Temperature rise test loop of low-voltage complete switch equipment and test method thereof

A switchgear, low-voltage complete set of technology, applied in the field of low-voltage electrical equipment inspection and testing, can solve the problems of power pollution, large volume, huge workload, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

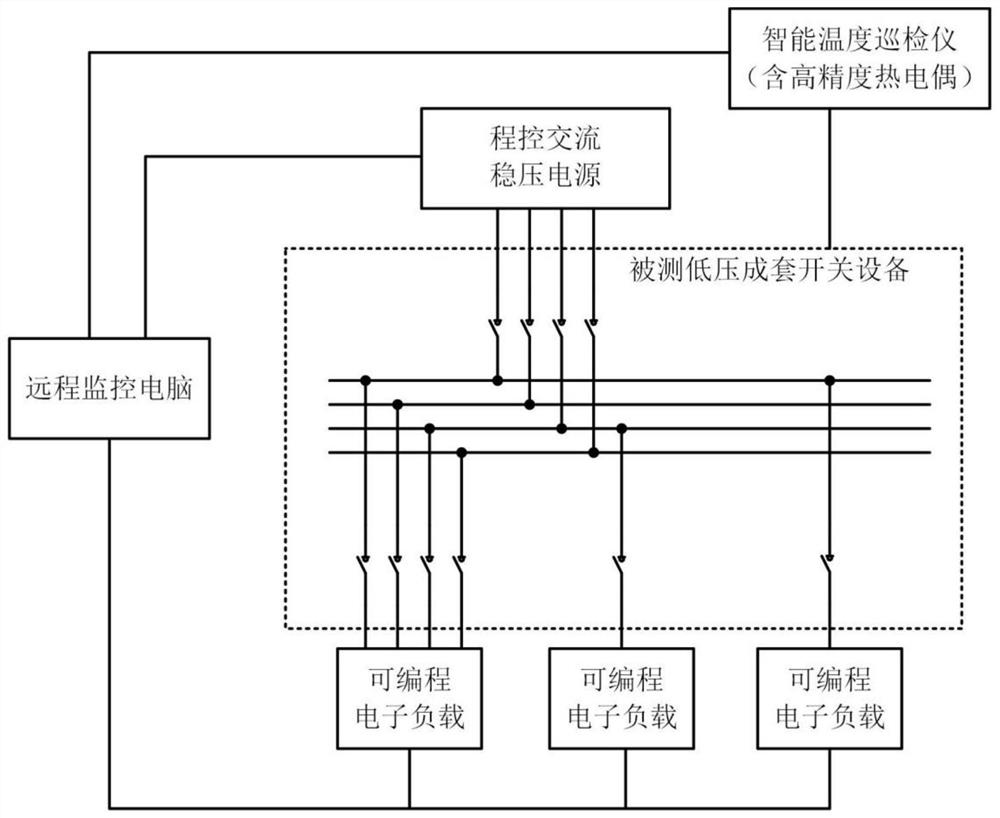

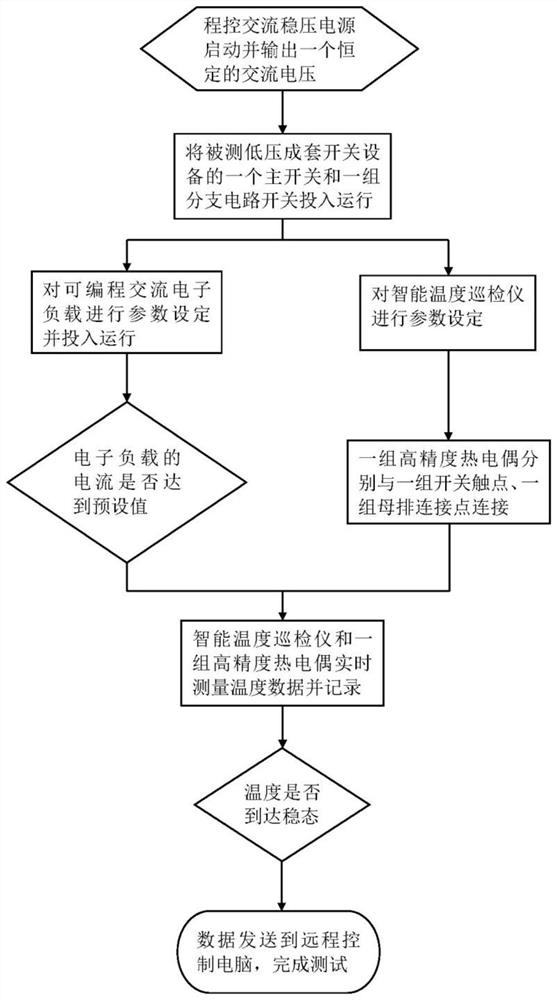

[0027] Such as figure 1 As shown, a low-voltage complete set of switchgear temperature rise test circuit, including a program-controlled AC power supply, intelligent temperature inspection instrument, a set of high-precision thermocouples, a set of programmable AC electronic loads, remote control computer, the measured low-voltage Complete set of switchgear, the output terminal of the program-controlled AC regulated power supply is connected to the main switch of the tested low-voltage complete set of switchgear, and each branch circuit of the tested low-voltage complete set of switchgear is connected to a programmable AC electronic load. The precision thermocouple is connected to the low-vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com