A flexible pH sensor based on nano-gap electrodes and its manufacturing method

A nano-gap electrode and manufacturing method technology, applied in the direction of nanotechnology, material resistance, etc., can solve the problems of sensor sensitivity and response time that cannot meet the requirements of high-precision sensors, sensors that cannot conform to the shape, and that cannot meet the requirements of sensors, etc., to achieve low test voltage , simple structure, broad development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

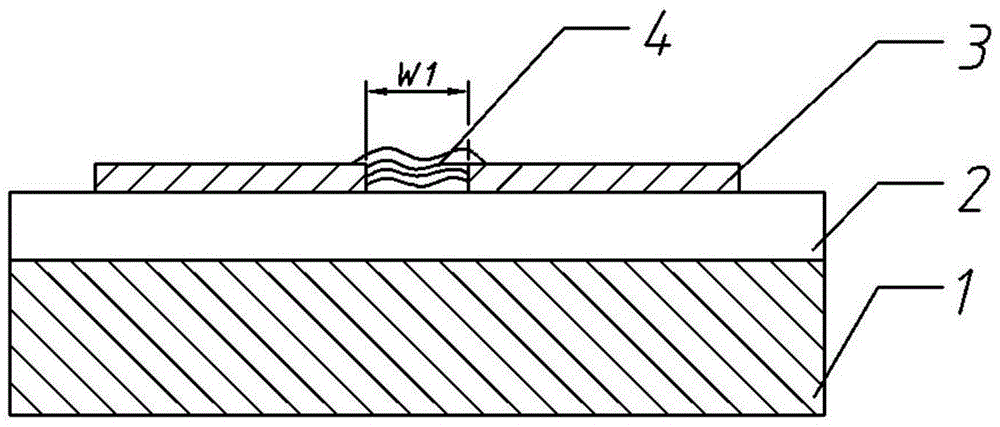

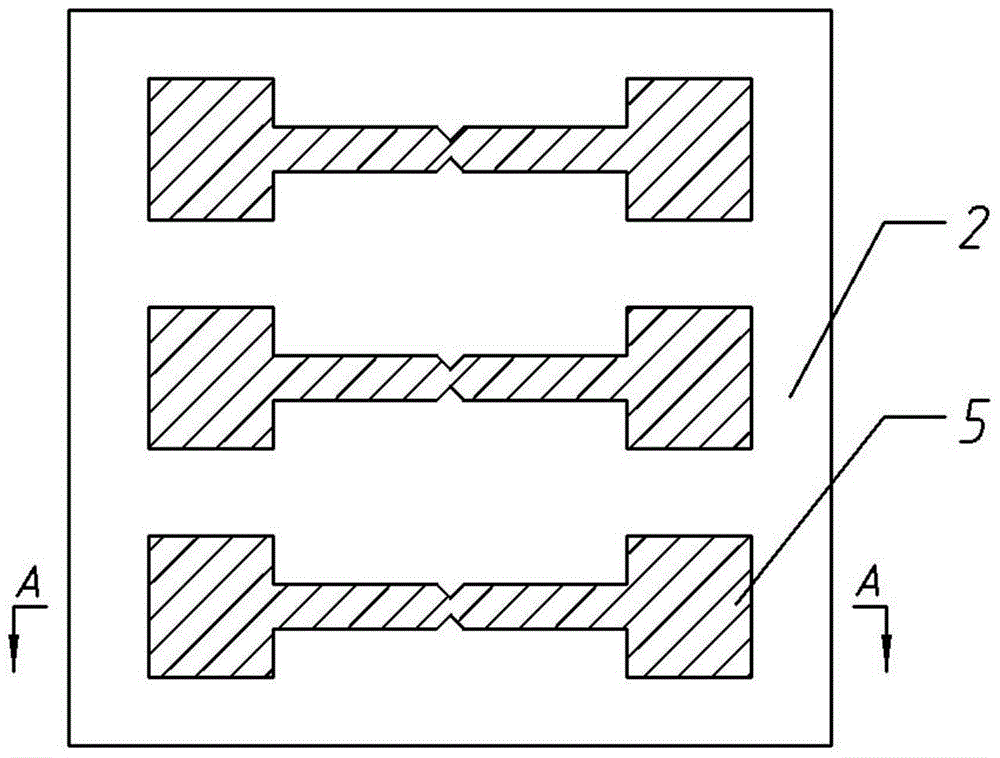

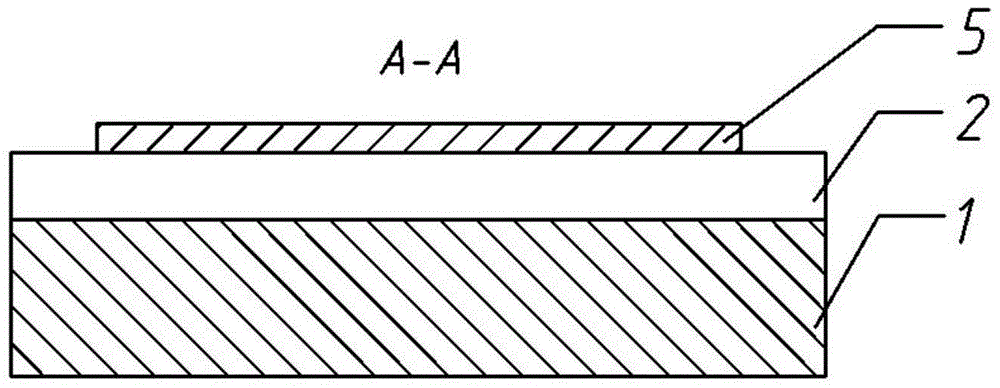

[0019] refer to figure 1 , a flexible pH sensor based on nano-gap electrodes, including a flexible substrate 1, an epoxy resin layer 2 is spin-coated on the flexible substrate 1, and more than one pair of nanometer electrodes of 50 to 500 nanometers are prepared on the epoxy resin layer 2. The gap electrodes 3 are assembled between each pair of nano-gap electrodes 3 with carboxyl-functionalized single-walled carbon nanotubes 4 , and the pH value of the solution is detected through the change of the resistance of the carboxyl-functionalized single-walled carbon nanotubes 4 .

[0020] Described a kind of manufacturing method of the flexible pH sensor based on nano-gap electrode, comprises the steps:

[0021] The first step, surface modification of SWNTs: first weigh 5mg SWNTs and 100ml 67% HNO 3 Ultrasonic treatment in a beaker at 100W for 30min to fully mix the two;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com