Pipe joint of corrugated hose

A technology for corrugated hoses and pipe joints, applied in the field of pipe joints, can solve the problems of corrosivity of glue weakening the pipe wall, unfavorable material cost and environmental protection, and inability to reuse, etc., and achieves convenient and fast docking process, simple and ingenious structure, and manufacturing cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

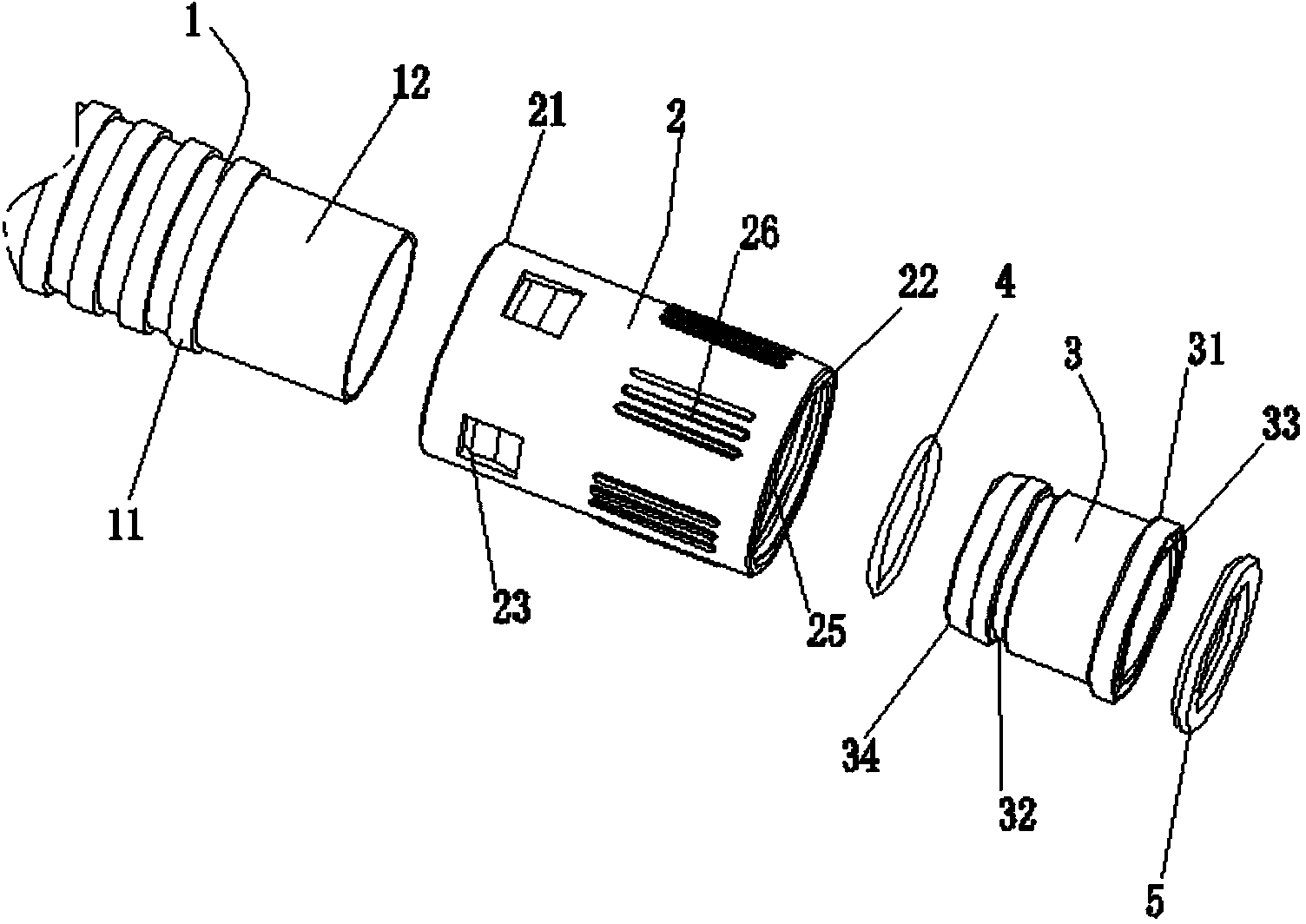

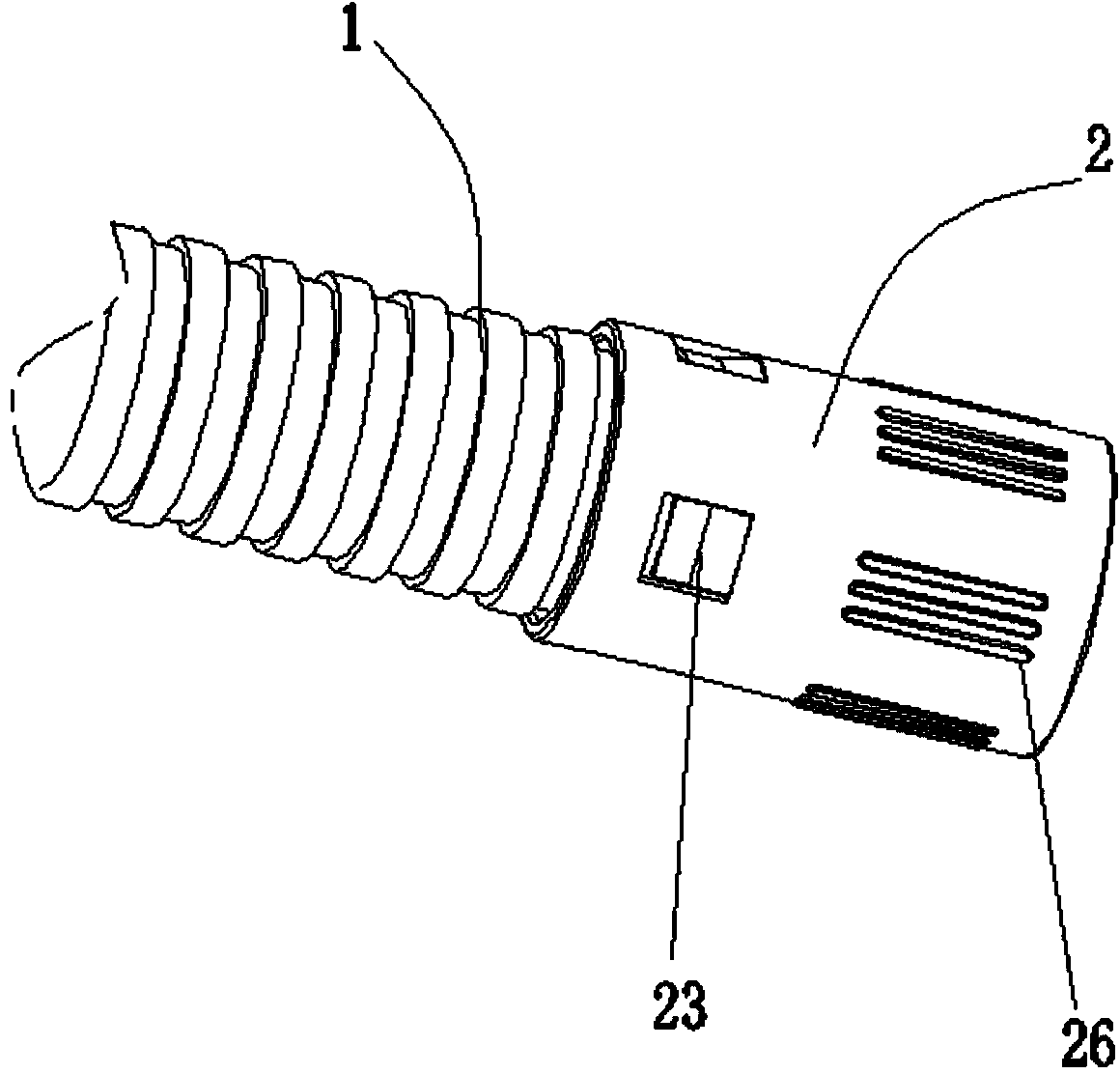

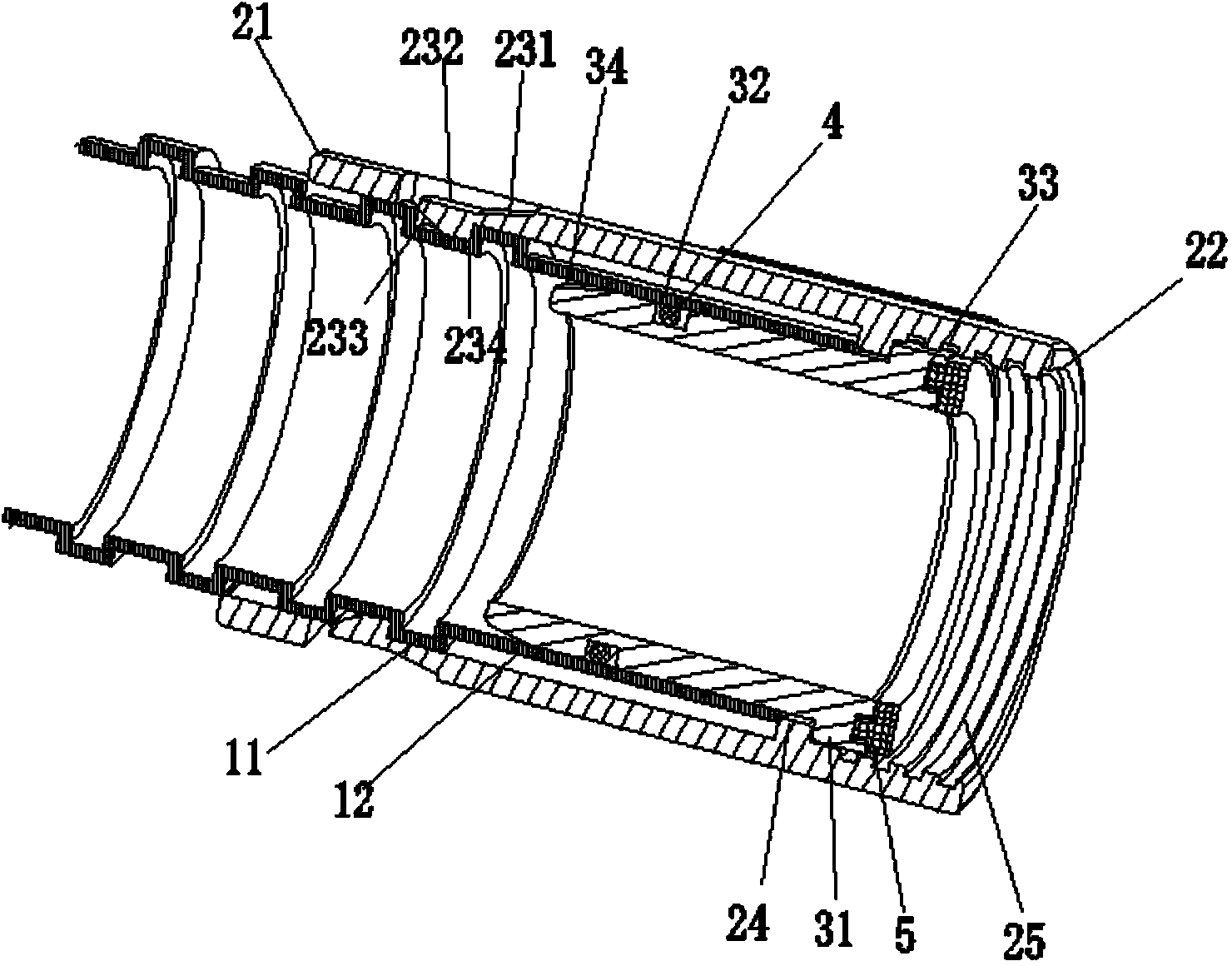

[0032] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a pipe joint of a corrugated hose, the corrugated hose 1 includes several corrugated nodes 11 in the middle and a light pipe 12 at the end, the pipe joint includes a tubular joint body 2 and a tubular ferrule 3, the The joint body includes an insertion end 21 for connecting to the corrugated hose and a connection end 22 for connecting to an external device. There are several spacers on the outer periphery of the joint body near the insertion end that can be clamped on the corrugated hose. The elastic claw 23 on the joint; the positioning sleeve on the outer peripheral side of the middle part of the ferrule is provided with a first sealing ring 4, and one end of the ferrule is positioned and sleeved in the joint body close to the coupling end, and the end face A second sealing ring 5 is positioned, and the other end and middle part of the ferrule can penetrate into the light pipe, so that the first sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com