High-efficiency mine tailing metal concentrating machine

A tailings, high-efficiency technology, applied in the direction of solid separation, classification, chemical instruments and methods, etc., can solve the problems of inconvenient installation and maintenance, poor selection effect, increased production costs, etc., to improve machine utilization and reduce production costs , Easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

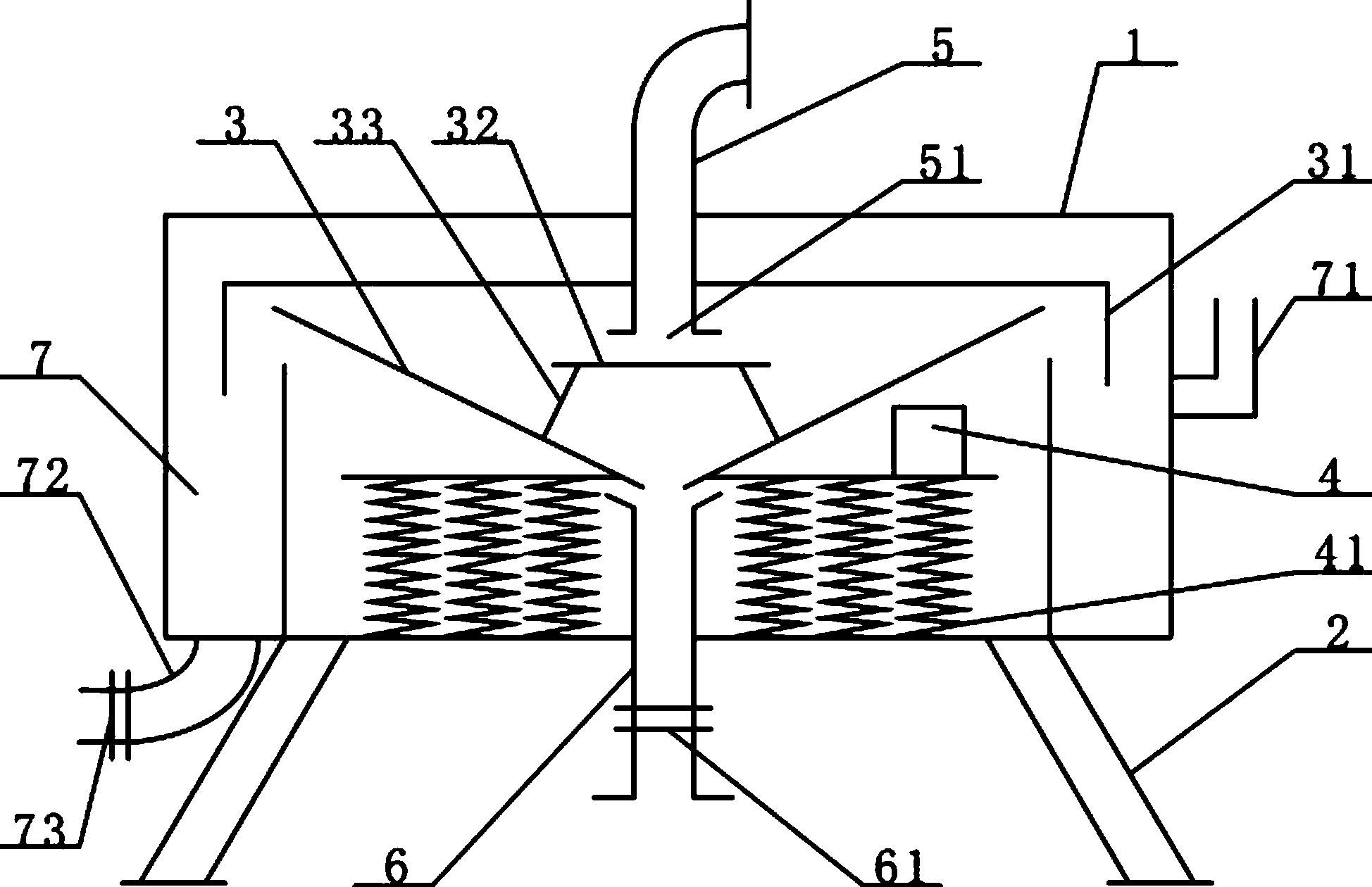

[0021] like figure 1 , a high-efficiency tailings metal enrichment machine, including a casing 1, a frame 2, a hopper 3, a vibrator 4 and an annular waste sand tank 7, the casing 1 is cylindrical, and the top center of the casing 1 is provided with an ore inlet pipe 5. The ore discharge pipe 6 is set at the bottom of the casing 1, and an annular waste sand tank 7 is arranged inside the casing 1 along the wall of the casing 1, and the annular waste sand tank 7 is provided with a water adding pipe 71 and a sand discharge pipe 72;

[0022] The upper part of the distribution hopper 3 is provided with a bucket cover 31, and there is a gap between the bucket cover 31 and the distribution hopper 3. The aforementioned ore feeding pipe 5 passes through the casing 1 and the bucket cover 31 and communicates with the distribution hopper 3. Inside the distribution hopper 3 A mine-blocking plate 32 opposite to the mouth of the ore feeding pipe 5 is set, and the bottom of the mine-blocking p...

Embodiment 2

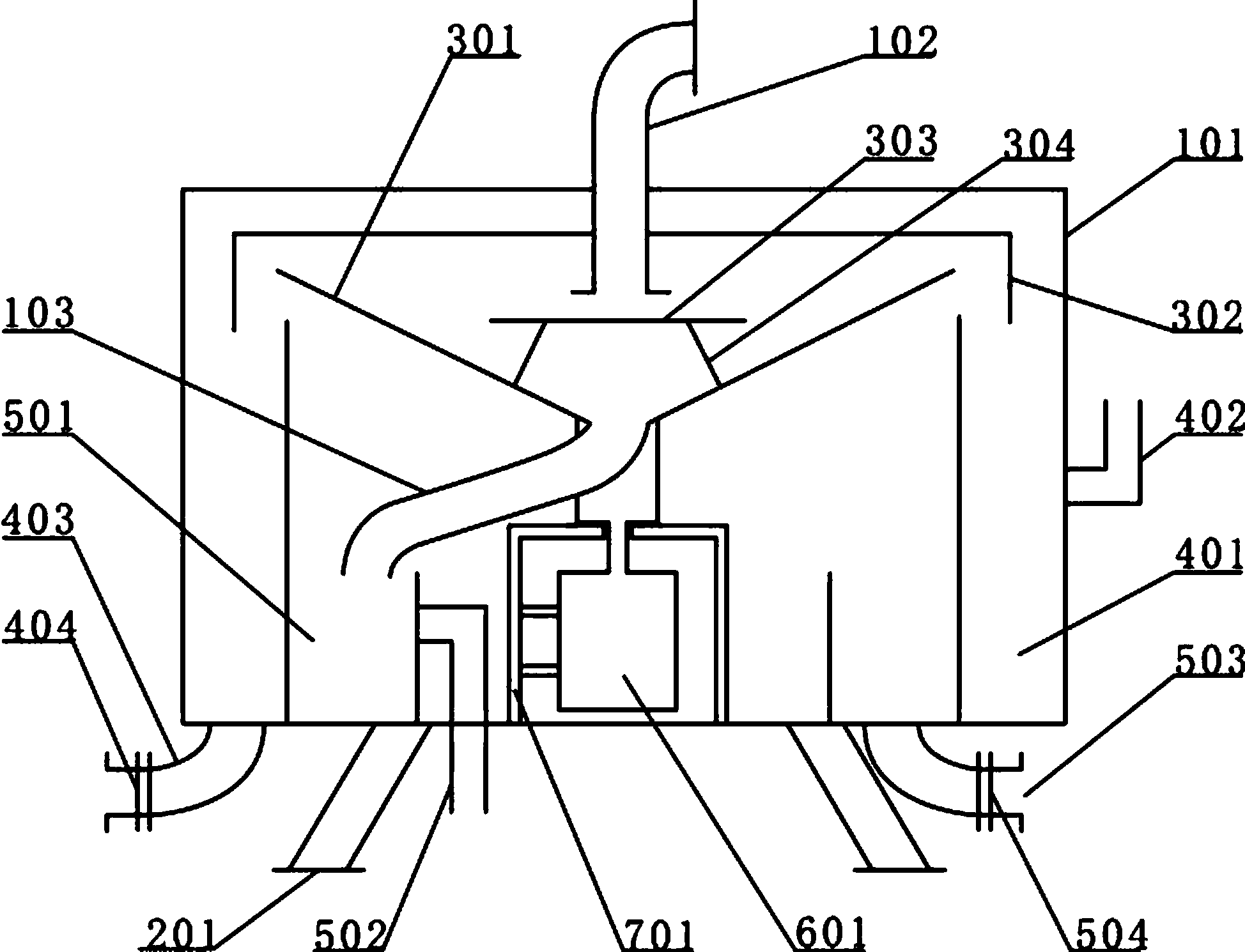

[0026] like figure 2 ,, high-efficiency tailings metal enrichment machine, including a casing 101, a frame 201, a hopper 301, a motor 601, an annular waste sand tank 401 and a concentrate tank 501, the casing 101 is cylindrical, and the top of the casing 101 An ore inlet pipe 102 is arranged in the center, an ore outlet pipe 503 is arranged at the bottom of the casing 101, an annular waste sand tank 401 is arranged inside the casing 101 along the wall of the casing 101, and the annular waste sand tank 401 is provided with a water adding pipe 402 and a sand discharge pipe 403;

[0027] The upper part of the sub-hopper 301 is provided with a bucket cover 302, and there is a gap between the bucket cover 302 and the sub-hopper 301. The aforementioned ore feeding pipe 102 passes through the casing 101 and the bucket cover 302 and communicates with the sub-hopper 301. Inside the sub-hopper 301 A mineral blocking plate 303 opposite to the mouth of the ore feeding pipe 102 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com