°C, the melt mixing time was 15min, and the extrusion temperature was 185°C; the organic layer was placed between two glass layers for thermocompression molding, and the thermocompression molding temperature was 160 ℃, the material of the glass layer is ultra-clear glass, and its thickness is 4mm, that is, the first laminated glass layer and the second laminated glass layer are obtained;

[0055] b. paste a transparent graphene electrothermal film with a thickness of 0.5mm on one side of the first laminated glass layer; paste a photochromic film in the upper third area of one side of the second laminated glass layer, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com