Material compressing device, material compressing method thereof and sintering machine pallet

A material compaction, machine trolley technology, applied in lighting and heating equipment, furnace types, furnaces, etc., can solve the problems of loose material compaction and poor use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

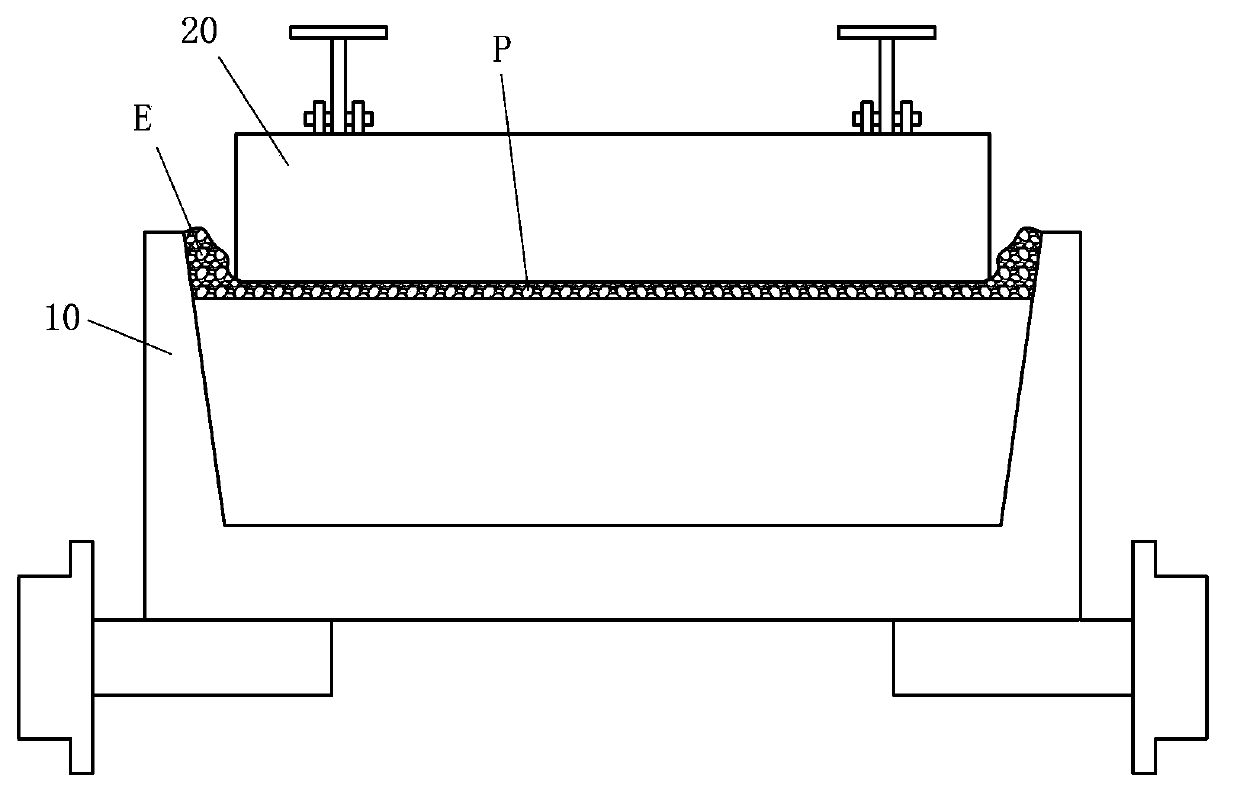

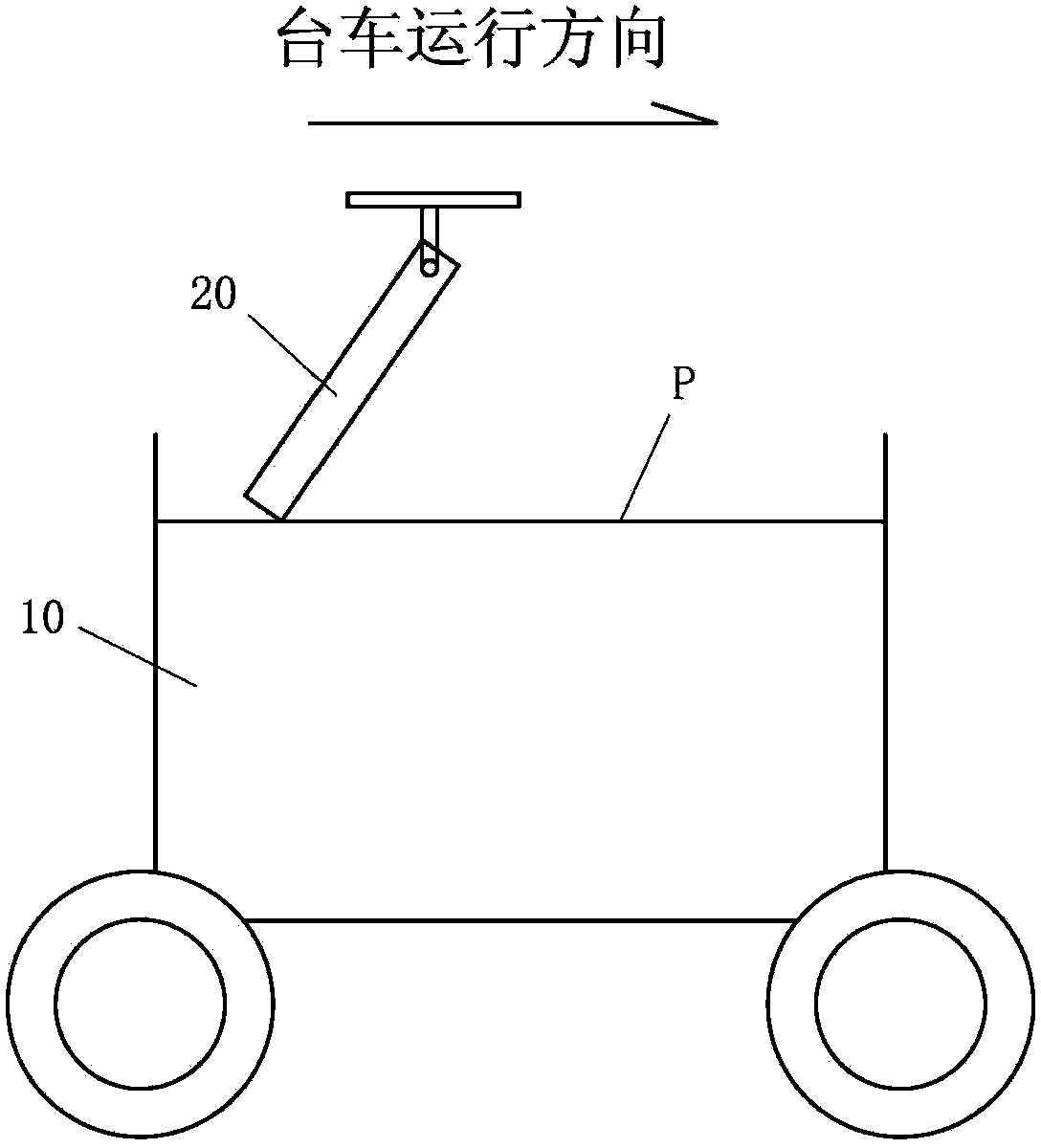

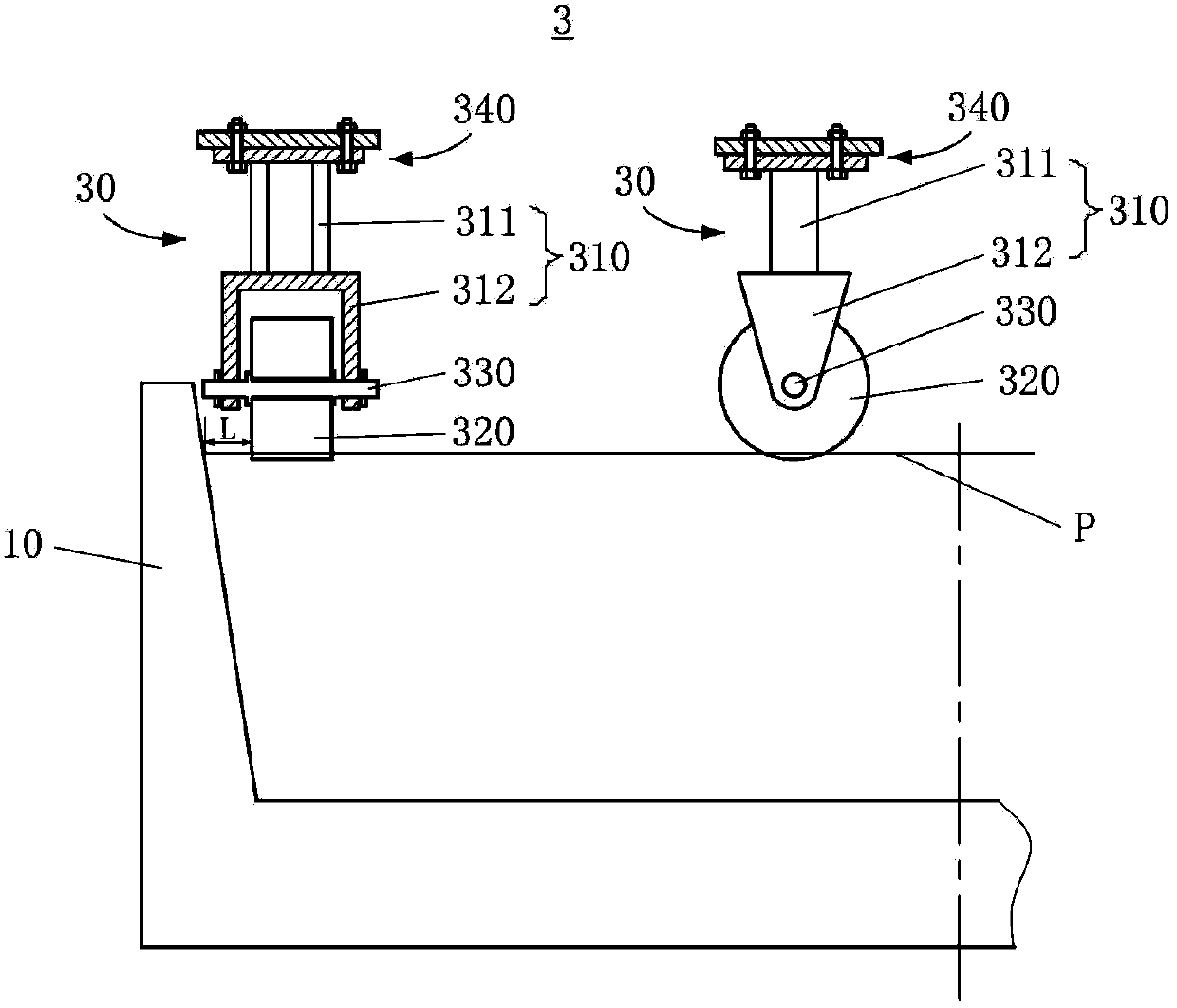

[0022] Examples of embodiments of the present invention will now be described in detail with reference to the accompanying drawings. In the accompanying drawings, for clarity, the regions or elements in the drawings will be exaggerated, and elements are not necessarily drawn to scale, and the same reference numerals always indicate the same elements or structures.

[0023] Different from the prior art dual-support fixed material pressing device, the material pressing device according to the embodiment of the present invention has a simpler structure, which can not only approach the trolley fence to the maximum, so that the edge loose materials can be effectively compressed, but also operate Flexible, good sealing, and the pressure wheel can move up and down with the articulated movement of the movable force arm. The edge of the pressure wheel is always in contact with the material surface. At the same time, it is free to increase or decrease the counterweight on the force arm to im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com