High-performance current transformer intelligent analyzer

A current transformer, intelligent analysis technology, applied in the direction of instruments, measuring electrical variables, measuring devices, etc., can solve the problems of cumbersome test equipment, inability to output, and low work efficiency, so as to reduce the weight of test equipment, reduce power outages, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

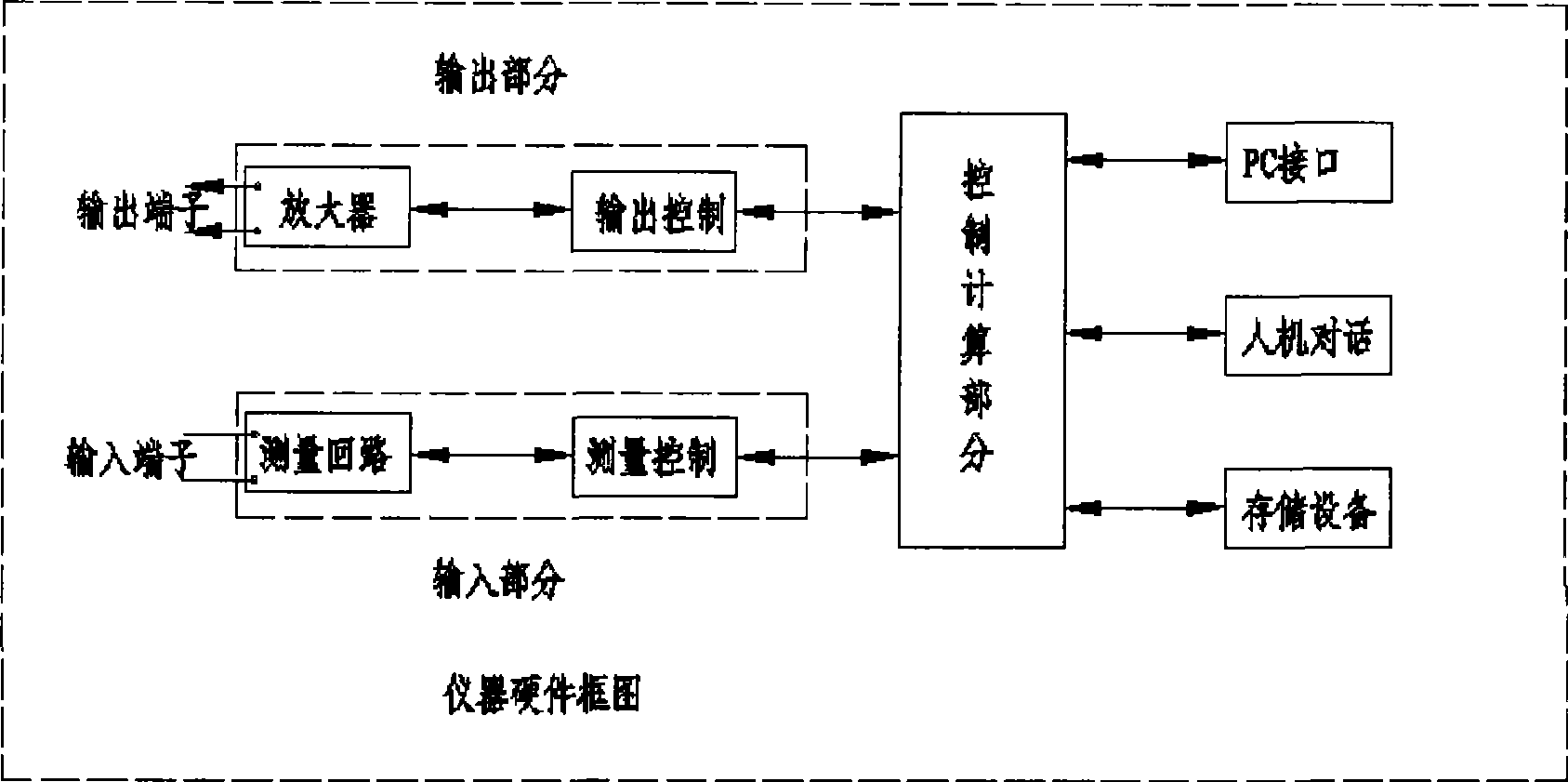

[0024] The present invention is further described in conjunction with the accompanying drawings and embodiments. The present invention is composed of a control calculation part, an output part connected with the control calculation part, an input part, a PC interface, a man-machine dialogue part and a storage device.

[0025] 1. The volt-ampere characteristic test of the transient current transformer and the conventional high saturation characteristic transformer, according to the formula Es=(N 2 ×2πfBAc) / , Ac and N2 remain unchanged, assuming that the magnetic flux does not change when B is saturated, then changing the size of f, Es will also change linearly. Then f becomes smaller, and the voltage input by the tester will also become smaller. After the test, through the inverse relationship between the electromotive force and the magnetic flux, the electromotive force required to achieve saturation can be calculated when f = 50Hz (that is, the power frequency voltage).

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com