Treatment liquid flow rate meter

A technology for processing liquids and flowmeters. It is applied in liquid/fluid solids measurement, flow measurement/mass flow measurement, and measurement devices, etc., and can solve the problems of complicated and easy-to-change complicated supply piping and its surroundings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

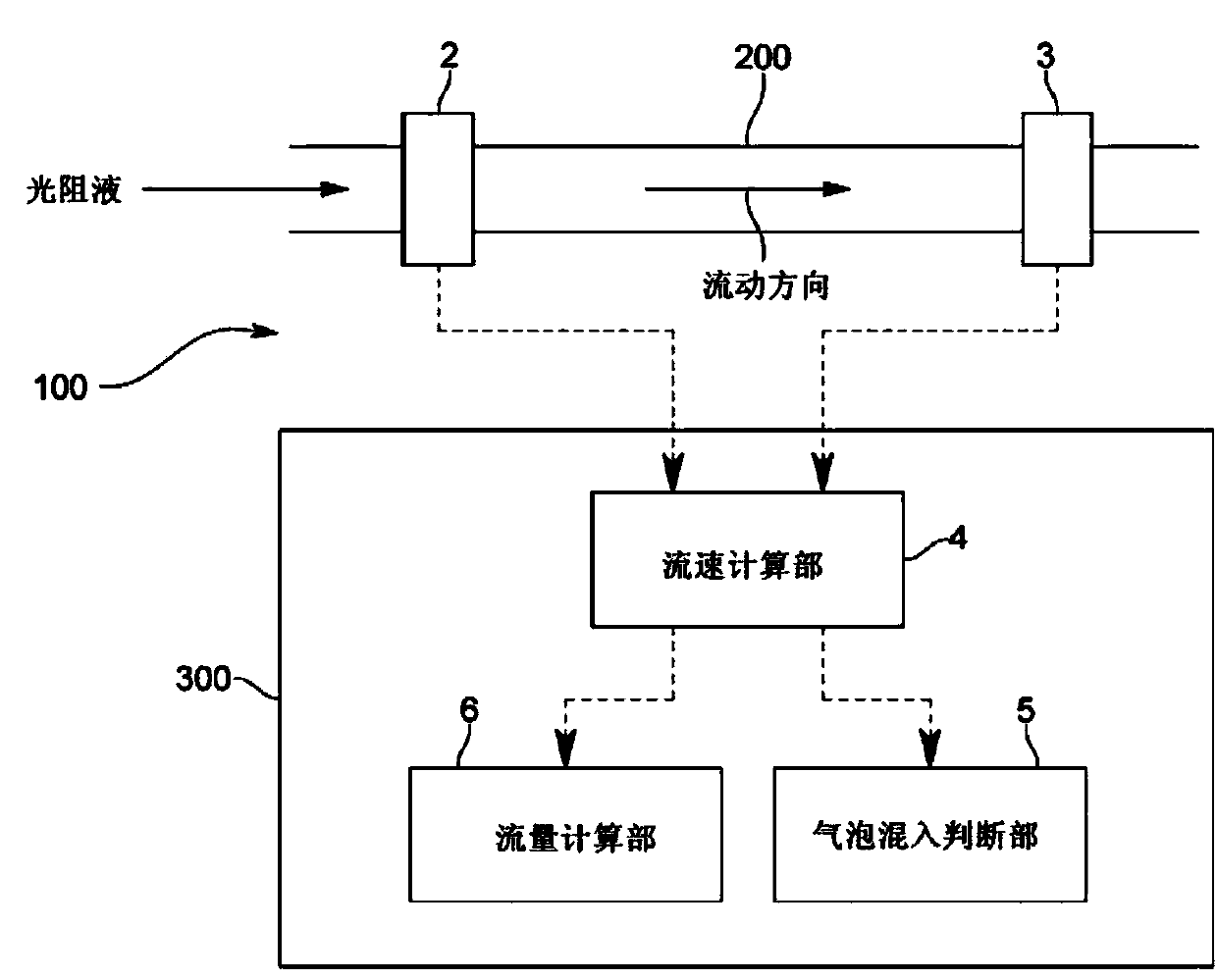

[0032] The process liquid flow meter 100 of this embodiment measures the flow velocity and flow rate of the photoresist liquid flowing in a supply pipe 200 including, for example, a fluorinated polyacrylate (PFA) tube (tube). It is connected to a photoresist coating device of an unillustrated semiconductor manufacturing device. In addition, since the supply piping 200 is constituted by a PFA pipe, there is no pressure loss such as a throttle valve, so air bubbles are less likely to be generated.

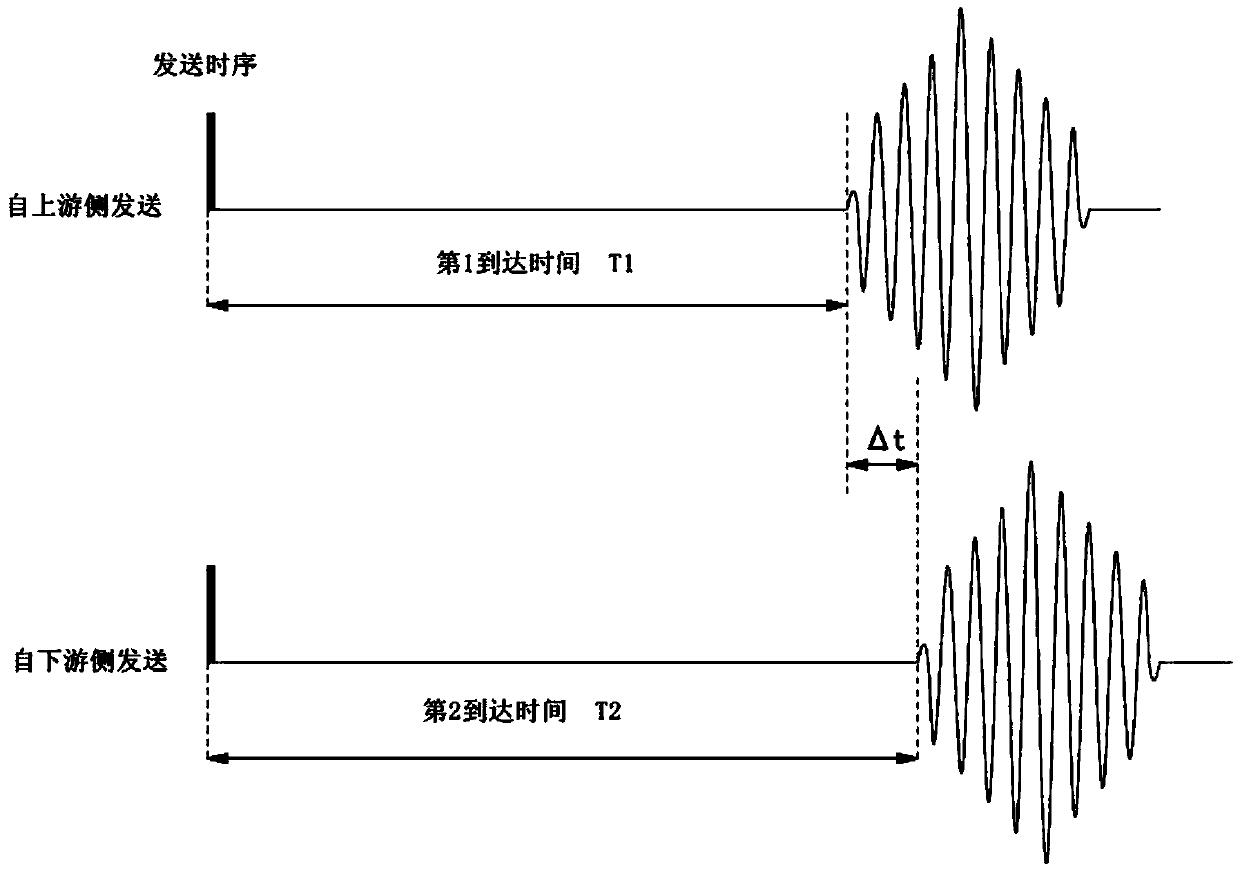

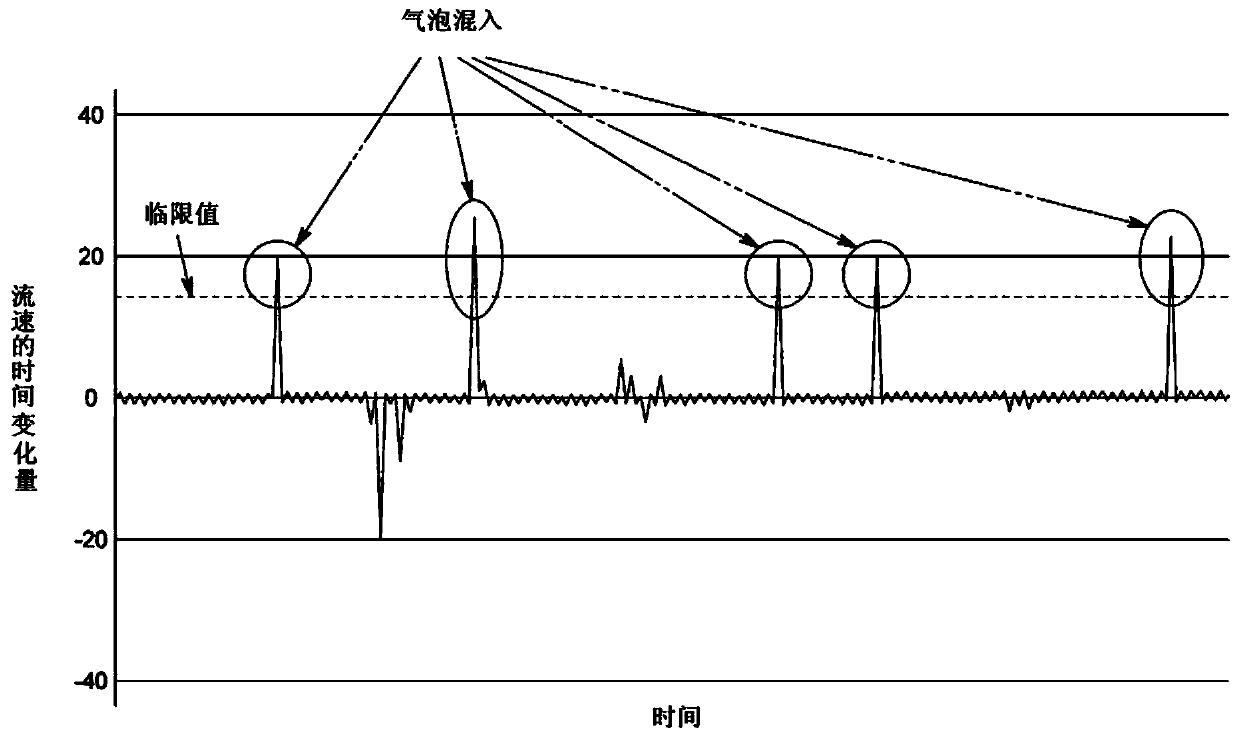

[0033] Specifically, as figure 1 As shown, the flowmeter 100 for processing liquid includes: a pair of ultrasonic vibrators 2, 3 arranged at a fixed distance apart in the flow direction of the supply pipe; The detection signals obtained by the sonic vibrators 2 and 3 calculate the flow velocity of the photoresist liquid; the bubble mixing judging part 5 judges whether bubbles are mixed in the photoresist liquid based on the calculated time variation of the flow velocity of the photo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com