Dual-lifting-mechanism universal milling machine

A lifting mechanism and milling head technology, used in milling machines, milling machine equipment, metal processing equipment, etc., can solve the problems of limited processing range and capacity, limited maximum working height of the worktable, etc., to improve the working range and improve flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

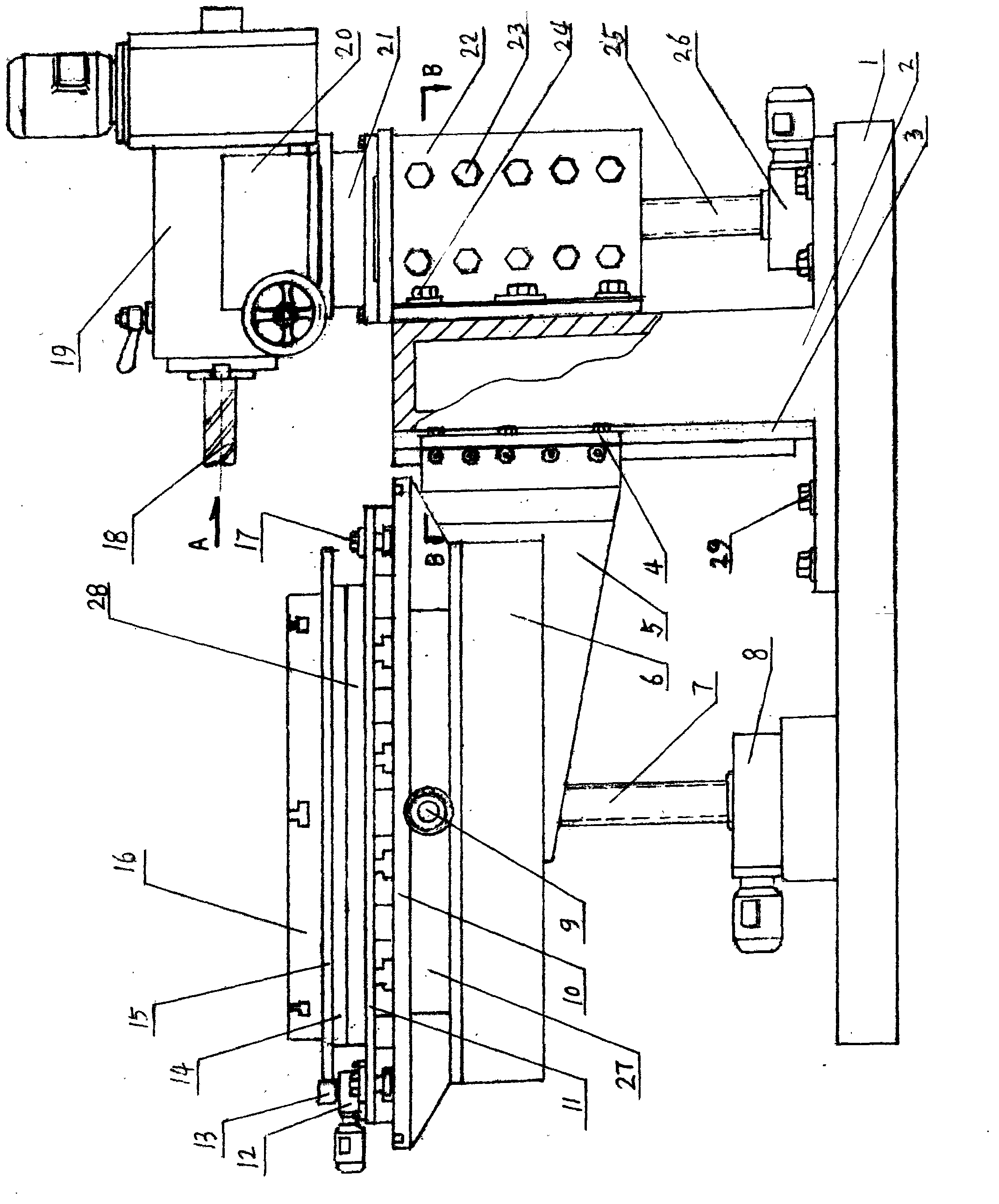

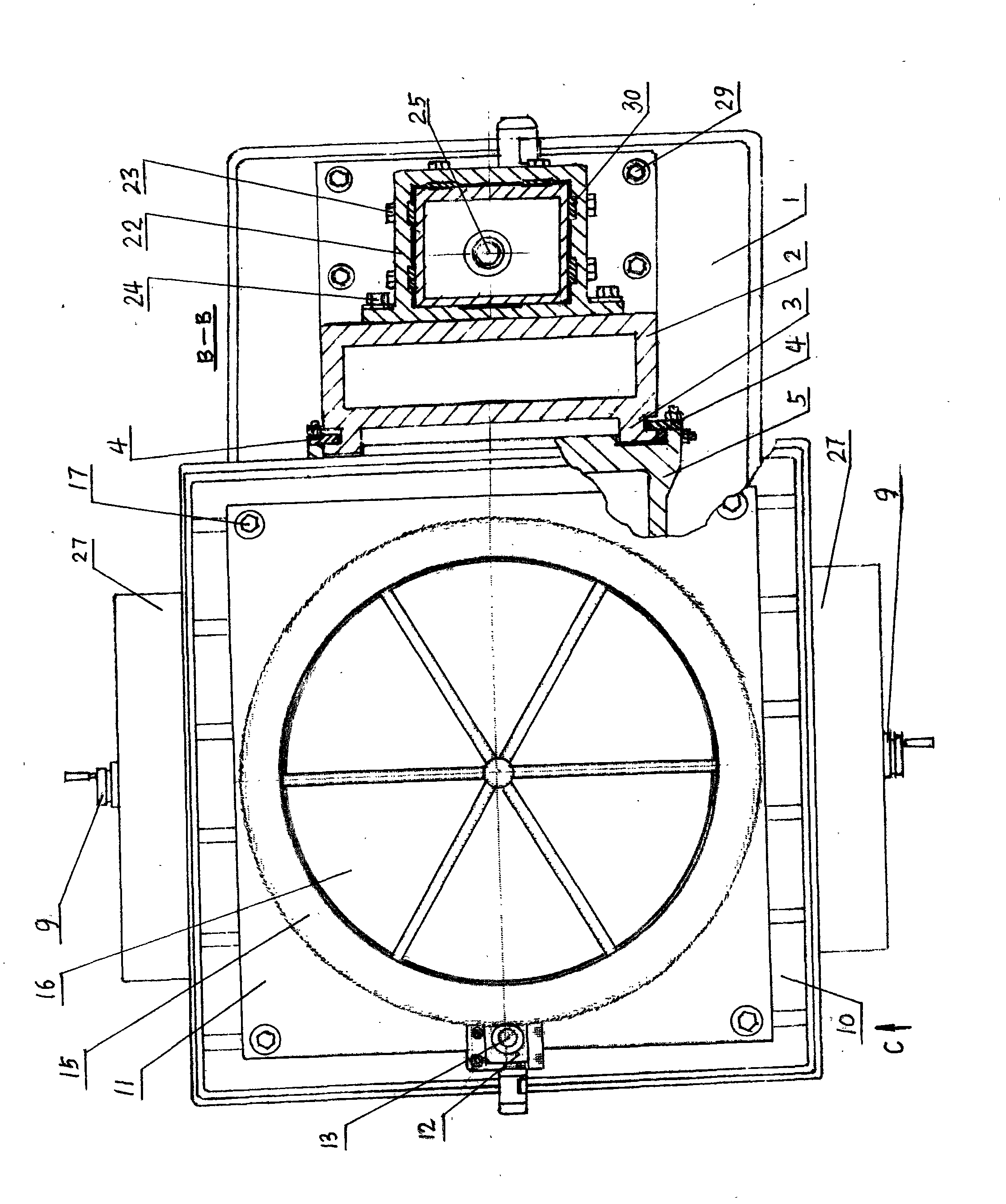

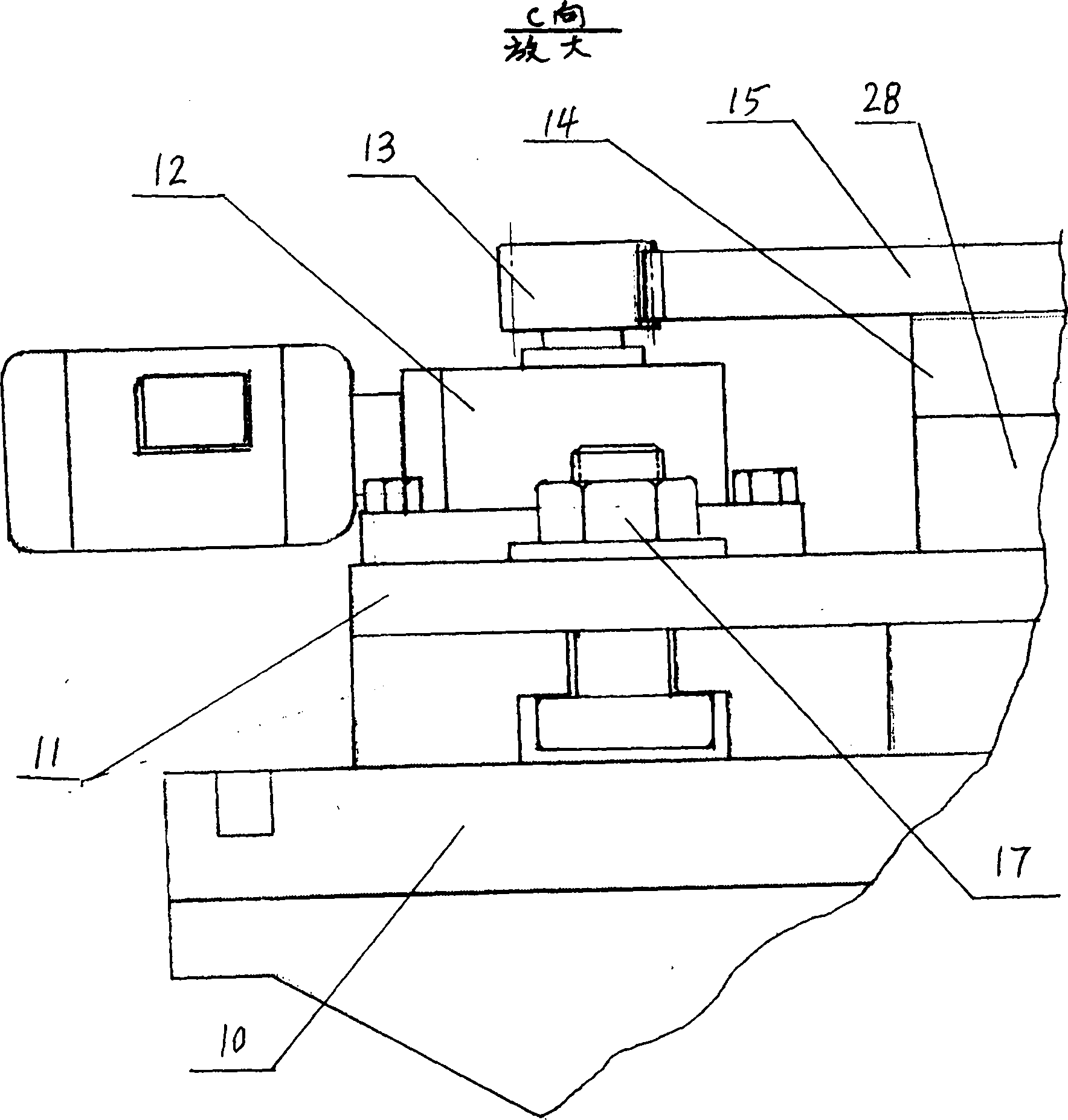

[0012] exist figure 1 Among them, the upper end of the lifting screw [I] (7) is fixed on the bottom surface of the box frame (6) and does not rotate, and the lifting screw [I] (7) is connected to the axis of the bottom worm gear set [I] (8). When the bottom worm gear set [I] (8) rotates positively and negatively, the nut synchronously rotates to make the lifting screw [I] (7) rise or fall, because the guide rail box (5) under the workbench The vertical chute is slidingly matched with the vertical guide rail (3) by the pressing plate (4) and then rises or falls, and the box-type frame (6), support box (27), workbench ( 10) and the rotating mechanism above the workbench (10) also rises or falls simultaneously thereupon. The rotating mechanism drives the pinion (13) to rotate synchronously through the positive and negative rotation of the worm gear set [III] (12), and the pinion (13) meshes with the ring gear (15) to make the ring gear (15) rotate in the forward and reverse dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com