Spot welding fixture capable of heating by vortex and having storage box

A technology of eddy current heating and storage boxes, which is applied in the direction of manufacturing tools, welding equipment, welding equipment, etc., can solve the problems of nowhere to put personal items of workers, hidden dangers of production safety, inconvenient preheating, etc., and achieve fast heating and easy removal. Use convenience, avoid the effect of waste of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

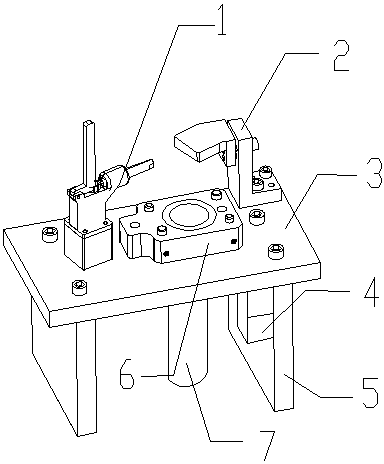

[0021] Such as figure 1 As shown, a spot welding fixture that can be heated by eddy current and has a storage box includes a clamp 1, a positioning device 2, a base 3, a support plate 5 and a positioning table 6, and the clamp 1 is located on the upper surface of the base 3 There are two support plates 5, which are respectively located on both sides of the lower surface of the base 3; the positioning device 2 is located on one side of the upper surface of the base 3; the positioning platform 6 is located on the upper surface of the base 3 central part; also includes a locker 4 and an eddy current heater 7, the upper surface of the locker 4 is fixed on the lower surface of the base 3, the side of the locker 4 and the side of the support plate 5 are fixed ; The eddy current heater 7 is located in the middle of the lower surface of the base 3 . Locker 4 is a cuboid, divided into upper and lower two-layer structure, and locker 4 has 1. The power of the eddy current heater 7 is ...

Embodiment 2

[0023] With embodiment 1, difference is that locker 4 has 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com