Gas-Solid Phase Catalytic Reactor

A catalytic reactor, gas-solid phase technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as reducing bed resistance, and achieve the effect of large flow area and low pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Maleic anhydride tail gas treatment

[0052] In the process of preparing maleic anhydride by air oxidation of benzene, its composition and flow rate are shown in Table 1.

[0053] Table 1 Maleic anhydride tail gas of a company

[0054] composition

Content (%wt)

0.05

14

74

water

6.5

1.6

4.0

flow

20000kg / h

temperature

45℃

pressure

10KPa

[0055] Reactor structure parameters:

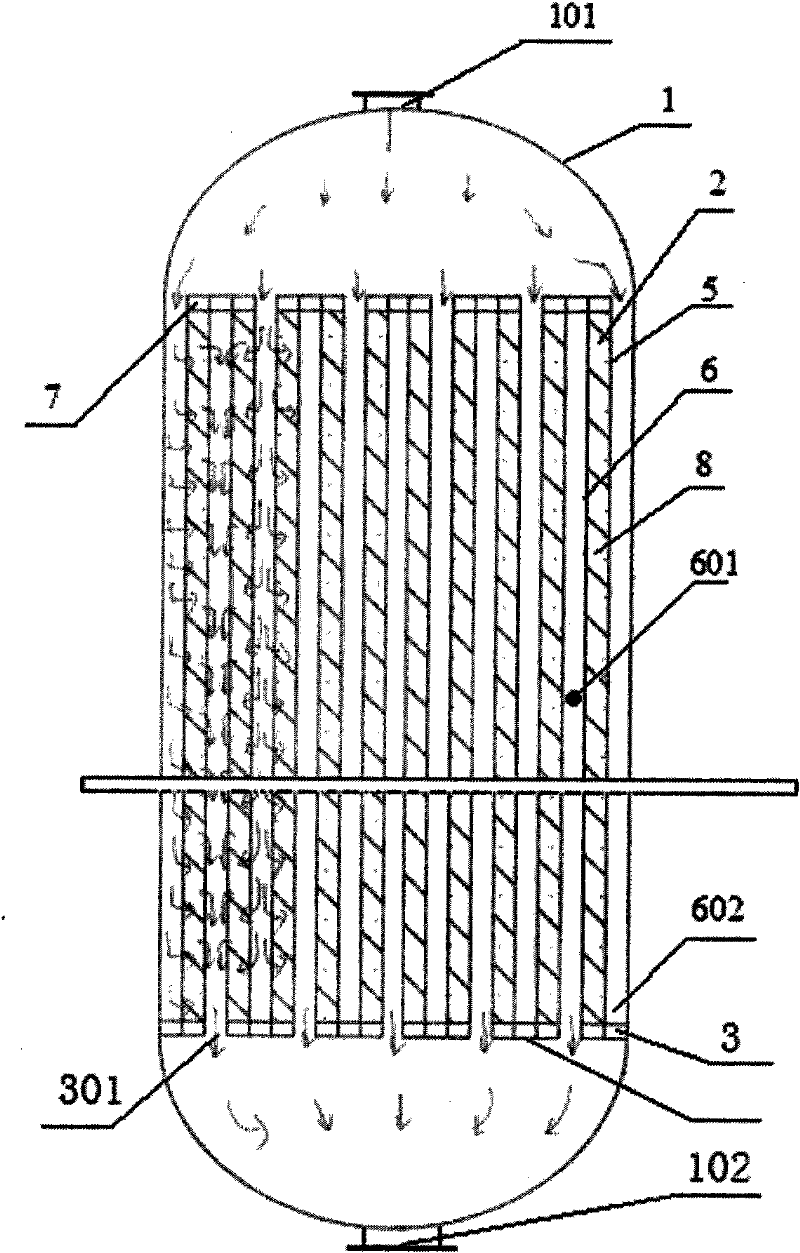

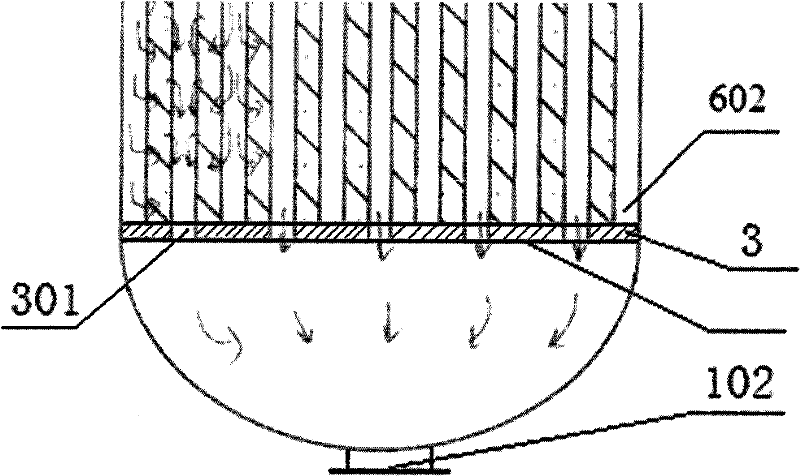

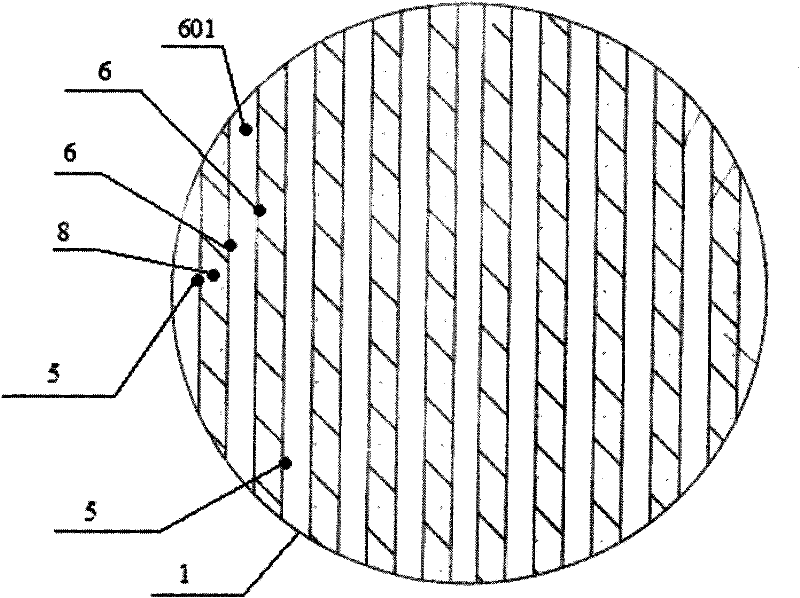

[0056] Diameter: 1000mm, using figure 1 with image 3 The ring-column catalytic bed assembly 2 shown has 15 pieces, the inlet distribution member 5 is a round tube with a diameter of 150mm, the outlet distribution member 6 is a round tube with a diameter of 50mm, and the opening ratio of the porous material is 25%. 1.8mm;

[0057] The catalyst is a Cu-based catalyst modified with Mn, the particle size is Φ2...

Embodiment 2

[0060] use figure 1 with image 3 Sheet structure catalytic bed assembly.

[0061] The porosity of the porous material is 10%, and the aperture is 5mm; the thickness of the catalytic bed 8 is 300mm;

[0062] Others are the same as in Example 1, and the pressure drop of the reactor system is less than 1KPa, which is 400% lower than that of the existing reactor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com