Patents

Literature

30results about How to "Effective energy saving and consumption reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

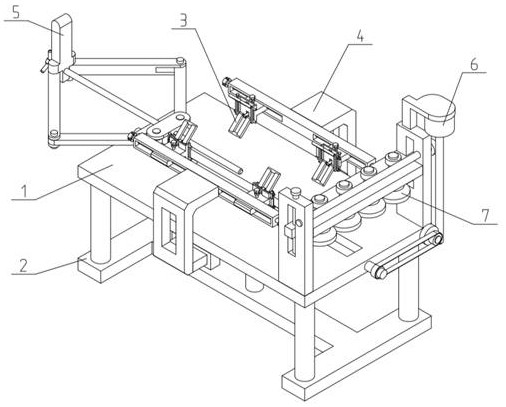

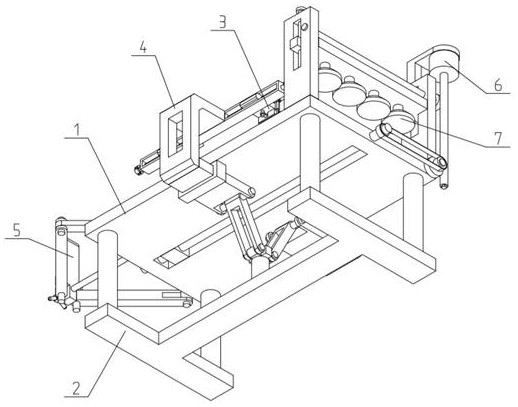

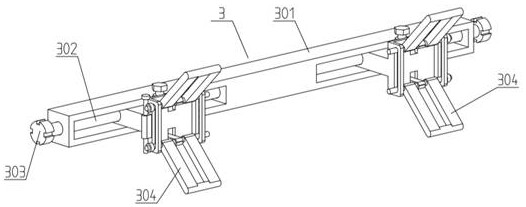

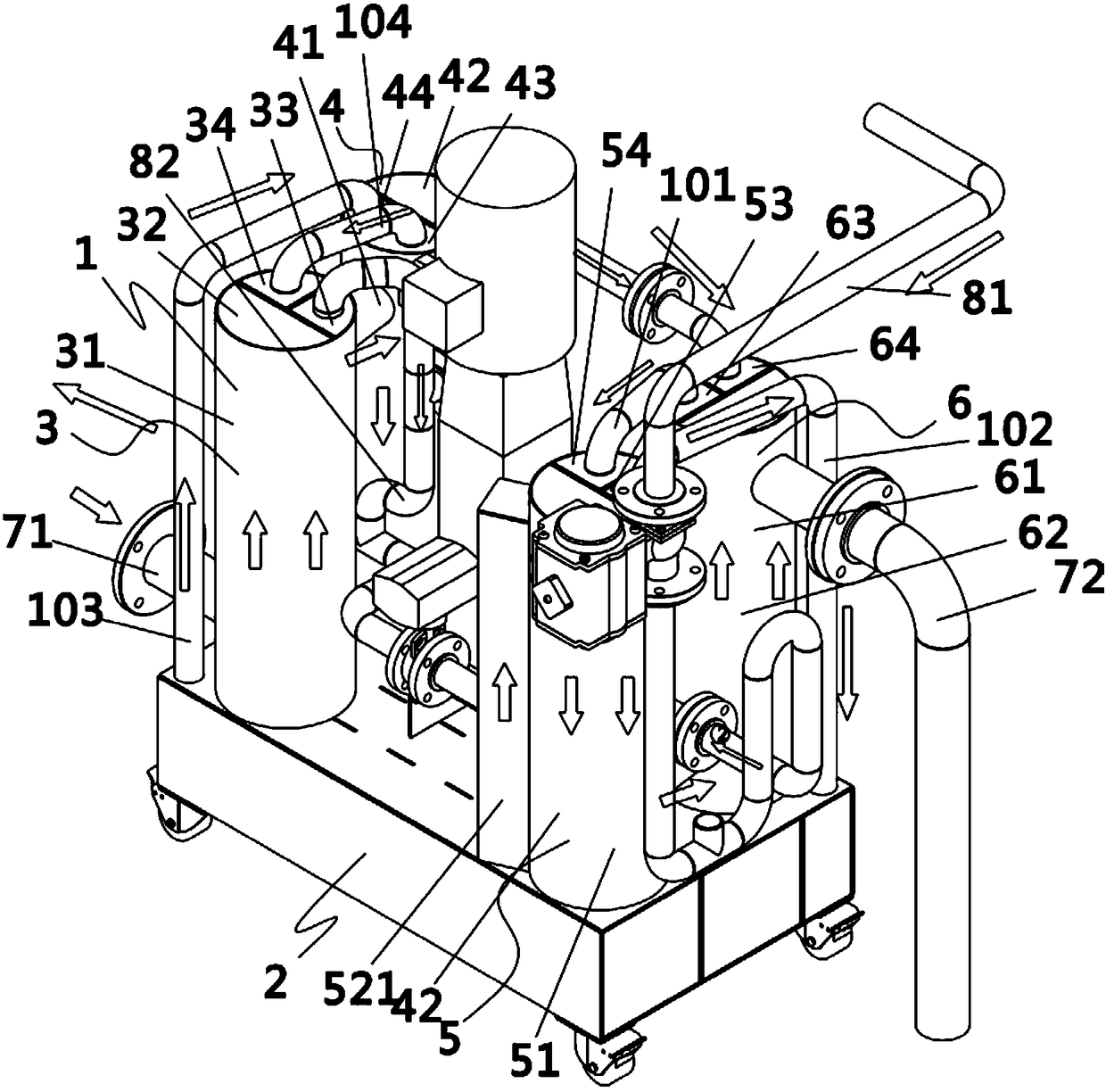

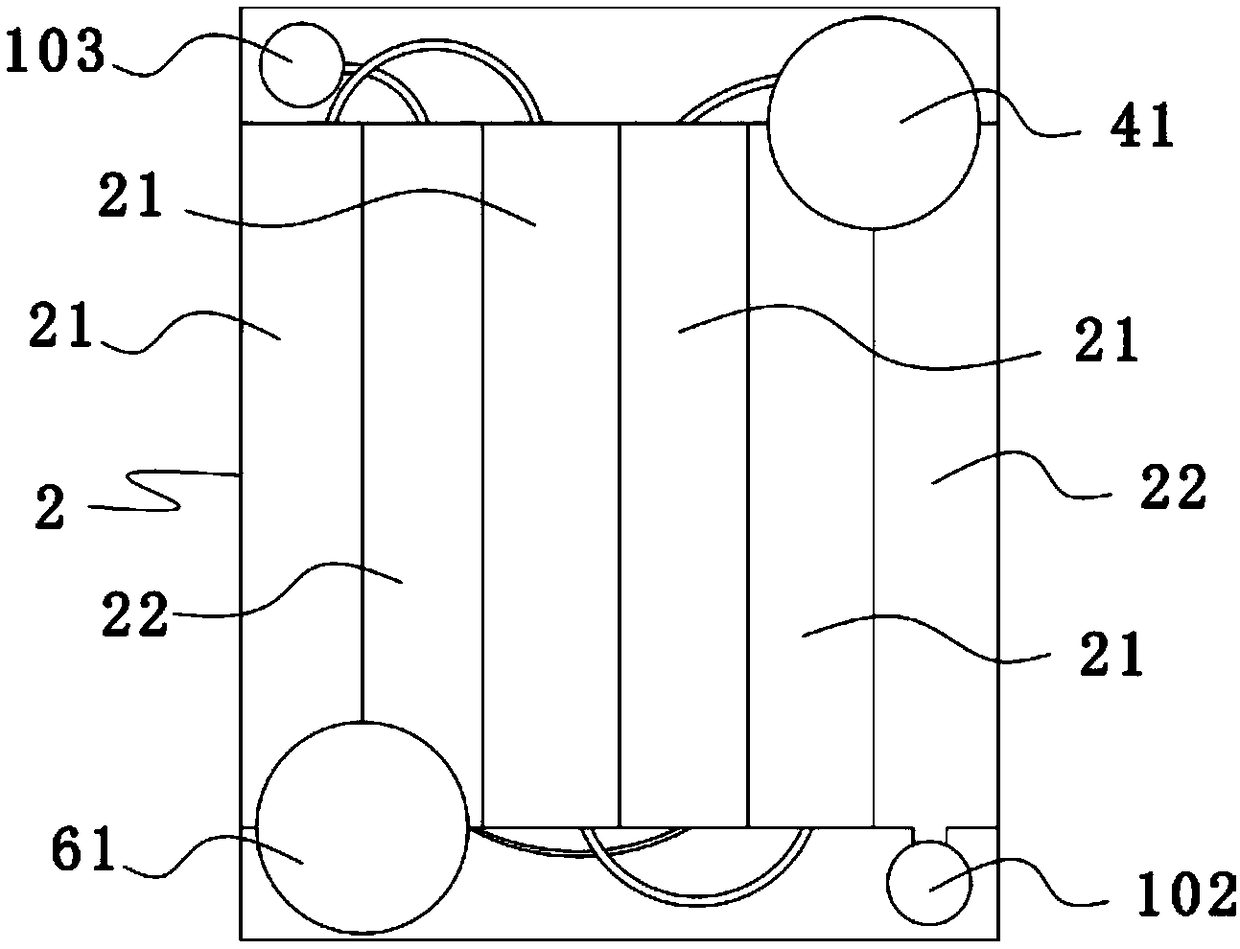

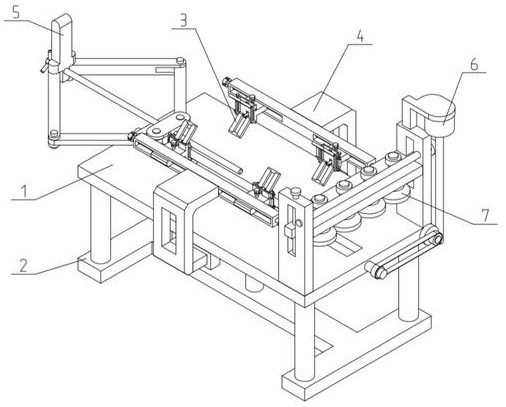

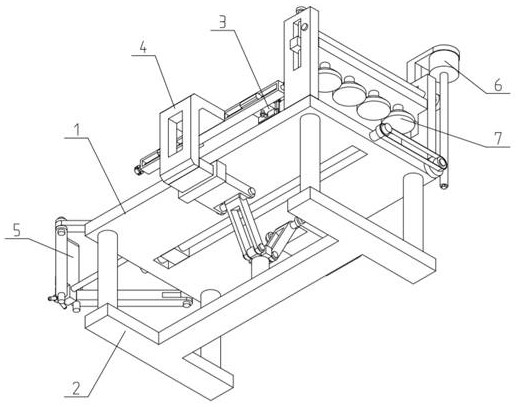

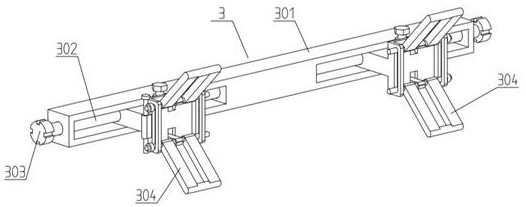

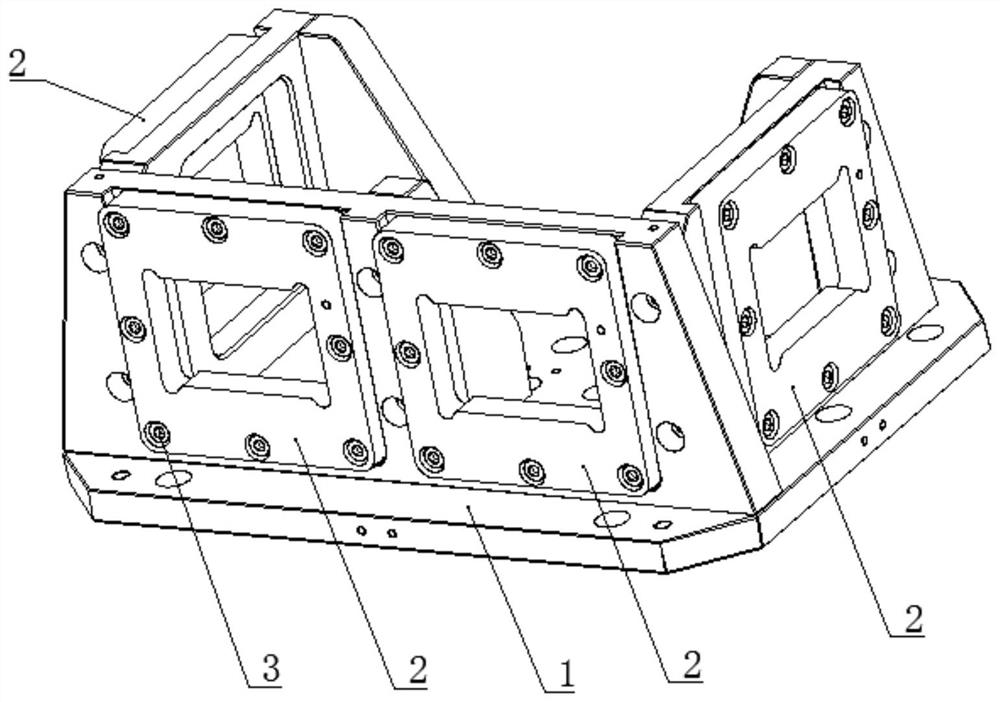

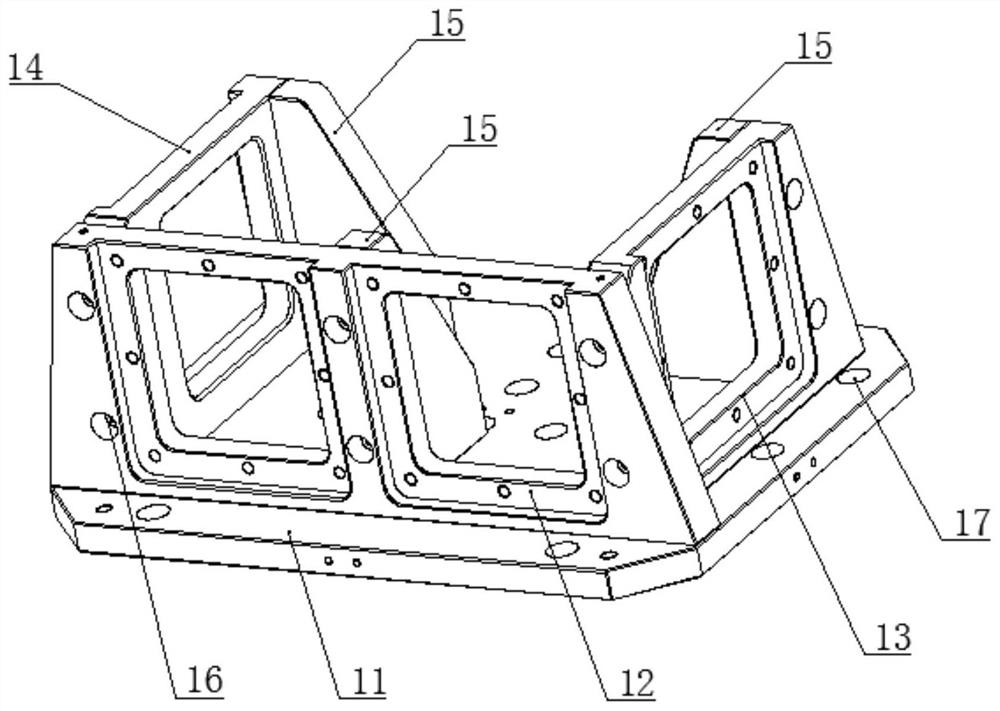

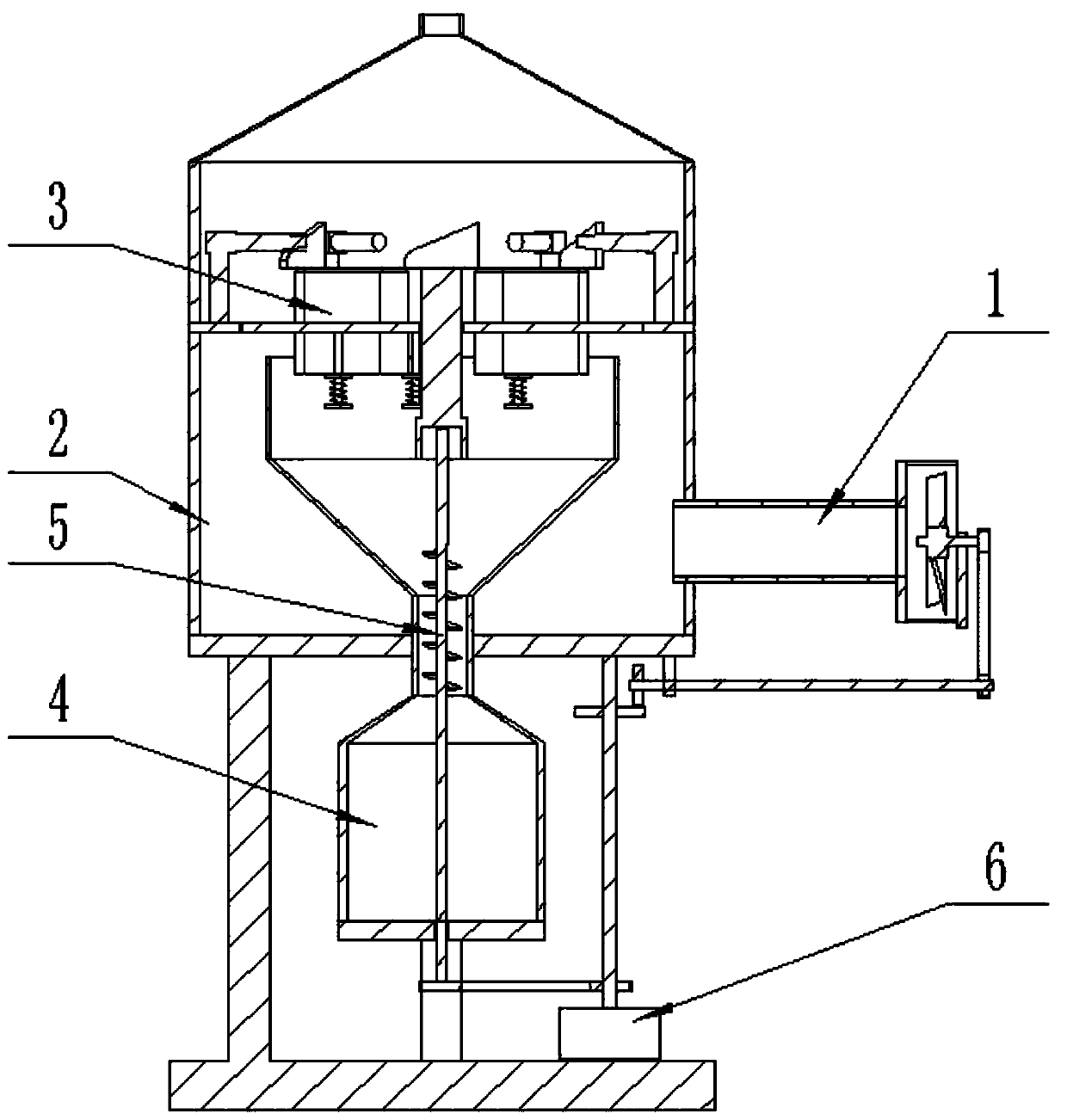

Steel derusting device for building engineering

ActiveCN111843788ASolve problems such as low work efficiencyImprove rust removal efficiencyGrinding drivesGrinding machinesSteel platesSteel tube

The invention relates to the technical field of building steel processing equipment, in particular to a steel derusting device for building engineering. The steel derusting device comprises a workingtable, a support frame, a steel clamping mechanism, a movable bracket, a pushing mechanism, a driving mechanism and a derusting mechanism; the working table is fixedly connected with the support frame; the pushing mechanism and the derusting mechanism are connected with the working table relatively; the lower end of the movable bracket is connected with the support frame; the upper end of the movable bracket is connected with the working table; and the two steel clamping mechanisms are provided and connected with the both sides of the upper end of the movable bracket relatively fixedly. According to the steel derusting device, steel pipes or steel plates in different sizes are clamped, dragged and dropped through regulation of the steel clamping mechanisms, thereby facilitating cooperationwith the pushing mechanism to push the steel pipes or the steel plates to the lower end of the derusting mechanism for derusting work.

Owner:ZHONGQI JIAOJIAN GRP

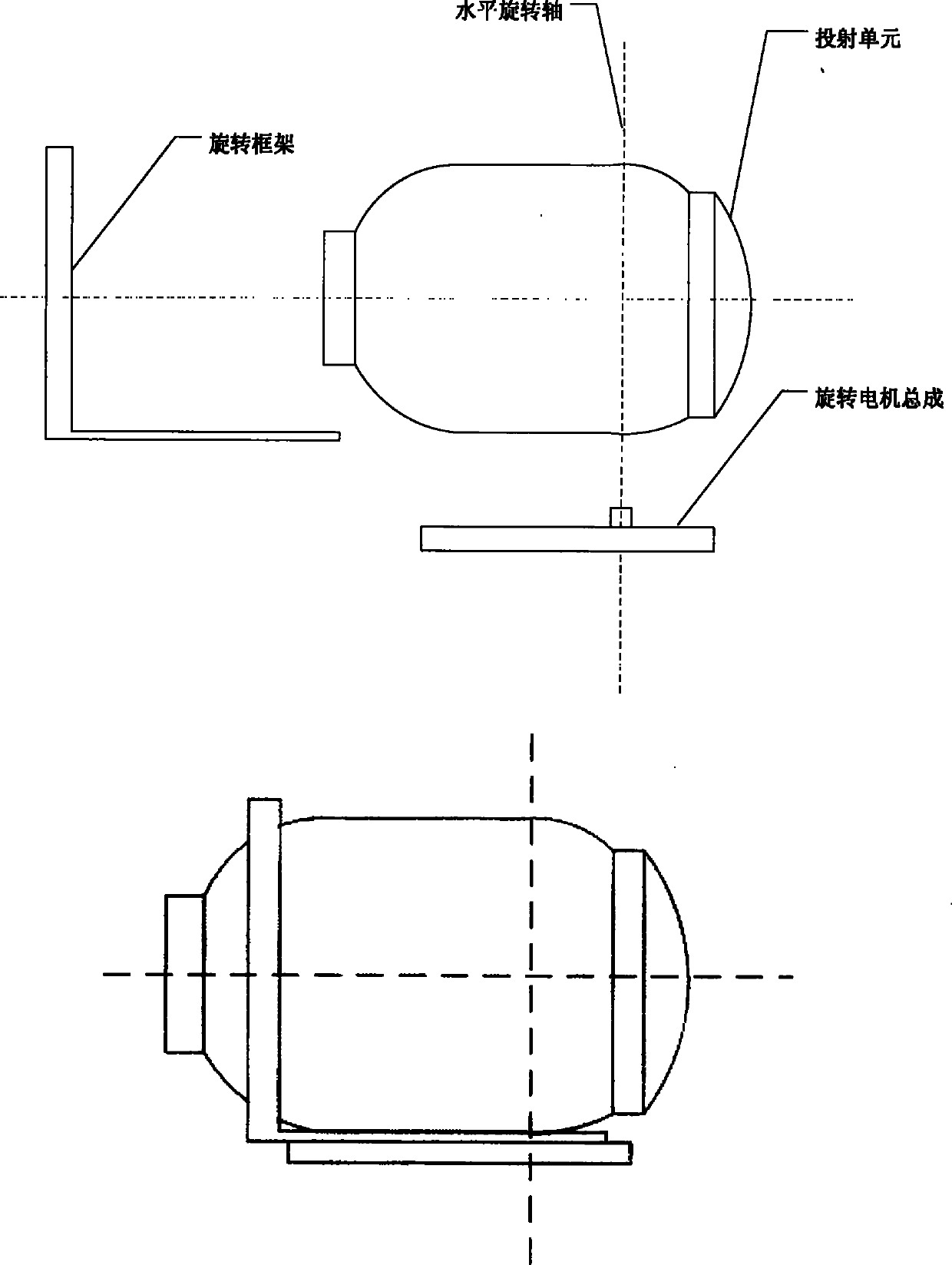

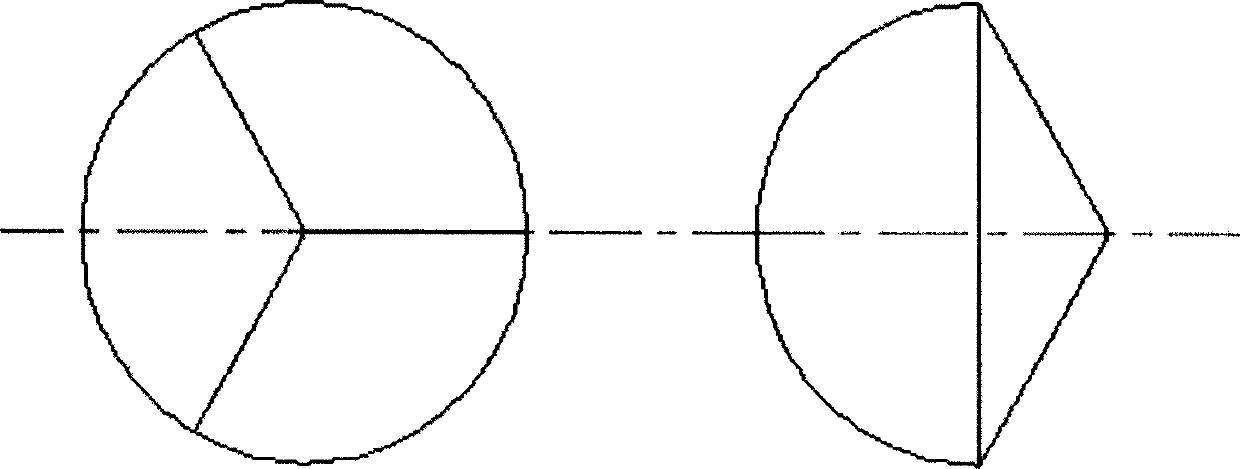

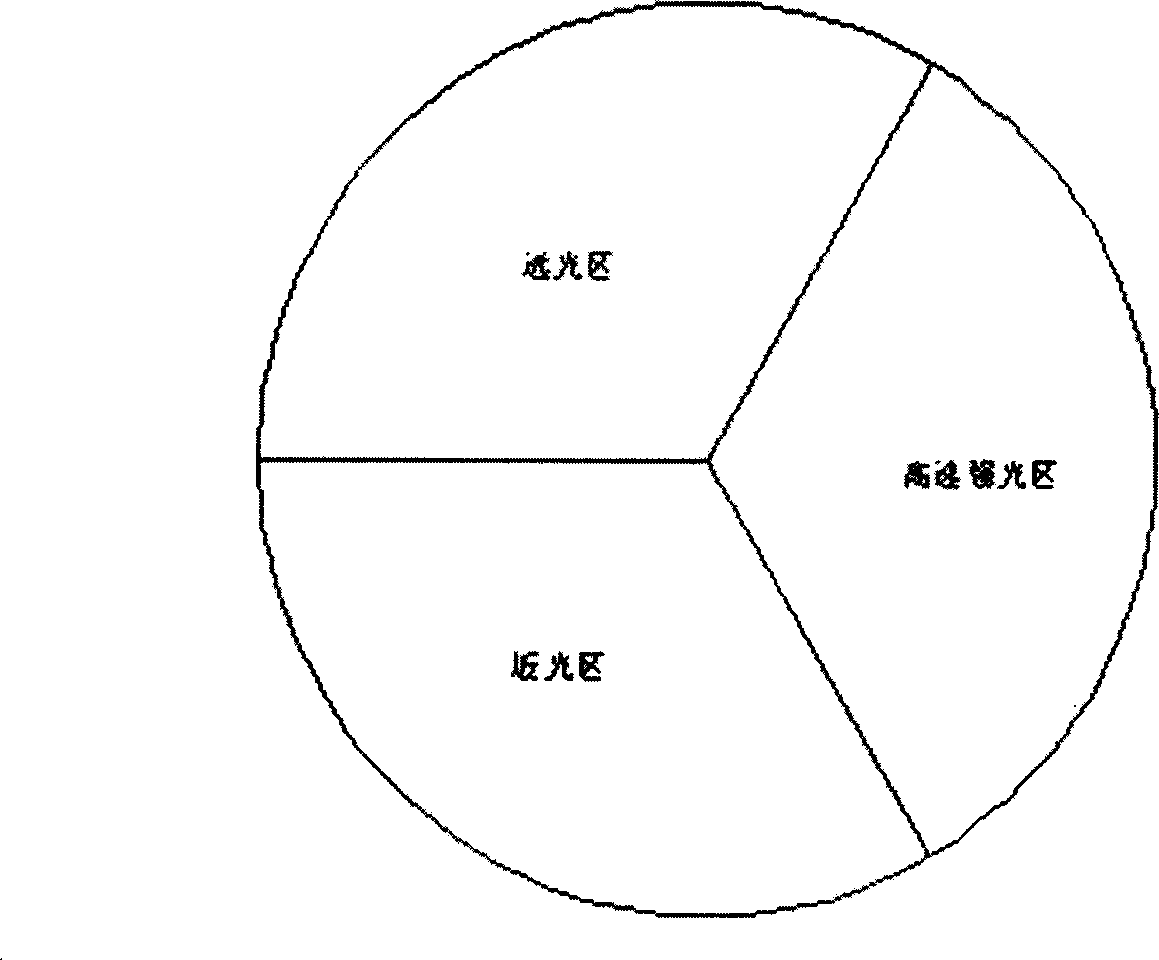

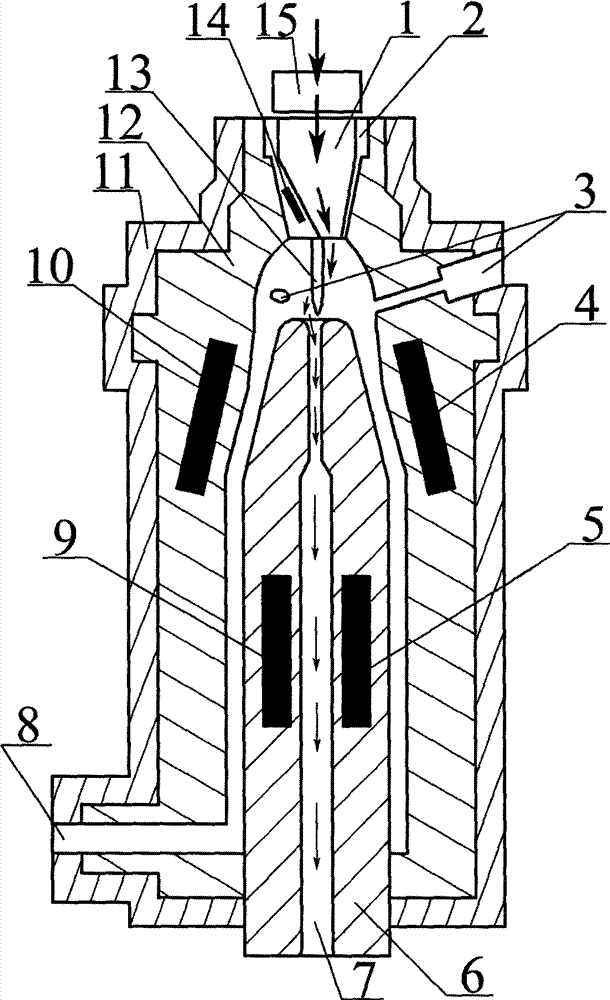

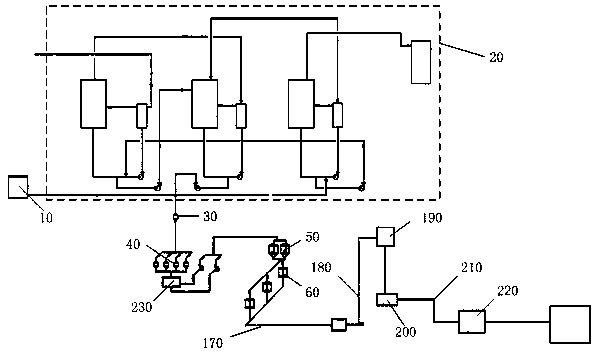

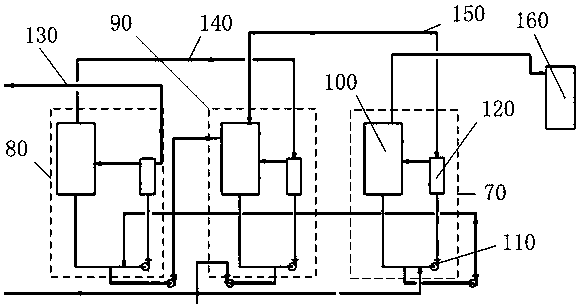

Adaptive front-lighting system (AFS) control system for intelligent turning of headlight of automobile

The invention relates to an adaptive front-lighting system (AFS) control system for the intelligent turning of a headlight of an automobile. The system is based on the control of a fuzzy neural network and is divided into two classes which are a hardware system and a software system. The hardware system comprises a master controller, an actuator, a sensor module and the like; and the software system comprises a master program and each subprogram. The invention particularly relates to the regulation of the horizontal and vertical directions of the light rays of a headlight, the realization of the function of automatic switching of far and near light, the preliminary aiming technology of the headlight and effective combination between the headlight and a global positioning system (GPS) navigation system. The structure and the curvature of a road in front are forecast as much as possible according to navigation information, and the light type of required lamplight is provided. According to the device disclosed by the invention, the intelligent control of the headlight of the automobile is realized. The AFS control system for the intelligent turning of the headlight of the automobile has the characteristics of energy saving, intelligence and long service life. The running safety of an automobile is increased. The AFS control system for the intelligent turning of the headlight of the automobile has better humanization and universality and has popularization value and use value.

Owner:丹阳众诚汽车部件科技有限公司

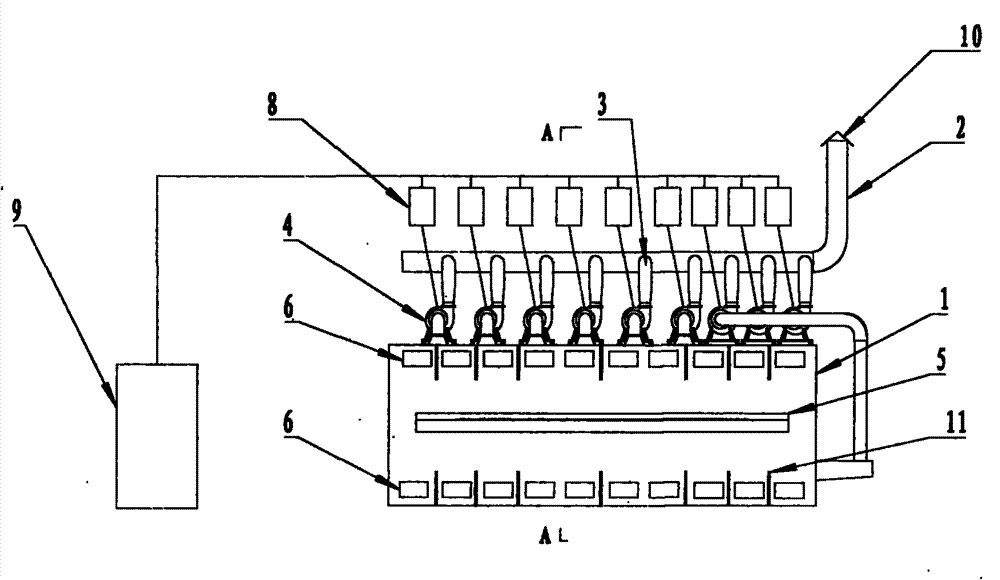

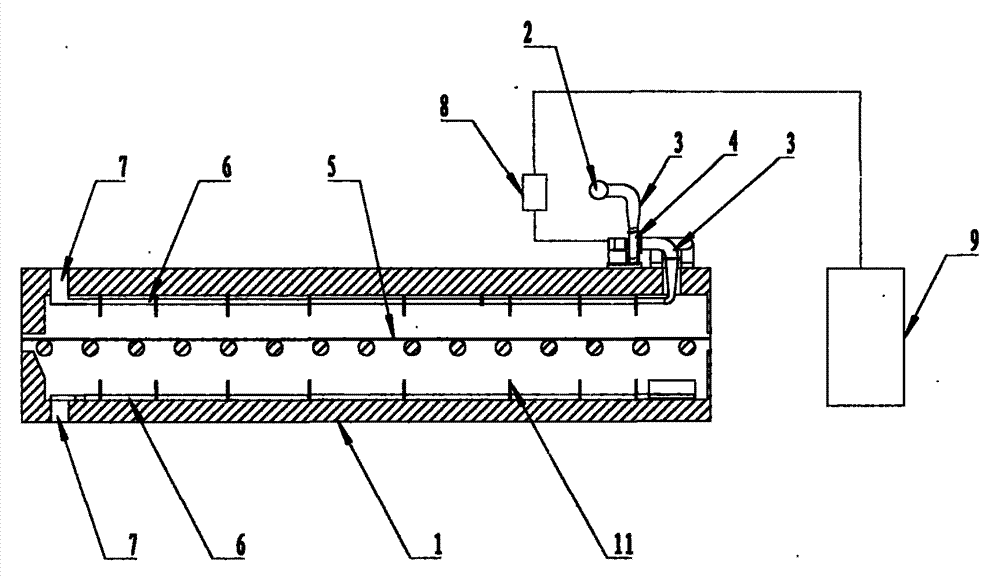

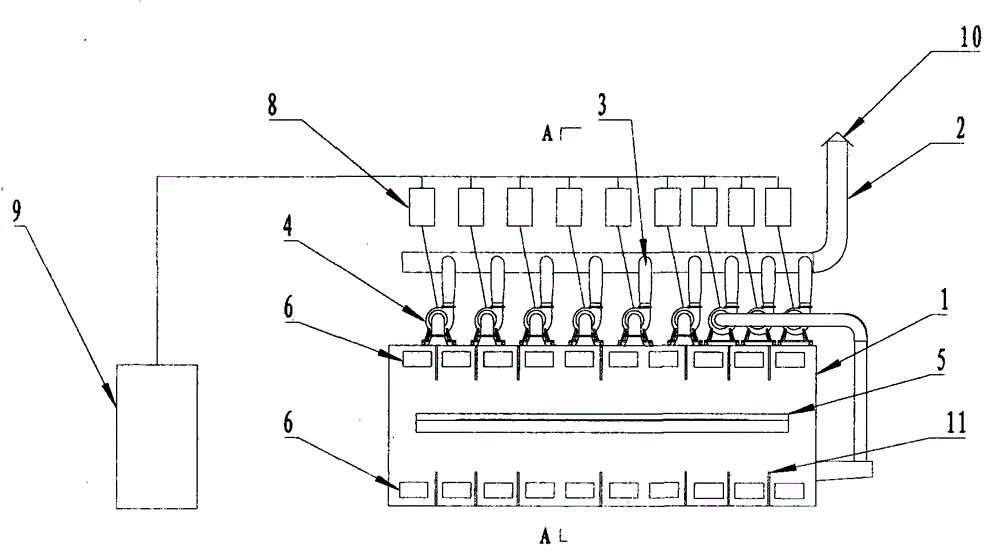

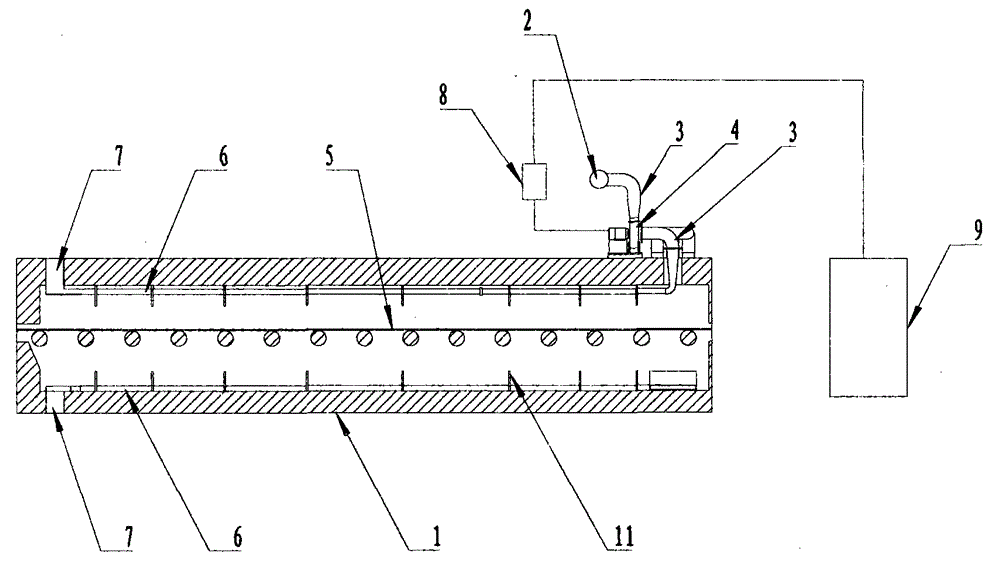

Energy-saving system of cooling air hose of glass annealing kiln and cooling method of glass tape

The invention relate to an energy-saving system of a cooling air hose of a glass annealing kiln and a cooling method of a glass tape. Each pipeline is equipped with a draught fan which is provided with a frequency converter, and the frequency converters are freely controlled by an industrial personal computer to reaching the purpose of adjusting the rotating speed of the draught fans, so that each branch air hose is more convenient to control. The size of the cooling air amount of each branch air hose can be conveniently adjusted according to the temperature adjusting demands of glass plates in different regions, so that the temperatures in each region in the annealing kiln is reasonable and the best glass annealing effect is achieved. The equipment investment is reduced, the pipeline system is simplified, the energy utilization rate of the manufacturer is greatly improved and the electric energy consumption of the ventilating system of the annealing kiln is reduced, so that the effect of saving energy and protecting the environment is realized.

Owner:洛阳建材机械厂

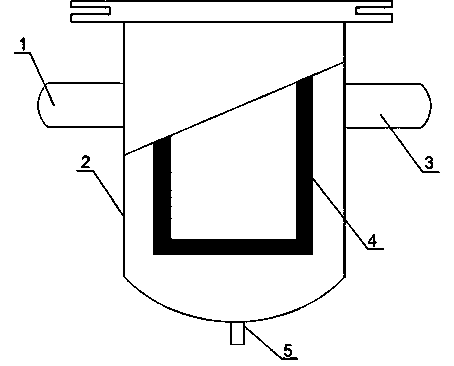

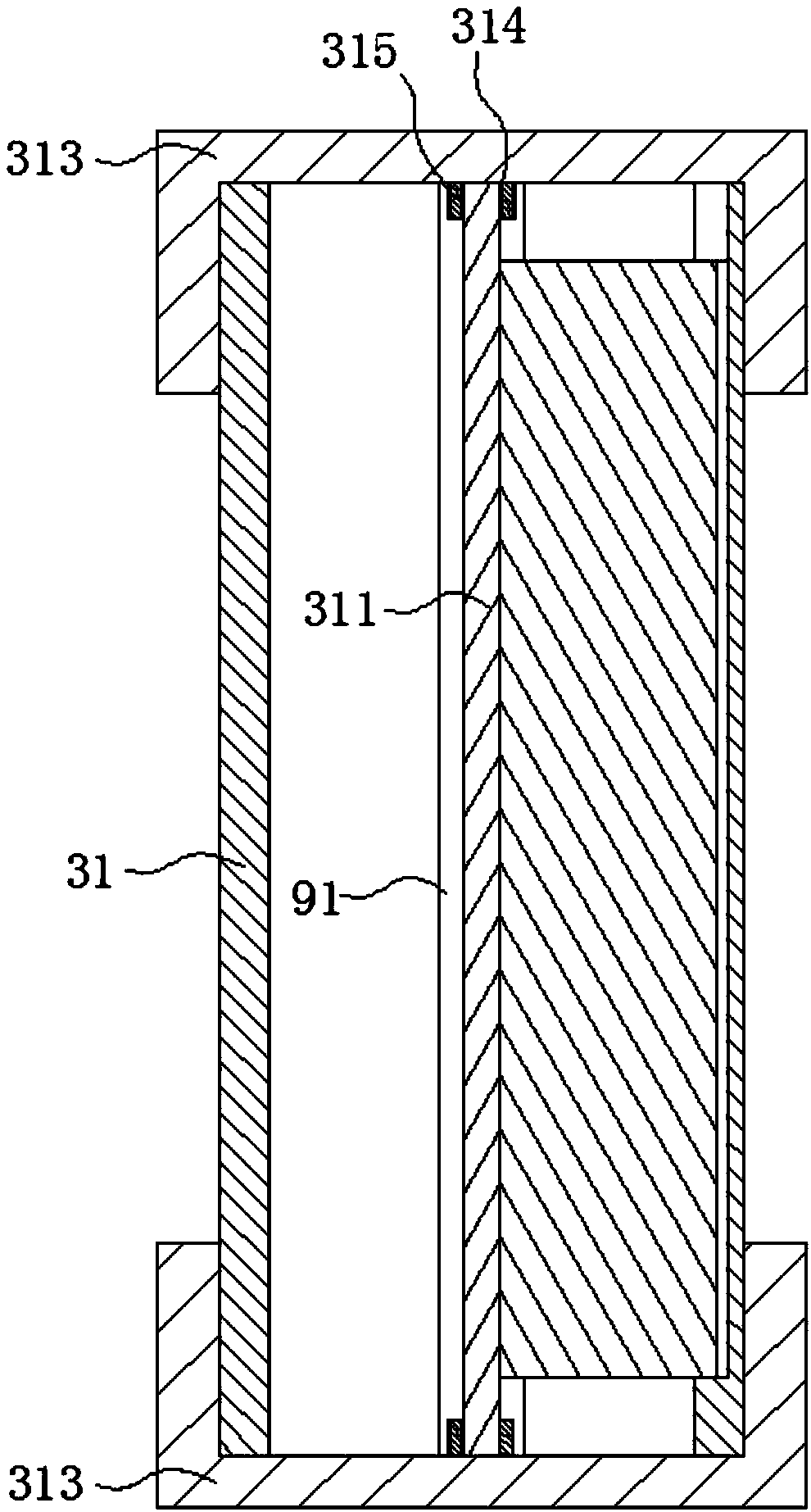

Filter

InactiveCN103405971AEasy to clean and maintainPlay the role of evacuation and pressure reliefDispersed particle filtrationEngineeringSolid particle

The invention discloses a filter. The filter comprises a shell, wherein an air inlet and an air outlet are formed in the shell; a sewage discharging valve is arranged at the bottom of the shell; a filter cartridge is arranged inside the shell and is communicated with the air inlet; the air outlet is communicated with the interior of the shell; the filter cartridge comprises a plurality of layers of filter screens; the upper part of the shell is fixedly welded together with an external installation rack. By arranging the sewage discharging valve at the bottom of the shell, effects of evacuation and decompression can be achieved, solid particles or liquid impurities isolated from the interior of the filter cartridge can be removed, and the filter cartridge is convenient to clean and maintain.

Owner:CHENGDU TIANYI NATURAL GAS COMPRESSOR MFG

Method for improving performances of yarns formed by vortex spinning

InactiveCN102691143BImprove yarn tightnessLow modulusContinuous wound-up machinesOpen-end spinning machinesEngineeringYarn strength

The invention relates to a method for improving performances of yarns formed by vortex spinning by reducing the modulus and the rigidity of fibers on line and belongs to the field of textile processing. According to the method disclosed by the invention, a sectional softening treatment method is applied for carrying out progressive softening treatment on fibers subjected to vortex spinning on a vortex spinning machine, and thus the fiber modulus and the bending rigidity are quickly reduced on line and the performances of the resultant yarns prepared from fibers by vortex are improved. For a vortex yarn structure, the structure compactness is improved, the yarn strength is enhanced and residual torque of the yarns is small; in addition, the non-spinning fibers can be subjected to vortex spinning on the vortex spinning machine; the fibers with poorer quality for the resultant yarns formed by the vortex spinning are subjected to high-quality spinning on the vortex spinning machine; and particularly, the improvement on the spun count of the fibers on the vortex spinning machine is facilitated and the smooth production of high grade cotton yarns formed by vortex spinning is realized. The method disclosed by the invention has the advantages of short work procedure flow, strong pertinence, high efficiency, lower cost, reasonable structure, convenience in operation and easiness in large-area popularization and use.

Owner:WUHAN TEXTILE UNIV

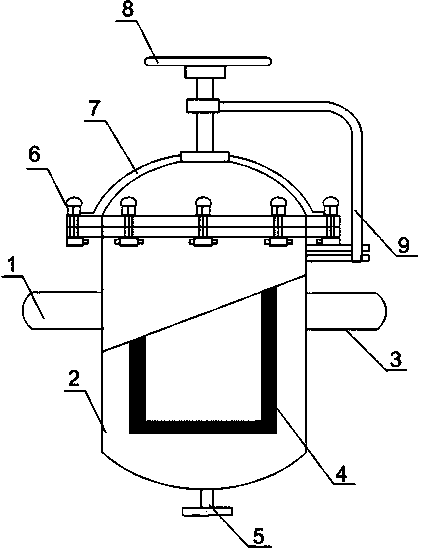

Quick-opening natural gas filter

InactiveCN103405973AShorten the timeReduce labor intensityDispersed particle filtrationGaseous fuelsEngineeringUltimate tensile strength

The invention discloses a quick-opening natural gas filter which comprises a barrel body and an upper cover, wherein an air inlet and an air outlet are formed in the barrel body, a blow-down valve is arranged at the bottom of the barrel body, a filter core is arranged inside the barrel body and is communicated with the air inlet, the air outlet is communicated with the inside of the barrel body, the barrel body is connected with the upper cover through an eyebolt, the top of the upper cover is connected with a hand wheel through a screw rod, and the top of the upper cover is matched with the screw rod through a thread. The quick-opening natural gas filter further comprises a rotary arm arranged on the barrel body, wherein the end part of the rotary arm is connected with the screw rod through a thread. After being used for a long time, the quick-opening natural gas filter needs to be cleaned, the upper cover and the barrel body are separated by rotating the eyebolt, and meanwhile the hand wheel at the top of the upper cover is regulated, the upper cover is lifted up for a distance, the upper cover and the barrel body are misplaced through rotating the rotary arm, and then the filter core is quickly taken out for being cleaned; compared with a conventional flange bolt connection mode, the quick-opening natural gas filter has the advantages that the time of opening the cover of the filter is greatly shortened, the labor intensity of workers is reduced, and the work efficiency is increased.

Owner:CHENGDU TIANYI NATURAL GAS COMPRESSOR MFG

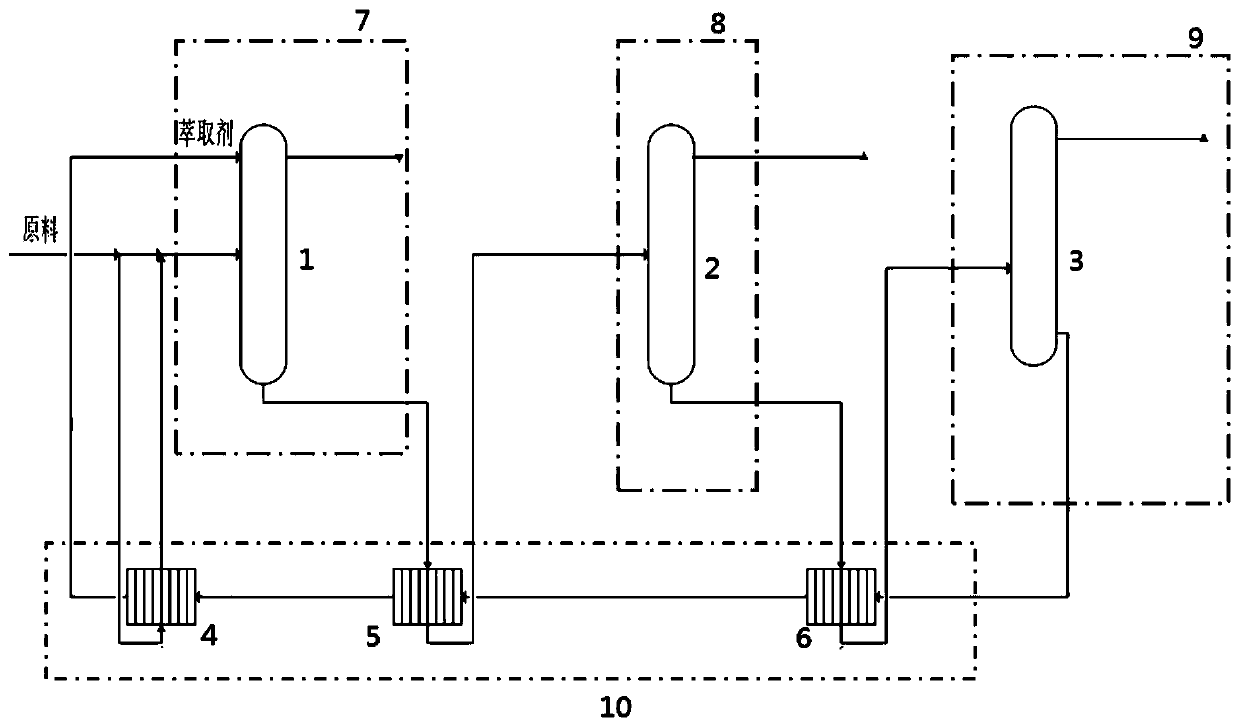

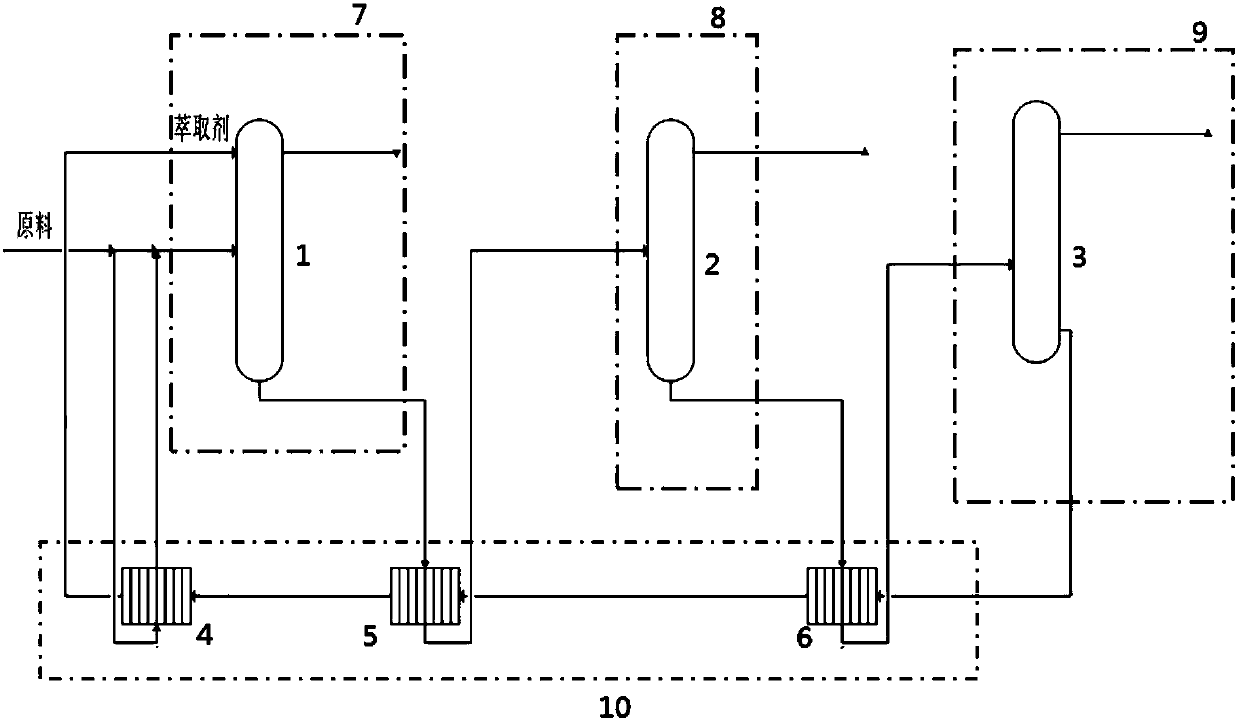

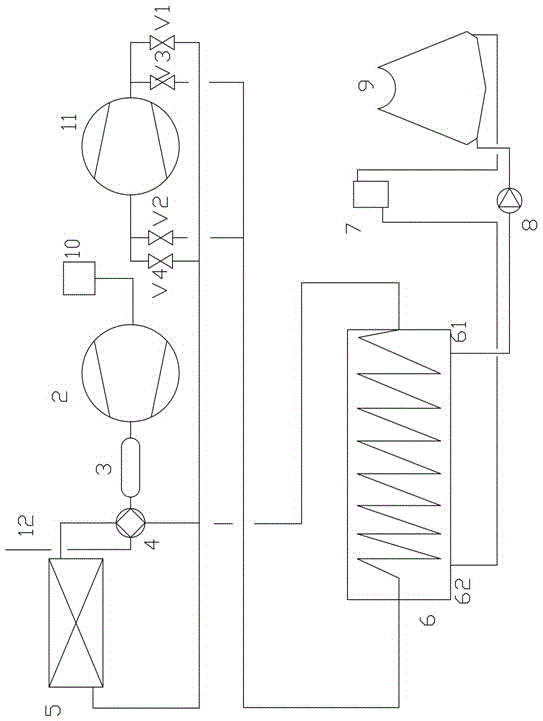

A system and method for recovering refined methylcyclopentane and its application

ActiveCN107935807BEasy extractionEasy to prepareChemical industryDistillation purification/separationSulfolaneDistillation

The invention relates to a system and a method for recycling refined methyl cyclopentane and application of the system and the method. The system comprises a dehydrogenation unit, a purification unit,a solvent recycling unit as well as a heat exchange unit, wherein the dehydrogenation unit, the purification unit and the solvent recycling unit are sequentially connected; the dehydrogenation unit is a first extraction distillation column; the purification unit is a second extraction rectification unit; the heat exchange unit comprises a first heat exchanger, a second heat exchanger and a thirdheat exchanger which are independent from one another; a raw material input pipeline penetrates through the first heat exchanger and then is connected with a raw material inlet in the first extractiondistillation column; a first pipeline is arranged at the bottom of the first extraction distillation column, and so on in a similar manner. An extraction agent used in the method is a mixed solvent which is composed of one or a combination of at least two of sulfolane, ethylene glycol, glycerin, NMF (N-Formylmorpholine), NMP (N-Methyl Pyrrolidone) and DMF (Dimethyl Formamide), and a deep-eutecticsolvent in a compounded manner. By adopting the system and the method, a methyl cyclopentane product of which the purity is greater than 99.95wt% can be purified at one time, and the recycling rate of methyl cyclopentane is greater than 99%.

Owner:JIANGXI INST OF RARE EARTHS CHINESE ACAD OF SCI

System and method for recycling refined methyl cyclopentane and application of system and method

ActiveCN107935807AEasy extractionEasy to prepareChemical industryDistillation purification/separationDimethyl formamideChemistry

The invention relates to a system and a method for recycling refined methyl cyclopentane and application of the system and the method. The system comprises a dehydrogenation unit, a purification unit,a solvent recycling unit as well as a heat exchange unit, wherein the dehydrogenation unit, the purification unit and the solvent recycling unit are sequentially connected; the dehydrogenation unit is a first extraction distillation column; the purification unit is a second extraction rectification unit; the heat exchange unit comprises a first heat exchanger, a second heat exchanger and a thirdheat exchanger which are independent from one another; a raw material input pipeline penetrates through the first heat exchanger and then is connected with a raw material inlet in the first extractiondistillation column; a first pipeline is arranged at the bottom of the first extraction distillation column, and so on in a similar manner. An extraction agent used in the method is a mixed solvent which is composed of one or a combination of at least two of sulfolane, ethylene glycol, glycerin, NMF (N-Formylmorpholine), NMP (N-Methyl Pyrrolidone) and DMF (Dimethyl Formamide), and a deep-eutecticsolvent in a compounded manner. By adopting the system and the method, a methyl cyclopentane product of which the purity is greater than 99.95wt% can be purified at one time, and the recycling rate of methyl cyclopentane is greater than 99%.

Owner:JIANGXI INST OF RARE EARTHS CHINESE ACAD OF SCI

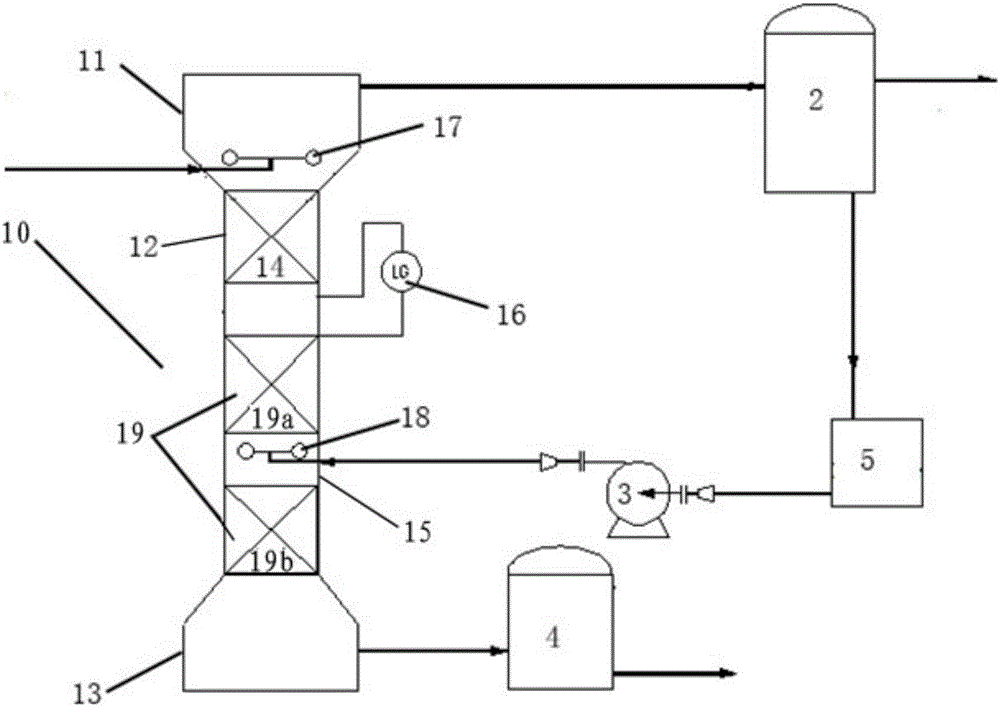

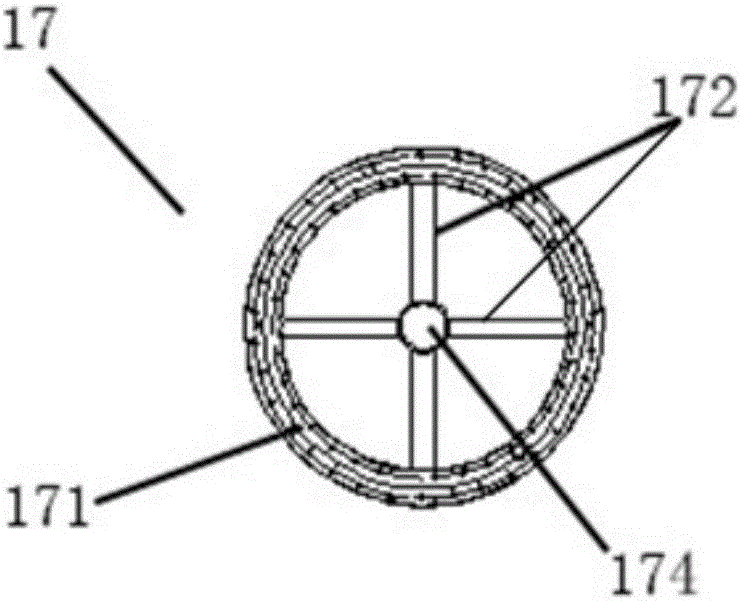

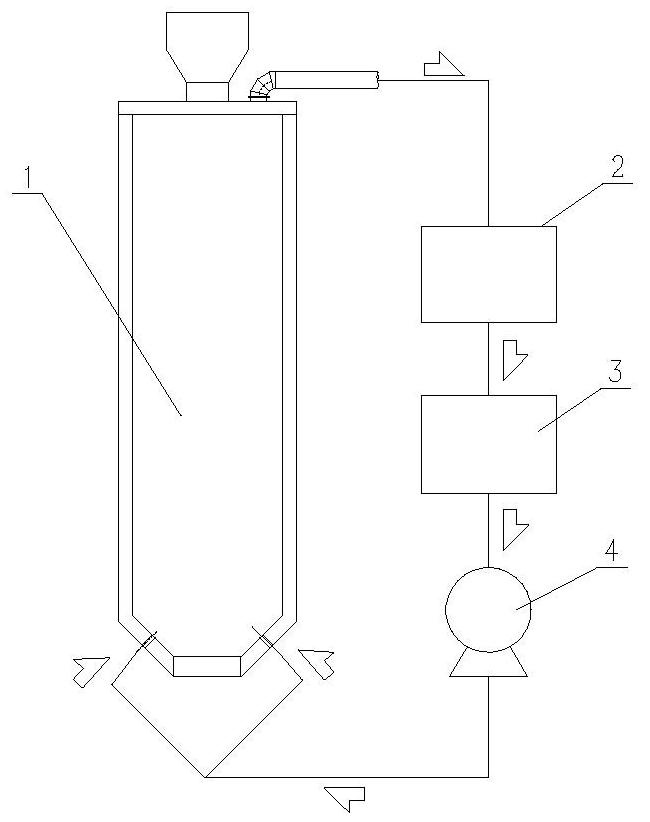

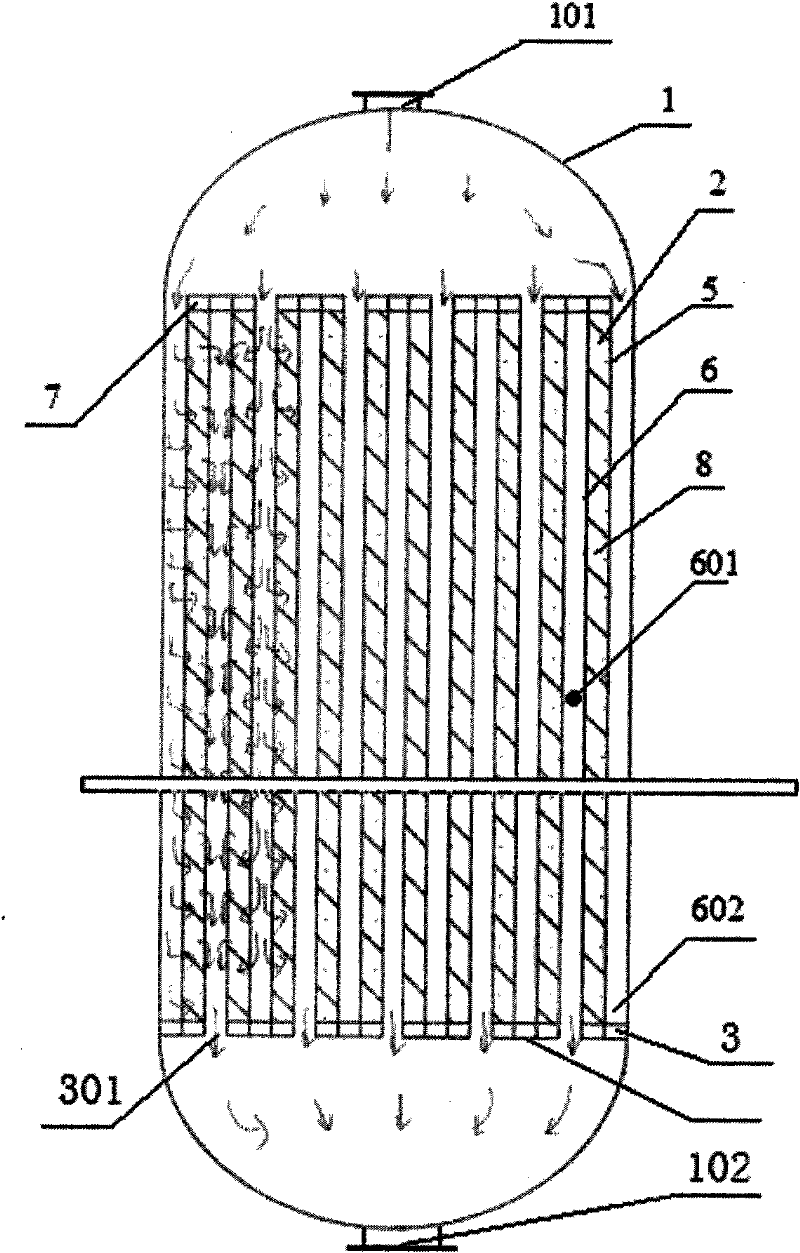

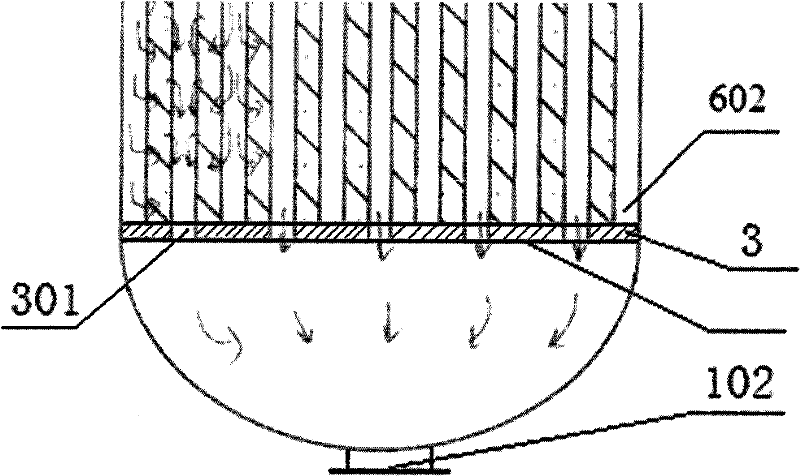

Oil-water separation tower and oil-water separation method

PendingCN106241952AReduce manufacturing costAdvanced concept of oil-water separationFatty/oily/floating substances removal devicesLiquid separationSeparation processSewage

The invention discloses an oil-water separation tower. The oil-water separation tower comprises an upper oil discharging section, a lower water draining section and an oil-water separation section located between the oil discharging section and the water draining section. The oil-water separation section allows separated sump oil to ascend to be discharged out of the oil discharging section and allows separated wastewater to descend to be drained out of the water draining section; the oil-water separation section further comprises an oil phase section and a water phase section, oleophylic hydrophobic filler and a feeding distributor located on the oleophylic hydrophobic filler are arranged in the oil phase section, and hydrophilic oleophobic filler is arranged in the water phase section. The invention also relates to an oil-water separation method. Demulsifying agent, flocculating agent and the like are not added in the oil-water separation process, the structure is simple, operating is convenient, the method and other processes are easily combined and used, and the oil-water separation tower and the oil-water separation method are particularly suitable for oil removing treatment of industrial wastewater with complex ingredients.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

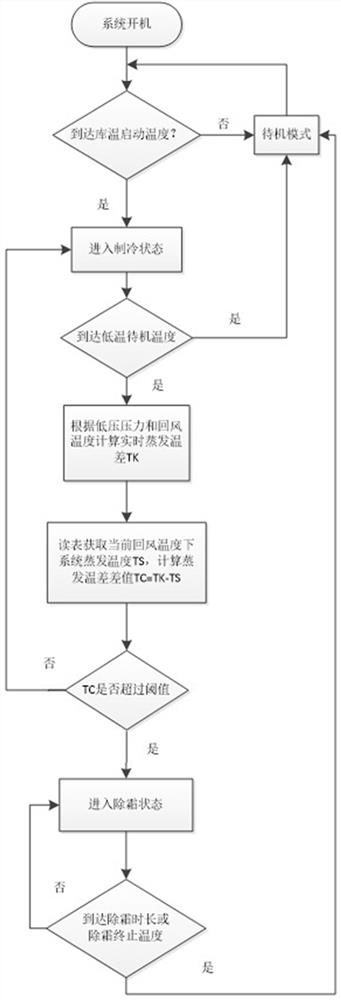

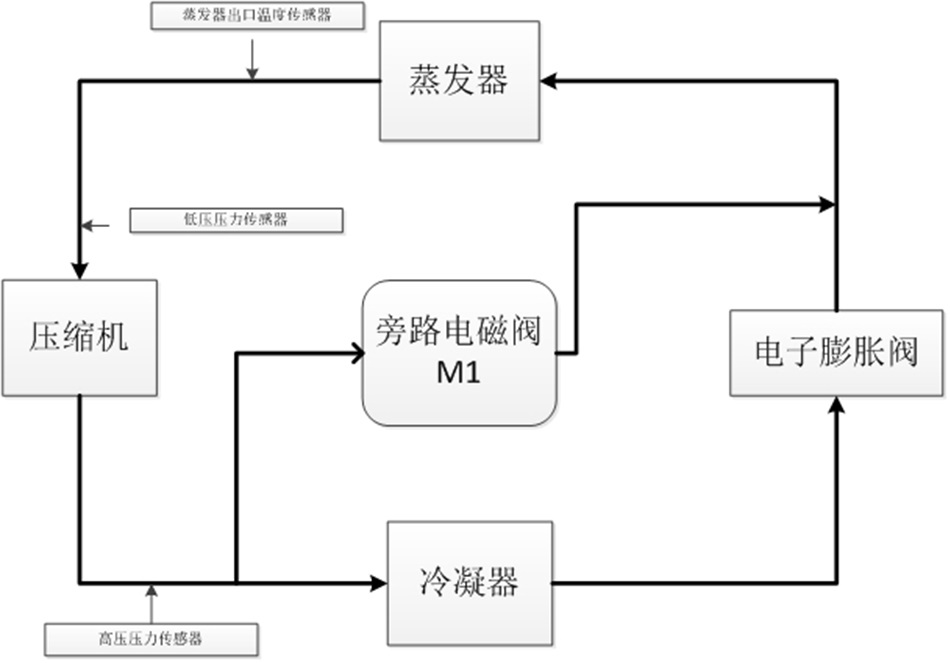

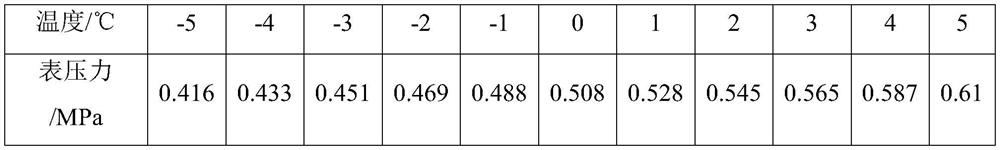

Intelligent defrosting method for refrigerating system based on evaporation temperature difference and refrigerating system

PendingCN112728854AImprove operational efficiencyEffective energy saving and consumption reductionMechanical apparatusRefrigeration safety arrangementFrostProcess engineering

The invention discloses an intelligent defrosting method for a refrigerating system based on an evaporation temperature difference and the refrigerating system, and belongs to a refrigerating technology. The characteristics of strong repeatability and time lag of the refrigerating system in a normal operation state are used, on the basis of mark point data of the evaporation temperature pre-measured by the system, through adoption of the situation that the evaporation temperature difference of the system deviates from a preset point at the moment, the frosting condition of an evaporator of the refrigerating system is judged, and a defrosting process of the refrigerating system is performed as required to finish the on-demand defrosting of the refrigerating system. According to the method, the frost amount of the evaporator can only be predicted and judged, a reliable basis is provided for on-demand defrosting of the refrigerating system, the overall operation efficiency of the refrigerating system is improved, and the purposes of effectively saving energy and reducing consumption are achieved.

Owner:天津华冷科技有限公司

Printing and dyeing wastewater treatment method

ActiveCN108314207AImprove adsorption capacityReduce COD contentSpecific water treatment objectivesWater/sewage treatment by ion-exchangePhosphoric acidDyeing wastewater

The invention discloses a printing and dyeing wastewater treatment method. The method comprises the following steps: (1) after heat exchange treatment of printing and dyeing wastewater by a heat exchange device, introducing the wastewater into an adjusting tank to adjust the pH value to 8-8.5 and the COD to 300-500mg / L; (2) adding phosphate substances into the wastewater, and carrying out mixing to reaction for 4-6h; and (3) introducing the wastewater in step (2) into a hydrolysis acidification tank for reaction for 2-3h, and then introducing the water into a neutralization tank for neutralization reaction. According to the method provided by the invention, floras in the printing and dyeing wastewater are effectively removed through the coordination of pH value adjustment and acidificationhydrolysis, and then the COD content in the wastewater is effectively reduced, thereby achieving a good water treatment effect.

Owner:海宁华翔漂染科技有限公司

Steel derusting device for construction engineering

ActiveCN111843788BSolve problems such as low work efficiencyImprove rust removal efficiencyGrinding drivesGrinding machinesClassical mechanicsWorkbench

Owner:ZHONGQI JIAOJIAN GRP

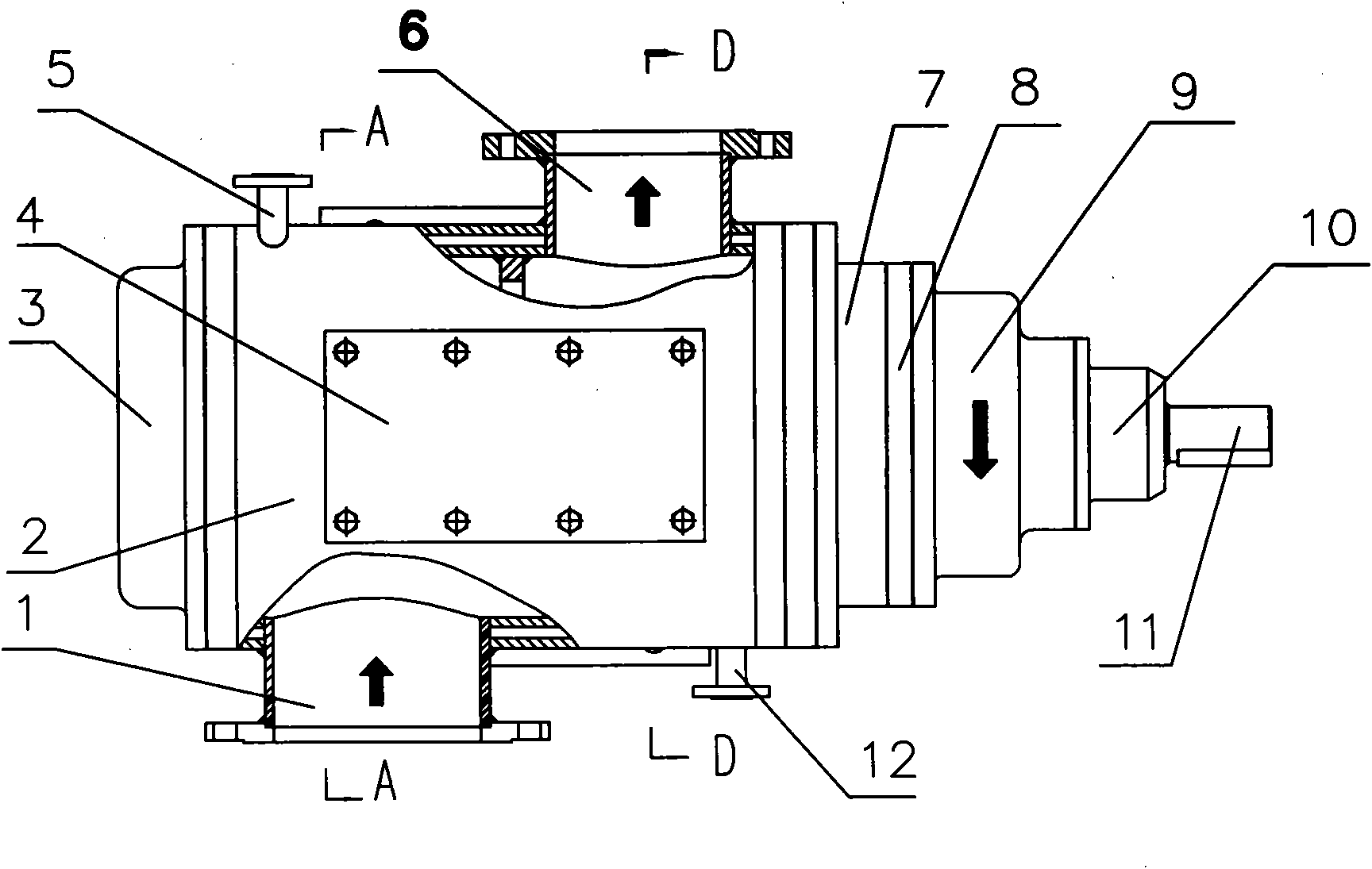

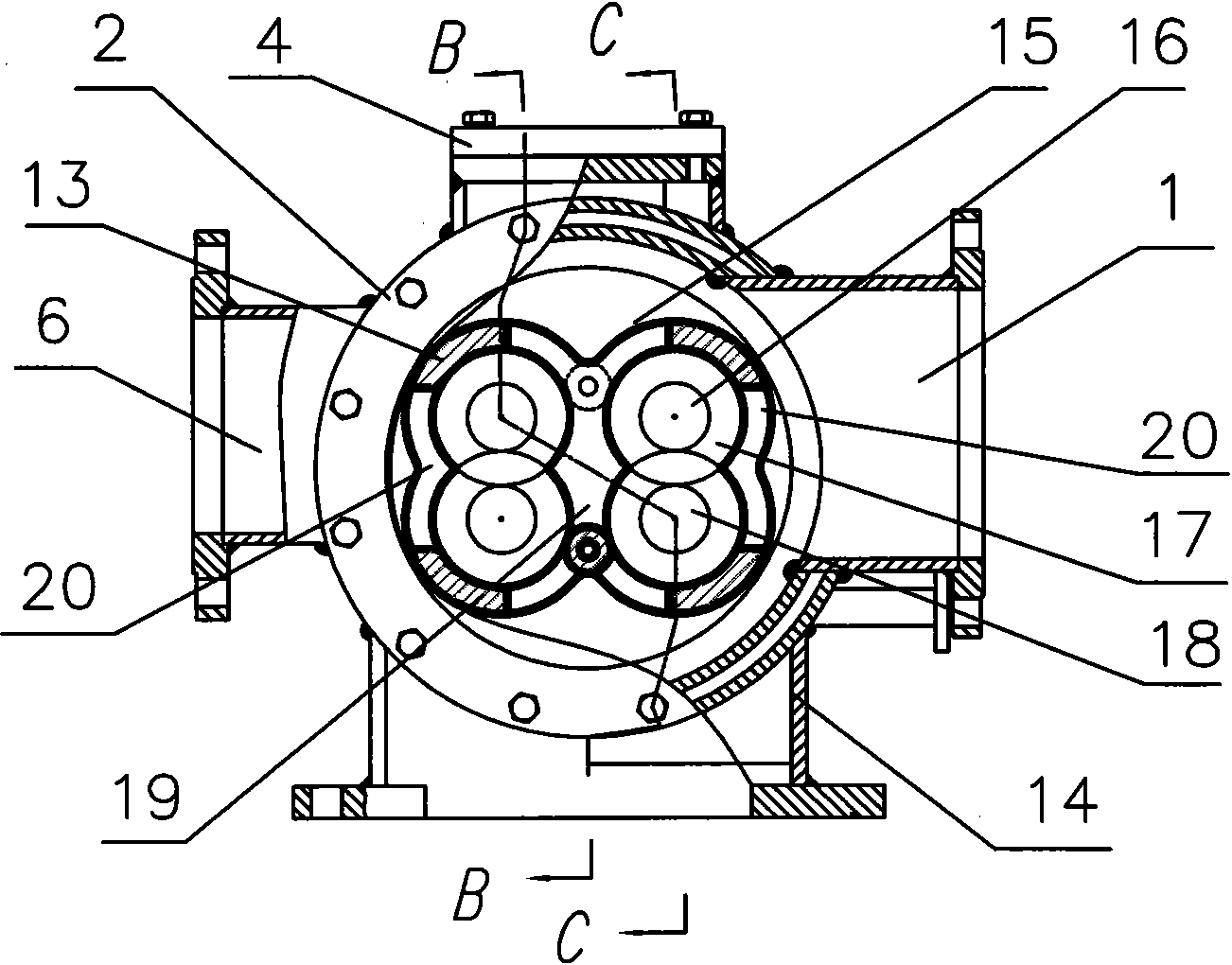

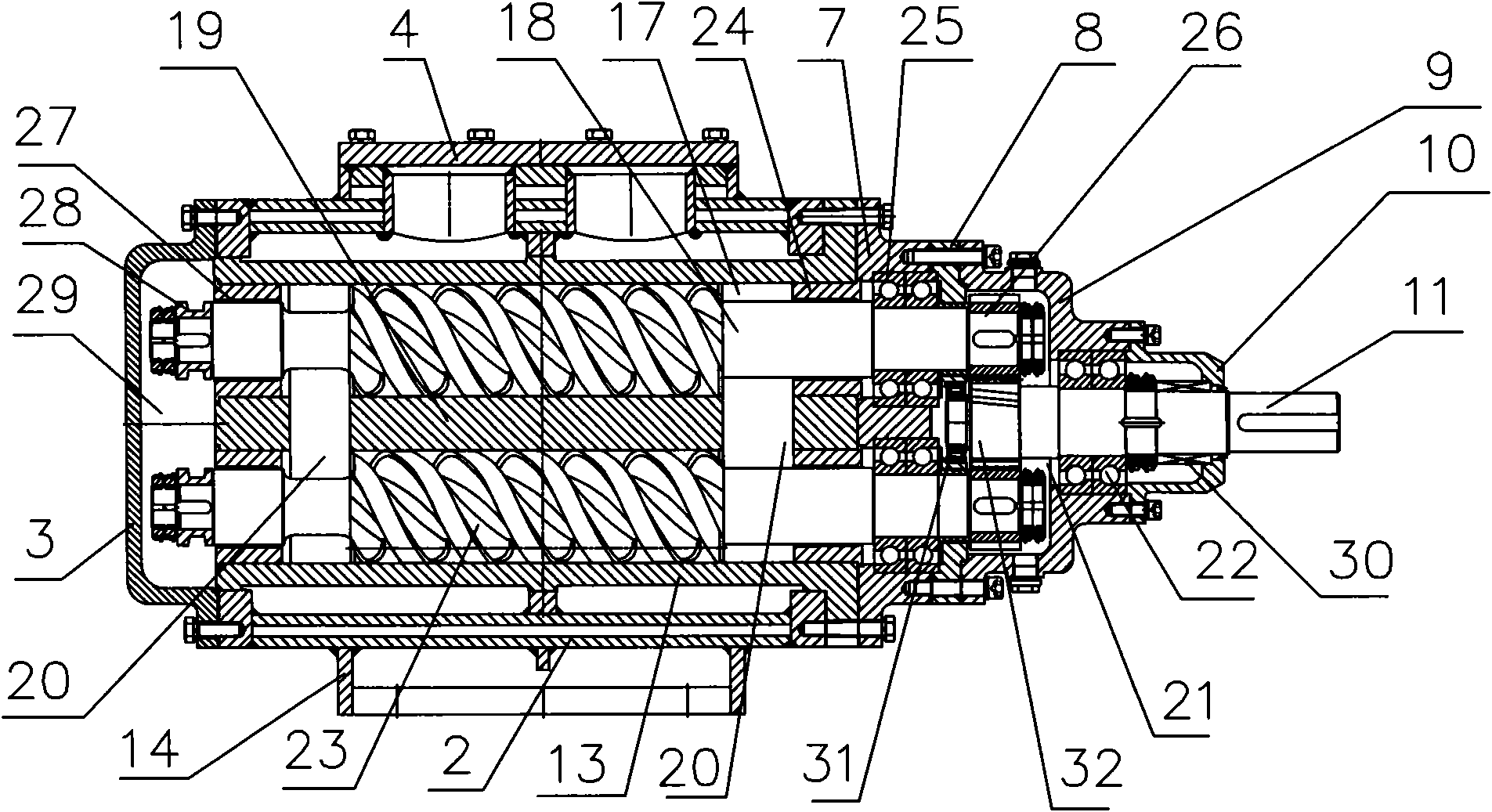

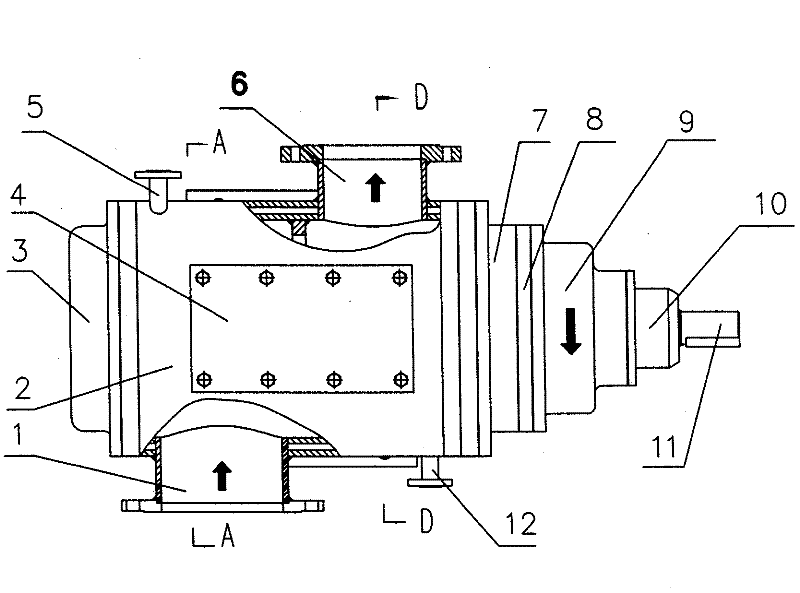

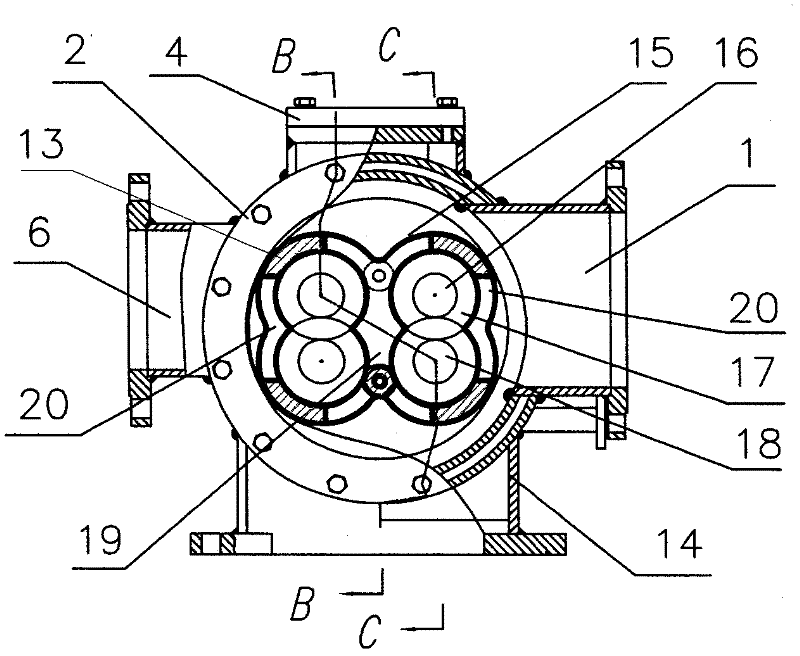

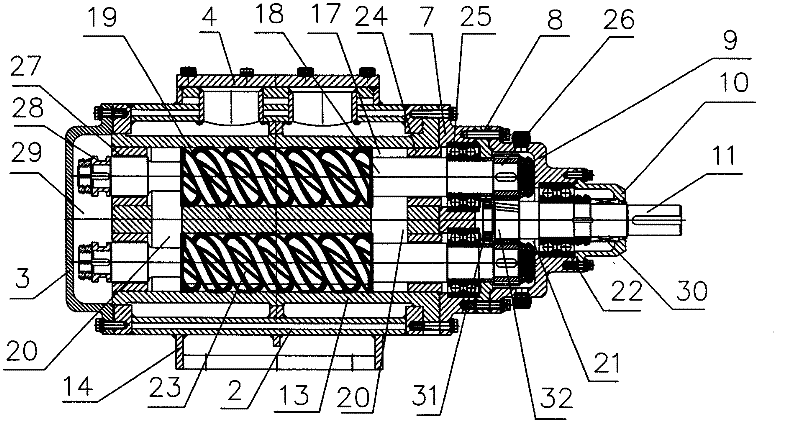

Parallel connection type double-screw-rod pump

InactiveCN101852206ALarge output flowHigh trafficRotary piston pumpsRotary piston liquid enginesConnection typeMotive power

The invention discloses a parallel connection type double-screw-rod pump, which comprises a pump body, a pump core, a medium gateway, a front end cover, a back end cover and a machine sealing cover, wherein the middle of the pump cover is a pump cavity. The invention is characterized in that the right end of a gear shaft is connected with a main shaft of a driving machine, the left end of the gear shaft extending into a gear cavity is sheathed with a main gear, two groups of mutually engaged driving screw rods and driven screw rods are placed in the pump cavity, two driving screw rod gears are respectively engaged with the main gear, and a driving screw rod friction wheel positioned in a back cavity is mutually engaged with a driven friction wheel. The invention transfers the motive power to the driving screw rods through the engagement of gear shafts and the two driving gears, and then, the driving screw rods transfer the driving torque to the driven screw rods. The invention has the advantages of capability of effectively saving energy and reducing consumption, compact structure, small size and low manufacture cost. The flow rate of the pump can be improved by one time under the conditions that the diameter and the pitch of the screw rods are not enlarged, and the rotating speed of the pump is not improved.

Owner:江西凯峰泵业有限公司

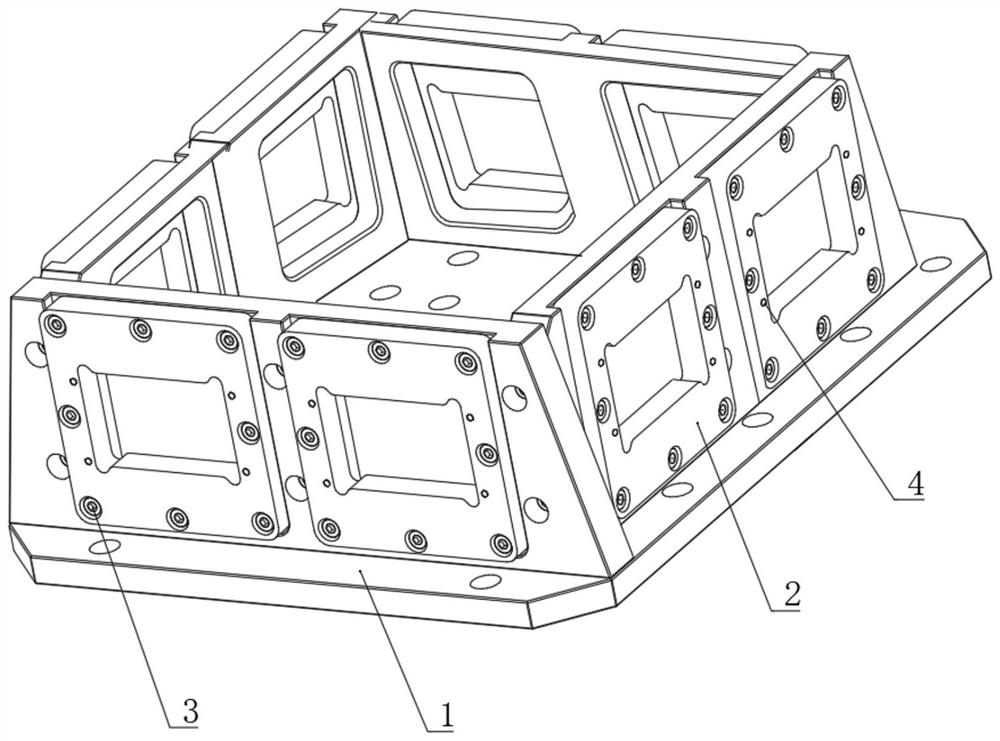

Universal vibration clamp and vibration test method

PendingCN114427946AReduce weightLow costMaterial strength using repeated/pulsating forcesVibration testingChinese charactersStructural engineering

Owner:中航华东光电有限公司

Production system and production method for producing copper sulfate by using copper electrolysis waste liquid

InactiveCN110092409AImprove evaporation efficiencyHigh degree of automationEvaporator accessoriesEnergy inputChemistryLiquid waste

The invention provides a production system and a production method for producing copper sulfate by using a copper electrolysis waste liquid, wherein the production system adopts a three-effect evaporation concentration device to carry out evaporation concentration on the copper electrolysis waste liquid, the evaporation efficiency is high, the waste heat of secondary steam can be recycled, energycan be effectively saved, and consumption can be reduced; a crystallization tank, a stirring tank and a centrifuge are matched to carry out cooling crystallization and solid-liquid separation on the copper electrolysis waste liquid after evaporation concentration, and the prepared copper sulfate finished product can also be automatically weighed and packaged, so that the automation degree is high,the operation is simple, and the labor force is greatly reduced.

Owner:YUNNAN COPPER CO LTD

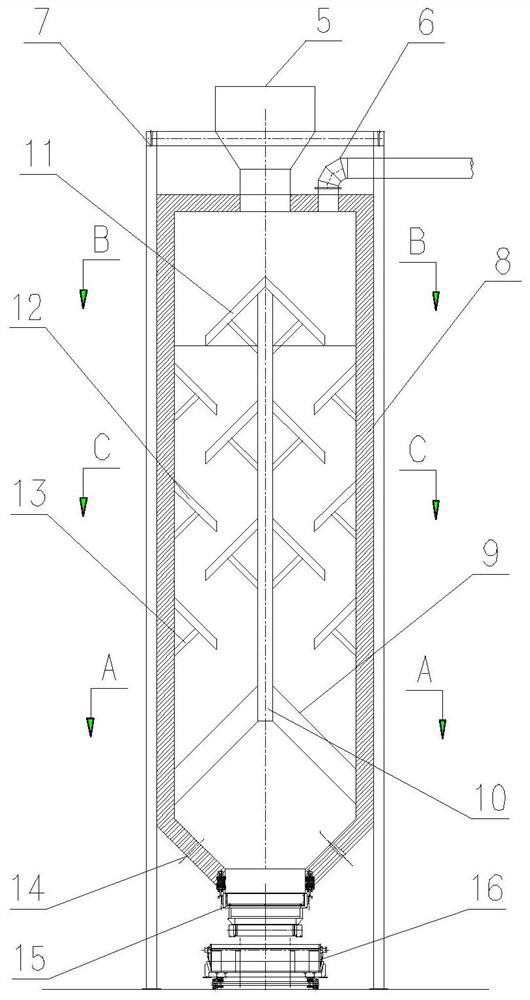

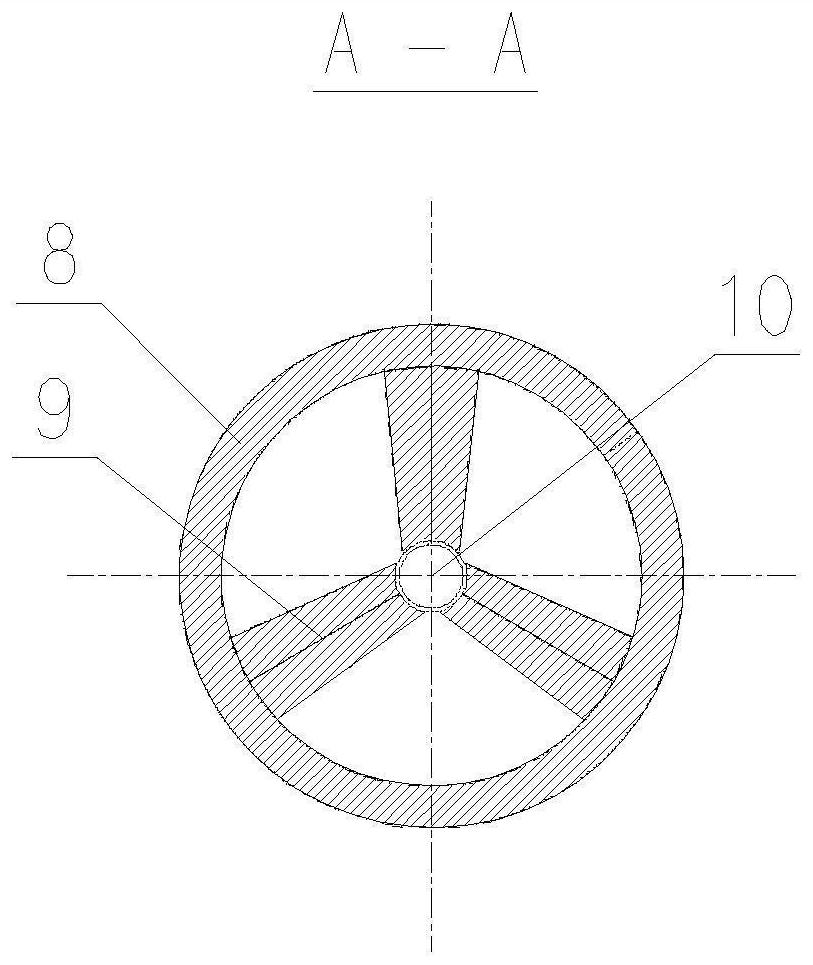

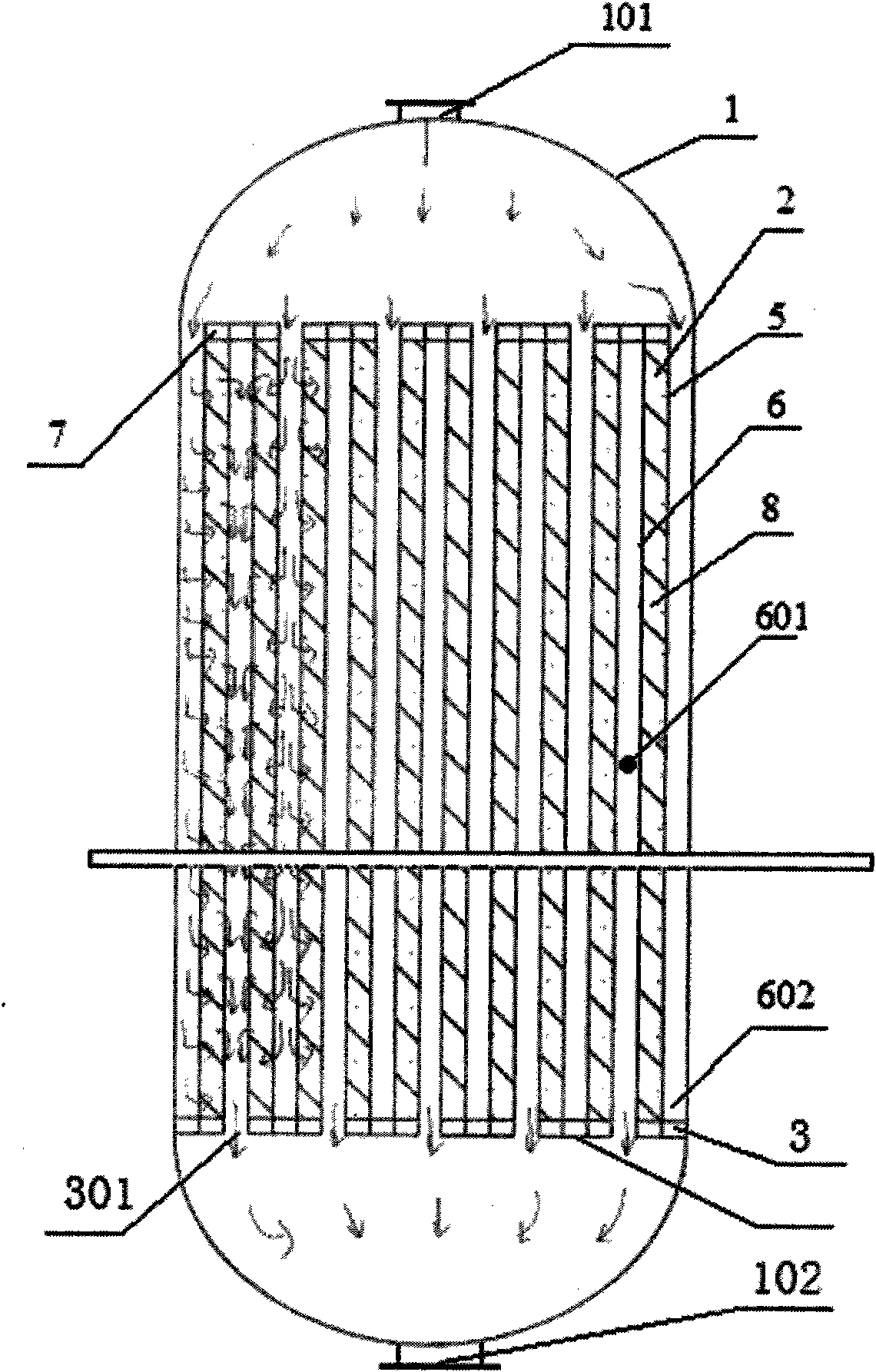

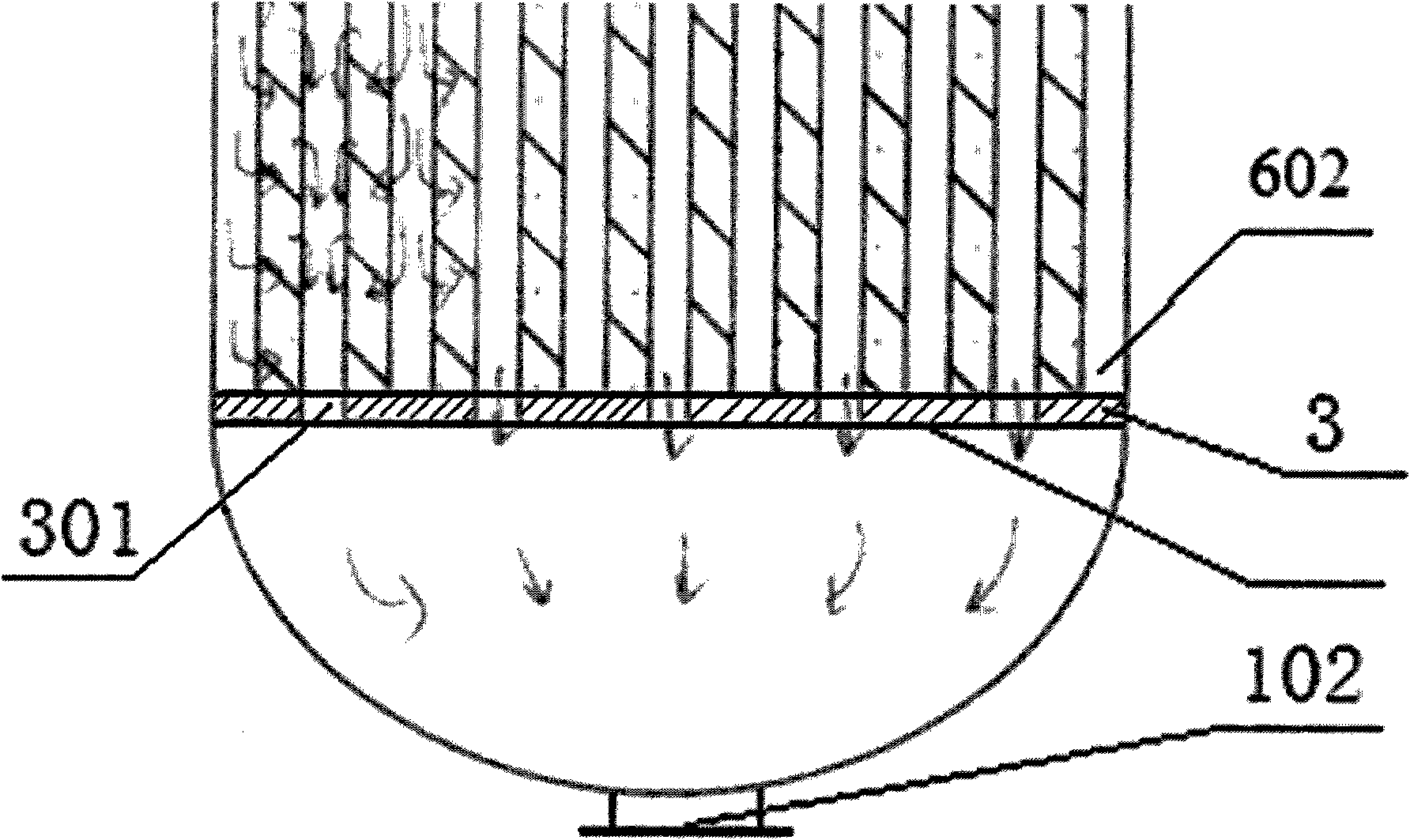

Method for recycling waste heat of high-temperature materials and device

PendingCN113720156AEffective energy saving and consumption reductionCharge manipulationIncreasing energy efficiencyCombustion chamberThermodynamics

The invention relates to a method for recycling waste heat of high-temperature materials and a device, and belongs to the technical field of energy conservation and environmental protection. According to the method, the high-temperature materials are evenly distributed in a combustion chamber under the action of a material distributing device after entering the combustion chamber, low-temperature gas exchanges heat with the high-temperature materials flowing downwards in the upward flowing process, the cooled materials are discharged out of a furnace, and the high-temperature gas is discharged into a gas recycling module for recycling waste heat. The invention further provides a device used for the method, the device at least comprises a recuperative furnace and the gas recycling module, the recuperative furnace at least comprises a recuperative furnace shell, the material distributing device, a feeding mechanism and a discharging mechanism, and the gas recycling module at least comprises a high-temperature gas exhausting device, a system pipeline, a waste heat boiler, a circulating gas dust removal device and an air blower. According to the method and the device, the waste heat of the high-temperature materials can be fully recycled, and the high-quality materials which are uniform in particle cooling, non-sticky and non-broken can be obtained.

Owner:WUHAN KEHONG IND FURNACE

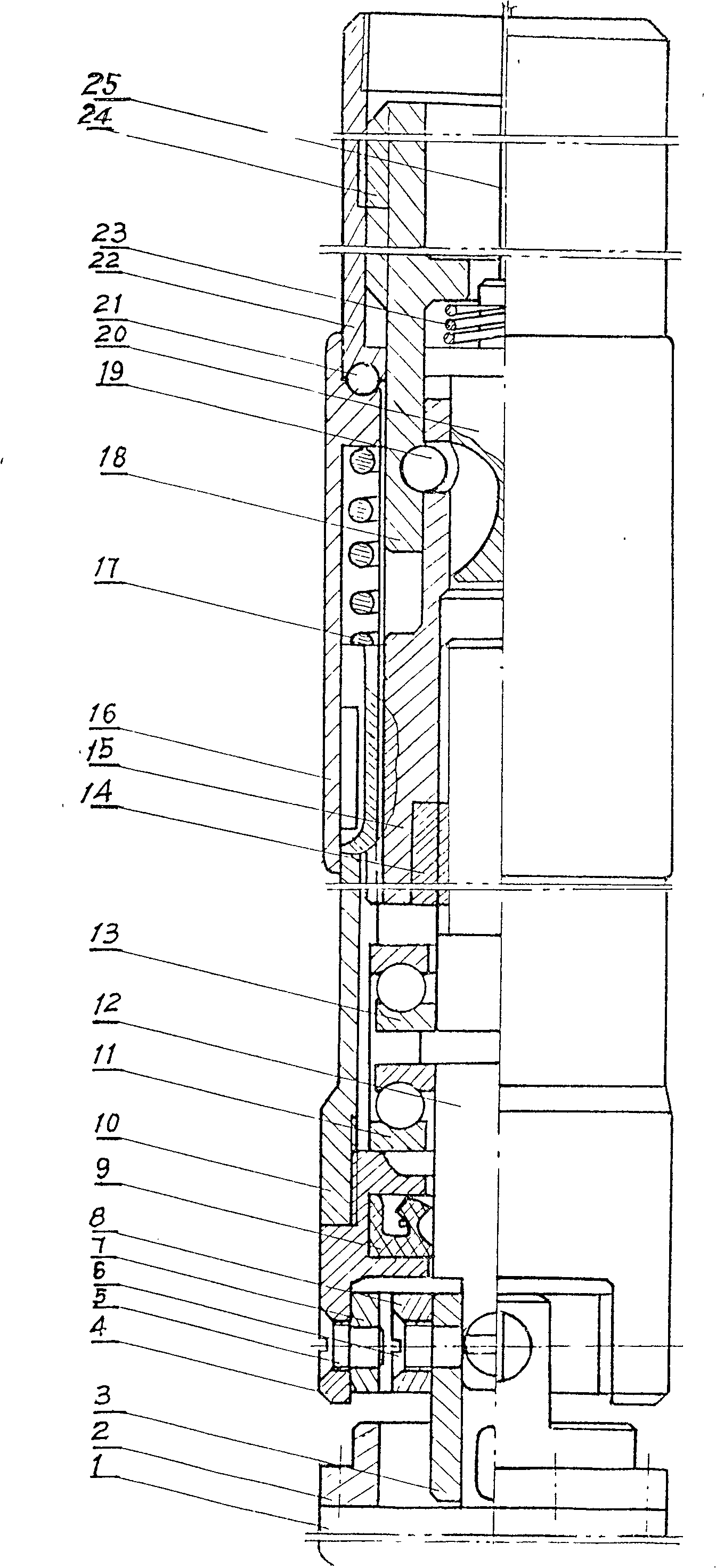

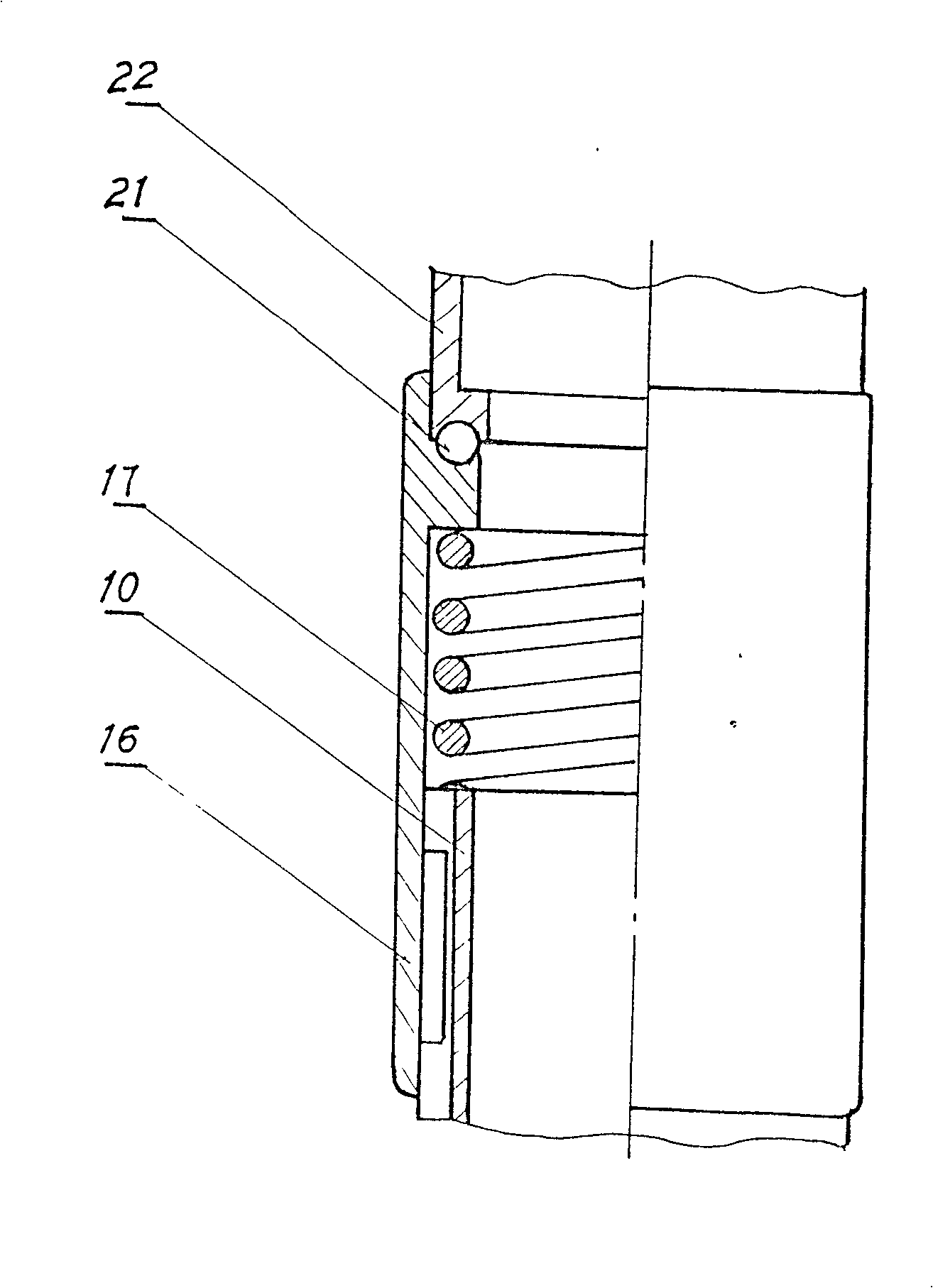

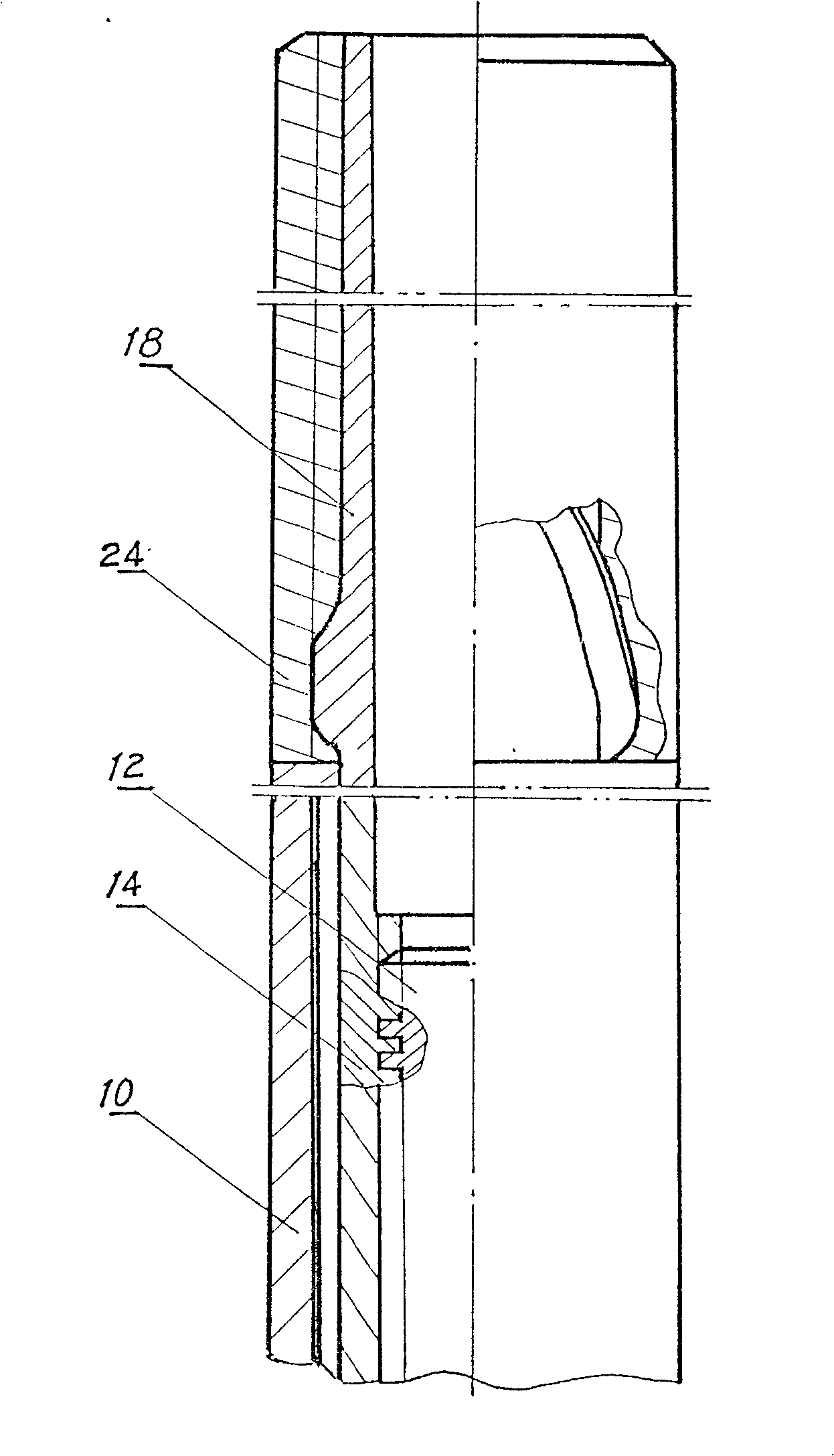

Coach passenger door unloading type-electric door pump device

InactiveCN100529321CLow powerWith self-locking abilityPower-operated mechanismElectric machineEngineering

The invention relates to an unloading-type electric gantry pump device for passenger carriage door, comprising electric machine, unloading mechanism and spiral reducing mechanism, and characterized in that: a small-lead input screw connected with the electric machine engages with a bottom push pipe externally provided with spline and internally provided with nut; a top push pipe provided with large-lead thread engages with the nut of an output sleeve; an unloading spring is arranged between fixed outer sleeve and output sleeve; steel balls and slide blocks for controlling engaging and disengaging are arranged in the top and bottom push pipes. And it can save energy and damp vibration, and its shape is a small-diameter round pipe, and it has small bulk, simple structure, novel style, beautiful appearance, complete functions, and operating convenience, applied to various carriage doors.

Owner:王晓员

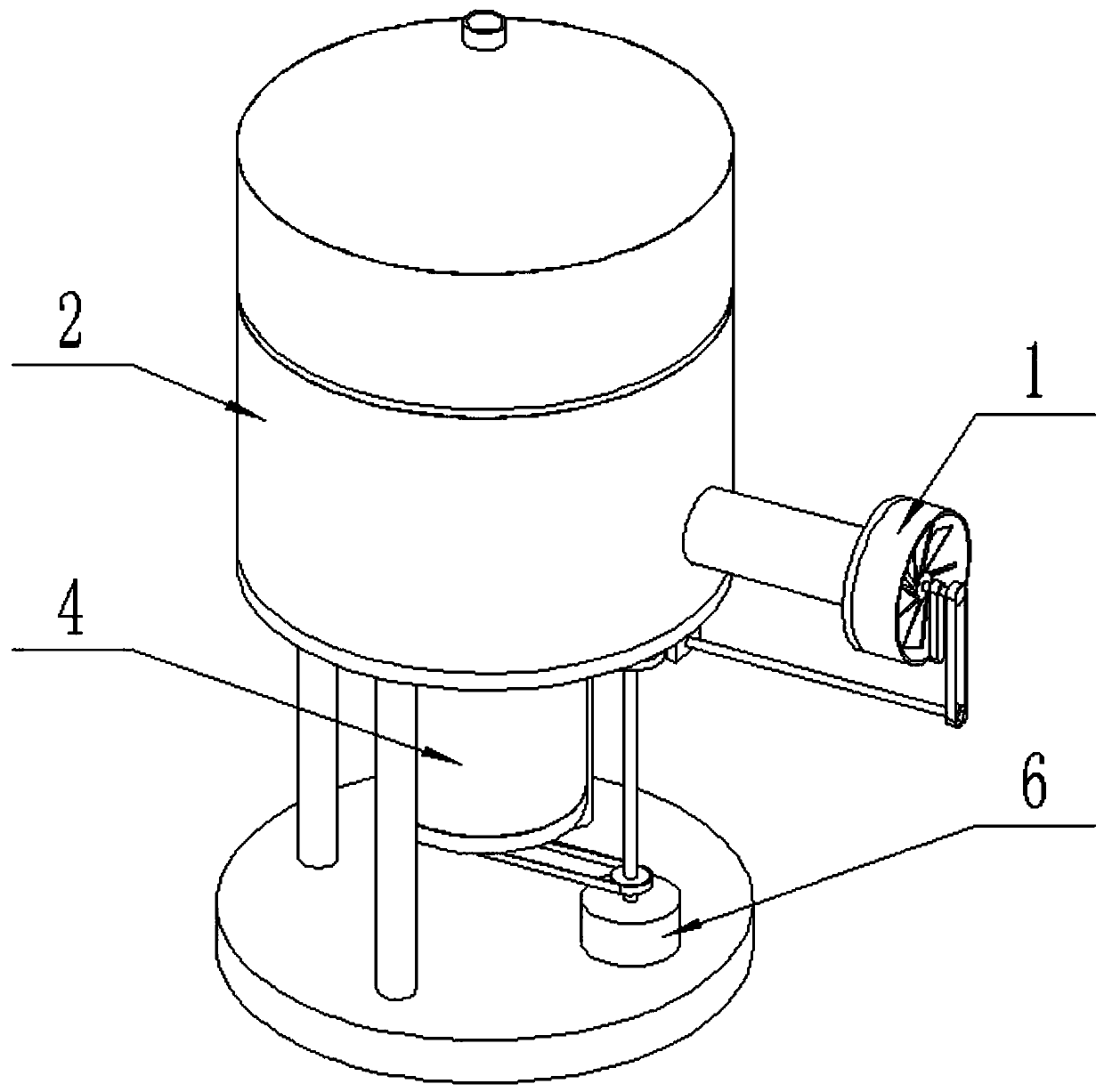

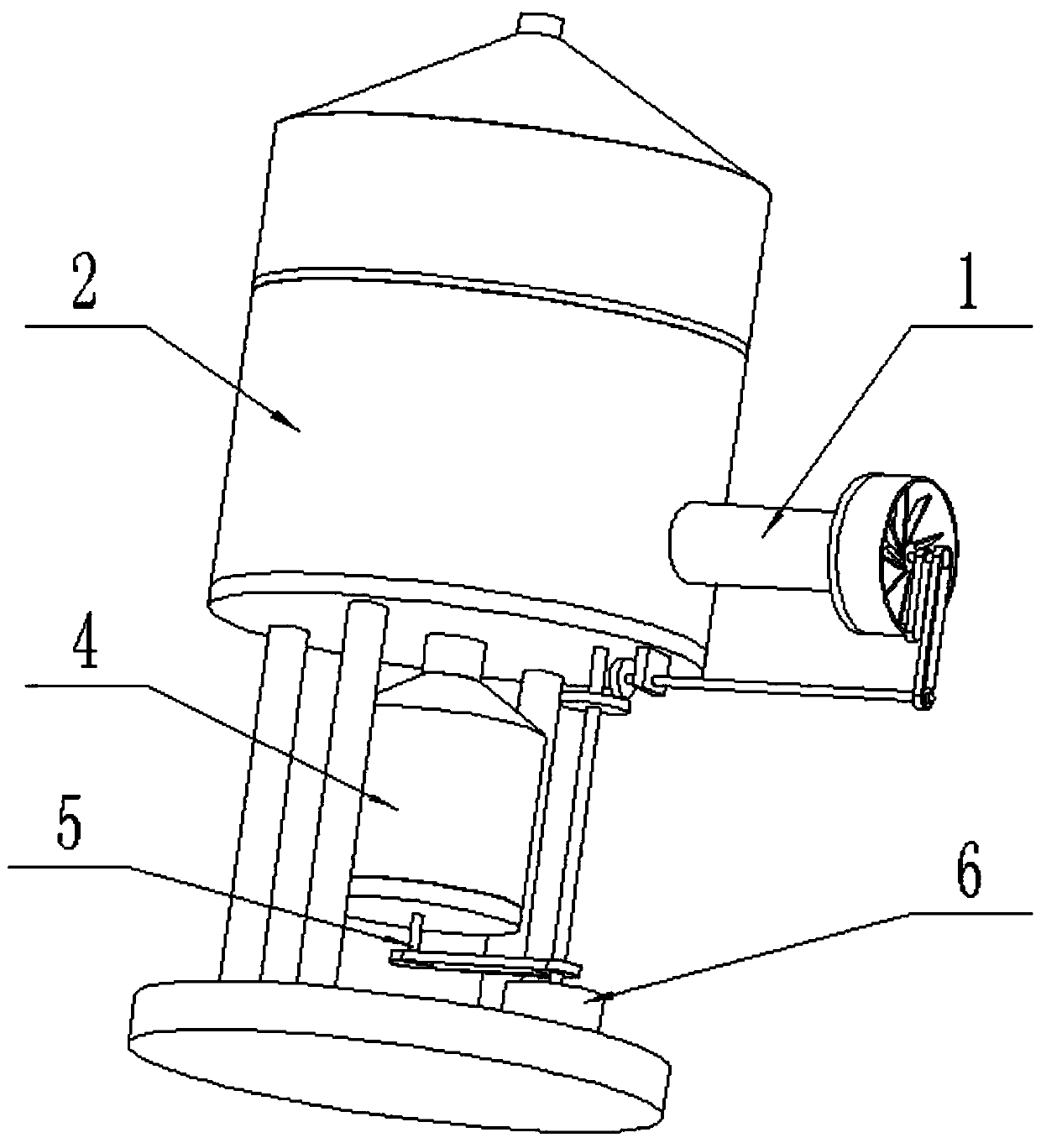

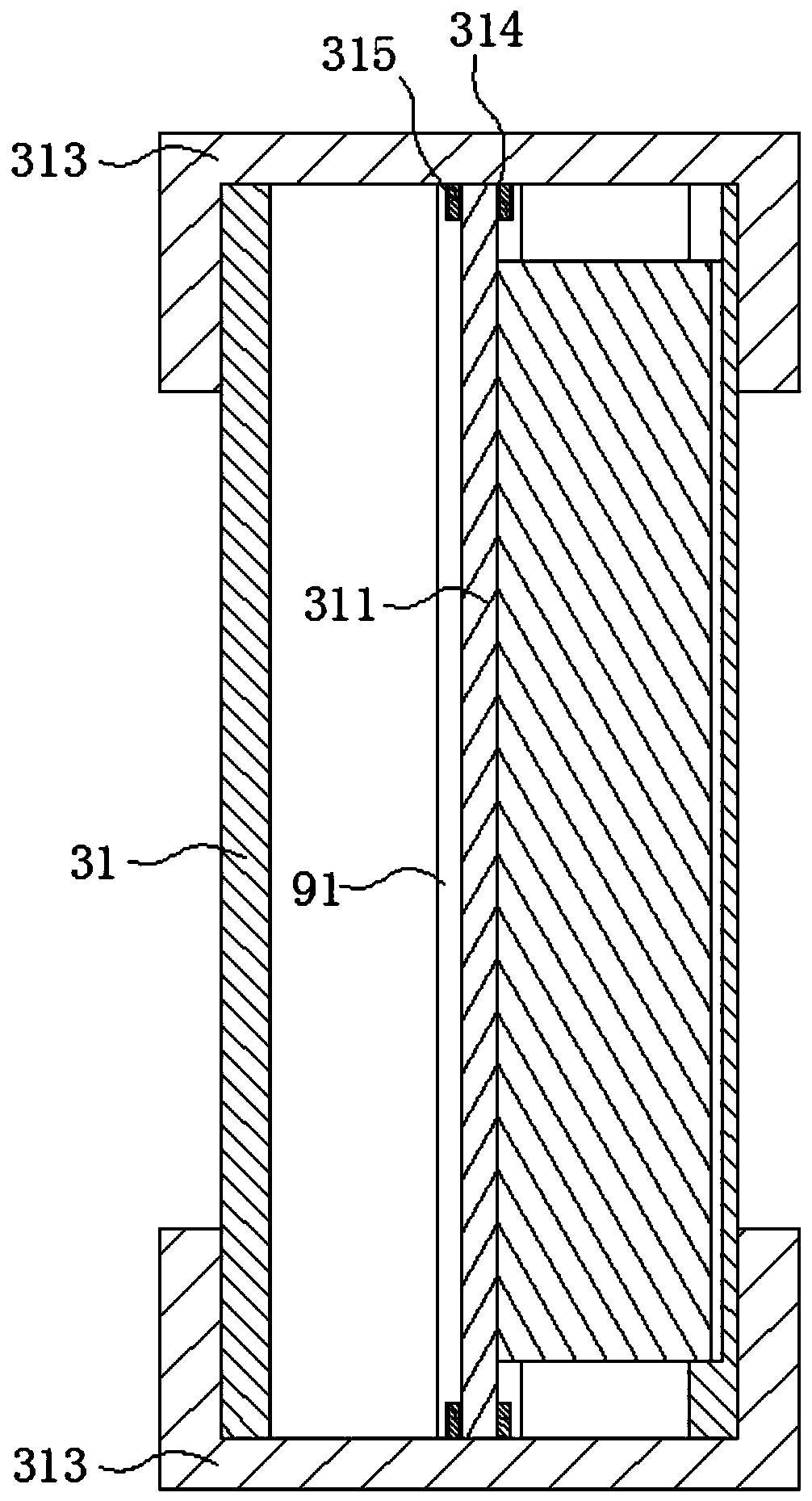

Dust recycling device for industrial waste gas treatment

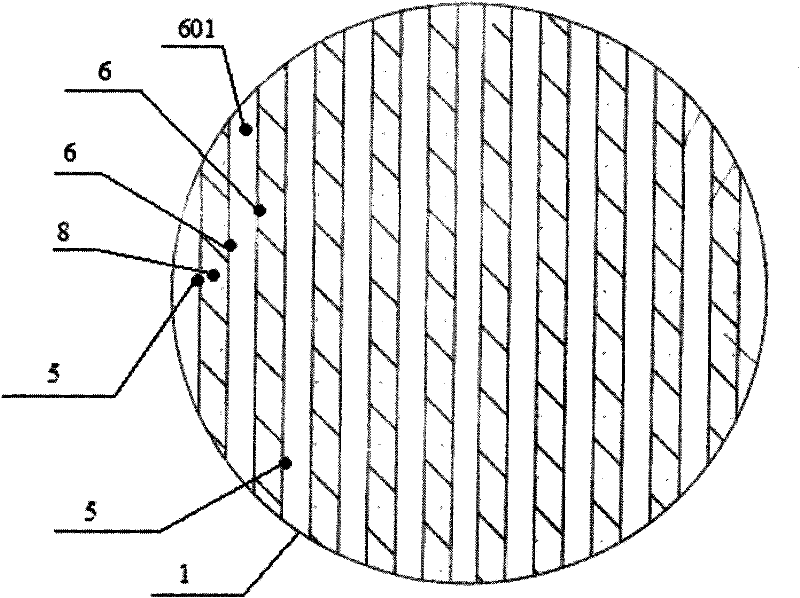

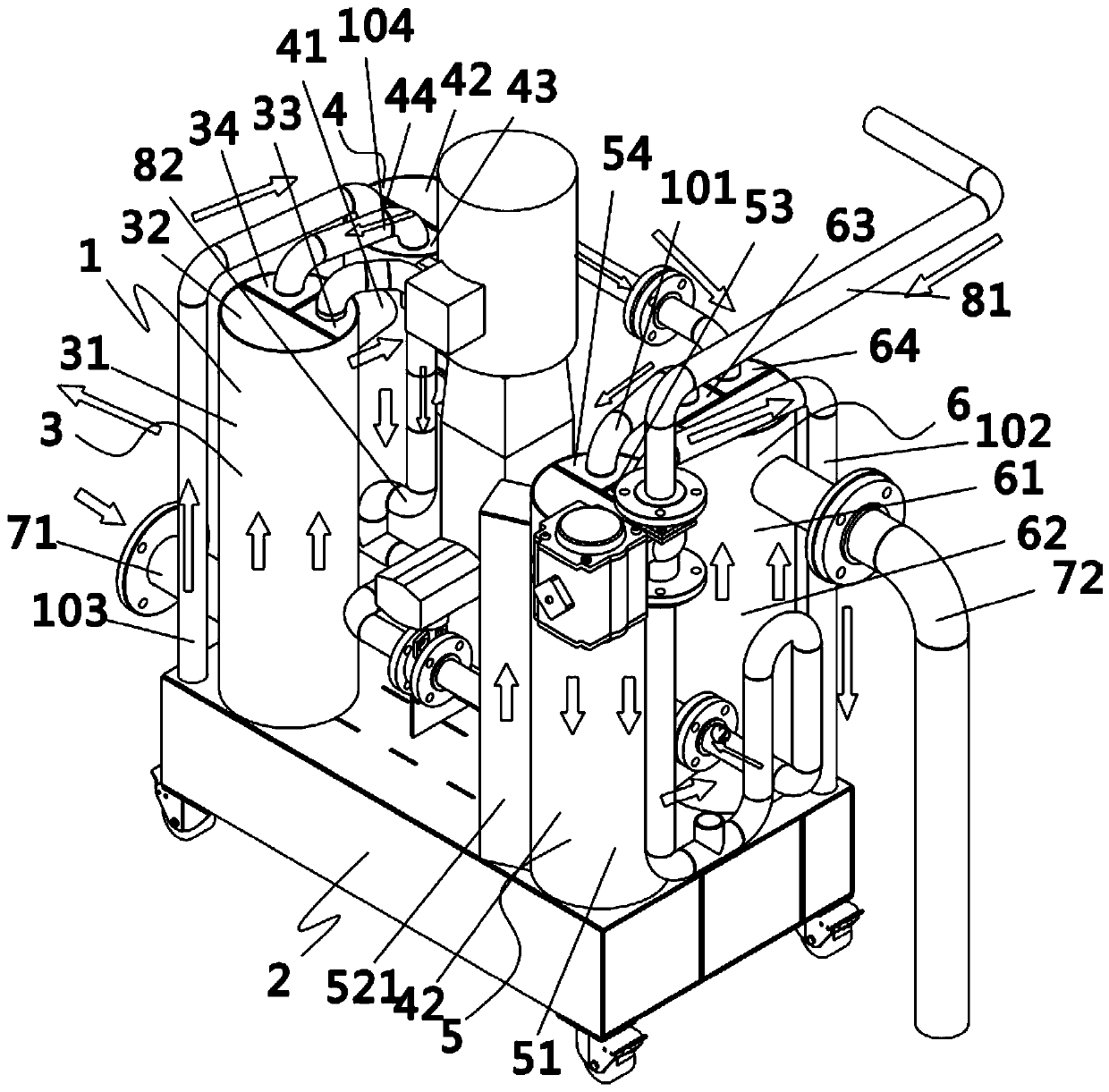

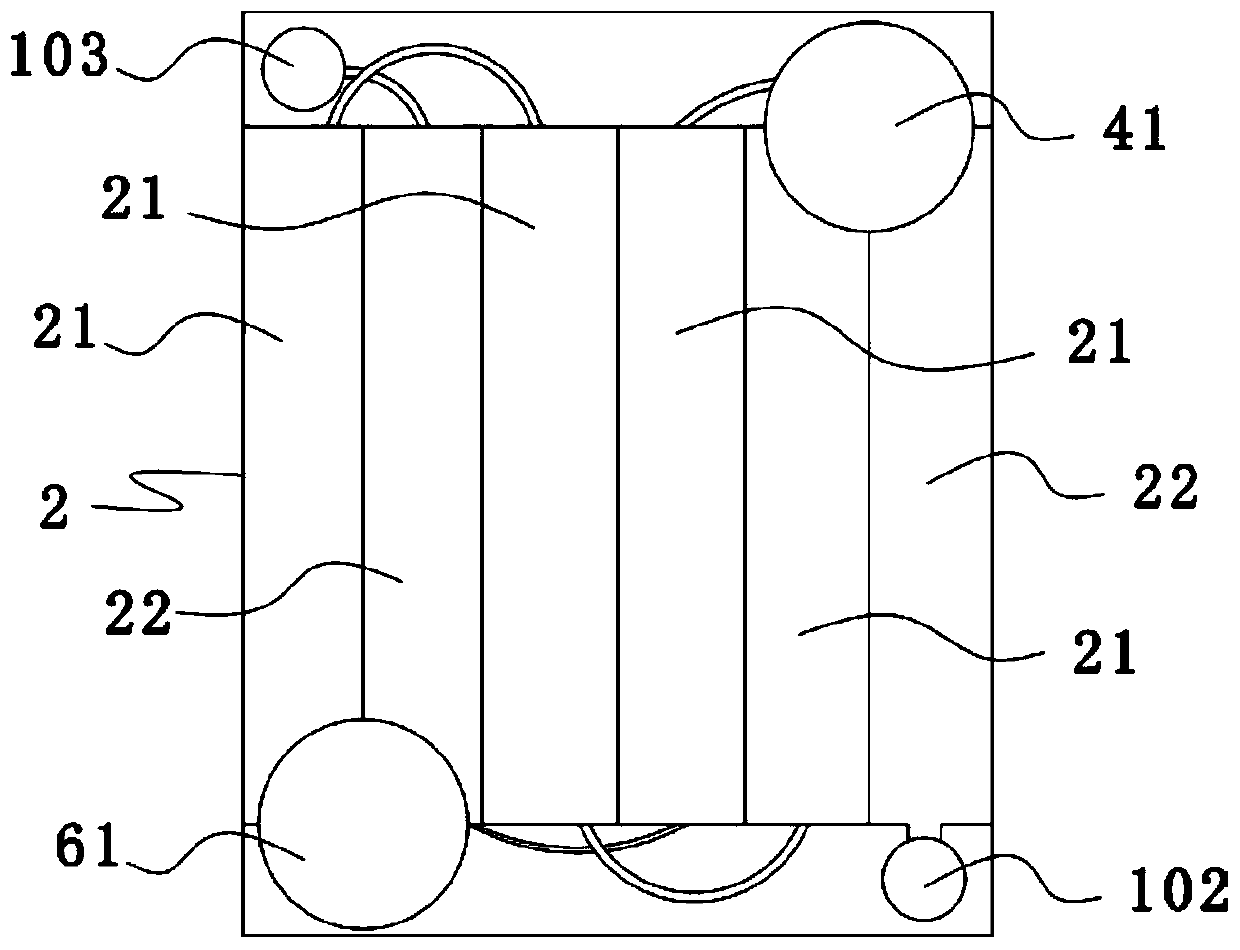

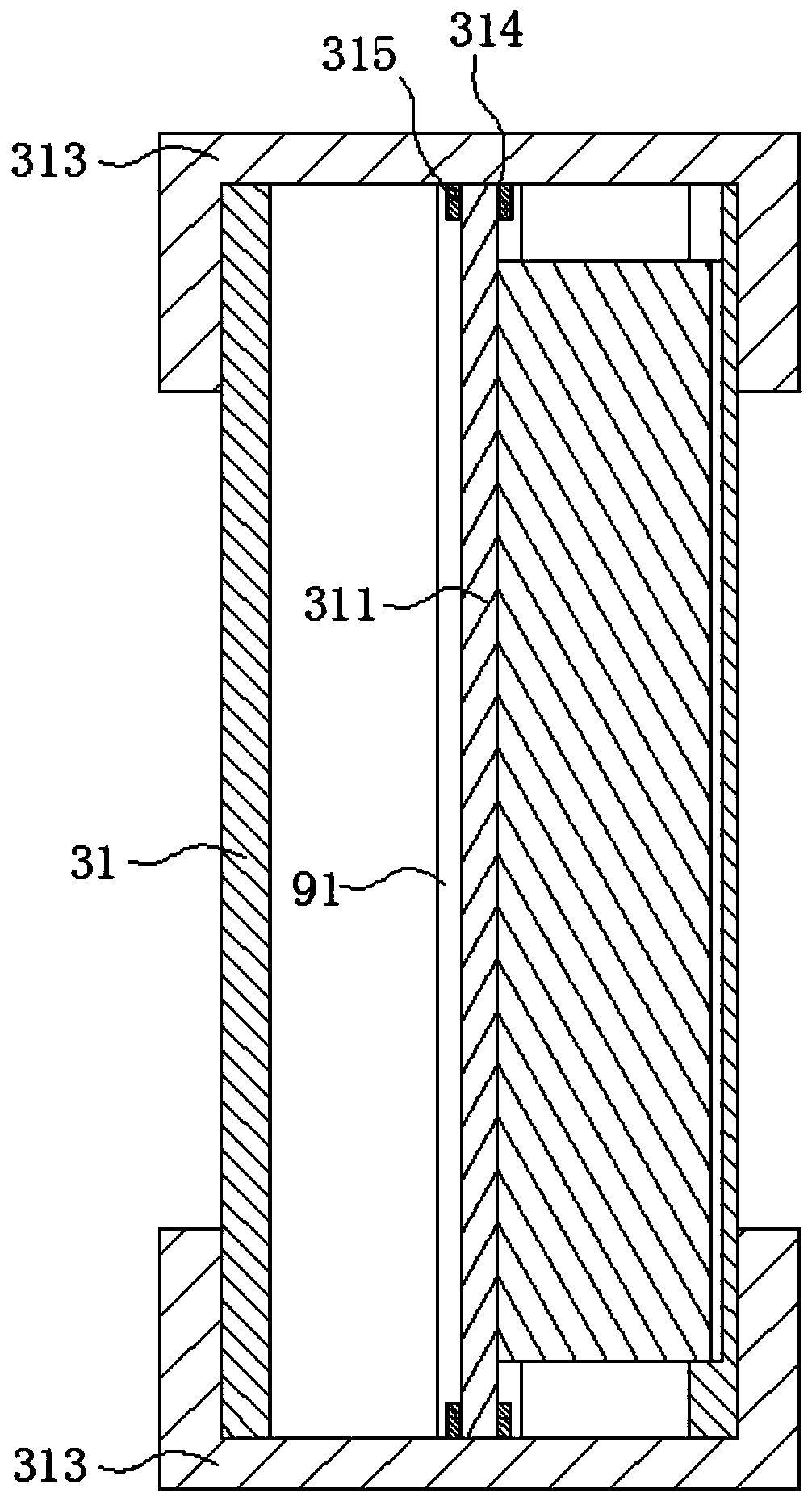

ActiveCN108499246BEffective energy saving and consumption reductionEasy to recycleCombination devicesDispersed particle filtrationDust controlExhaust fumes

The present invention relates to the field of industrial waste gas treatment, in particular to a dust recovery and utilization device for industrial waste gas treatment, including a suction pipe assembly, a dust removal cylinder assembly, a rotary dust filter device, a dust collection box assembly, an auxiliary dust collection device and Drive control device, the dust removal cylinder assembly includes an upper cylinder, a lower cylinder, an annular mounting plate, a blocking dust rod, a support base and an air outlet pipe; the upper end of the annular mounting plate is fixedly connected to the upper cylinder, and the ring mounting plate The lower end is fixedly connected to the lower cylinder body, and the bottom end of the lower cylinder body is connected to the support base through a plurality of support columns; the top end of the upper cylinder body is welded and connected to the air outlet pipe; There are six blocking dust-falling rods, and six blocking dust-falling rods are arranged inside the upper cylinder; the present invention can effectively solve the problem that the internal filter screen of the industrial waste gas treatment device in the prior art is easily blocked.

Owner:湖南核工业宏华机械有限公司

Energy-saving system for cooling air duct of glass annealing kiln and method for cooling glass ribbon

Owner:洛阳建材机械厂

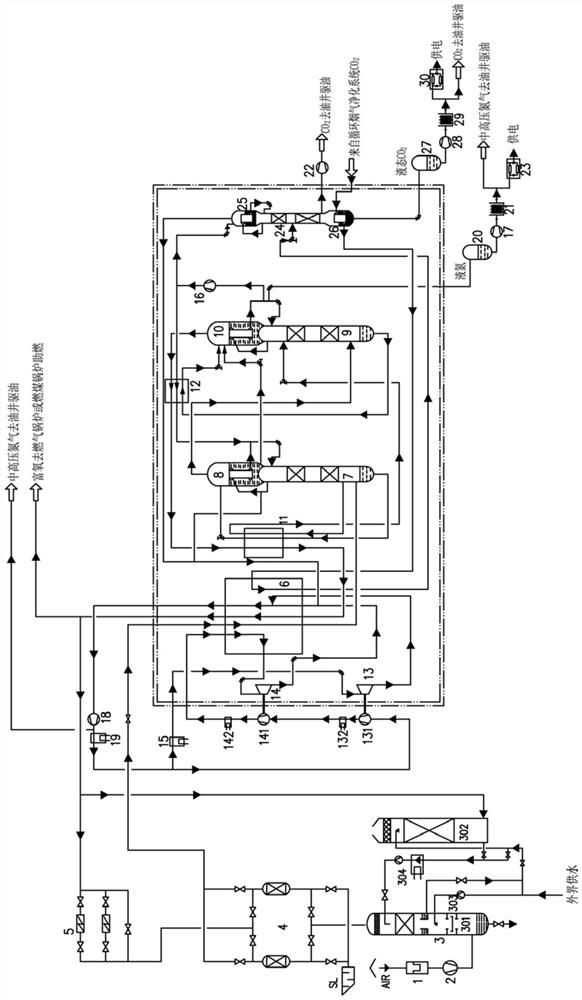

Process for efficiently converting green electricity into low-energy-consumption air separation energy storage and purifying and liquefying CO2

ActiveCN114791205AEnhanced overall recoveryEfficient conversionSolidificationLiquefactionCo2 storageAir compressor

The invention discloses a process for efficiently converting green electricity into low-energy-consumption air separation energy storage and purifying and liquefying CO2. The required device comprises a filter, an air compressor, an air pre-cooling system, a molecular sieve adsorber, an electric heater, a main heat exchanger, rectifying towers I and II, main condensation evaporators I, II, III and IV, subcoolers I and II, a high-temperature expansion machine, a low-temperature expansion machine, a low-temperature refrigerator, a liquid nitrogen pump I, a circulating nitrogen compressor, a water cooler behind the circulating nitrogen compressor, a liquid nitrogen storage tank, a CO2 rectifying tower, a CO2 supercharger and a liquid CO2 storage tank, wherein the molecular sieve adsorber, the electric heater, the main heat exchanger, the rectifying towers I and II, the main condensation evaporators I, II, III and IV are alternately used. According to the invention, medium and high pressure nitrogen, high purity rich oxygen and liquid nitrogen are prepared by using green electricity, CO2 enriched and purified by a circulating flue gas purification system is purified and liquefied to prepare gaseous and liquid CO2 products, the medium and high pressure nitrogen and the gaseous CO2 products are subjected to oil displacement in an oil well, the green electricity is stored in a liquid form by the liquid nitrogen and the liquid CO2 products, and the green electricity is subjected to oil displacement in the oil well and / or expansion power generation after being pressurized and vaporized. And efficient conversion and utilization of green electricity are realized.

Owner:HANGZHOU TURNING ENERGY TECH DEV CO LTD

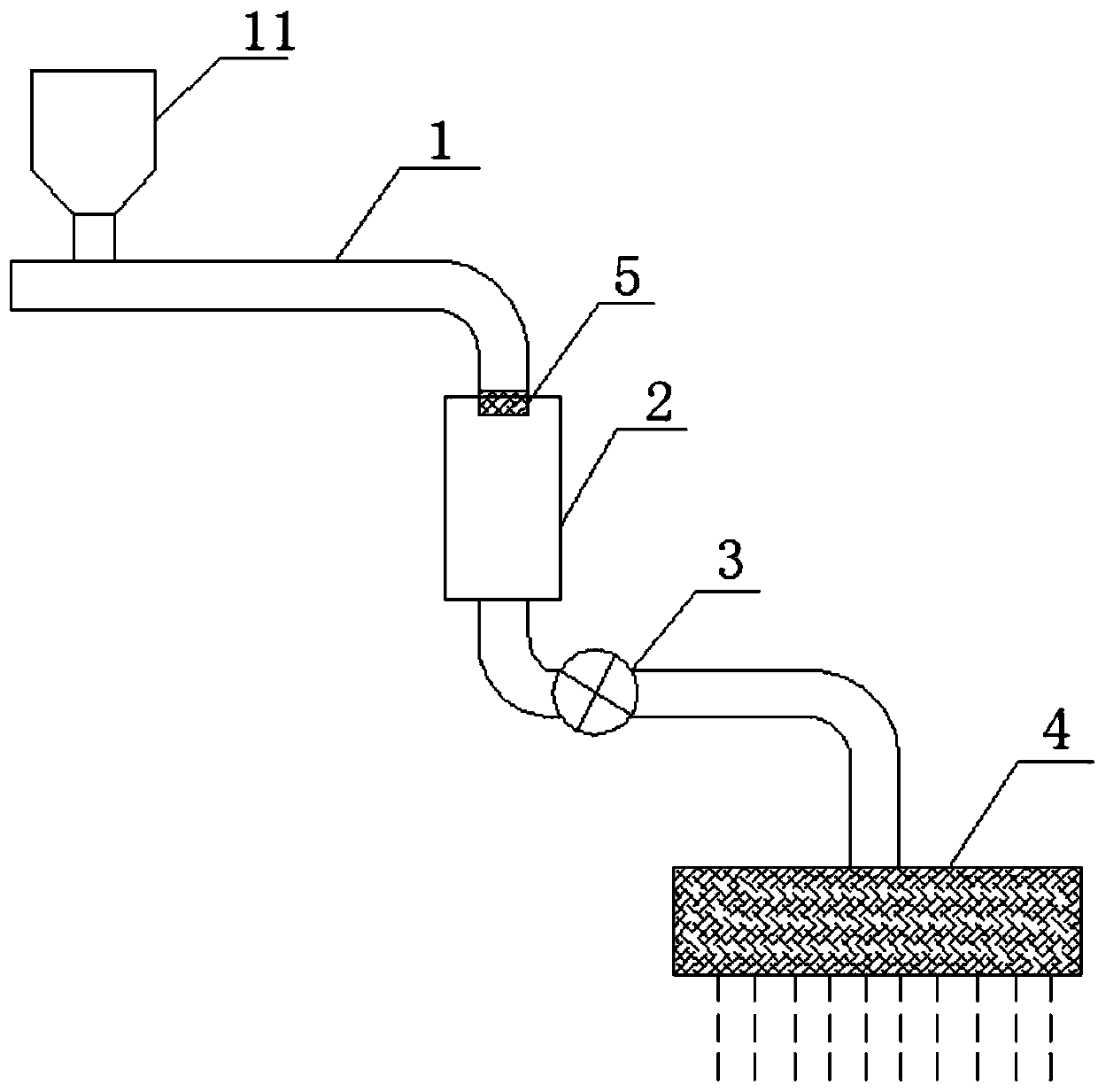

Moisture removal device for chemical fiber spinning raw material

InactiveCN107904680AFully heated to volatilizeEffective energy saving and consumption reductionMelt spinning methodsEngineeringMoisture

The invention discloses a moisture removal device for a chemical fiber spinning raw material. The device comprises a threaded rod extruder, a porous screen mesh, a moisture volatilization material cylinder, a spinning pump and a spraying mold, the porous screen mesh is located at an outlet of the threaded rod extruder, and the moisture volatilization material cylinder is located below the porous screen mesh; the spinning pump is located below an outlet of the moisture volatilization material cylinder, the spraying mold is located below the spinning pump, the porous screen mesh is connected with the threaded rod extruder through a pipe, and the spinning pump is connected with the moisture volatilization material cylinder and the spraying mold through pipes separately. The moisture removal device for the chemical fiber spinning raw material has the advantages that a heat preservation material cylinder which can be heated is arranged below the threaded rod extruder, the heating temperature is controlled within 180-230 DEG C, the extruded chemical fiber spinning raw material can pass through screen holes and form a thin filament shape through the porous screen mesh, accordingly, the moisture of chemical fiber spinning in the falling process is sufficiently heated and volatilized, the raw material drying operation before production in the prior art does not need to be conducted, andaccordingly energy can be effectively saved and consumption can be effectively lowered.

Owner:江苏惠沣环保科技有限公司

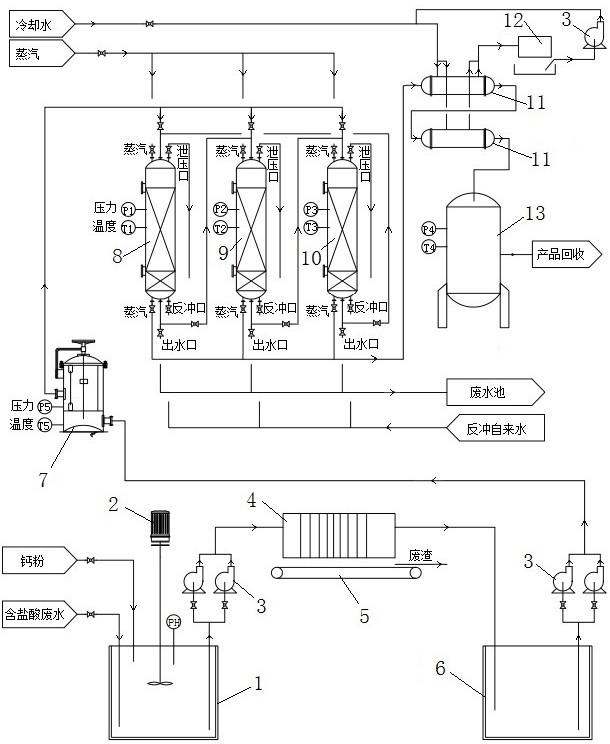

Method for extracting n-butyl alcohol from hydrochloric acid-containing wastewater

InactiveCN111718024AReduce COD valueShort processing cycleSpecific water treatment objectivesTreatment involving filtrationN-Butyl AlcoholChlorosilane

The invention belongs to the technical field of wastewater treatment, and particularly relates to a method for extracting n-butyl alcohol from hydrochloric acid-containing wastewater. The method comprises the following steps: sending hydrochloric acid-containing wastewater generated by preparing organic silicon resin from chlorosilane into a pretreatment unit, and sequentially neutralizing and filtering; sending the wastewater treated by the pretreatment unit into a resin treatment unit, carrying out adsorption treatment on n-butyl alcohol in the wastewater, and discharging the treated wastewater into a wastewater pool; after a period of time, introducing steam into the resin treatment unit, and desorbing the adsorbed n-butyl alcohol; and the desorbed steam enters an n-butyl alcohol recovery unit for n-butyl alcohol recovery. The method not only can effectively reduce the COD value in the wastewater generated by preparing the organic silicon resin by adopting chlorosilane, shorten thewastewater treatment period and increase the wastewater treatment capacity, but also can extract n-butyl alcohol from the wastewater for recycling so that the aims of effectively saving energy, reducing consumption and realizing clean production are achieved.

Owner:PAMICA TECH CORP

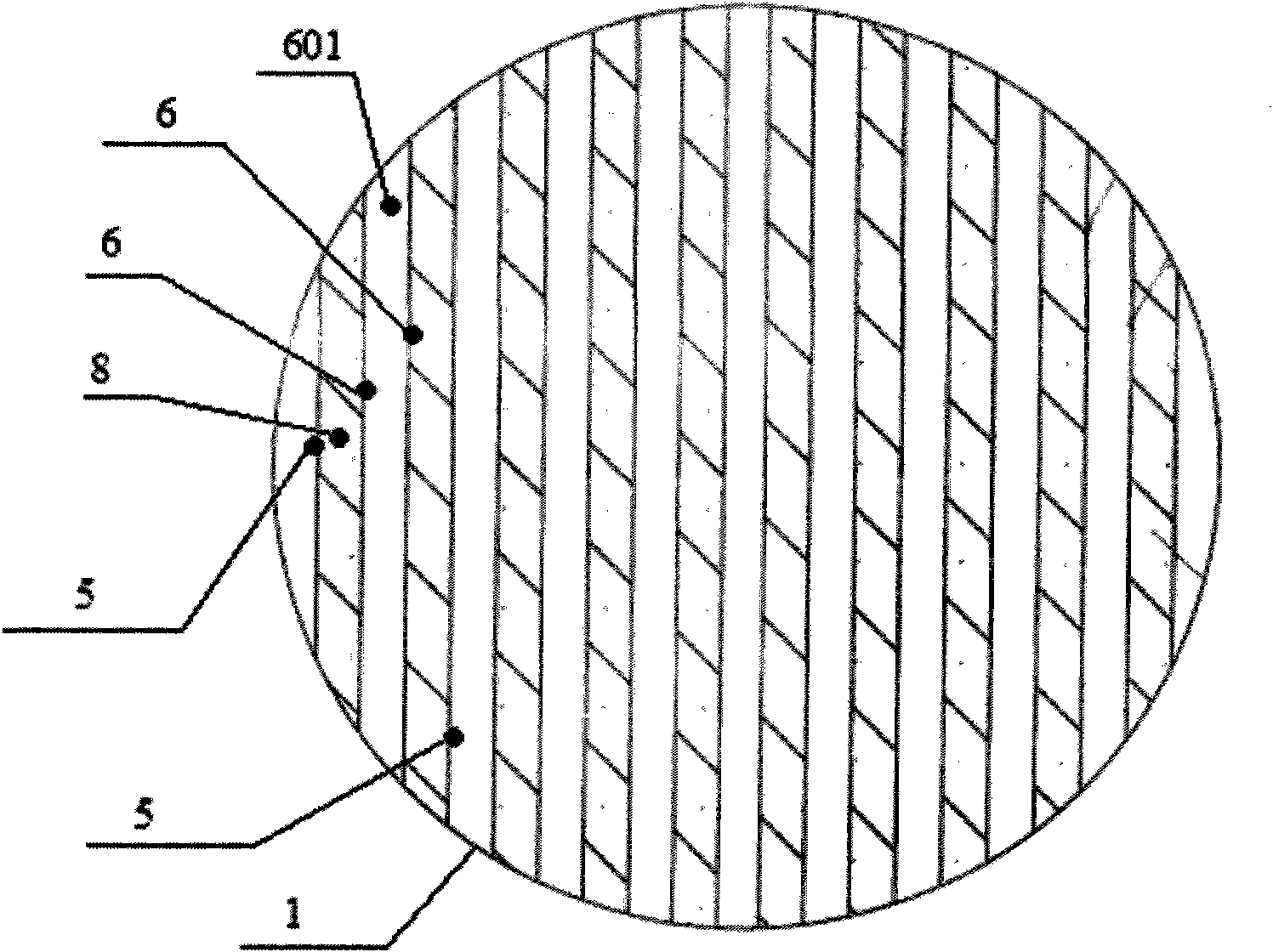

Gas-Solid Phase Catalytic Reactor

The invention discloses a gas solid phase catalytic reactor. The gas solid phase catalytic reactor comprises a shell of which the upper part is provided with an inlet and the lower part is provided with an outlet, catalytic bed assemblies and flower plates provided with passage ports; each catalytic bed assembly comprises an inlet distribution member with small holes, an outlet distribution member with small holes and a seal plate; the seal plate is arranged on the top of the inlet distribution member and the outlet distribution member; the gap between the inlet distribution member and the outlet distribution member is provided with a catalytic bed filled with the catalyst; the other side of the inlet distribution member is a fluid inlet passage which is communicated with an inlet; and the other side of the outlet distribution member is a fluid outlet passage which is communicated with a passage port on each flower plate; and the flower plates are fixed on the lower part in the shell,and the lower end of each inlet distribution member, the lower end of each outlet distribution member and the flower plate are hermetically sealed. The formed bed is extremely low in pressure drop, can effectively save energy and reduce consumption, and can be widely applied to petrochemical industry, inorganic chemistry industry, or organic chemical industry.

Owner:CHANGZHOU RUIHUA CHEM ENG&TECH

A kind of printing and dyeing wastewater treatment method

ActiveCN108314207BImprove adsorption capacityReduce COD contentSpecific water treatment objectivesWater/sewage treatment by ion-exchangeChemical oxygen demandPhosphoric acid

Owner:海宁华翔漂染科技有限公司

Parallel connection type double-screw-rod pump

InactiveCN101852206BHigh trafficImprove performanceRotary piston pumpsRotary piston liquid enginesConnection typeEngineering

Owner:江西凯峰泵业有限公司

Air compression expand air-conditioning clothes

InactiveCN106490713ASimple structureGood effectCompression machines with reversible cycleHeating and refrigeration combinationsEngineeringFour-way valve

The invention discloses an air compression expand air-conditioning clothes which includes an air compressor. Through a dry filter, a four-way valve and a first heat exchanger and a second heat exchanger successively and through the four-way valve again, the air compressor is connected with an evacuation. The air compressor is provided with an air filter. The second heat exchanger includes an inlet and an outlet. The outlet is connected with the inlet through a water pump, an air-conditioning clothes and an expansion water pot. An expansion machine is disposed between the first heat exchanger and the second exchanger. The air compression expand air-conditioning clothes has the advantages of using the air as refrigerant and drawing material anyway and being suitable for field use; due to the function of the expansion machine, expansion work is recycled fully, which conserves energy and reduces consumption; the air compression expand air-conditioning clothes has the advantages of simple construction, obvious effect and high practicability.

Owner:滕振亚

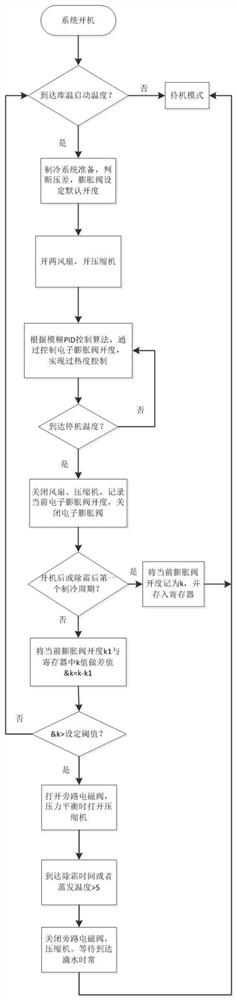

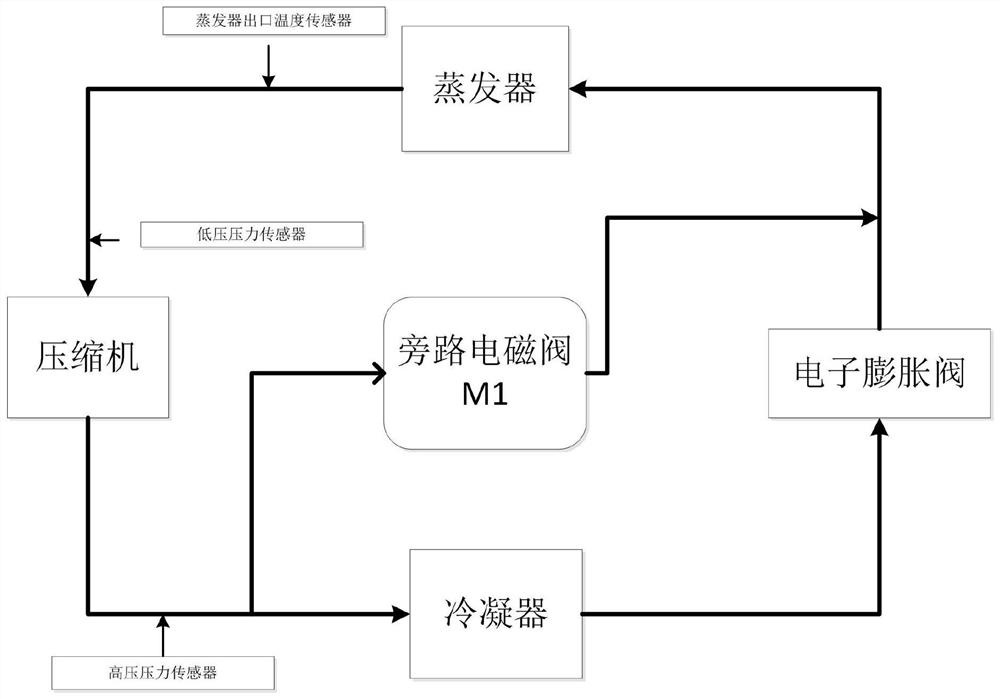

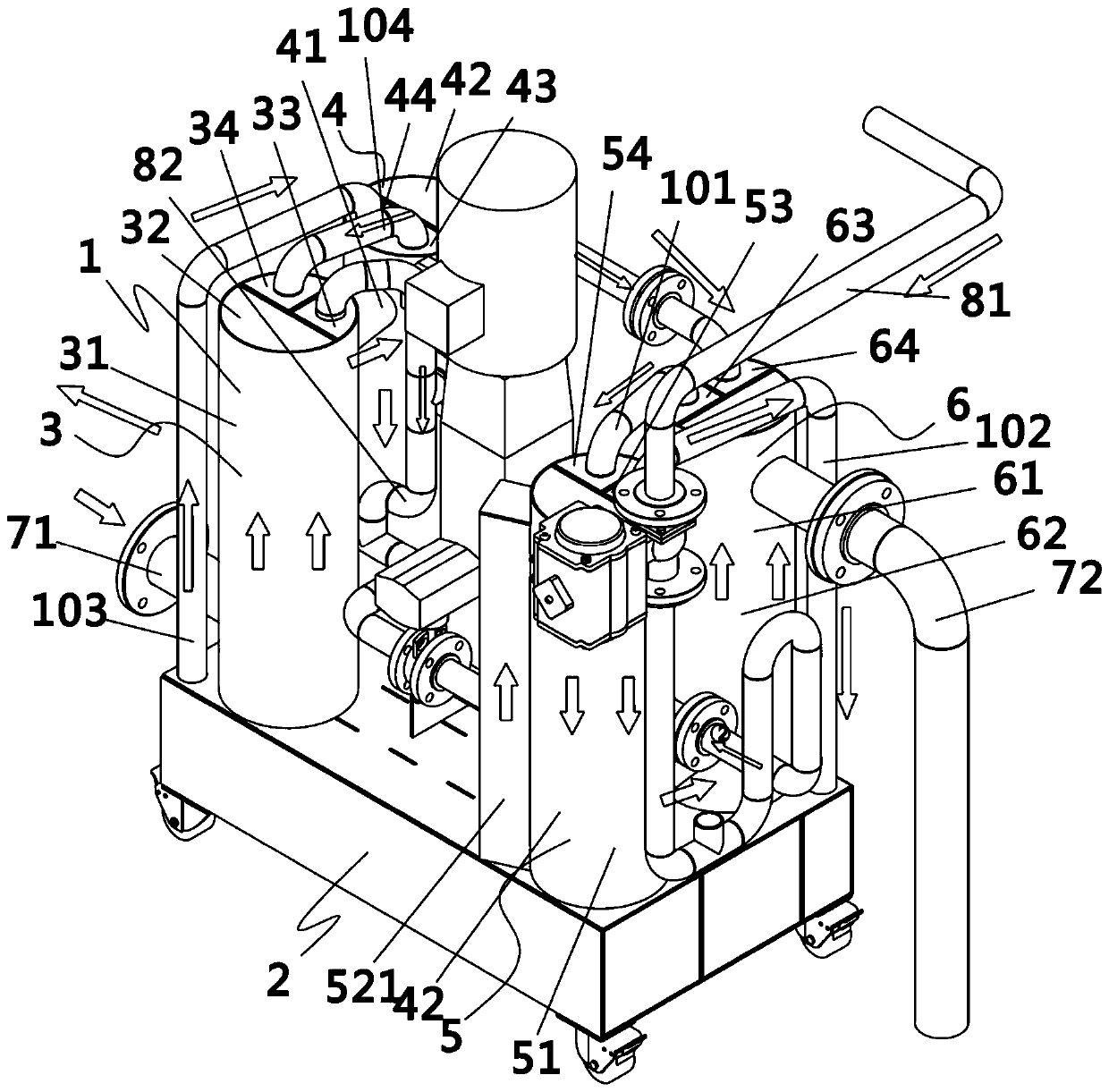

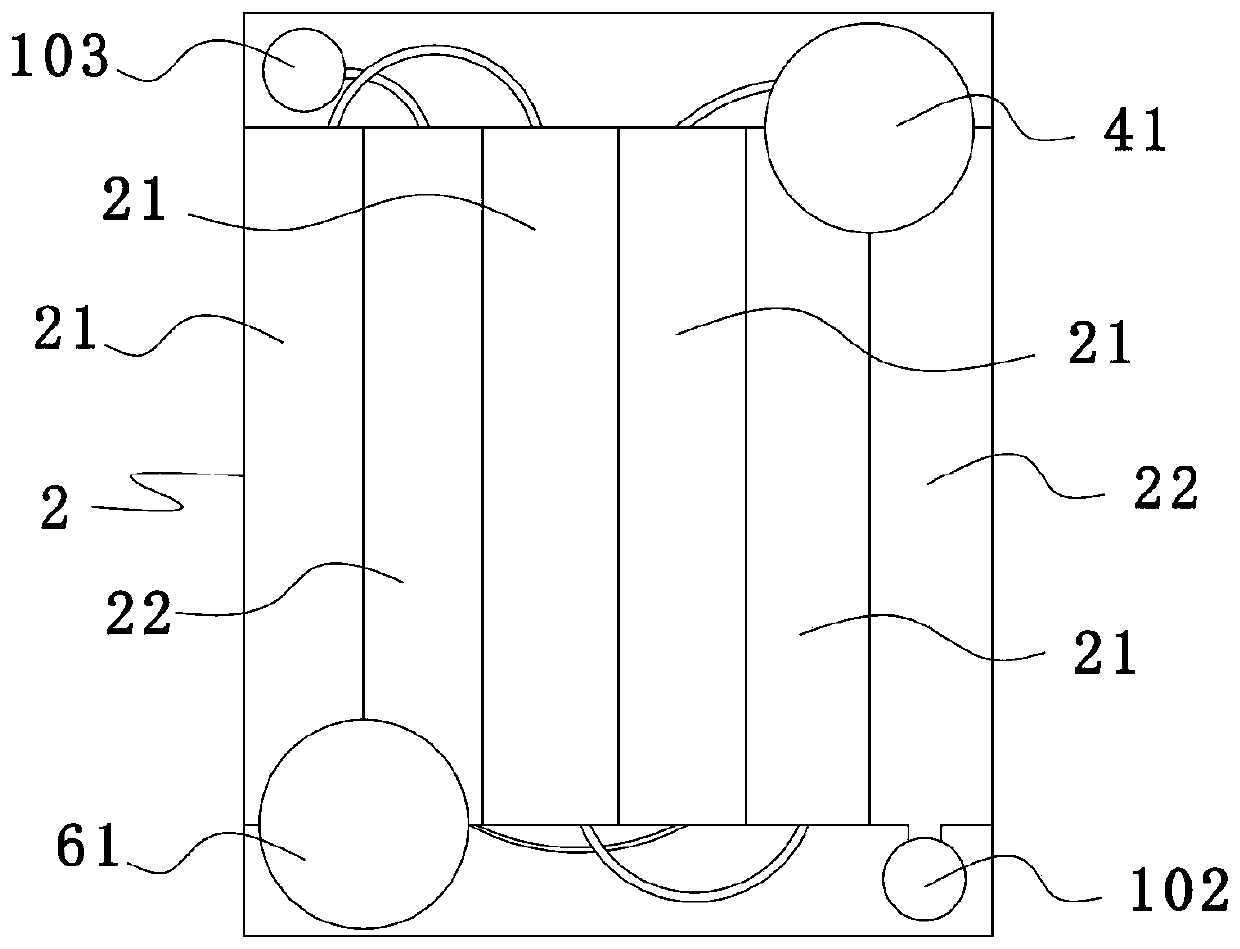

A method for intelligent defrosting of refrigeration system based on electronic expansion valve opening

InactiveCN110762915BGuaranteed uptimeImprove running stabilityMechanical apparatusCorrosion preventionCooling effectControl engineering

The invention relates to a method for intelligent defrosting of a refrigeration system based on the opening degree of an electronic expansion valve. The method uses a fuzzy PID algorithm combined with an electronic expansion valve to control the superheat parameter of the refrigeration system, and on this basis, utilizes the strong reliability of the entire refrigeration system. With the characteristics of repeatability and time lag, modern intelligent technologies such as Internet of Things technology and fuzzy control are comprehensively used, and the end opening of the last refrigeration cycle of the electronic expansion valve and the reference opening of the electronic expansion valve are used as parameters, combined with intelligent algorithms, to judge the cooling effect. The frosting condition of the system evaporator, and enter the defrosting process of the refrigeration system as needed, and complete the defrosting of the refrigeration system on demand. The application of this technology realizes the intelligent prediction and discrimination of the amount of frost in the evaporator, provides a reliable basis for realizing the on-demand defrosting of the refrigeration system, improves the overall operating efficiency of the refrigeration system, and achieves the purpose of effectively saving energy and reducing consumption.

Owner:NANKAI UNIV

Environment-friendly treatment method based on printing and dyeing wastewater

ActiveCN110615555AImprove adsorption capacityReduce COD contentSpecific water treatment objectivesWater/sewage treatment by ion-exchangeChemical oxygen demandPhosphoric acid

The invention discloses an environment-friendly treatment method based on printing and dyeing wastewater. The method comprises the following steps: (1) carrying out heat exchange treatment on the printing and dyeing wastewater through heat exchange equipment, feeding the printing and dyeing wastewater into an adjusting tank, and adjusting the pH value to be 8-8.5 and the COD (Chemical Oxygen Demand) to be 300-500 mg / L; (2) adding phosphate substances into the wastewater, and carrying out mixed reaction for 4-6 hours; and (3) introducing the wastewater obtained in the step (3) into a hydrolysisacidification pool, carrying out a reaction for 2-3 h, introducing water into a neutralization pool, and carrying out a neutralization reaction. According to the invention, through the cooperation ofpH value adjustment and acidification hydrolysis, flora in the printing and dyeing wastewater is effectively removed, the COD content in the wastewater is effectively reduced, and a good water treatment effect is achieved.

Owner:JIEYANG EXPERIMENTAL ZONE & NEW DYEING & FINISHING CO LTD

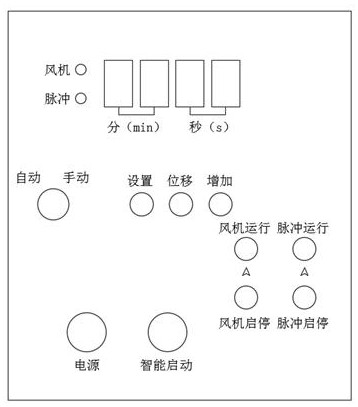

Pulse control method for powder tank dust remover

InactiveCN114307421AReduce uncertaintyEffective energy saving and consumption reductionDispersed particle filtrationThermodynamicsDust control

The invention relates to the technical field of dust collector pulse control, in particular to a powder tank dust collector pulse control method, which comprises the following steps that S1, an intelligent pulse dust collector is electrified uniformly, a dust collection fan and a pulser are in a working mode, before feeding of a powder tank, one key is started, the dust collection fan is not started in advance, only the pulser is electrified, and a filter bag is thoroughly cleaned; s2, when the powder tank starts feeding, a dust removal fan is started, the dust filtering speed is increased, the pressure difference in the powder tank is kept balanced, and at the moment, a pulser is powered off and does not work; s3, after feeding of the powder tank is completed, the dust removal fan stops working, the pulser is electrified again, and sufficient and thorough pulse cleaning is conducted on the filter element of the dust remover; and S4, after a standard work period is completed, the intelligent pulse dust collector control box automatically stops running. According to the method, uncertain factors caused by manual operation can be reduced, energy can be effectively saved, consumption can be effectively reduced, and economic benefits are improved.

Owner:湖南健成科技有限公司

Gas solid phase catalytic reactor

The invention discloses a gas solid phase catalytic reactor. The gas solid phase catalytic reactor comprises a shell of which the upper part is provided with an inlet and the lower part is provided with an outlet, catalytic bed assemblies and flower plates provided with passage ports; each catalytic bed assembly comprises an inlet distribution member with small holes, an outlet distribution member with small holes and a seal plate; the seal plate is arranged on the top of the inlet distribution member and the outlet distribution member; the gap between the inlet distribution member and the outlet distribution member is provided with a catalytic bed filled with the catalyst; the other side of the inlet distribution member is a fluid inlet passage which is communicated with an inlet; and the other side of the outlet distribution member is a fluid outlet passage which is communicated with a passage port on each flower plate; and the flower plates are fixed on the lower part in the shell,and the lower end of each inlet distribution member, the lower end of each outlet distribution member and the flower plate are hermetically sealed. The formed bed is extremely low in pressure drop, can effectively save energy and reduce consumption, and can be widely applied to petrochemical industry, inorganic chemistry industry, or organic chemical industry.

Owner:CHANGZHOU RUIHUA CHEM ENG&TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com