Quick-opening natural gas filter

A filter and natural gas technology, applied in the fields of dispersed particle filtration, gas fuel, chemical instruments and methods, etc., can solve the problems of frequent opening of natural gas filters and increased work intensity, shorten the time for opening the cover, reduce labor intensity, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

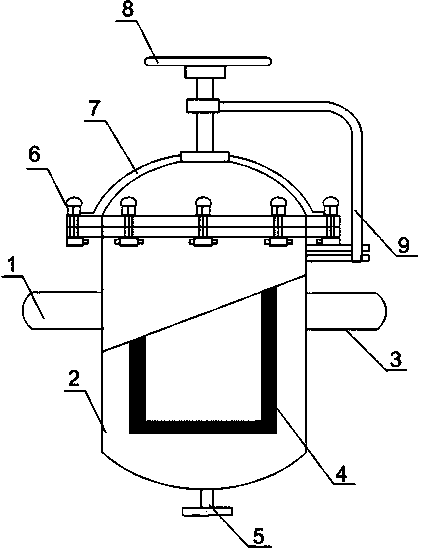

[0019] Such as figure 1 As shown, this embodiment includes a cylinder body 2 and an upper cover 7, the cylinder body 2 is provided with an air inlet 1 and an air outlet port 3, the bottom of the cylinder body 2 is provided with a drain valve 5, and a filter element 4 is installed inside the cylinder body 2, The filter element 4 communicates with the air inlet 1, the air outlet 3 communicates with the inside of the cylinder body 2, the cylinder body 2 is connected with the upper cover 7 through the eyebolt 6, the top of the upper cover 7 is connected with the handwheel 8 through the screw, and the top of the upper cover 7 is connected with the screw The threaded fit also includes a rotating arm 9 arranged on the barrel 2, and the end of the rotating arm 9 is threadedly connected with the screw rod. The upper part of the cylinder 2 is connected and fixed with the external mounting frame by welding, and the bottom of the cylinder 2 is equipped with a drain valve, which can not on...

Embodiment 2

[0022] Such as figure 1 As shown, on the basis of Embodiment 1, this embodiment also includes a differential pressure gauge arranged on the surface of the cylinder body 2, and the two ends of the differential pressure gauge communicate with the air inlet 1 and the air outlet 3 respectively. Generally, the filter will be cleaned regularly, but due to uncertain factors, the filter element net will be damaged, and the failure to clean and check in time will greatly reduce the filtering effect of natural gas; the differential pressure gauge can indicate the pressure change value at the front and rear ends of the filter in real time, It provides a scientific basis for the filter to count the appropriate cleaning time, saves cost, time, and facilitates maintenance, and can effectively save energy and reduce consumption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com