Pulse control method for powder tank dust remover

A technology of pulse control and dust collector, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles, etc., can solve problems such as dust collector rushing out of the top cover, fan with high exhaust power, and loss of function, so as to reduce uncertainty factors, the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

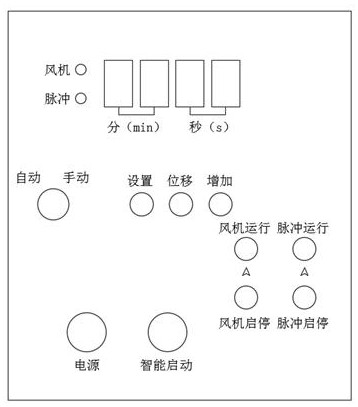

[0019] Embodiment 1: (in conjunction with figure 1 )

[0020] Before turning on the power, select "automatic mode", the device will run according to the set fan and pulse duration, if you need to modify the duration, press and hold the set button for 2 seconds, press the shift and increase buttons to adjust the time, and then press the set button to save the set time .

[0021] S1. The intelligent pulse dust collector is powered on uniformly. The dust removal fan and pulser are in the working mode. Before the powder tank is fed, one key is started. The default setting is 5min, adjustable;

[0022] S2. When the powder tank starts feeding, the dust removal fan is turned on to accelerate the dust filtration speed and maintain the pressure difference balance in the powder tank. At this time, the pulser is powered off and does not work. The default time is 30 minutes, which is adjustable;

[0023] S3. After the feeding of the powder tank is completed, the dust removal fan stops ...

Embodiment 2

[0027] Embodiment 2: (the following is the alternative of embodiment 1)

[0028] The above purpose can also be achieved by manually controlling the dust collector and pulse dust removal in the ash feeding process by using dual circuits to separately control the dust removal fan and pulse dust removal. However, the initial construction cost is high, and the probability of misoperation and missed operation is very high. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com