Process for efficiently converting green electricity into low-energy-consumption air separation energy storage and purifying and liquefying CO2

A low-energy, high-efficiency technology, applied in liquefaction, refrigeration, liquefaction, solidification, etc., can solve the problems of restricting the large-scale development of renewable energy, not being effectively utilized, and the difficulty of heavy oil production, so as to avoid oxygen corrosion on the well wall , efficient conversion and utilization, and the effect of improving fuel utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further explained below with reference to the embodiments and the accompanying drawings. The following examples are only used to illustrate the present invention, but are not intended to limit the scope of implementation of the present invention.

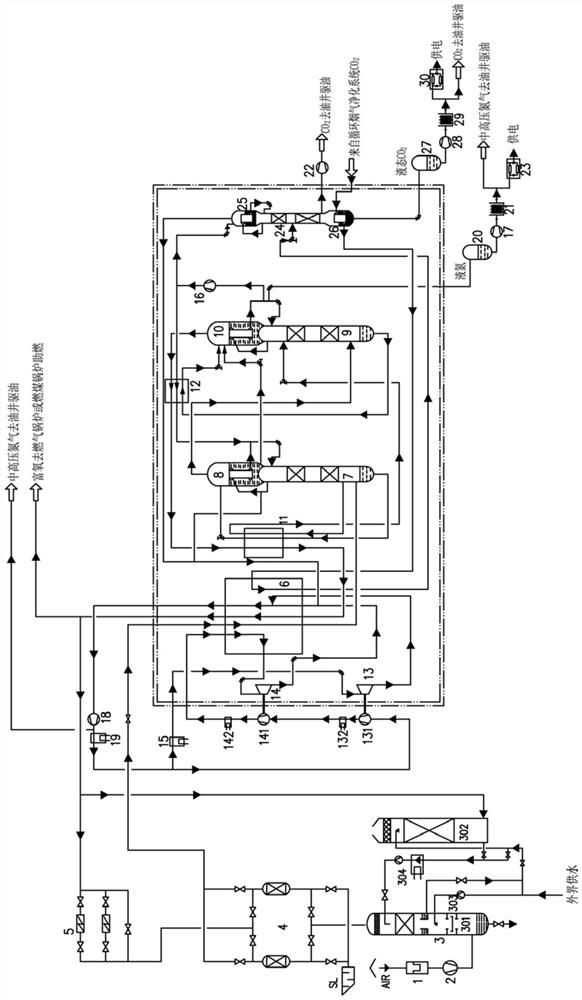

[0045] A high-efficiency conversion of green electricity to low-energy air separation energy storage and CO 2 Purification and liquefaction process, the equipment required for the process is such as figure 1 As shown, including filter 1, air compressor 2, air pre-cooling system 3, alternately used molecular sieve adsorber 4, electric heater 5, main heat exchanger 6, rectifying tower 17, main condensing evaporator 18, Cooler I11, rectification tower II9, main condensing evaporator II10, subcooler II12, high temperature expander 13, low temperature expander 14, low temperature freezer 15, liquid nitrogen pump I16, circulating nitrogen compressor 18, circulating nitrogen compressor After water coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com