Method for recycling waste heat of high-temperature materials and device

A high-temperature material and waste heat recovery technology, applied in the field of energy conservation and environmental protection, can solve the problems of uneven distribution of high-temperature materials, insufficient waste heat recovery of materials, fragmentation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

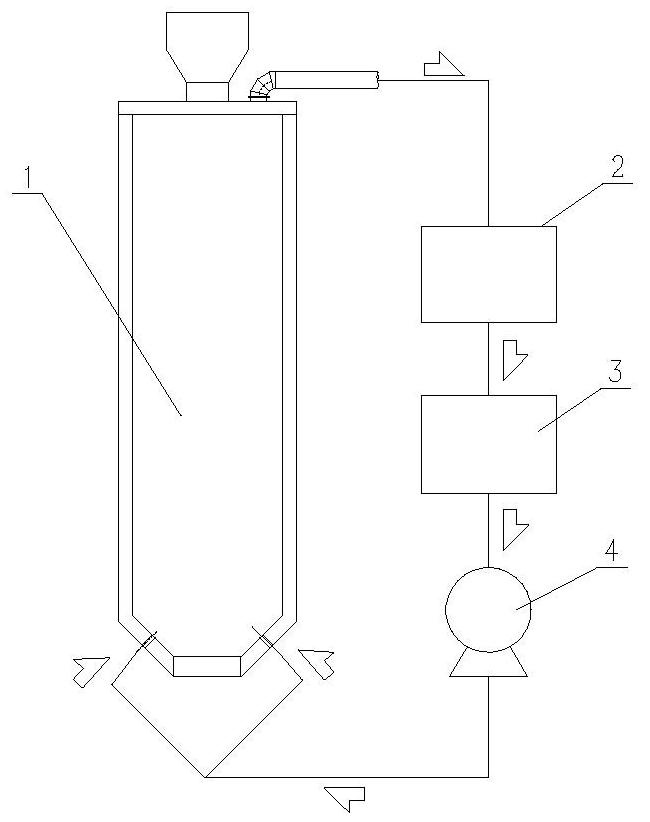

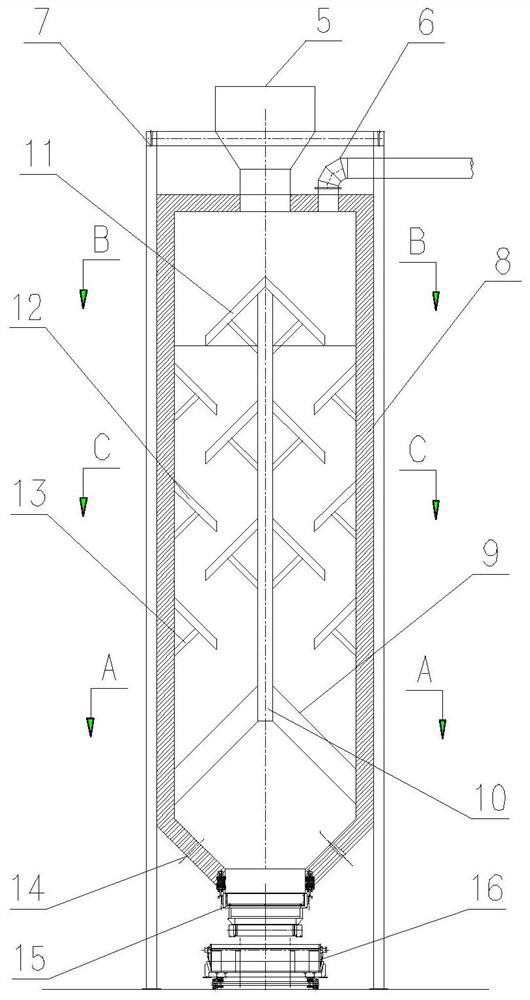

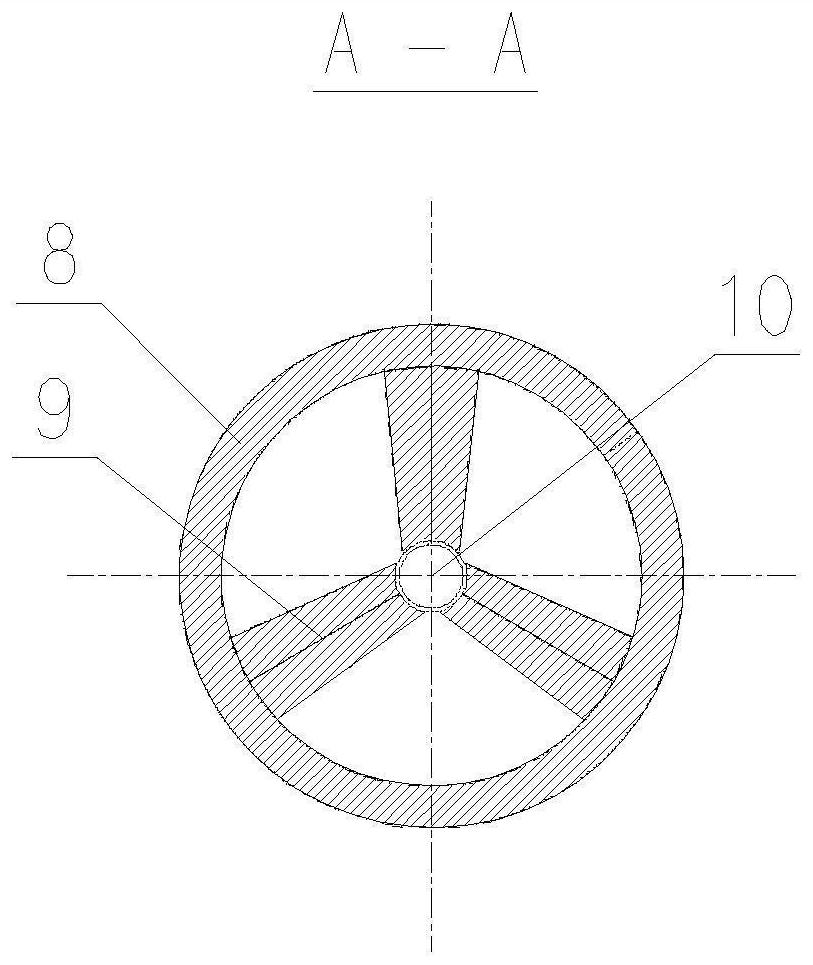

[0029] The invention provides a method and device for waste heat recovery and recycling of high-temperature materials. The overall diagram of the device is as follows figure 1 As shown, the processing capacity of the device is 20t / h. The device at least includes a heat exchange furnace 1 and a gas recycling module. The heat exchange furnace 1 includes a heat exchange furnace shell 8, a material distribution device, a feeding mechanism 5 and a discharging mechanism 15 , the inner lining of the heat exchange furnace shell 8 is refractory material, and the steel structure frame 7 used to support the heat exchange furnace shell is arranged outside the heat exchange furnace, and the center of the heat exchange furnace shell is provided with three furnace The inner support legs 9 are fixed on the center column 10 inside the furnace shell, and the center column 10 and the three furnace inner support legs 9 are used to fix the inner ring distribution unit 11 to evenly distribute the ma...

Embodiment 2

[0038] On the basis of Example 1, the processing capacity of the device is increased to 80t / h. Such as Figure 6 , the inner diameter of the heat exchange furnace 1 is doubled, and the heat exchange furnace 1 is equipped with a 10-level umbrella-shaped distribution device, including a 5-level inner ring distribution unit 11 and a 5-level outer ring distribution unit 12, the inner ring distribution unit and the outer ring distribution unit The units are arranged crosswise in the heat exchange furnace. The specific working steps of this device are the same as in Embodiment 1.

[0039] In this embodiment, when the processing capacity of high-temperature materials is relatively large and it is necessary to increase the processing capacity of a single high-temperature material, by increasing the inner diameter of the heat exchange furnace 1 and the distance between the inner ring distribution unit 11 and the outer ring distribution unit 12 in the heat exchange furnace 1 The metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com