Ejection header for hobbing die

A hobbing die and insert technology, which is applied in the field of hobbing dies, can solve problems such as the inability of the hobbing die to completely lock the workpiece, affect product quality, and wear and tear on the cone surface. The effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

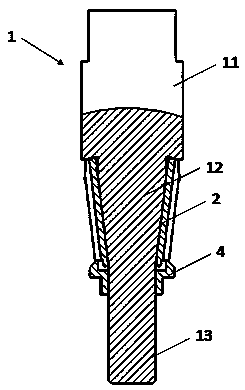

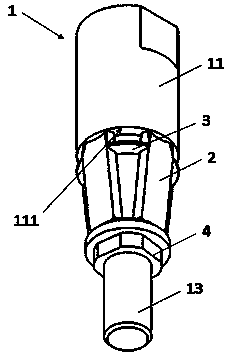

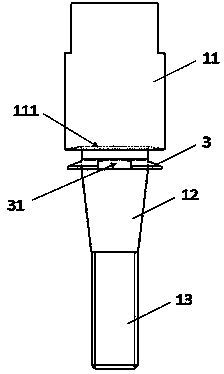

[0021] Such as figure 1 , figure 2 , Figure 8 The shown a plug for gear hobbing die includes a plug body 1, the plug body 1 is composed of a cylindrical section 11 matched with the mold body 5, a conical section 12 matched with the steel ball 6 on the mold body, and a mandrel 7 connected threaded sections 13, the cone section 12 is evenly provided with inserts 2 along its circumference, and the inserts 2 form a line contact with the steel balls on the mold.

[0022] Further, such as Figure 5-7 As shown, the mating surface 21 of the insert 2 and the steel ball 6 is an inwardly concave arc surface, and the arc of the arc coincides with the arc of the steel ball. Setting the insert 2 can not only make the insert 2 form a line contact with the steel ball to disperse the force transmission when the mandrel drives the plug body down, but also can reduce the difficulty of d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com