Patents

Literature

44results about How to "Solve the impossible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

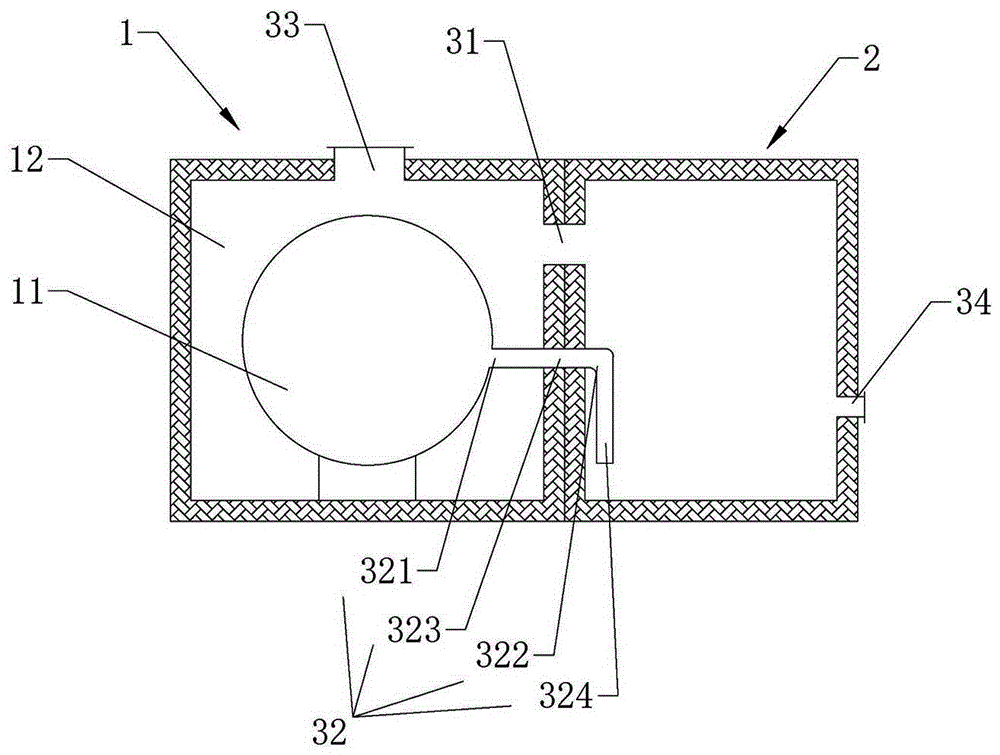

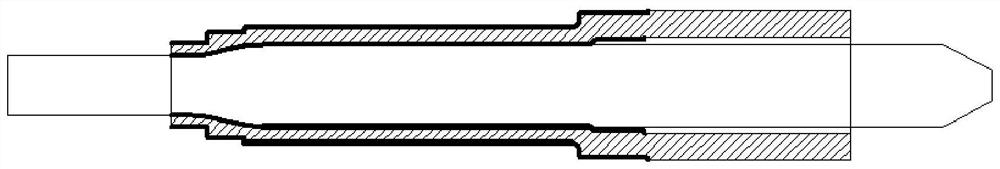

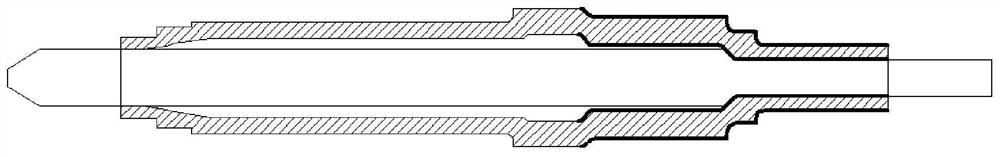

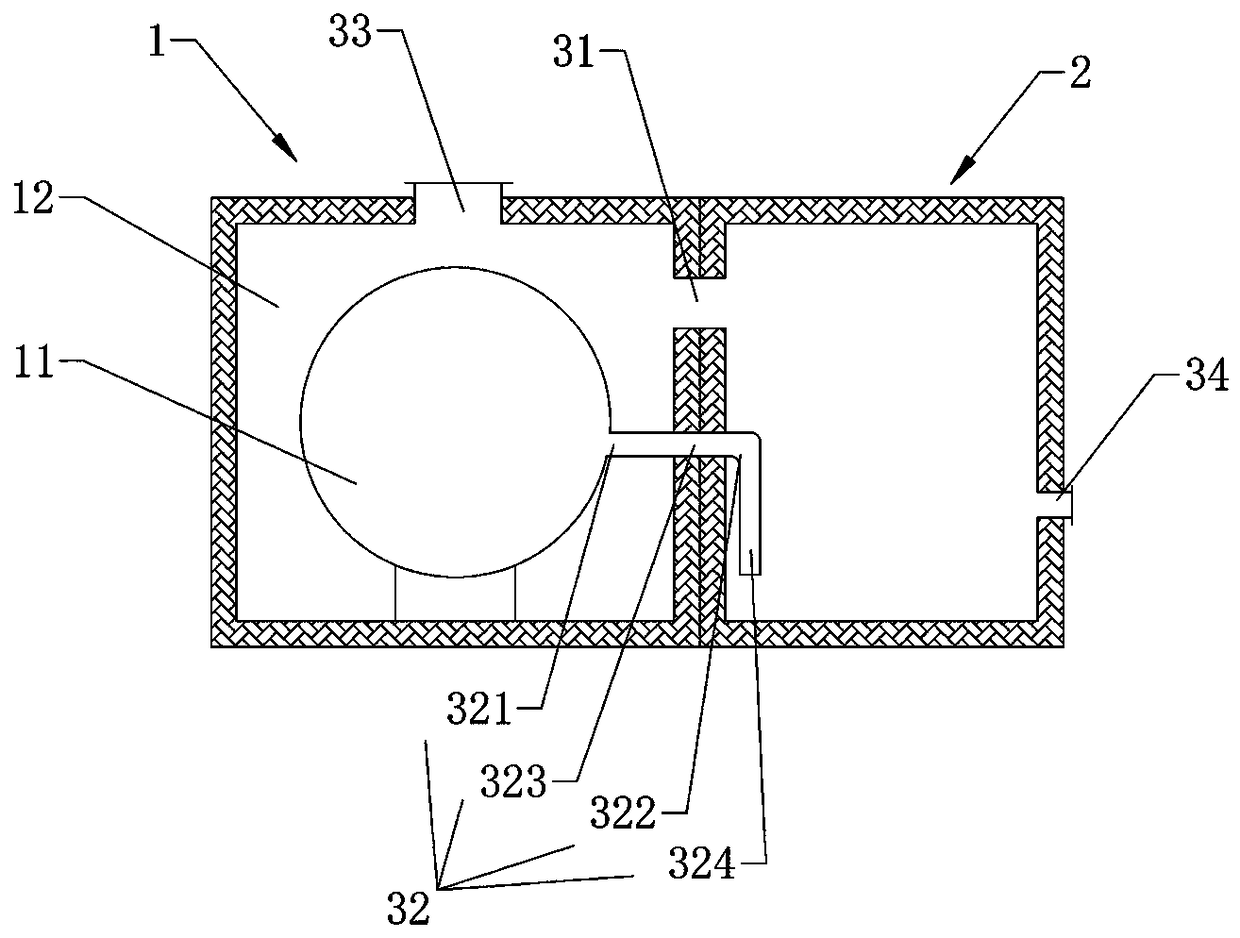

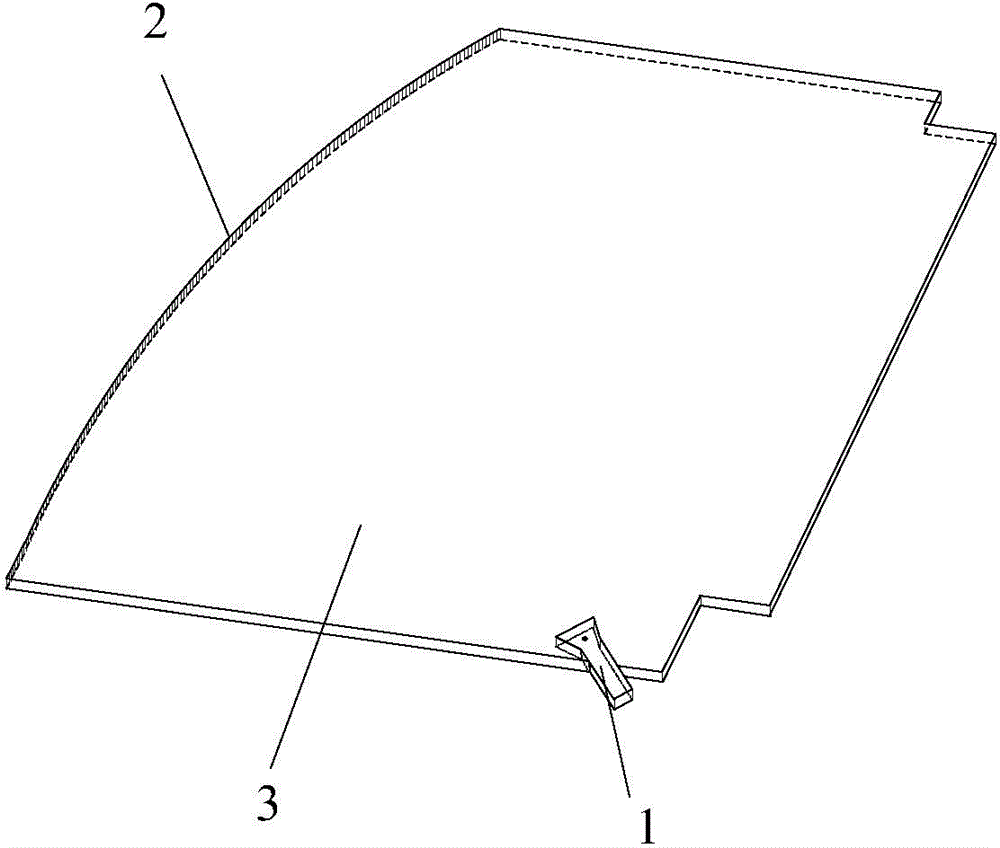

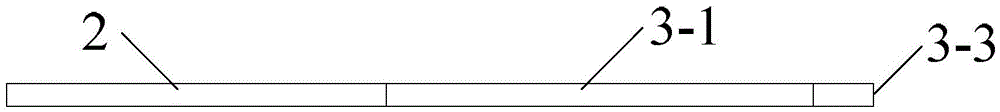

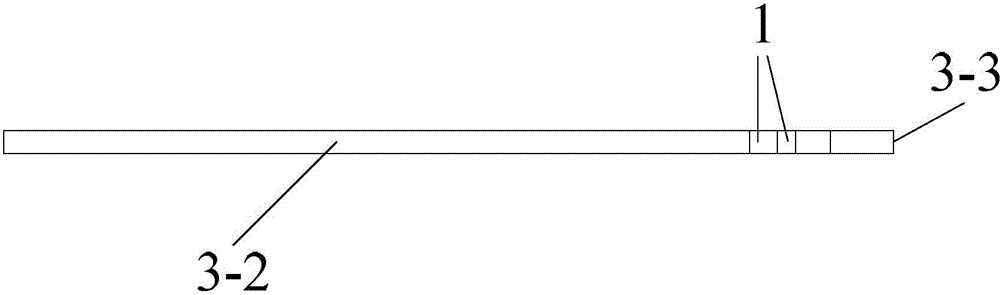

Broadband wire source for planar waveguide CTS antenna feed device

The invention discloses a broadband wire source for a planar waveguide CTS antenna feed device. The broadband wire source comprises an H-plane sectorial horn antenna, a bias parabolic reflection plane and a flat waveguide. The H-plane sectorial horn antenna and the bias parabolic reflection plane are arranged inside the flat waveguide, and the phase center of the H-plane sectorial horn antenna is arranged at the focus of the bias parabolic reflection plane. According to the invention, cylindrical waves are converted into plane waves, the plane waves are generated by using a reflector antenna principle, and the horn antenna is arranged at the focus of a paraboloid reflector so that a horn antenna radiation field passes through the reflector and generates the plane wave with equal amplitude and the same phase at the caliber surface of the reflector. The working frequency band is wide; the feed source shielding is eliminated and the caliber efficiency is enhanced through a bias; the structure is enclosed so that the edge diffraction effects of a conventional bias paraboloid are removed; and the structure is simple so that adjusting and assembling are easy, late use and maintenance are convenient, and the problem can be solved that the ideal wire source with equal amplitude and the same phase, generated by a conventional waveguide CTS antenna, cannot be realized in an actual project.

Owner:XIDIAN UNIV

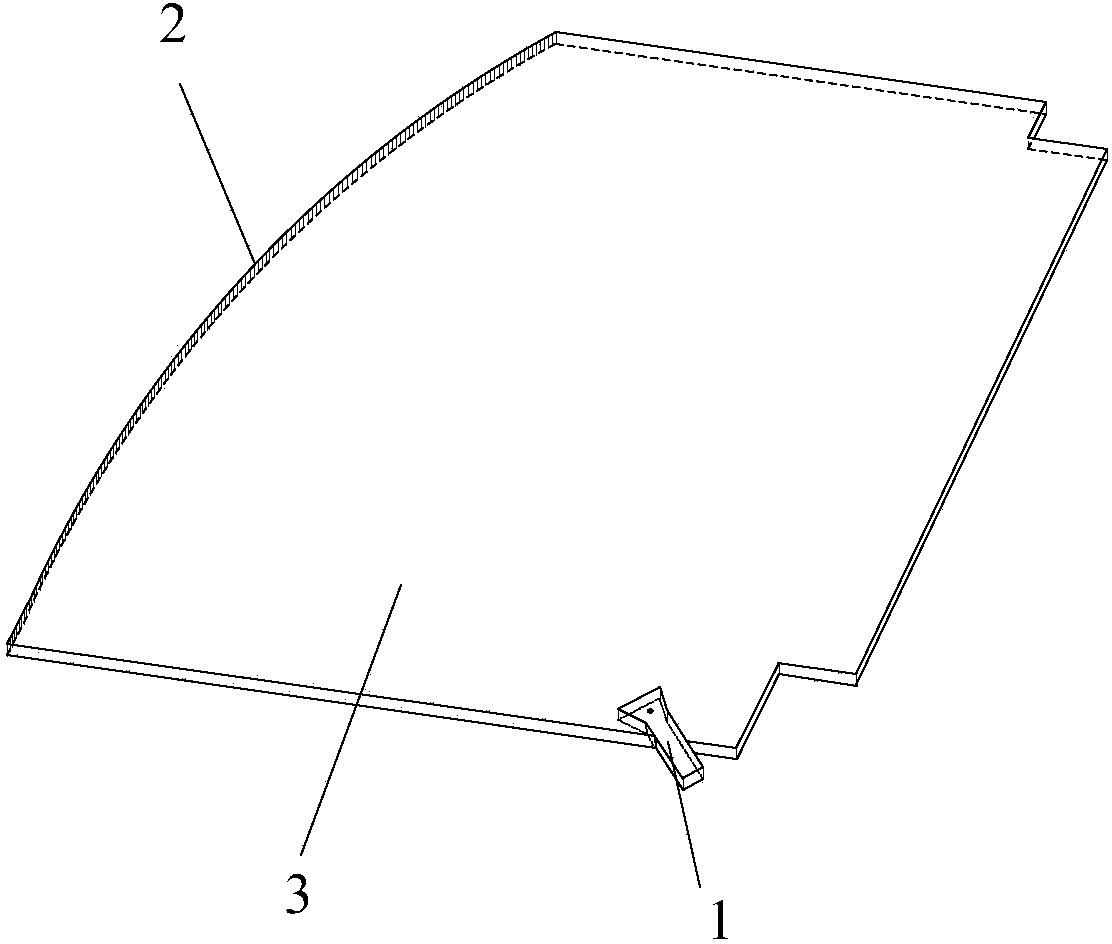

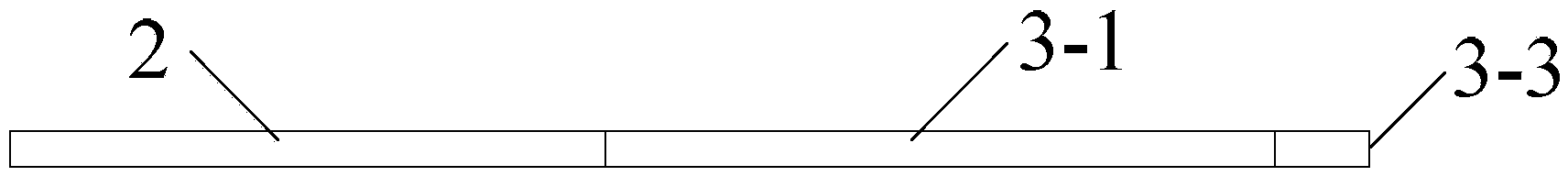

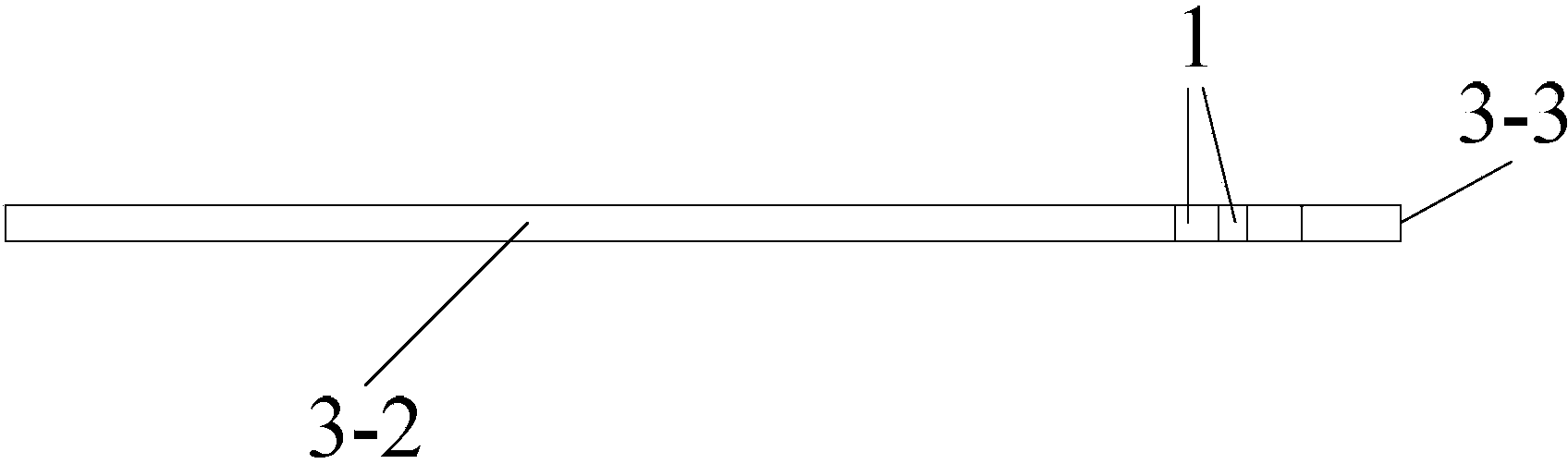

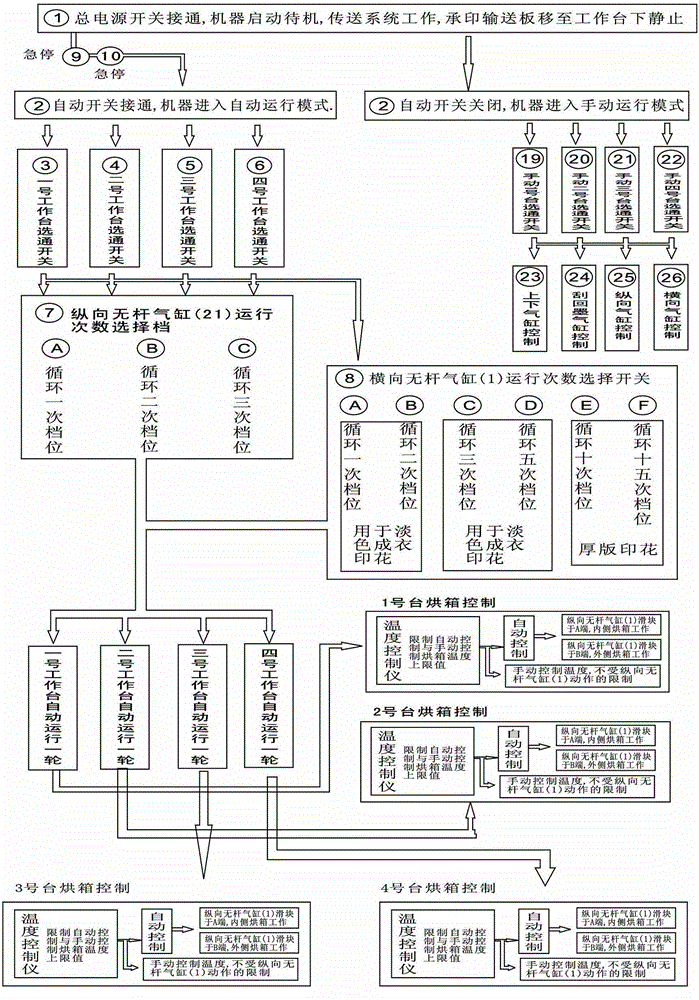

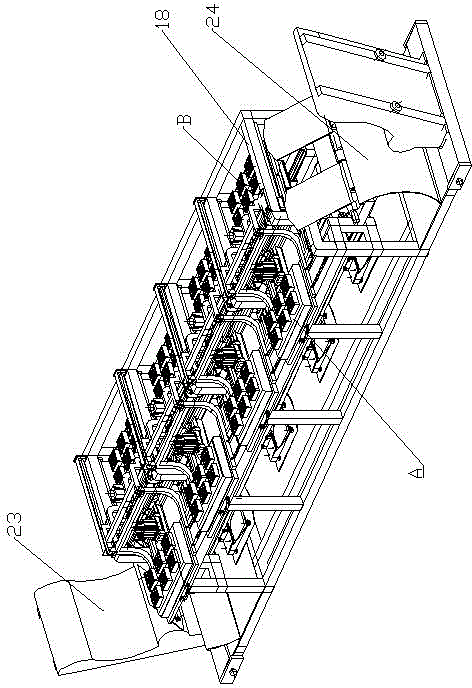

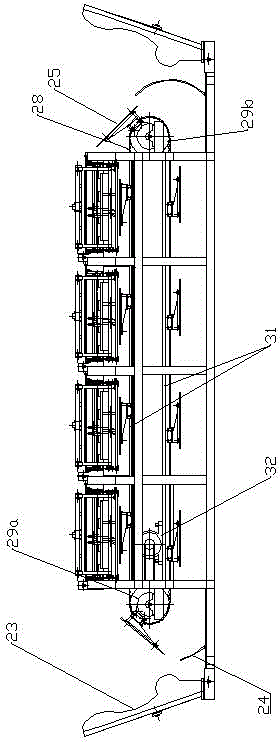

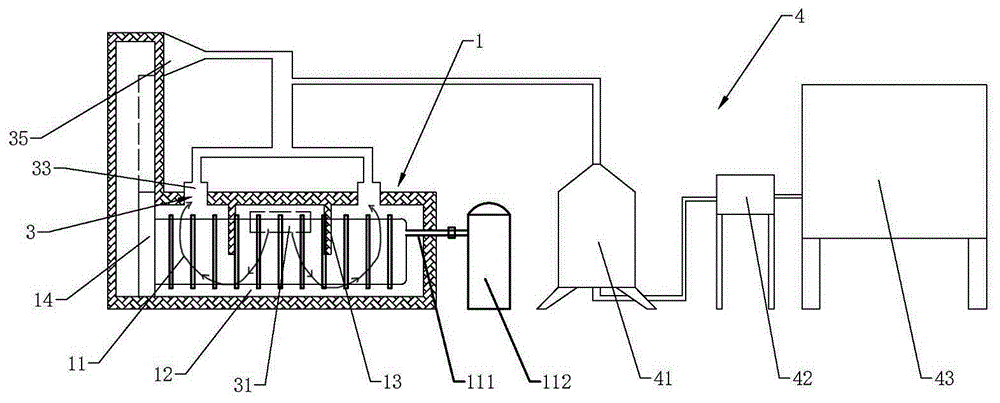

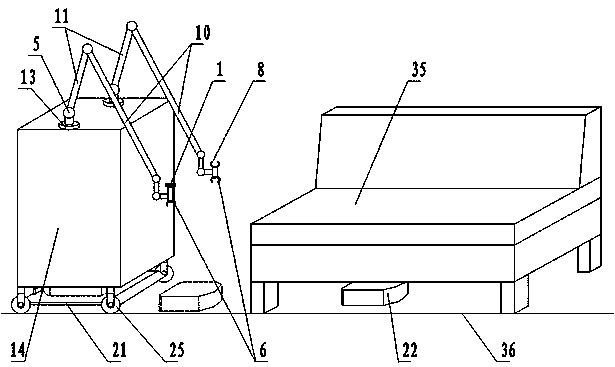

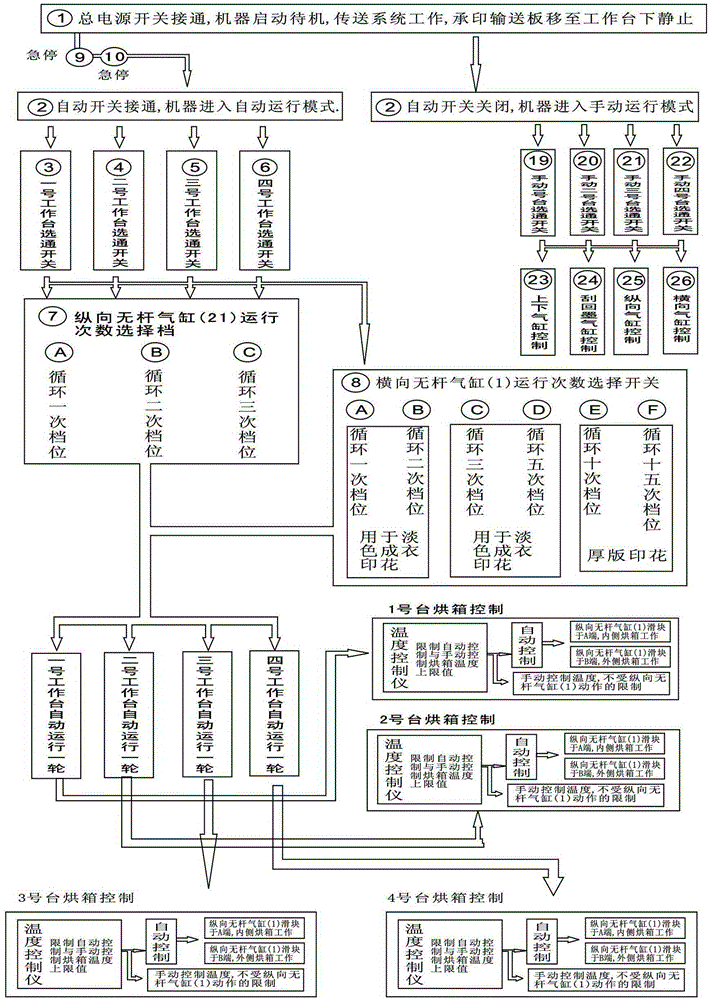

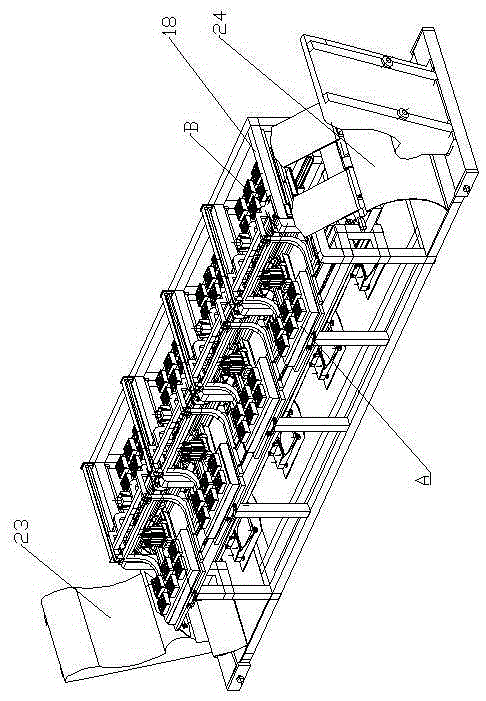

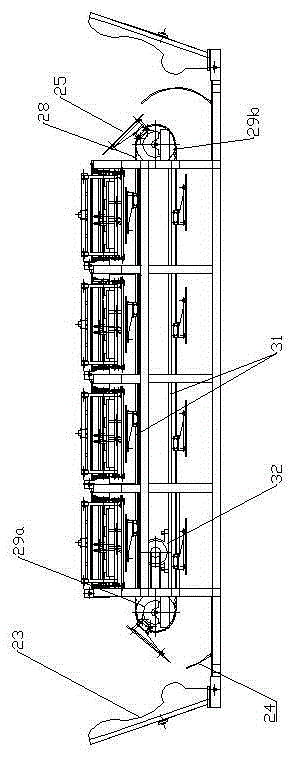

Composite-type linear full-automatic embossing machine

The invention provides a composite type linear full-automatic embossing machine. The composite-type linear full-automatic embossing machine is characterized by comprising an embossing system, a drying system, an upper clothing material taking auxiliary system and a ready-made clothing conveying system, wherein the ready-made clothing conveying system comprises two parallel linear guide rails which are arranged on a rack; an annular conveying belt is arranged between the guide rails, supported and unfolded by a driving synchronization wheel and a driven synchronization wheel which are respectively mounted at two ends of the rack; the driving synchronization wheel is connected with a motor by virtue of a transmission belt; a plurality of double-row embossing and conveying platens are uniformly arranged on the transmission belt; each double rows of embossing and conveying platens are taken as one group of embossing and conveying platens; two embossing and conveying table plates in each group are connected with each other by virtue of a connection bracket so as to form a whole body fixed at an equal interval; linear guide rail sliding blocks are respectively mounted under the two embossing and conveying platens in each group, so that each group of embossing and conveying platens stably and accurately run on the two parallel linear guide rails under the drive of the conveying belt.

Owner:李登峰

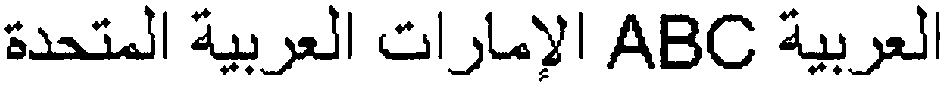

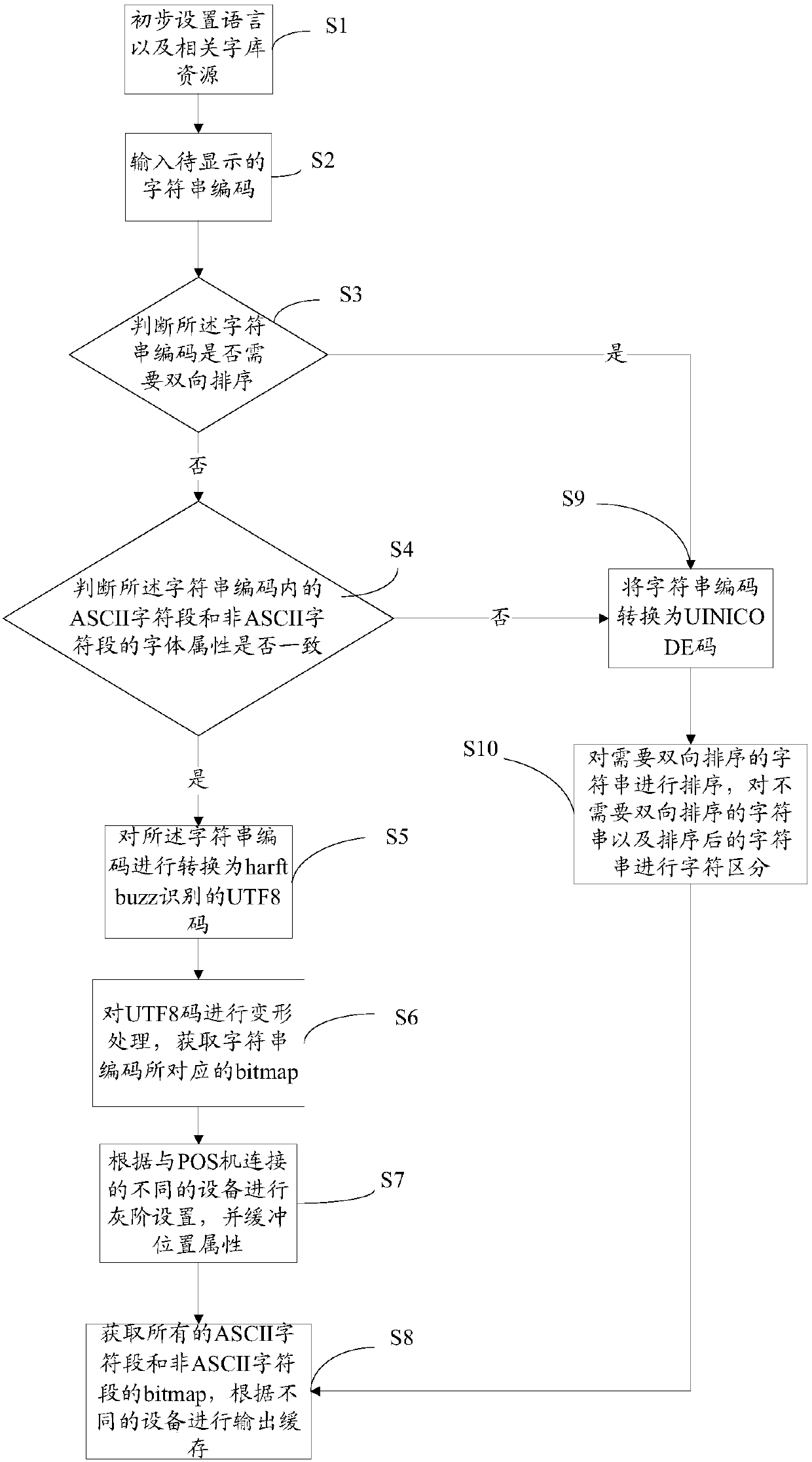

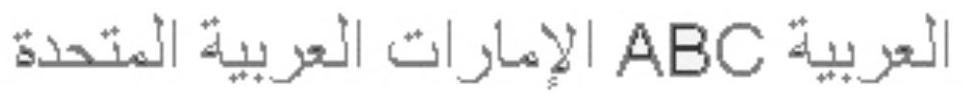

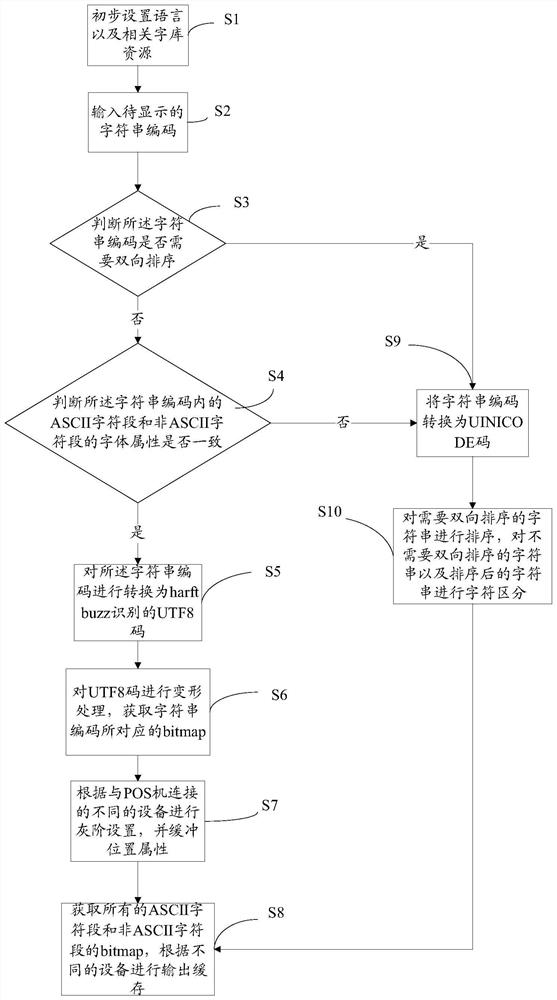

Multi-language achieving method and system of POS machine

ActiveCN107562480ARealize the unachievable problemAvoid restrictionsCash registersSpecific program execution arrangementsProgramming languageDot matrix

The invention relates to a multi-language achieving method and system of a POS machine. The method comprises the steps that languages and related word stock resources are preliminarily set; characterstring codes are input; whether bidirectional sorting is needed or not is judged; if not, whether the font properties of ASCII character fields and non-ASCII character fields are consistent or not isjudged; if yes, conversion and deformation processing is conducted on the character string codes to obtain bitmap of the character string codes; gray scale setting is performed according to differentdevices; the bitmap of both the ASCII character fields and non-ASCII character fields is obtained, and output caching is performed according to the different devices; if not, the character string codes are converted into UINICODE codes; character strings needing bidirectional sorting are sorted, and character distinguishing is conducted on character strings which do not need bidirectional sortingand the sorted character strings. The problem is solved that Arabic, Khmer and other complex languages and a language dot matrix word stock cannot be achieved, and the method supports multiple languages.

Owner:SHENZHEN XINGUODU PAYMENT TECH CO LTD

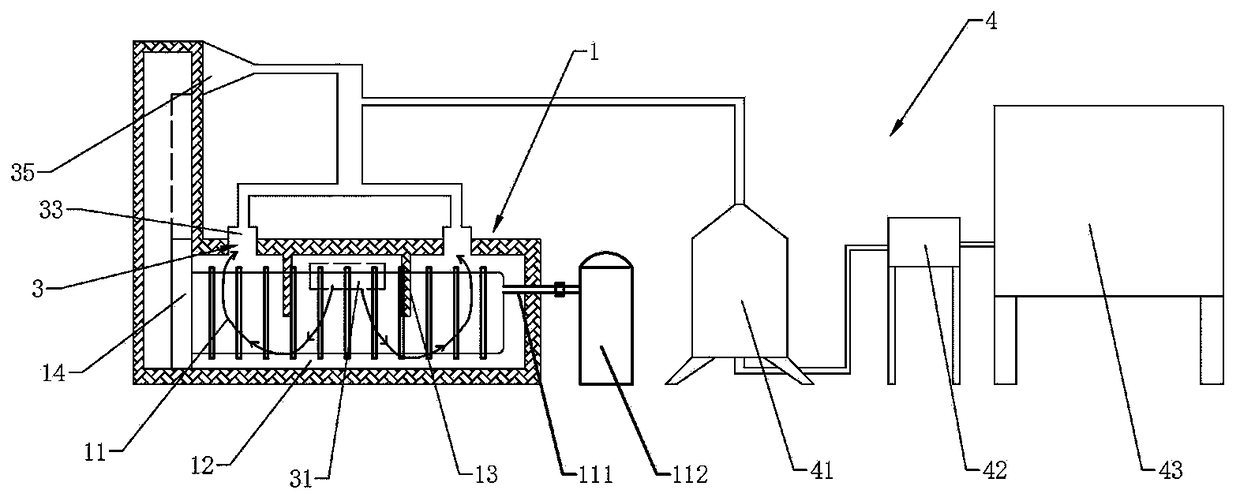

Discharging method for high-temperature carbonized material

ActiveCN105861000APrevent spontaneous combustionSolve the impossibleCombustible gas coke oven heatingSpecial form destructive distillationTemperature controlFlue gas

The invention relates to an animal carbonization treatment method, and in particular, relates to a discharging method for a high-temperature carbonized material. The method includes the following steps: gas replacement: after a carbonization process is finished, immediately introducing non-flammable inert gas into a carbonization tank, and adopting the non-flammable inert gas to replace flammable pyrolysis gas in the carbonization tank; and temperature control and furnace opening: after the temperature in the carbonization furnace is dropped to 500 DEG C or less, opening the carbonization furnace, and making the high-temperature carbonized material in the carbonization tank discharged. The method can avoid low production efficiency caused by a lot of time requiring to be used in a cooling stage and energy loss generated during furnace body cooling, effectively solves the generation of dangerous problems of burning, exploding sounding and the like when a carbonization furnace door is opened at high temperature, successfully implements discharging of the carbonized material in a high temperature state, and solves the problems impossible to be achieved in industry; and at the same time, with combination of flue gas purification treatment, up-to-standard discharging of dioxin in tail gas is achieved.

Owner:ZHEJIANG WUNENG ENVIRONMENTAL TECH DEV

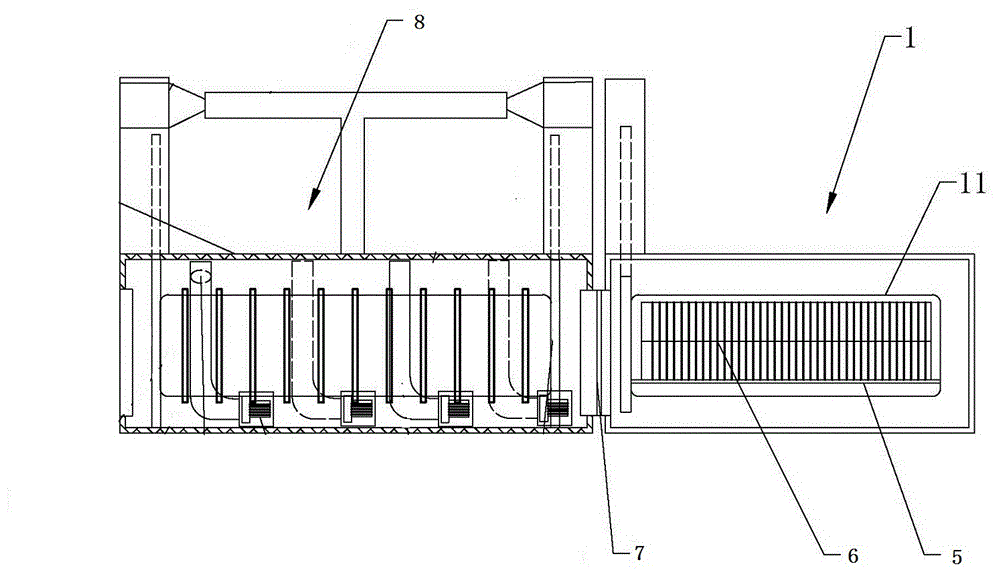

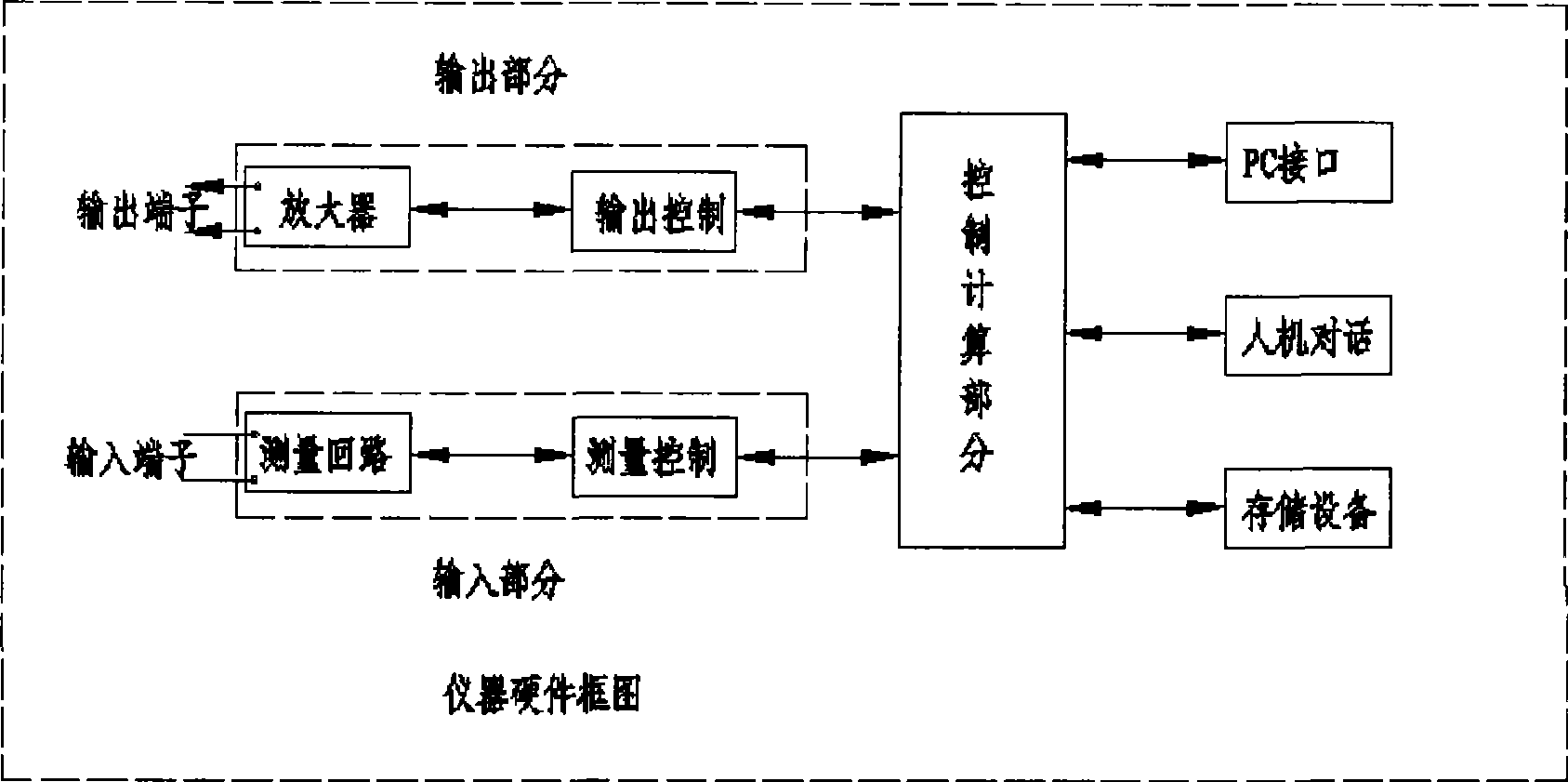

High-performance current transformer intelligent analyzer

InactiveCN101545963ALow test voltageCause safety hazardElectrical measurementsTransient stateDirect test

The invention relates to a high-performance current transformer intelligent analyzer, which is applied to a saturation characteristic test for a transient state current transformer, direct tests for a sleeve current transformer and a current transformer in GIS and all parameter tests for all conventional transformers, and belongs to the technical field of current transformer test instruments. During voltage current characteristic tests for the transient state current transformer and a conventional high saturation characteristic transformer, because only the output frequency needs to be changed during the tests, the intelligent analyzer can perform the test on the transient state current transformer of which the saturation voltage is 15,000 kilovolts when the maximum amplitude value is 120 volts, and change the blank that at present no domestic equipment performs test on a transient sate winding; besides, the instrument output test voltage is low, which cannot cause potential safety hazards to the equipment and the personal safety; and because a booster transformer (generally, the weight of a transformer is tens of kilograms) for boosting is not needed, the weight of equipment to be tested is greatly reduced.

Owner:扬州博达电气设备有限公司

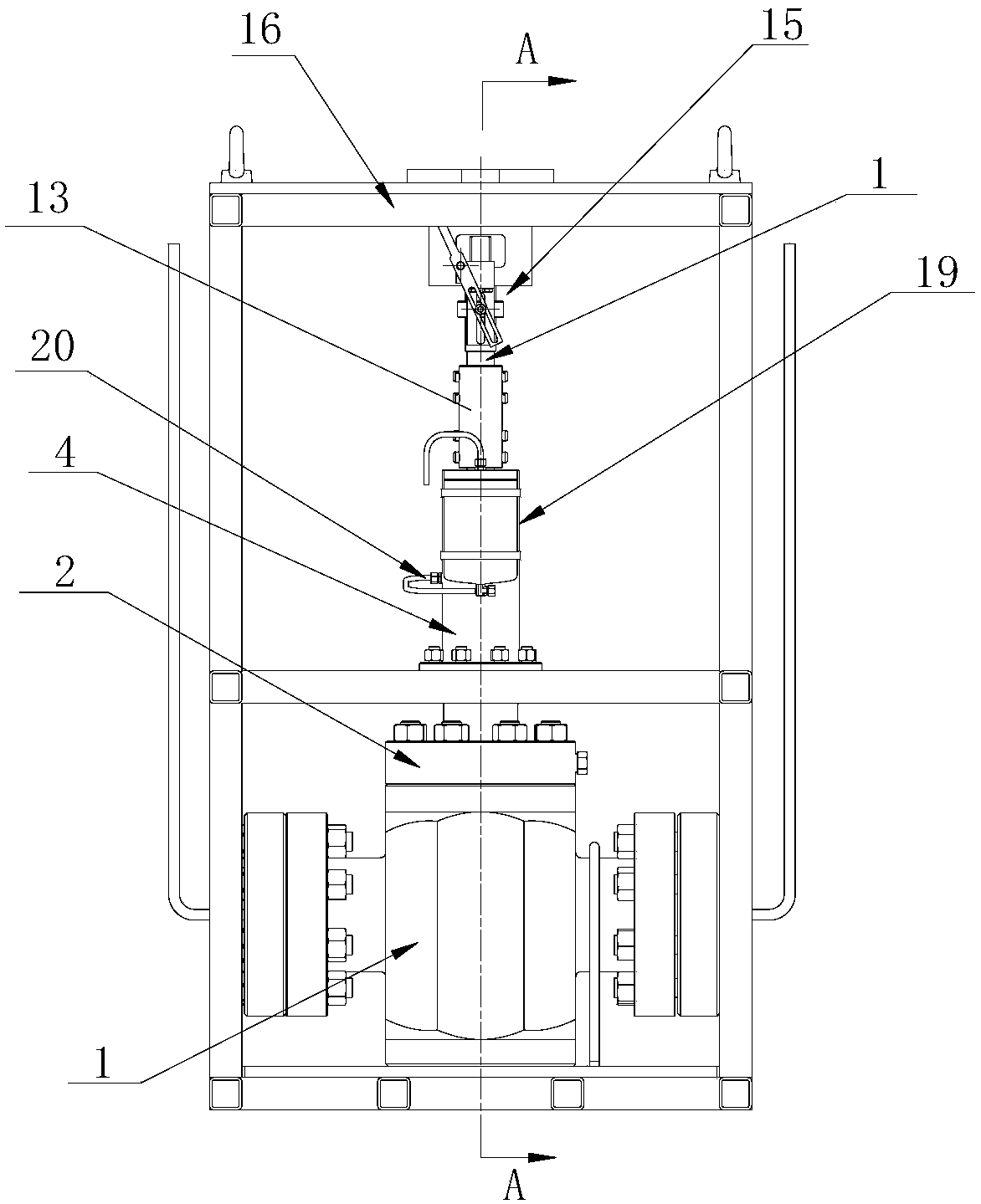

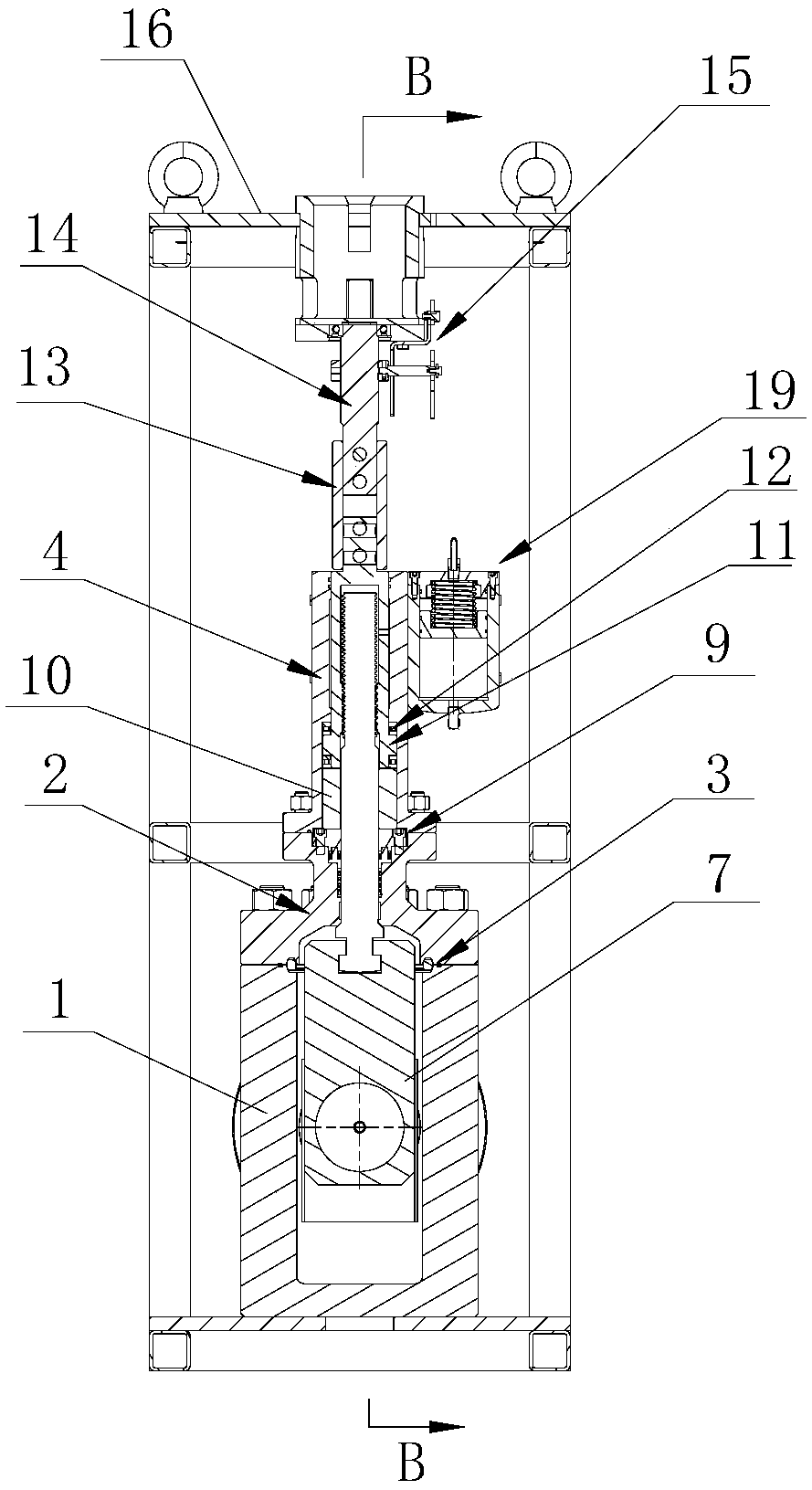

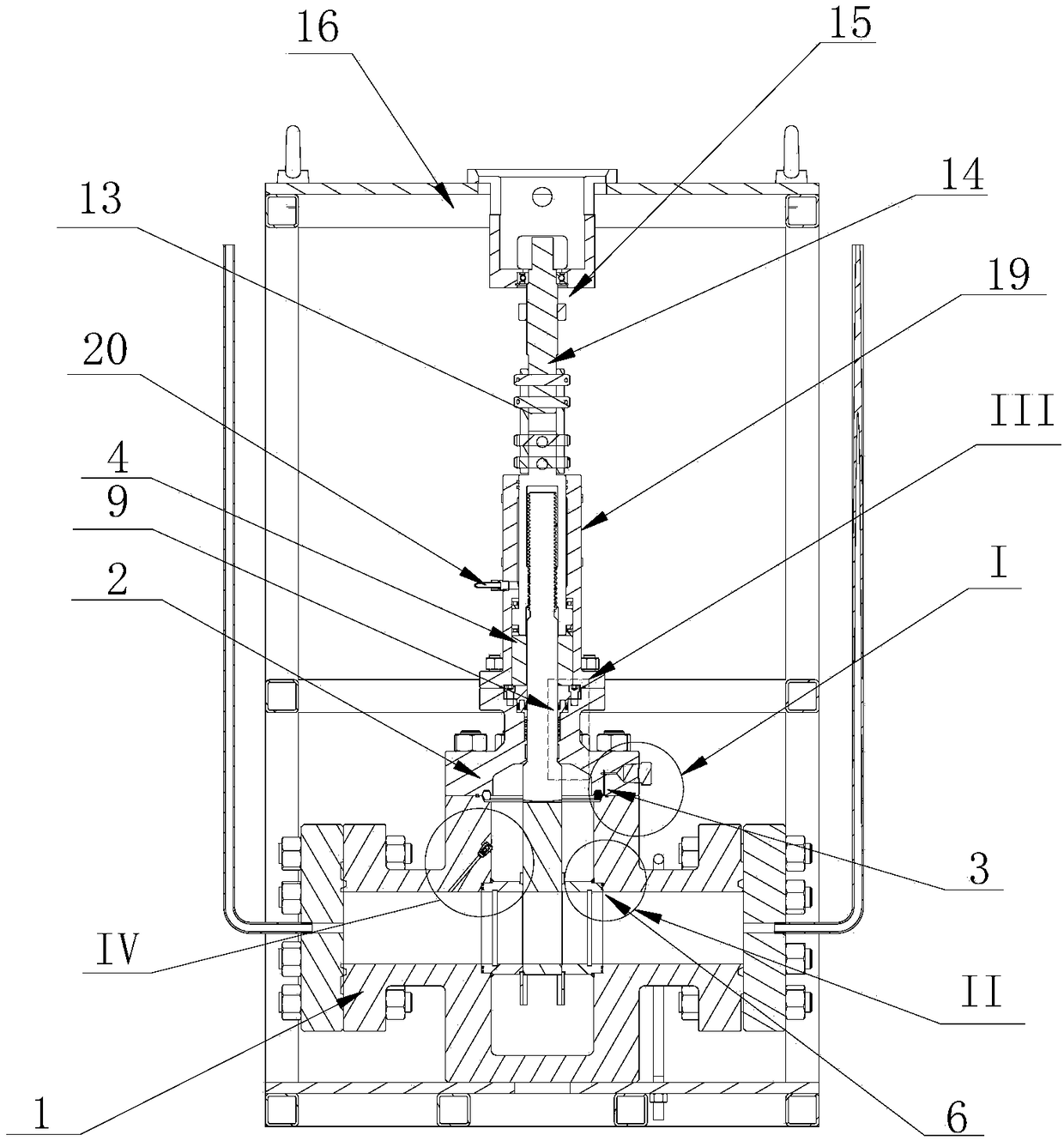

Underwater flat gate valve for sea bottom christmas tree

PendingCN108443524AReduce processing cumbersome proceduresRealize online replacement and maintenanceSlide valveValve housingsCorrosionRelief valve

The invention relates to an underwater flat gate valve for a sea bottom christmas tree. The underwater flat gate valve comprises a valve body, a valve cover, a gate plate, a support and a valve seat.A first sealing structure is arranged between the valve body and the valve cover. A second sealing structure is arranged between the valve seat and the valve body. A third sealing structure is arranged between the valve cover and a valve rod. A gasket ring and a valve rod nut are mounted in the support, and the valve rod stretches out of the valve cover to penetrate the gasket ring to be in threaded connection with the valve rod nut. The upper end of the valve rod nut is connected with a drive sleeve, the drive sleeve is connected with an upper valve rod, and the upper valve rod is connected with a valve position indication mechanism. The upper valve rod is connected with an ROV connector through a supporting bearing. A pre-pressing disc spring for providing initial specific pressure is mounted on the valve seat. A pressure relief channel extending in the upstream direction is arranged in the valve body, and a one-way pressure relief valve is mounted on an inner channel of a valve cavity of the valve body. A gate plate guide mechanism is detachably mounted at the symmetric positions of the middle of the valve seat. The underwater flat gate valve has the advantages that sealing performance is good, and the functions of gate plate guide and start and stop compensation are achieved; and meanwhile, for gate plate and valve seat hardening treatment, the corrosion resisting strengthis improved, corrosion resistance is high, and the service life is long.

Owner:天津祥嘉流体控制系统有限公司

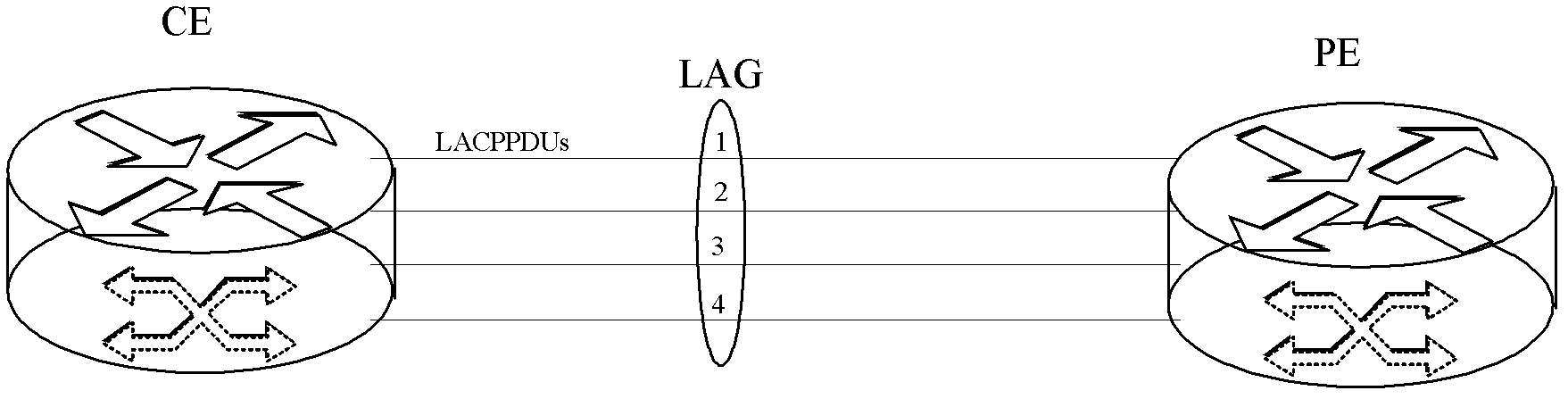

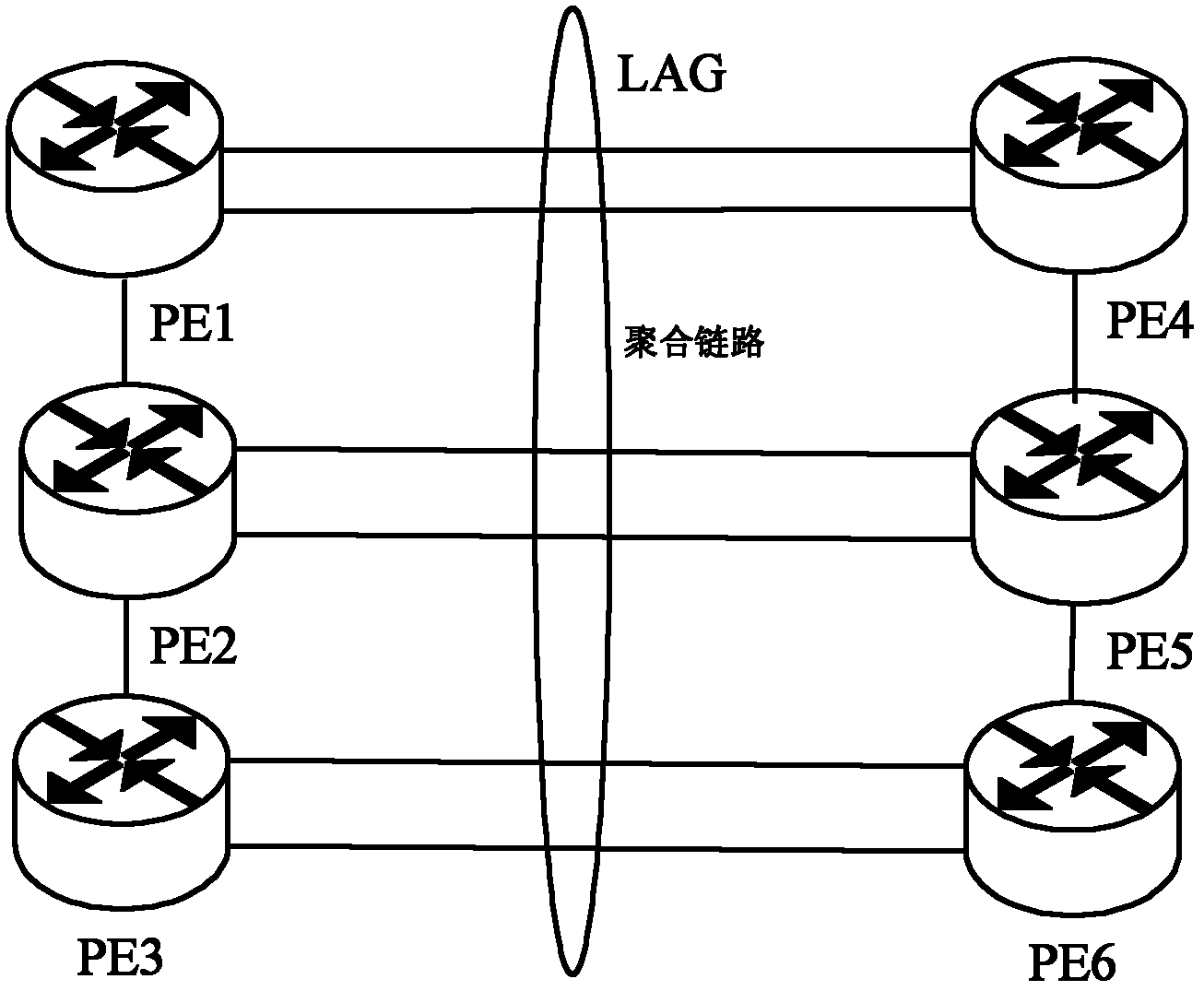

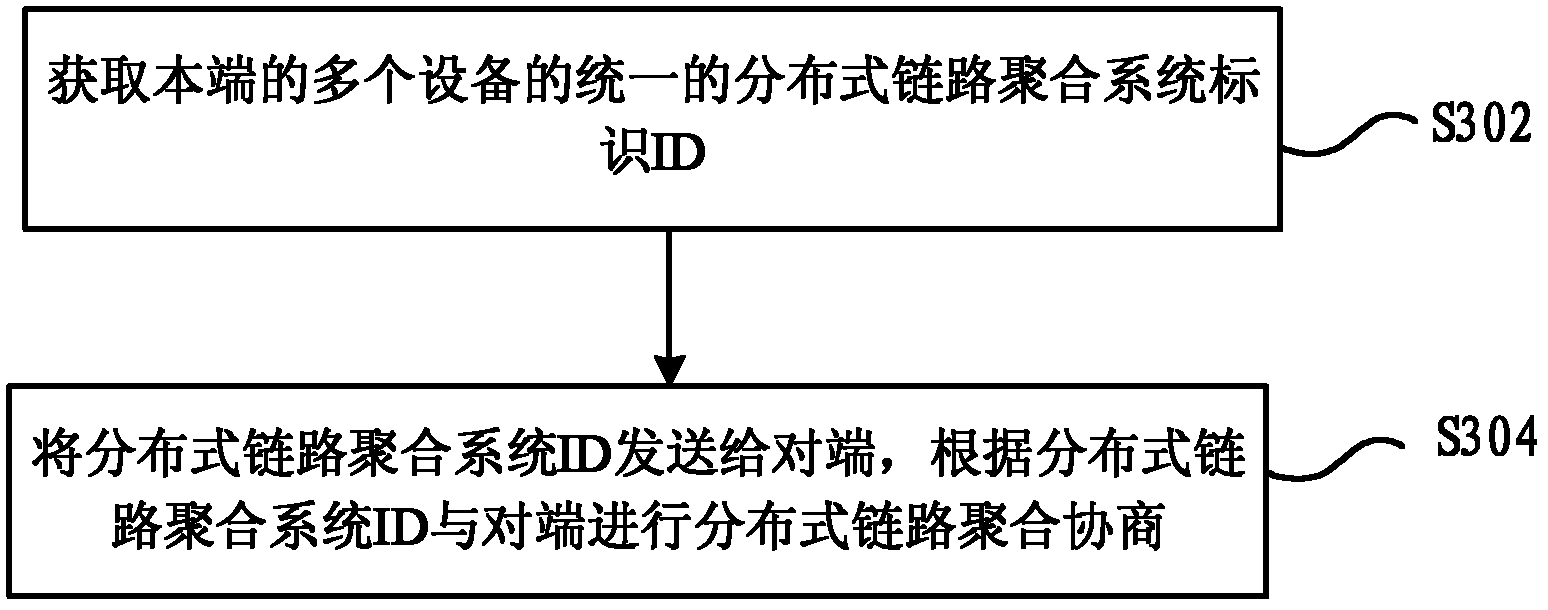

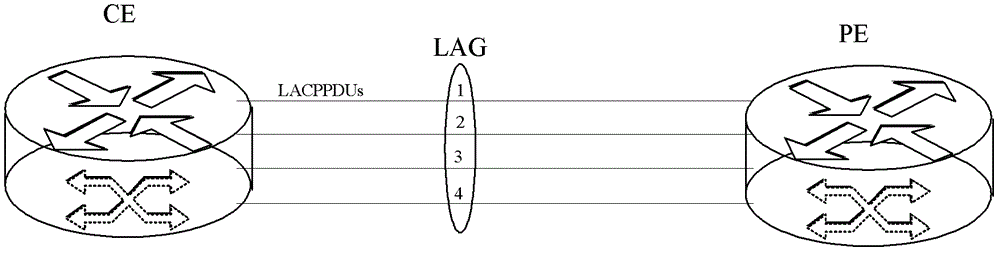

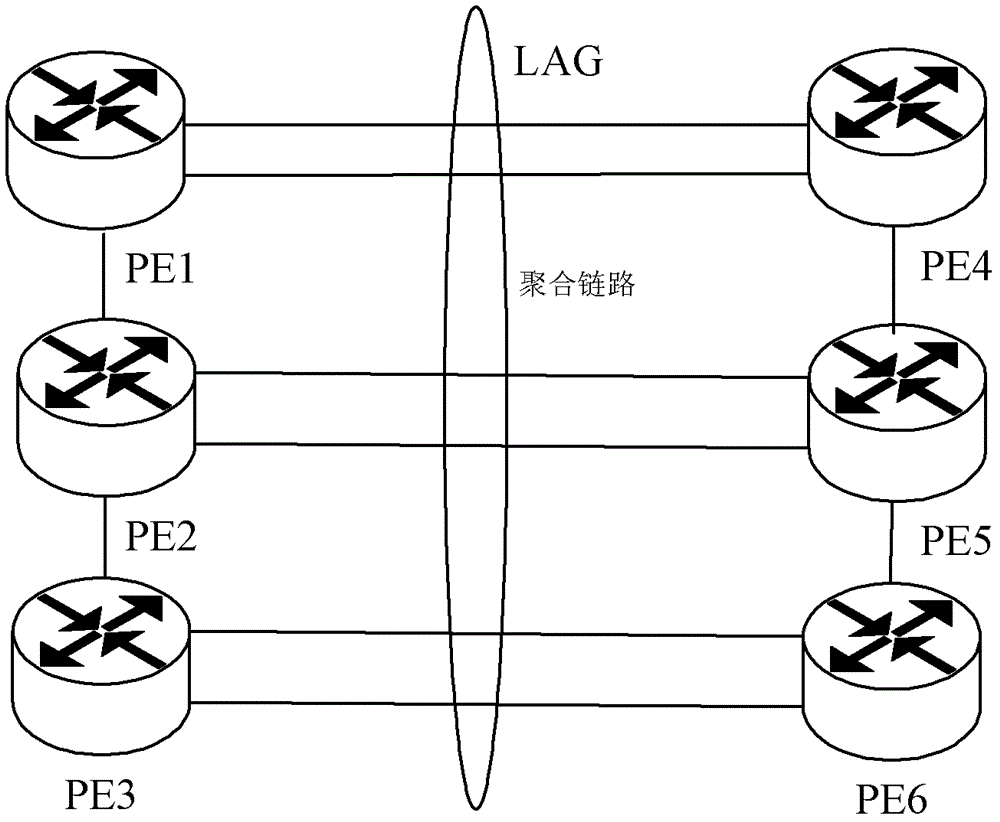

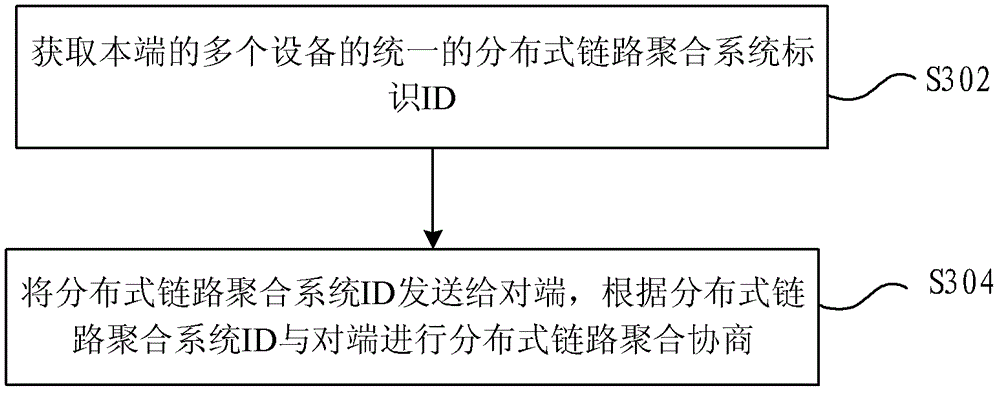

Method and device for distributed link aggregation

ActiveCN103023814AAchieve aggregationSolve the problem that the aggregation cannot be realizedData switching networksHigh level techniquesComputer networkLink aggregation

The invention discloses a method and a device for distributed link aggregation. The method comprises the following steps of: acquiring a uniform distributed link aggregation system identity (ID) of a plurality of equipment of a home terminal; and transmitting the distributed link aggregation system ID to an opposite terminal, and performing distributed link aggregation negotiation with the opposite terminal according to the distributed link aggregation system ID. By adopting the method and the device, the link aggregation of a distributed link aggregation system can be realized.

Owner:ZTE CORP

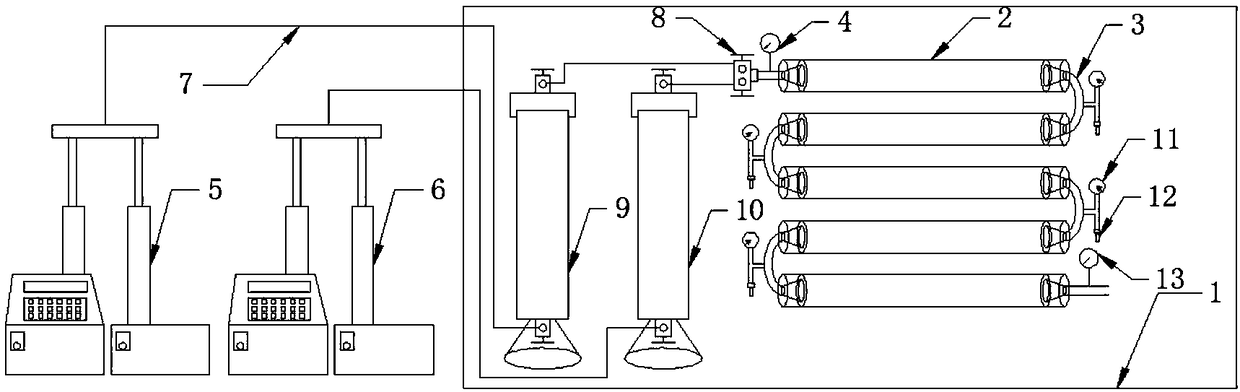

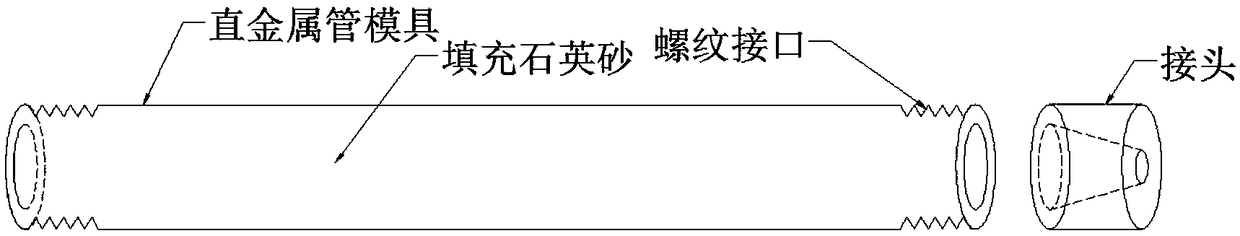

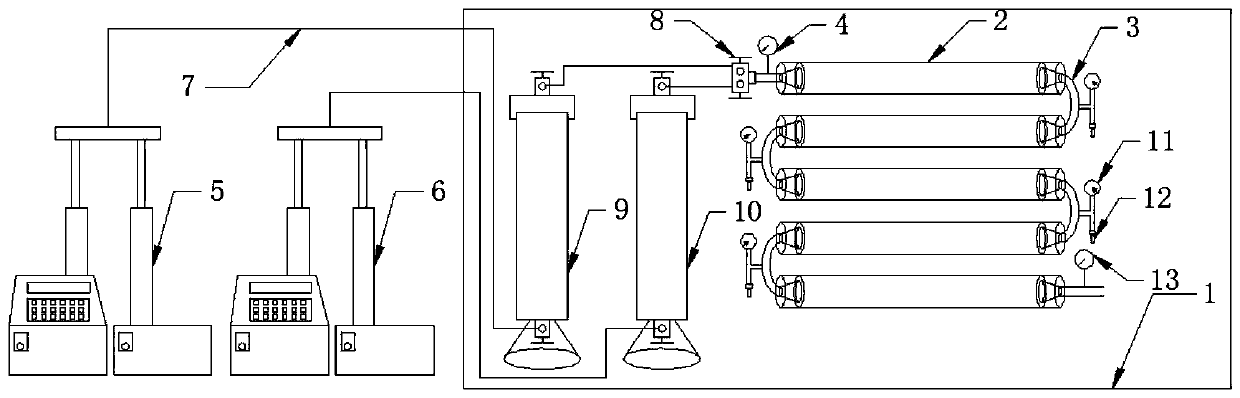

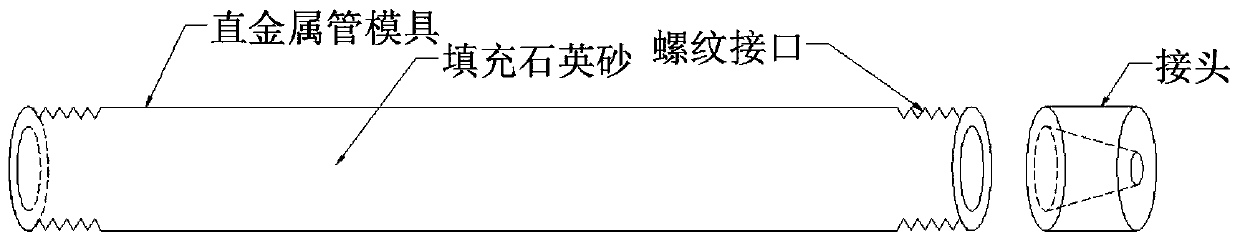

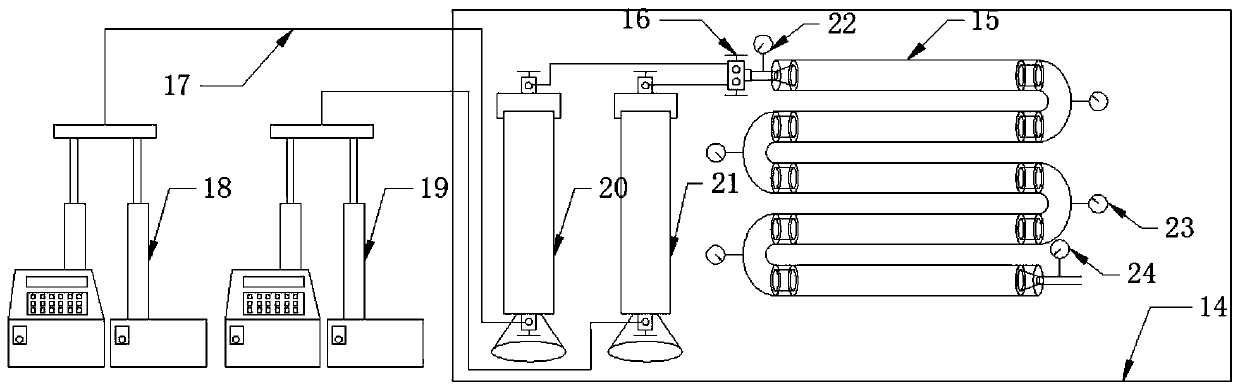

Method and device for judging emulsification generating position in long cementing tube

ActiveCN108952649ASolve the impossibleTroubleshoot build location issuesFluid removalLine tubingEmulsion

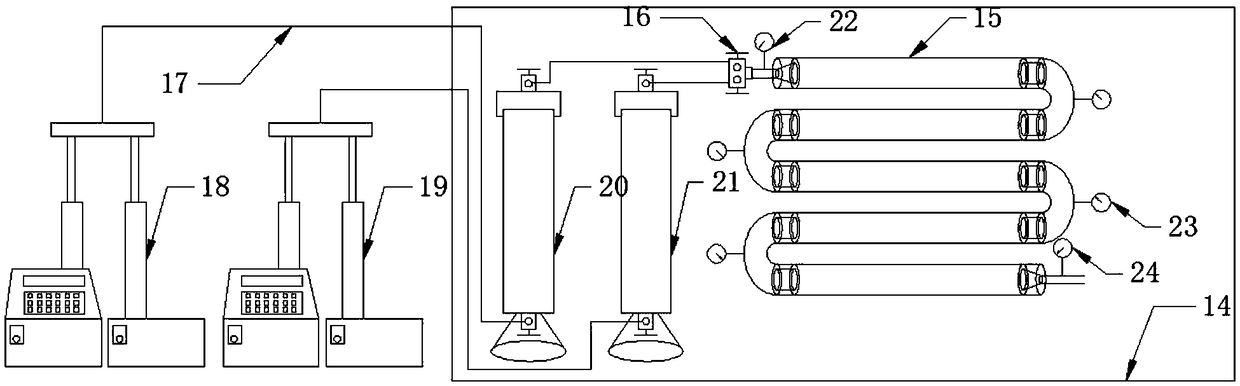

Provided are a method and device for judging emulsification generating position in a long cementing tube. According to the method, a short cementing tube series connection method is used, continuous phases are extracted at series connection areas, the state of the continuous phases is observed to serve as the primary basis for judging whether emulsification is generated at non-continuous phases atthe same position in the long cementing tube, and then the specific position where oil and a functional polymer solution generate emulsification in the long cementing tube is judged according to thepressure difference of emulsion in a rock core and an oil / water phase mixture. The device comprises a beaker, a long cementing tube model, pipelines, a displacement pump, a control valve, a tee joint,a pressure meter, an oil injection piston container, a functional polymer solution injection piston container and an incubator. The long cementing tube model is formed by a plurality of metal tube molds in a series connection mode, and all the metal tube molds are in communication through the bendable connecting pipelines. Sampling and pressure measuring points are distributed in the middles of the connecting pipelines, and the metal tube molds are filled with quartz sand resin cemented materials for pressing.

Owner:NORTHEAST GASOLINEEUM UNIV

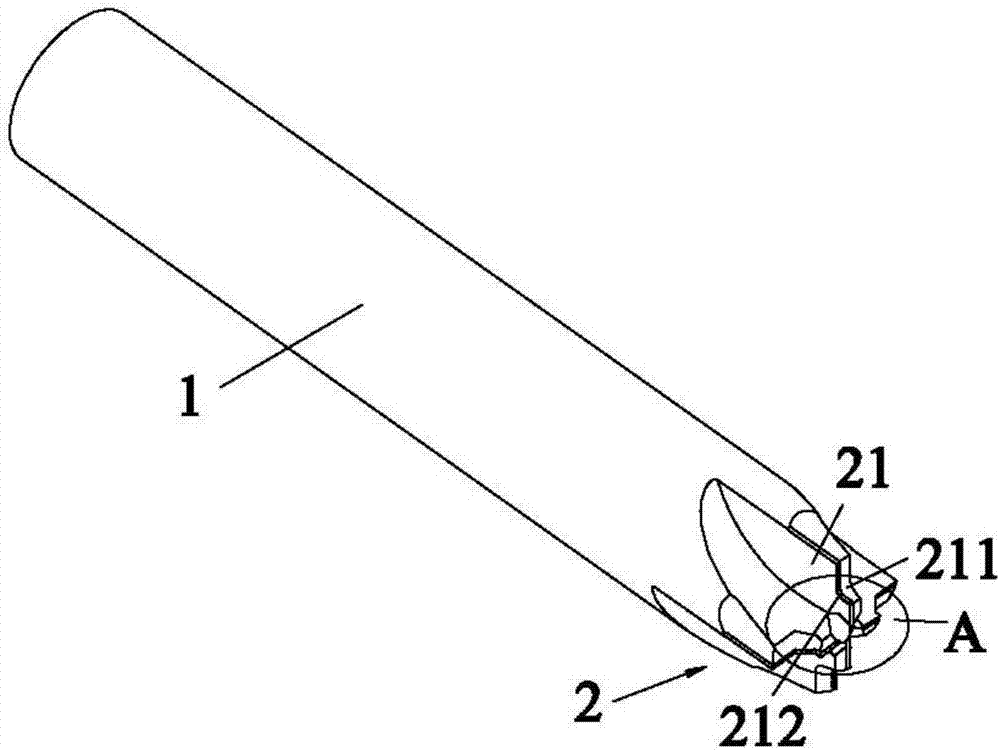

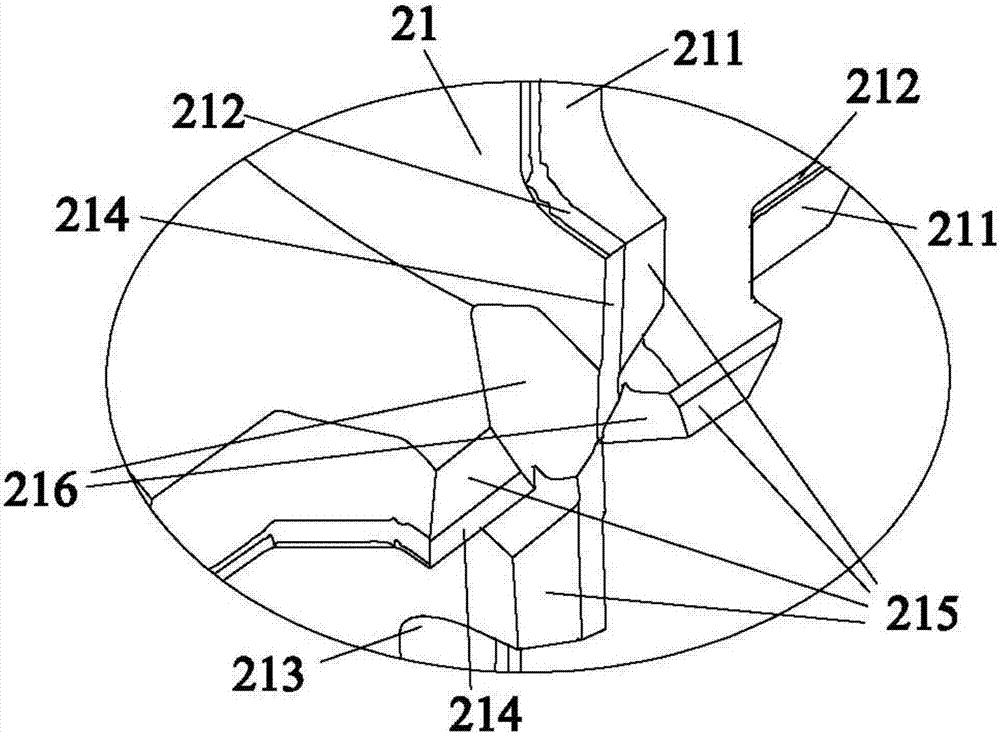

Staggered-tooth highlight milling cutter with chamfers and manufacturing method thereof

The invention relates to the technical field of cutters, in particular to a staggered-tooth highlight milling cutter with chamfers. The milling cutter comprises a cutter rod and a cutter head connected with the cutter rod into a whole; the cutter head is provided with a plurality of blades; each blade comprises a stepped blade body and a dress-smooth blade body connected with the stepped blade body; and the stepped blade bodies are provided with the arc chamfers. According to the milling cutter, a staggered-tooth cutter and a highlight cutter are integrated onto one cutter, and the technical problems that the machining efficiency is low, the smooth finish is poor, and the quality is poor are solved. In addition, the invention further discloses a manufacturing method of the staggered-tooth highlight milling cutter with the chamfers.

Owner:GUANGDONG DTECH TECH CO LTD

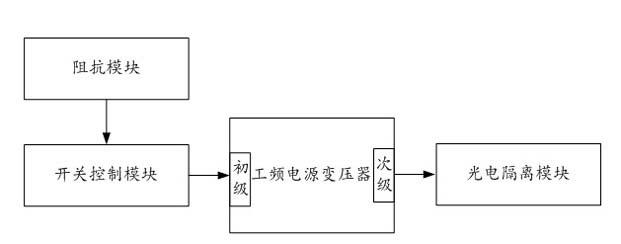

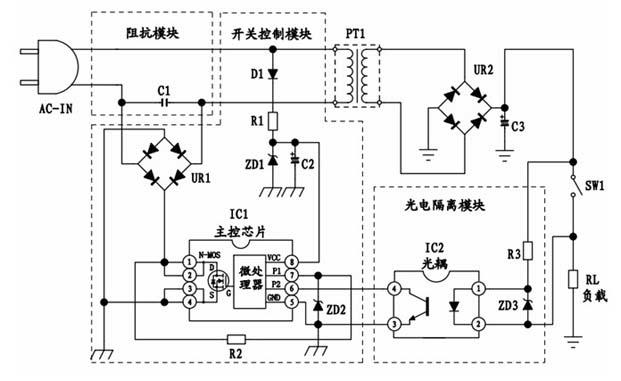

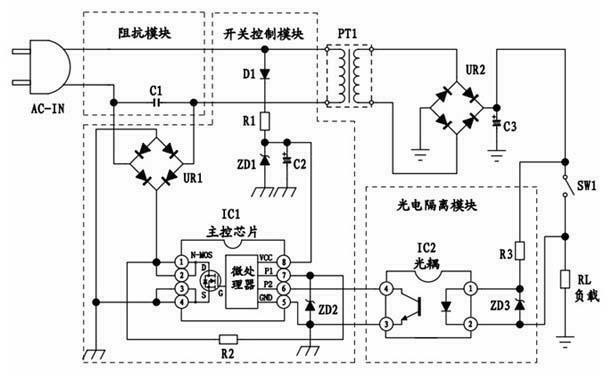

Low-power consumption standby circuit of power-frequency power supply transformer

InactiveCN102545576ASimple structureImprove reliabilityEfficient power electronics conversionPower conversion systemsElectricityTransformer

The invention is applicable to the field of energy conservation of transformers and provides a low-power consumption standby circuit of a power-frequency power supply transformer. The circuit comprises an impedance module, a switch control module and a photoelectric isolation module, wherein the impedance module is connected with the switch control module; the switch control module is also connected with the photoelectric isolation module; and when the transformer is connected, the switch control module is connected with the primary winding of the power-frequency power supply transformer, and the photoelectric isolation module is connected with the secondary winding of the power-frequency power supply transformer. Due to the adoption of an electric-optical-electric control way, the energy conversion efficiency is relatively high. A photodiode can enter a standby mode by only relatively low current, so the energy consumed by the circuit is low, and micro-power consumption standby is realized. The same power-frequency power supply transformer is adopted in both the standby mode and the work mode, so the cost is greatly reduced, and the circuit is very simple in structure, so the reliability of the circuit is improved.

Owner:聂明平

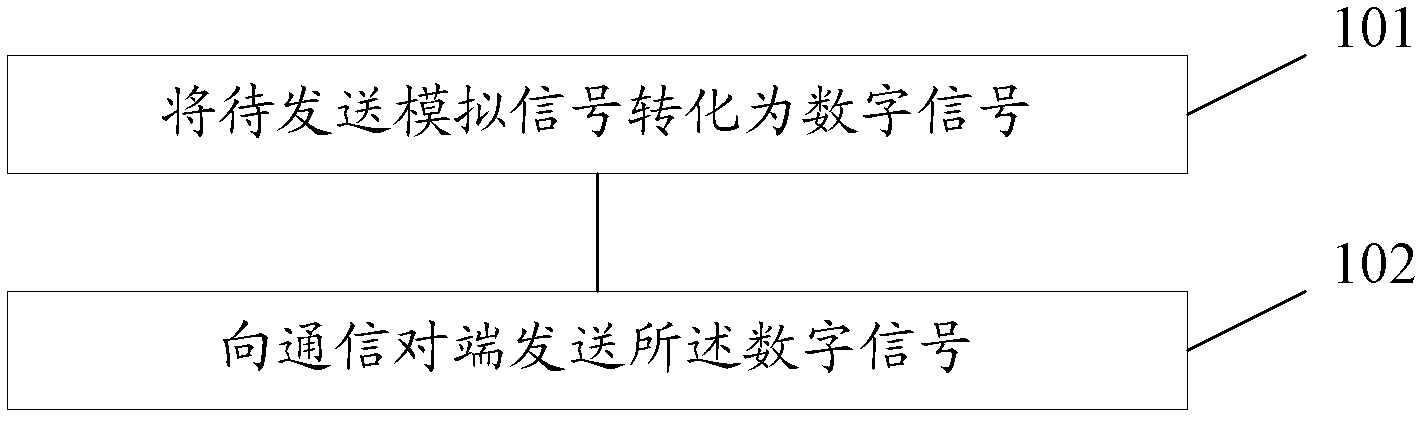

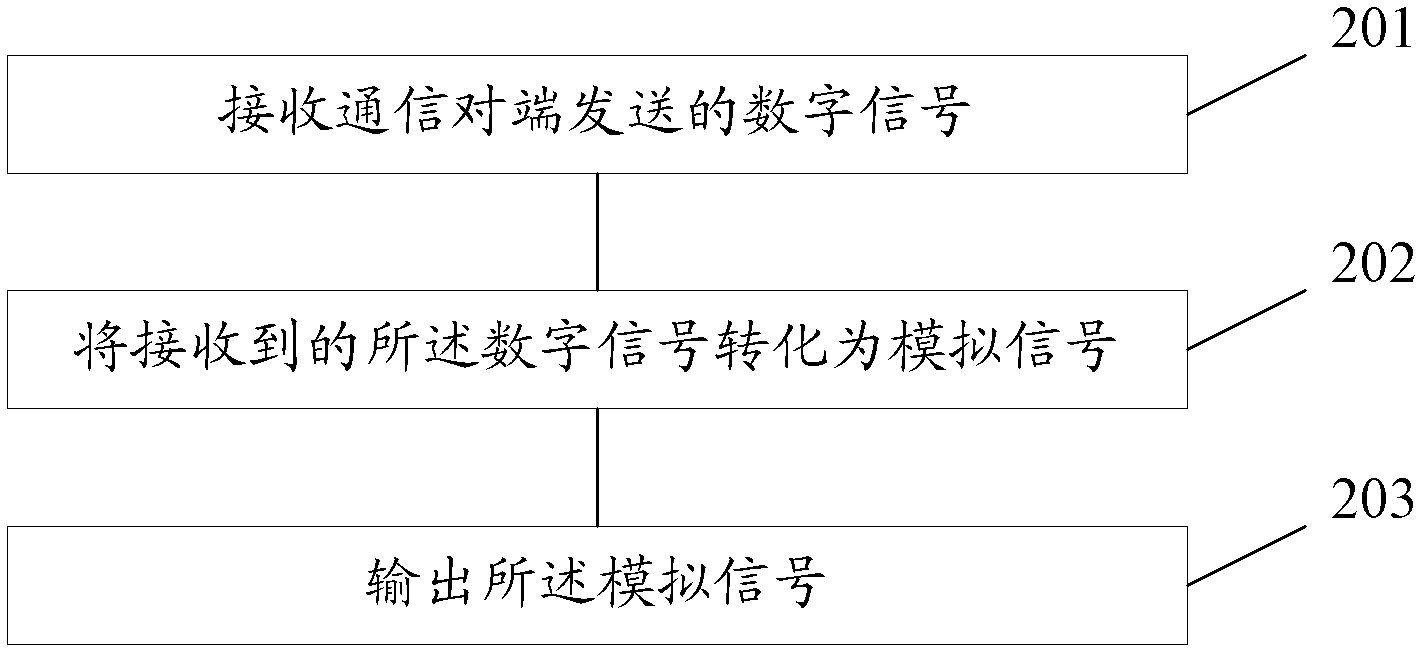

Signal relay method

InactiveCN103124340ARealize remote transmissionSolve the impossibleElectrical cable transmission adaptationReversible analogue/digital convertorsAnalog signalComputer science

The invention provides a signal relay method, and relates to the field of communication. The signal relay method solves the problem that remote signal transmission cannot be realized. The method includes the steps: converting an analog signal to be transmitted into a digital signal; and transmitting the digital signal to a correspondent node. The signal relay method is applicable to remote signal transmission.

Owner:BEIJING WATERTEK INFORMATION TECH

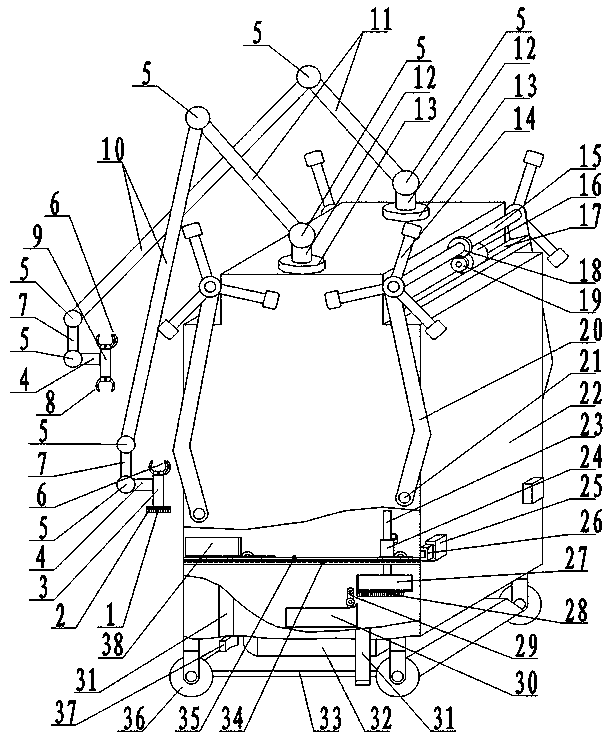

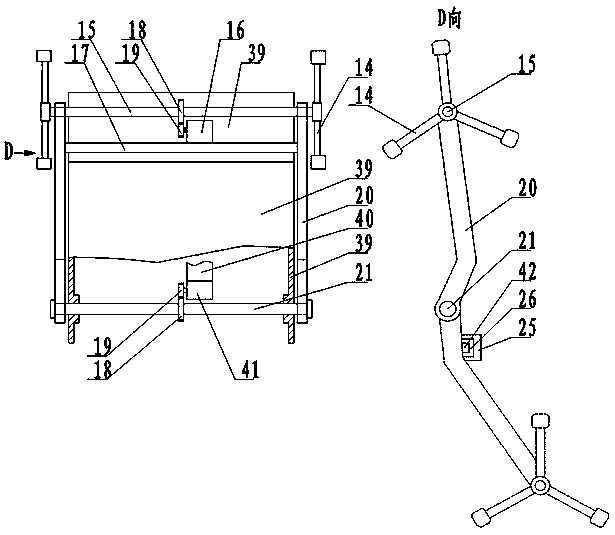

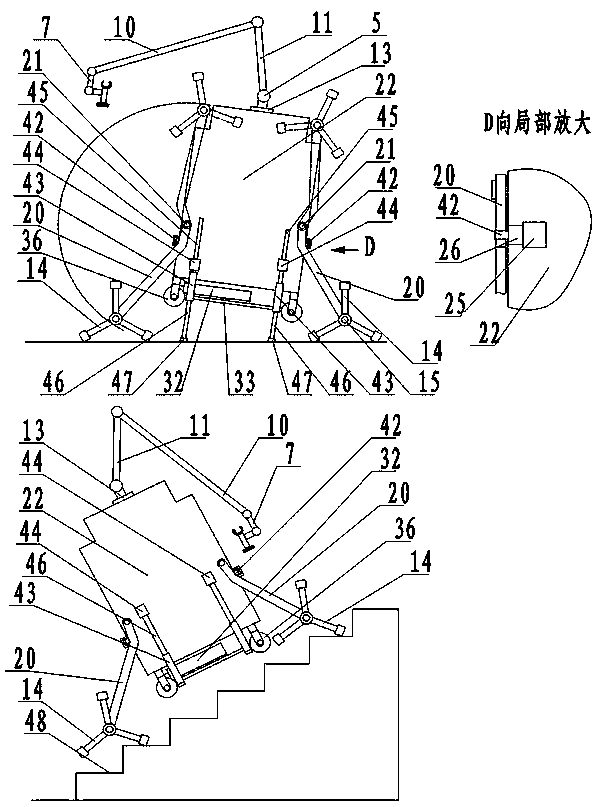

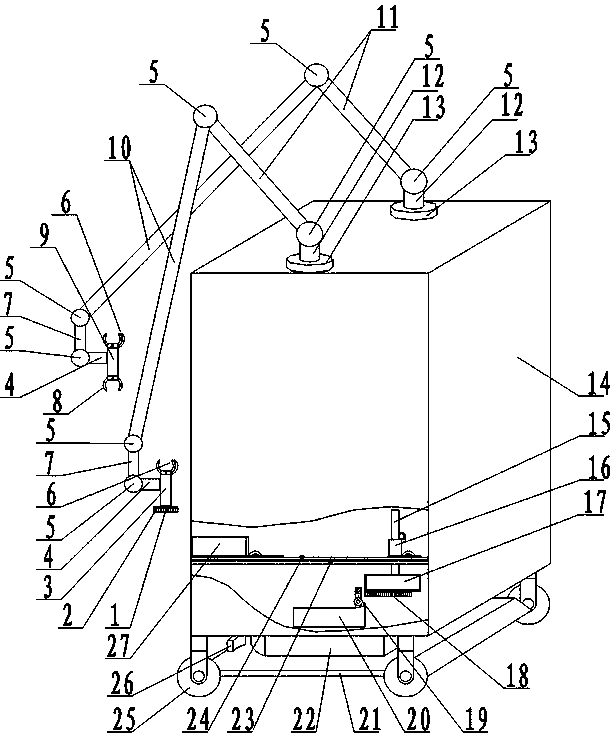

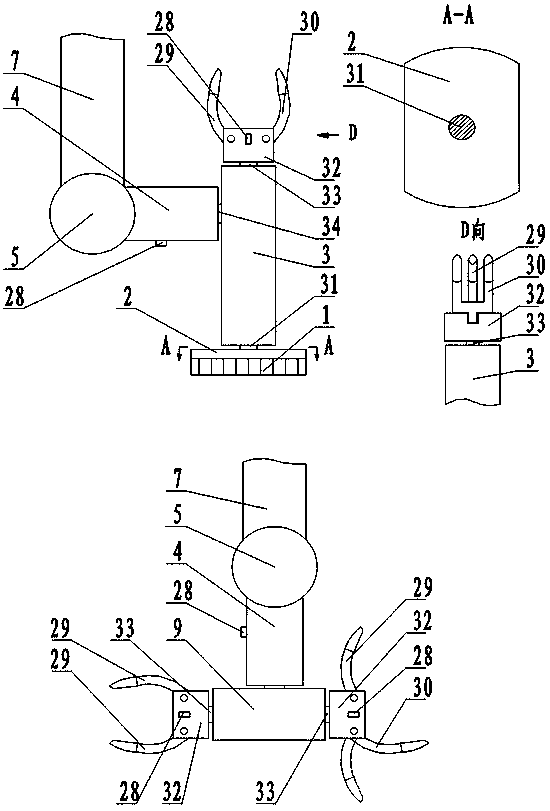

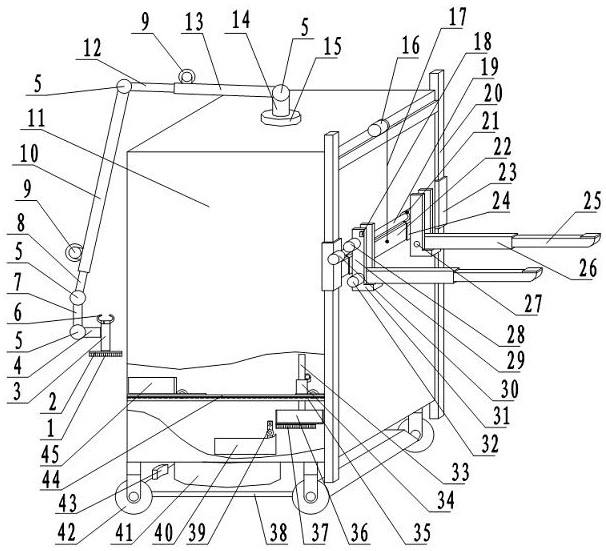

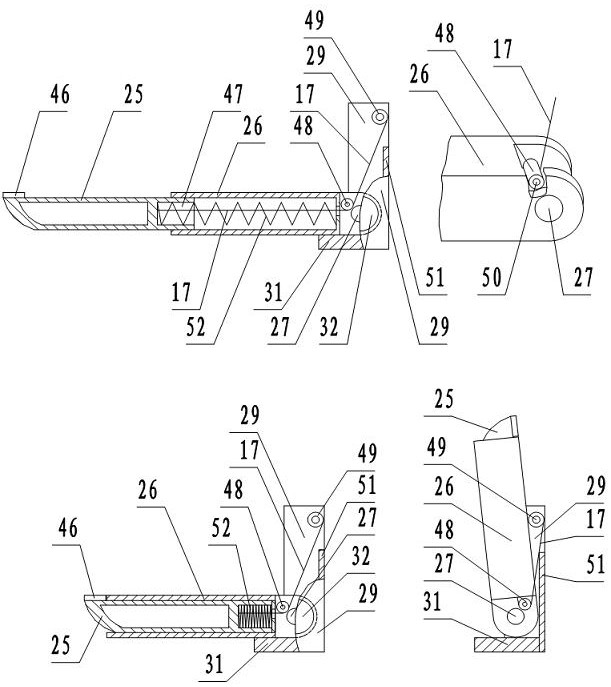

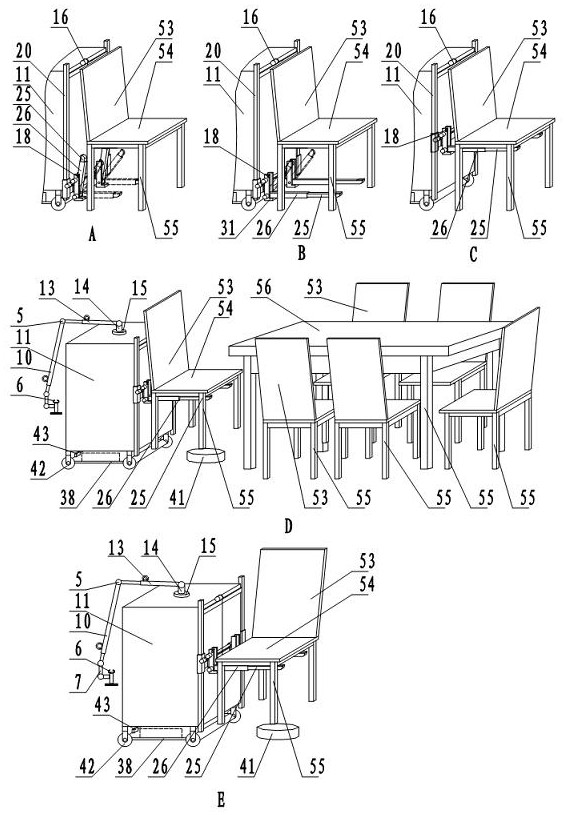

Floor sweeper capable of going upstairs

ActiveCN110025261ASolve the impossibleThe solution cannot be automatically uploadedCarpet cleanersFloor cleanersEngineeringMechanical engineering

The invention discloses a floor sweeper capable of going upstairs. The sweeper comprises a machine body, mechanical arms, an upstairs going mechanism, a machine body lifting device, a sweeper, mops, amop cleaning device, a wiper cleaning device, a correcting device, a double-shaft seat mechanism and a water injection mechanism, wherein the machine body lifting device, the upstairs going mechanismand two pairs of the mechanical arms are mounted on the machine body; clamping jaws and wipers are respectively mounted at the front ends of the two parts of the mechanical arms; the mop cleaning device and the wiper cleaning device are arranged in the machine body and can automatically clean the mops and the wipers; and the clamping jaws can clamp and lift objects such as chairs, stools, shoes,baskets and sweep the floor below. When sweeping the floor, the sweeper is remotely controlled by the host machine to climb down from a support plate below the host machine body to sweep, absorb dustand mop the floor, and after sweeping the floor, the sweeper climbs onto the support plate for parking; the mechanical arms drive the wipers to wipe the surfaces of tables, chairs, tea tables and thelike; when going up and down stairs, the upstairs going mechanism lowers a ladder climbing step, and when not going upstairs, the upstairs going mechanism is retracted upward; the sweeper can sweep the floor of both upstairs and downstairs; one machine has multiple functions and can automatically clean the mops; and the floor is cleaner after mopping the floor.

Owner:SUINING CHANGFENG MECHANICAL TECH

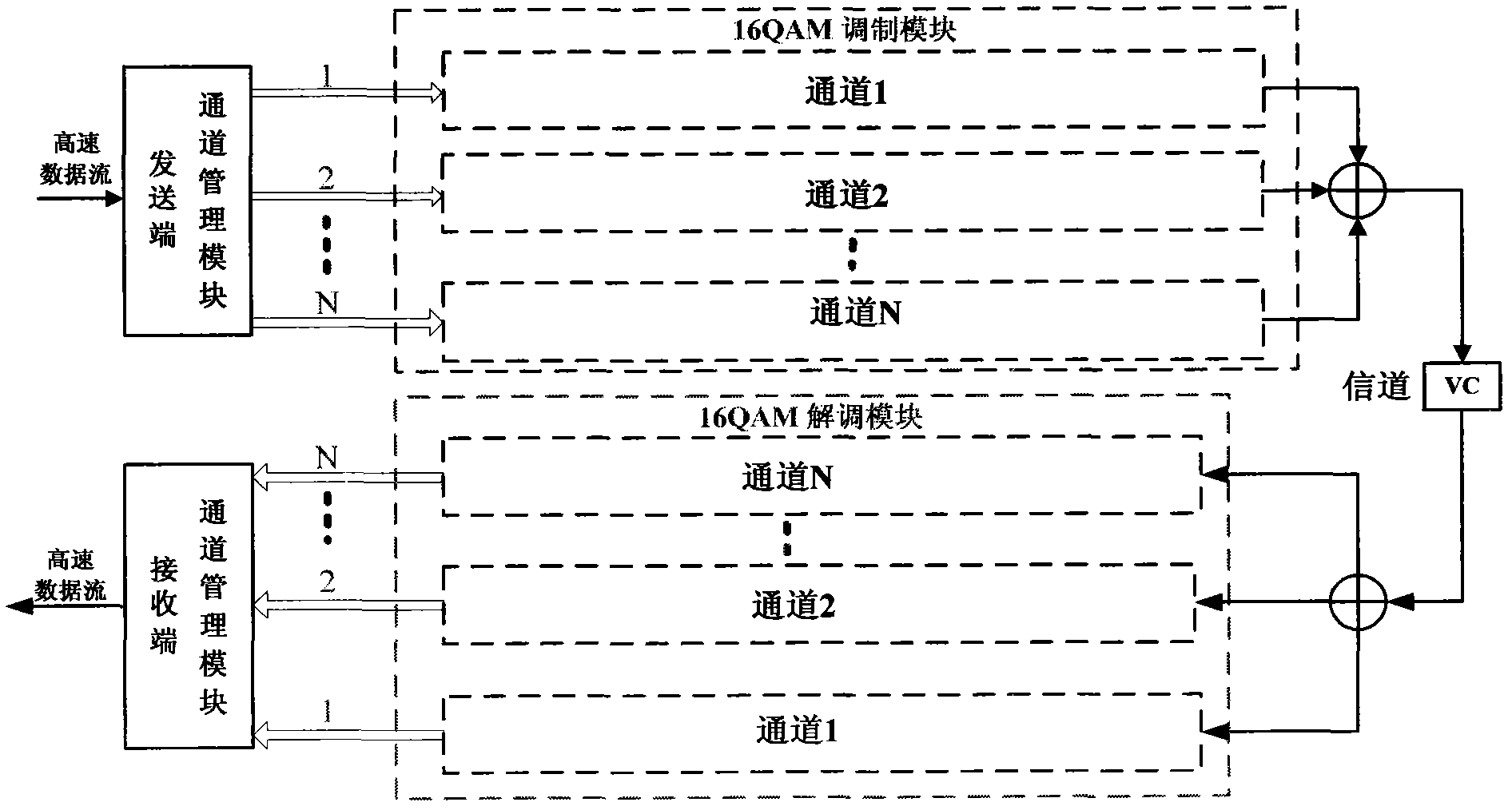

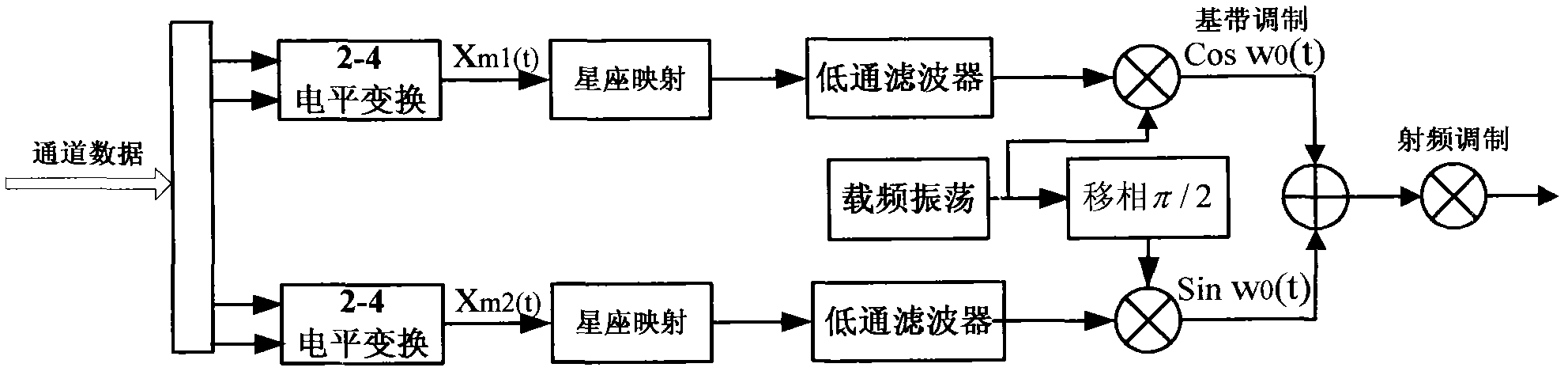

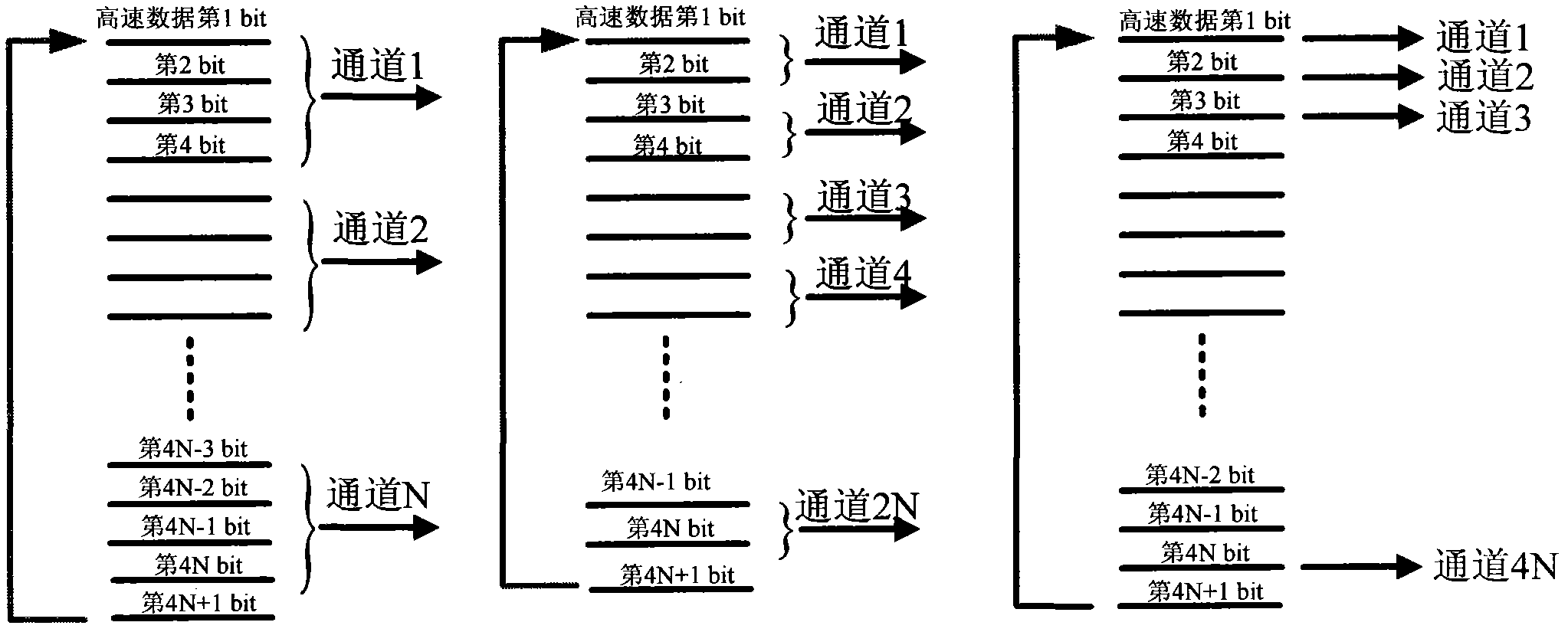

Base band (BB)-radio frequency (RF) multi-channel communication management design

ActiveCN102404042ALower requirementSatisfy the use effectRadio transmissionData switching networksHigh ratePhysical layer

The invention discloses a base band (BB)-radio frequency (RF) multi-channel communication management design method, which belongs to the technical field of satellite communication. The multi-channel communication management design method comprises management of the channel number under S1 multiple channels and data distribution under S2 multi-channel management. The BB- RF multi-channel communication management design method has the advantages that by means of multi-channel communication management control software, high-rate data can be transmitted, optimal communication effect and data transmission ratio of a system can be achieved, requirements of system devices are reduced, various device performance can be met, system cost is saved, the problem which is impossible to be resolved by a single channel is resolved well, and high speed data transmission of physical layers under various agreements is supported.

Owner:DALIAN UNIV

Double-clamping-arm floor sweeper

InactiveCN109998424ASolve the impossibleIncrease vacuumCarpet cleanersFloor cleanersEngineeringMechanical engineering

The invention provides a double-clamping-arm floor sweeper. The double-clamping-arm floor sweeper comprises a main machine body, mechanical arms, a floor sweeping device, a mop, a mop washing device,a wiping cloth washing device, a correcting device, a double-axis-base mechanism and a water injecting mechanism, wherein two pairs of mechanical arms are mounted on the machine body, a clamping jaw and wiping cloth are mounted at the front end of one pair of mechanical arm, and clamping jaws are mounted at the front end of the other pair of mechanical arm; the mop washing device and the wiping cloth washing device are arranged in the machine body, and the wiping cloth and the mop can be automatically washed; when the mop is washed, a washing base pulls out the dirty mop under the floor sweeping device and brings the dirty mop into a mop washing pond to be subjected to washing and dewatering, and after washing, the mop is inserted below the floor sweeping device; and the clamping jaws at the front ends of the mechanical arms can clamp and lift the objects including chairs, stools, shoes, baskets and the like and then the floor below is swept. During floor sweeping, the mop washing device climbs down from a support plate below the main machine body under the remote control of a main machine for carrying out the operations including floor sweeping, dust collecting and floor mopping;and after floor sweeping, the floor sweeping device climbs to the support plate to be stored. The mechanical arms can drive the wiping cloth to wipe the boards of the objects including tables, chairs,tea tables and the like. Multiple purposes are realized with one machine, and the floor is clearer after mopping.

Owner:SUINING CHANGFENG MECHANICAL TECH

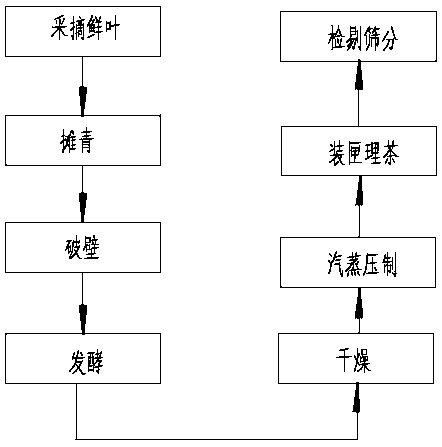

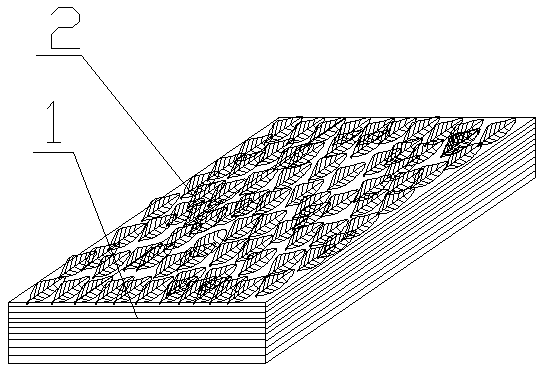

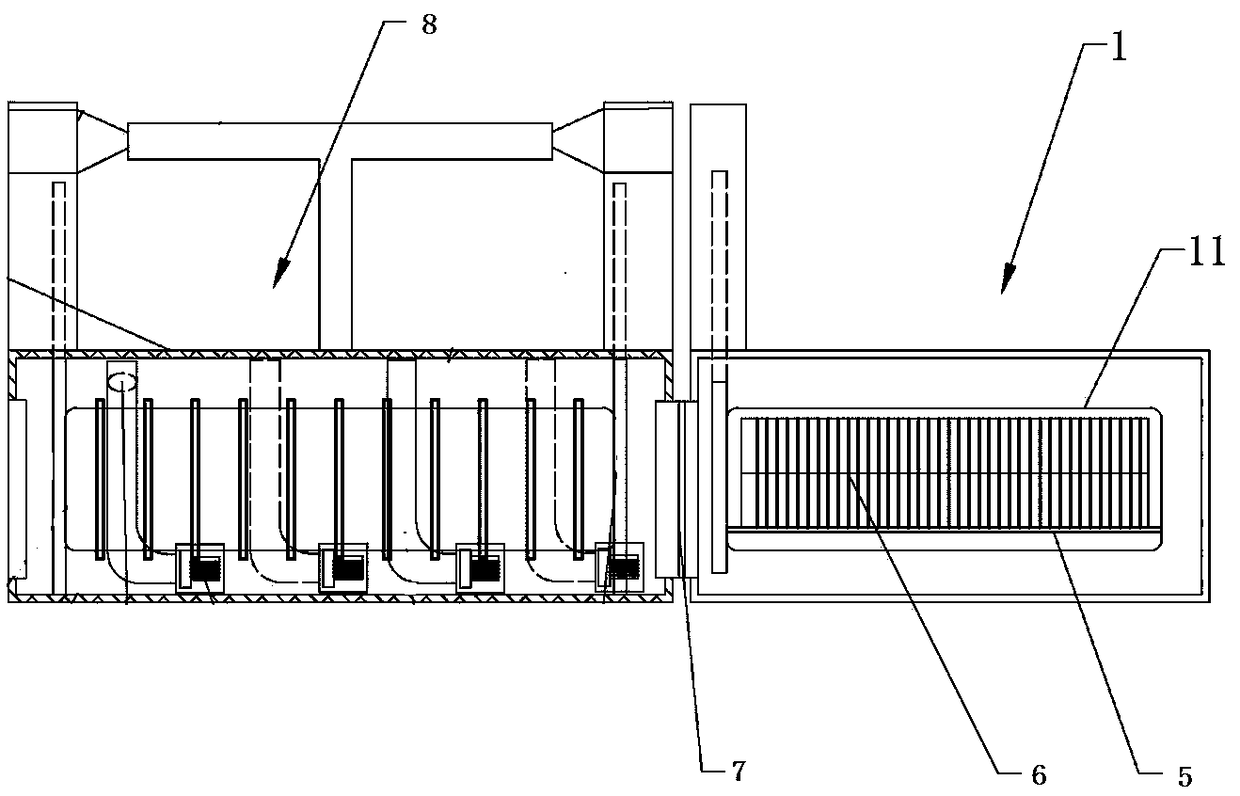

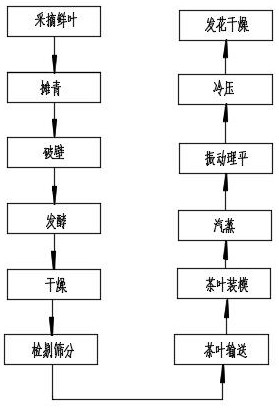

Shredded brick tea and making method thereof

ActiveCN110754540AImprove broken rateSolve the impossiblePre-extraction tea treatmentClimate change adaptationGreen teasProcess engineering

The invention discloses shredded brick tea and a making method thereof, which relate to a brick tea product and a processing method thereof. The brick body of the shredded brick tea is formed by laminating a plurality of layers of tea leaves, and each layer of tea leaves is full of a plurality of pieces of raw dark green tea keeping the original flat shape of the tea leaves. The making method comprises the following steps: preparing raw tea, steam pressing and drying. The making method of the raw tea comprises the following steps: spreading fresh leaves, putting the spread tea leaves into an extrusion container, applying a parallel wall-breaking extrusion force to perform wall-breaking extrusion, extruding the tea leaves into a semitransparent state at least facing light, and performing pile fermentation and drying to prepare the raw dark green tea keeping the original flat shape of the tea leaves; putting the raw dark green tea into a brick tea mold box into which steam can permeate,carrying out vibration finishing, and vibrating the raw dark green tea of which the original flat shape of the tea leaves is kept into flat tea leaves layer by layer. According to the invention, the inherent thinking of people is broken through, enzyme deactivating and rolling processes are canceled, the tea cells are broken in an extrusion manner, the wall breaking rate is up to 90% or above, andthe broken tea can keep the original shape; by the adoption of a tea boxing and sorting process, the tea leaves can be sorted into flat tea leaves layer by layer in a vibrating mode, the pressed hardbrick body can be decomposed through hand tearing without tools when drunk, and the problem that people think that the brick tea cannot be solved is solved.

Owner:湖南安化芙蓉山茶业有限责任公司

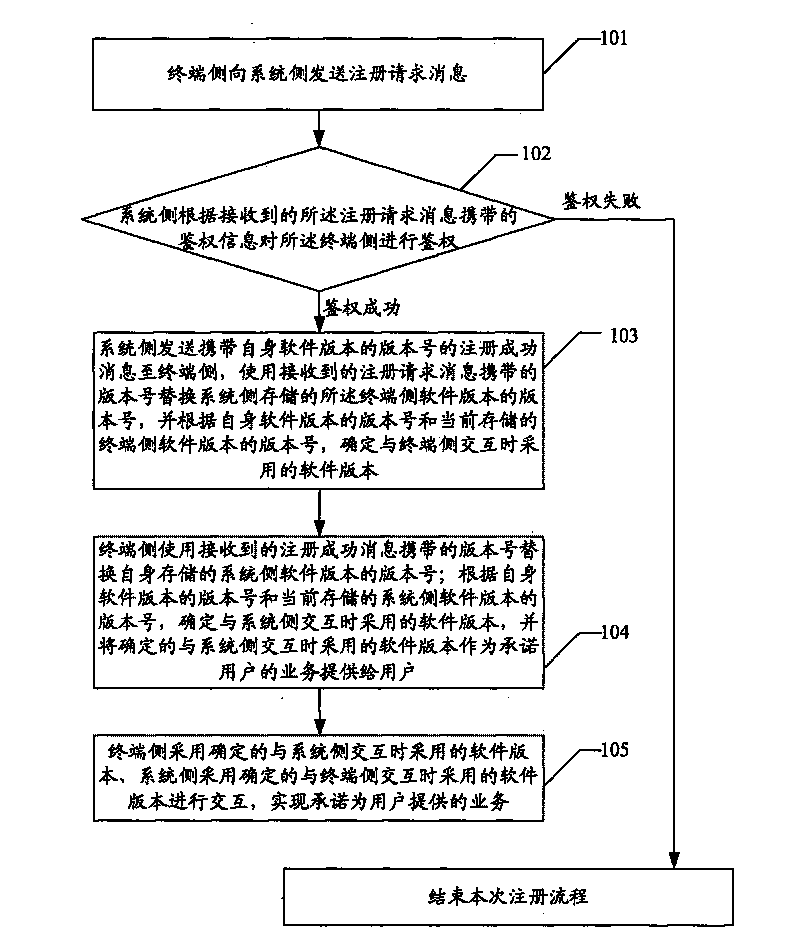

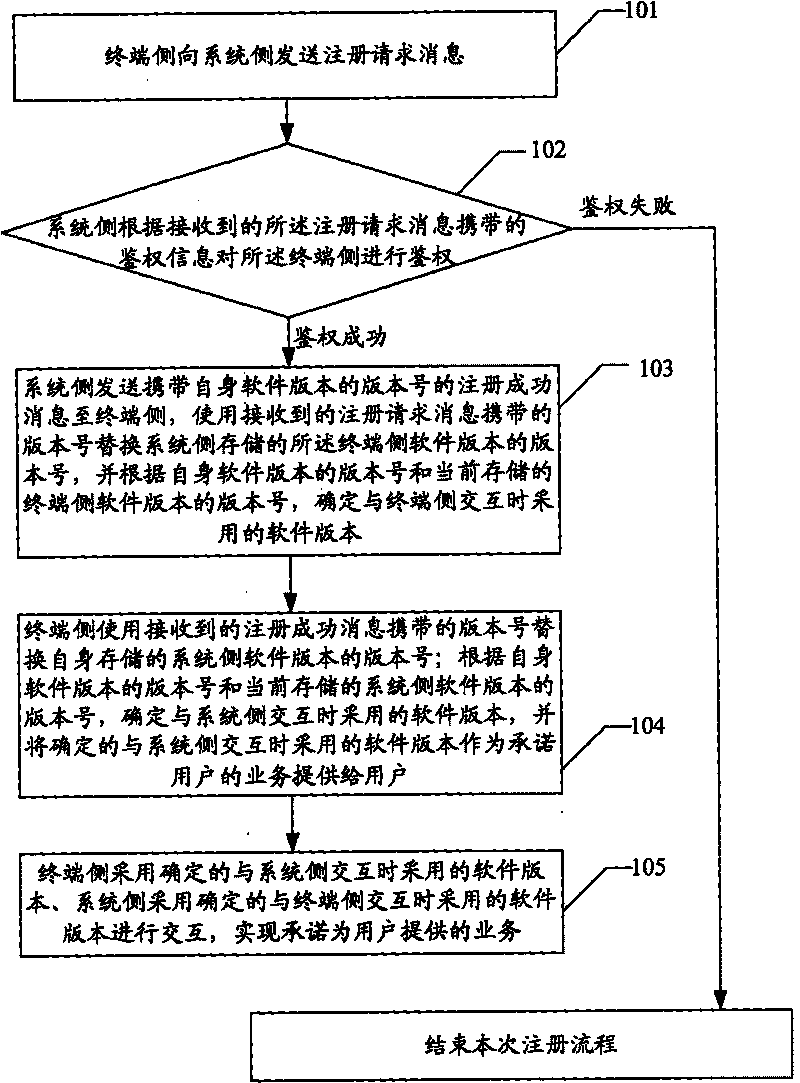

Method and system for registering tour guide navigation terminal

InactiveCN101715191ASolve the impossibleSolve the problem that the two parties cannot realize data interactionPosition fixationSecurity arrangementSoftware engineeringComputer terminal

The invention discloses a method for registering a tour guide navigation terminal. The method takes software versions with low version numbers in software versions on a terminal side and a system side as established software versions adopted during the interaction with the terminal side and established software versions adopted during the interaction with the system side, and takes services supported by the software versions with the low version numbers in the software versions on the terminal side and the system side as the services promised to be provided for users. The invention simultaneously discloses a system for registering the tour guide navigation terminal, which comprises the terminal side and the system side. By adopting the method and the system, the problems existing during the interaction between the tour guide navigation terminal side and the tour guide navigation system side can be solved.

Owner:ZTE CORP

Method and device for judging the location of emulsification in a long cemented tube

ActiveCN108952649BSolve the impossibleTroubleshoot build location issuesFluid removalEmulsionEngineering

A method and device for judging the position where emulsification occurs in a long cemented pipe. The method is to use the method of connecting short cemented pipes in series, extract the continuous phase at the series connection, and observe the state of the continuous phase as a preliminary basis for judging whether the discontinuous phase in the same position in the long cemented pipe is emulsified, and then according to the core The difference in pressure between the internal emulsion and the oil / water phase mixture can determine the specific location where the oil and functional polymer solution in the long cemented pipe are emulsified. The device includes a beaker, a long cemented pipe model, a pipeline, a displacement pump, a control valve, a tee, a pressure gauge, an oil injection piston container, a functional polymer solution injection piston container, and a constant temperature box. The long cemented pipe model consists of several Short and straight metal tube molds are connected in series, and the metal tube molds are connected by flexible connecting pipelines. Sampling and pressure measurement points are arranged in the middle of the connecting pipelines. The metal tubes are filled and pressed with materials cemented with quartz sand resin.

Owner:NORTHEAST GASOLINEEUM UNIV

A method for forming a lightweight motor shaft

ActiveCN110900122BLose weightIncrease profitManufacturing stator/rotor bodiesMaterials preparationElectric machinery

The present invention proposes a lightweight motor shaft forming method, comprising steps: 1), material preparation: material preparation of pipe material, first swaging die, second swaging die, first mandrel and second mandrel; 2) 1. Clamping in the first process: complete the clamping of the pipe material, the first swaging die and the first mandrel on the swaging machine; 3), the first process swaging: forming the pre-forged surface of the inner and outer surfaces of the bearing end of the hollow motor shaft; 4. ), the second process of clamping: complete the clamping of the pipe material, the second swaging die and the second mandrel on the swaging machine; 5), the second process of swaging: forming the inner and outer surfaces of the spline end of the hollow motor shaft to pre-satin ; 6), turning the end face of the motor shaft bearing, the end face of the spline and the outer circle; 7) the processing of the spline end. The light-weight motor shaft forming method disclosed in the present invention is formed by swaging twice through the tube material, without processing the inner hole of the motor shaft, so that the motor shaft can be hollowed out and lightened, the utilization rate of materials can be improved, and the motor shaft can be guaranteed. High precision on the inner and outer surfaces of the shaft.

Owner:WUHAN UNIV OF SCI & TECH

A method for releasing high-temperature carbonized products

ActiveCN105861000BPrevent spontaneous combustionSolve the impossibleCombustible gas coke oven heatingSpecial form destructive distillationTemperature controlFlue gas

The invention relates to an animal carbonization treatment method, and in particular, relates to a discharging method for a high-temperature carbonized material. The method includes the following steps: gas replacement: after a carbonization process is finished, immediately introducing non-flammable inert gas into a carbonization tank, and adopting the non-flammable inert gas to replace flammable pyrolysis gas in the carbonization tank; and temperature control and furnace opening: after the temperature in the carbonization furnace is dropped to 500 DEG C or less, opening the carbonization furnace, and making the high-temperature carbonized material in the carbonization tank discharged. The method can avoid low production efficiency caused by a lot of time requiring to be used in a cooling stage and energy loss generated during furnace body cooling, effectively solves the generation of dangerous problems of burning, exploding sounding and the like when a carbonization furnace door is opened at high temperature, successfully implements discharging of the carbonized material in a high temperature state, and solves the problems impossible to be achieved in industry; and at the same time, with combination of flue gas purification treatment, up-to-standard discharging of dioxin in tail gas is achieved.

Owner:ZHEJIANG WUNENG ENVIRONMENTAL TECH DEV

The preparation method of hand tearing machine pressed Fu brick tea

ActiveCN110810540BImprove toughnessAvoid stickingPre-extraction tea treatmentMechanical engineeringTea leaf

The invention relates to a preparation method of Fu brick tea pressed by a hand tearing machine, and relates to a processing method of Fu brick tea. First spread the tea leaves, and then put them into a squeeze container, apply a parallel extrusion force and squeeze them into at least a translucent shape against the light, and then ferment and dry them in a heap to make black hair tea that maintains the original flat shape of the tea leaves. ; After steaming, the tea leaves are put into the Fu brick tea mold box, placed on the vibrating table for vibrating and leveling, and the tea leaves that keep the original flat shape of the tea leaves are vibrated into layers of flat tea leaves, and cooled to within 50 ℃ Carry out cold pressing; and then carry out flower drying. The invention breaks through people's inherent thinking, adopts the extrusion method to break the tea cells, and the wall breaking rate reaches more than 90%. The prepared Fu brick tea can decompose the hard brick body by tearing it by hand without borrowing tools when drinking, which solves the problem that people think is impossible to solve.

Owner:湖南安化芙蓉山茶业有限责任公司

A method and system for realizing multi-language of POS machine

ActiveCN107562480BAvoid restrictionsSolve the impossibleCash registersExecution for user interfacesASCIIBitmap

The present invention relates to a POS machine multi-language implementation method and system thereof, the method includes initially setting language and related font resources; inputting character string codes; judging whether bidirectional sorting is required; if not, judging ASCII character segments and non-ASCII characters Whether the font attributes of the segment are consistent; if they are consistent, convert and deform the string encoding to obtain the bitmap of the string encoding; set the gray scale according to different devices; obtain the bitmap of all ASCII character segments and non-ASCII character segments, Output cache according to different devices; if inconsistent, convert the string encoding to UINICODE code; sort the strings that require bidirectional sorting, and distinguish between the strings that do not need bidirectional sorting and the sorted strings. The invention solves the problem that Arabic, Khmer and other complex and language dot matrix fonts cannot be realized, and supports multiple languages.

Owner:SHENZHEN XINGUODU PAYMENT TECH CO LTD

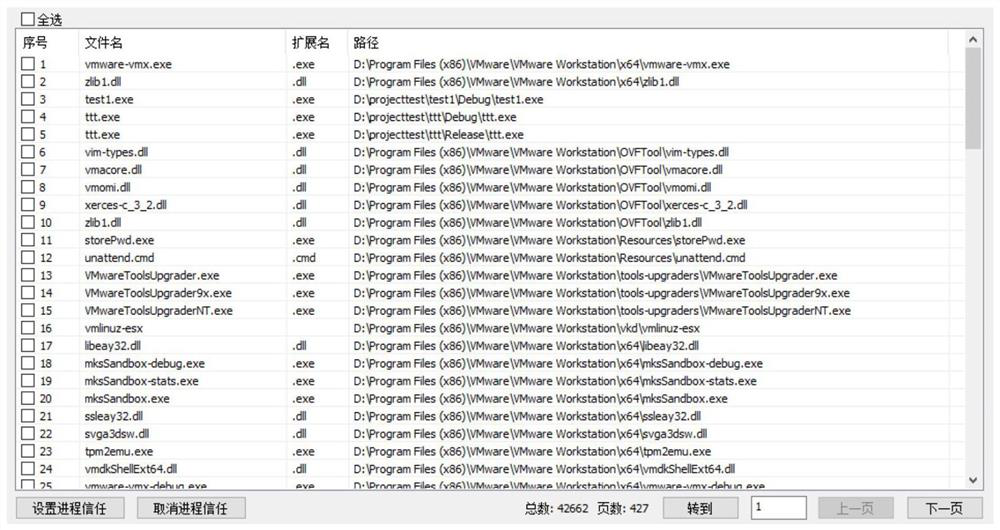

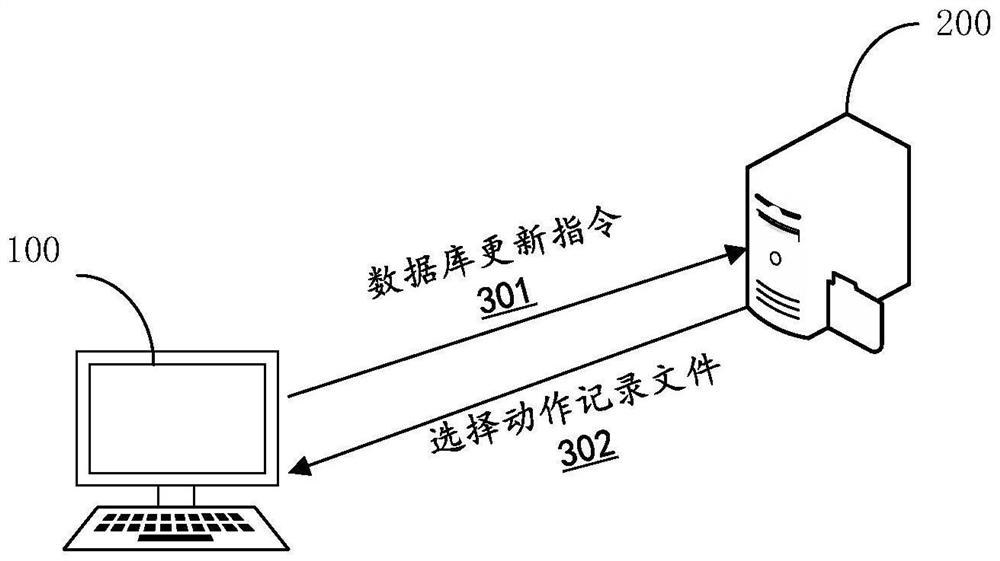

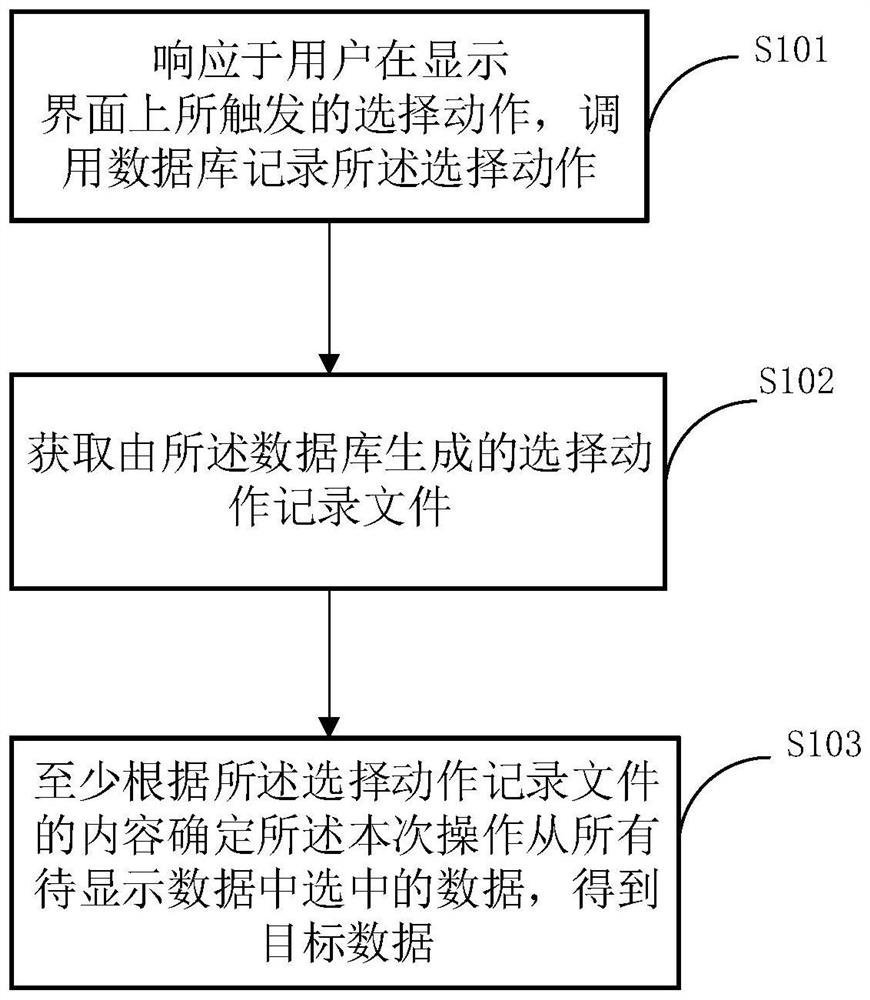

Data selection method and device

PendingCN114546566AFast updateProcessing speedDatabase updatingExecution for user interfacesData selectionEngineering

The embodiment of the invention provides a data selection method which comprises the following steps: in response to a selection action triggered by a user on a display interface, calling a database to record the selection action; a selection action recording file generated by the database is obtained, and the selection action recording file is used for recording all selection actions included in the operation; and at least according to the content of the selection action record file, determining data selected from all the to-be-selected data in the current operation to obtain target data. According to some embodiments of the invention, a method for recording the user selection action in real time by adopting the database is adopted, so that multi-page free selection of mass data of the display interface is realized, the software response rate during mass data selection is greatly improved, the system memory consumption is greatly reduced, and the user experience is enhanced.

Owner:BEIJING QIANXIN TECH +1

Broadband wire source for planar waveguide CTS antenna feed device

The invention discloses a broadband wire source for a planar waveguide CTS antenna feed device. The broadband wire source comprises an H-plane sectorial horn antenna, a bias parabolic reflection plane and a flat waveguide. The H-plane sectorial horn antenna and the bias parabolic reflection plane are arranged inside the flat waveguide, and the phase center of the H-plane sectorial horn antenna is arranged at the focus of the bias parabolic reflection plane. According to the invention, cylindrical waves are converted into plane waves, the plane waves are generated by using a reflector antenna principle, and the horn antenna is arranged at the focus of a paraboloid reflector so that a horn antenna radiation field passes through the reflector and generates the plane wave with equal amplitude and the same phase at the caliber surface of the reflector. The working frequency band is wide; the feed source shielding is eliminated and the caliber efficiency is enhanced through a bias; the structure is enclosed so that the edge diffraction effects of a conventional bias paraboloid are removed; and the structure is simple so that adjusting and assembling are easy, late use and maintenance are convenient, and the problem can be solved that the ideal wire source with equal amplitude and the same phase, generated by a conventional waveguide CTS antenna, cannot be realized in an actual project.

Owner:XIDIAN UNIV

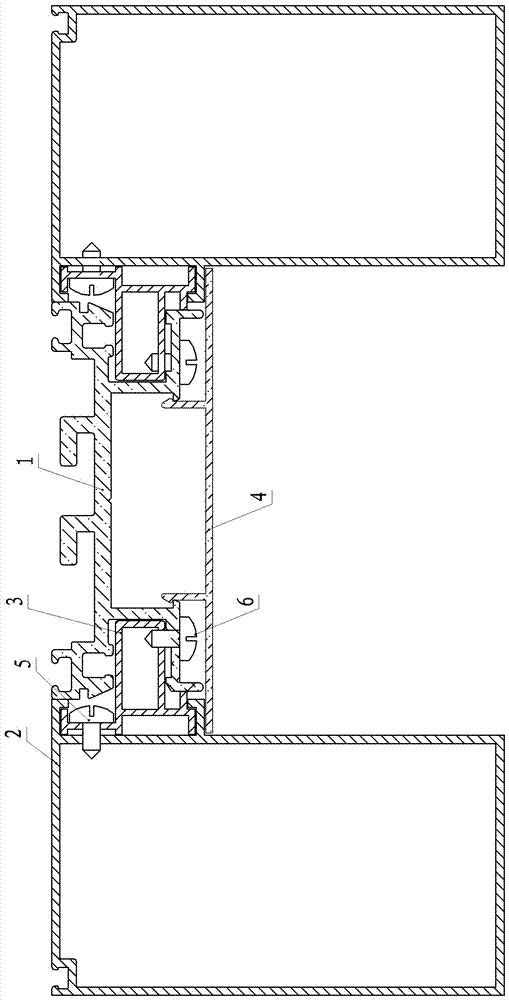

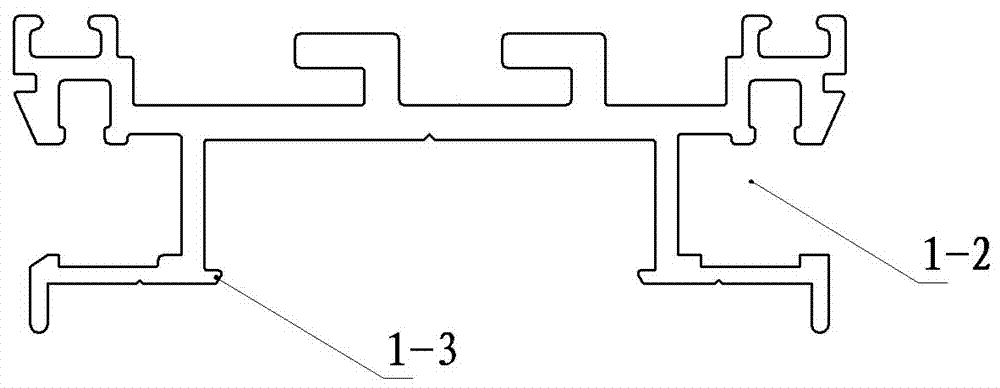

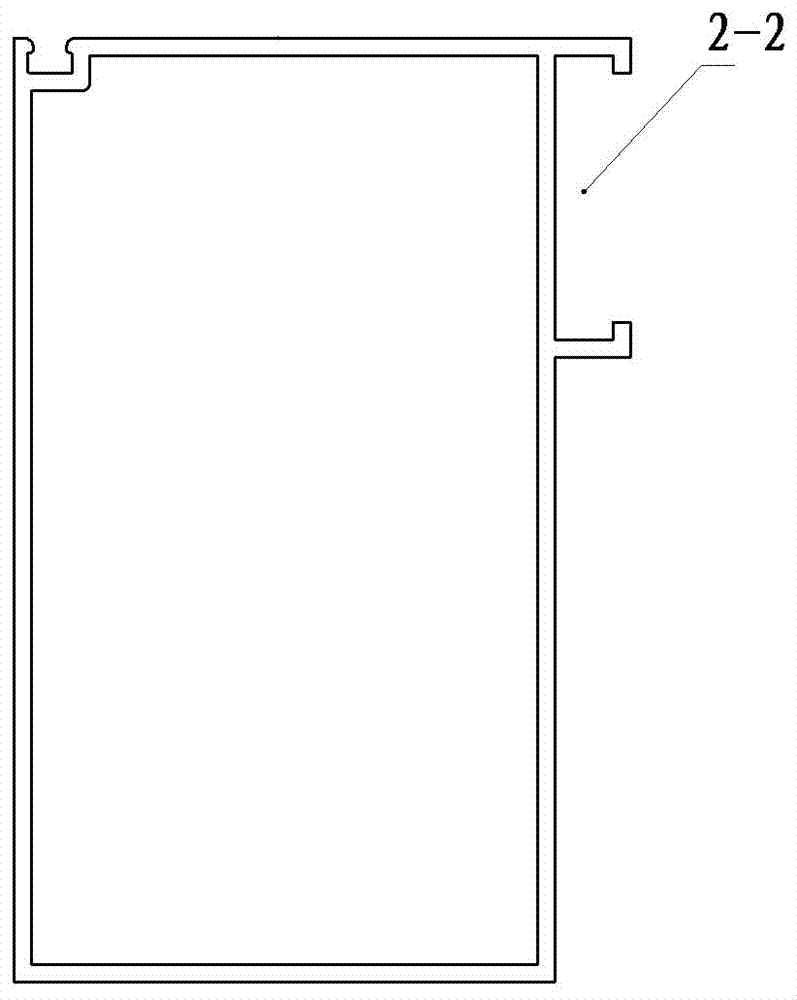

Thin-wall combined "concave" type exposed frame curtain wall exterior decoration profile

The invention discloses an outer decoration proximate matter of a thin-wall combined 'concave' type open frame curtain wall. The outer decoration proximate matter comprises a main body supporting piece, square tubular members symmetrically installed at both sides of the main body supporting piece through a connecting member, and a coverage plate covered on the outer surface of the main body supporting piece and situated between two square tubular members; the end part of one side face of the square tubular member closing to the main body supporting piece is provided with a T-shaped groove, and a matched connecting member is plugged in the T-shaped groove; the connecting member is inserted to the T-shaped groove through a chuck, and a bulge part perpendicular to the side face of the square tubular member is arranged on the side face of the connecting member; both sides of the main body supporting piece are respectively provided with symmetrical grooves, and the bulge part of the connecting member is inserted to the groove. The outer decoration proximate matter of the thin-wall combined 'concave' type open frame curtain wall effectively reduces cost of a big module in the process of manufacturing a big 'concave' shaped decoration line, and meets the demand of appearance decoration; the wall thickness of the proximate matter with thick wall of the big module proximate matter is replaced by thin wall of a small-sized material, and thereby the project material cost is reduced.

Owner:HENAN YEHAO CURTAIN WALL DECORATION ENG CO LTD

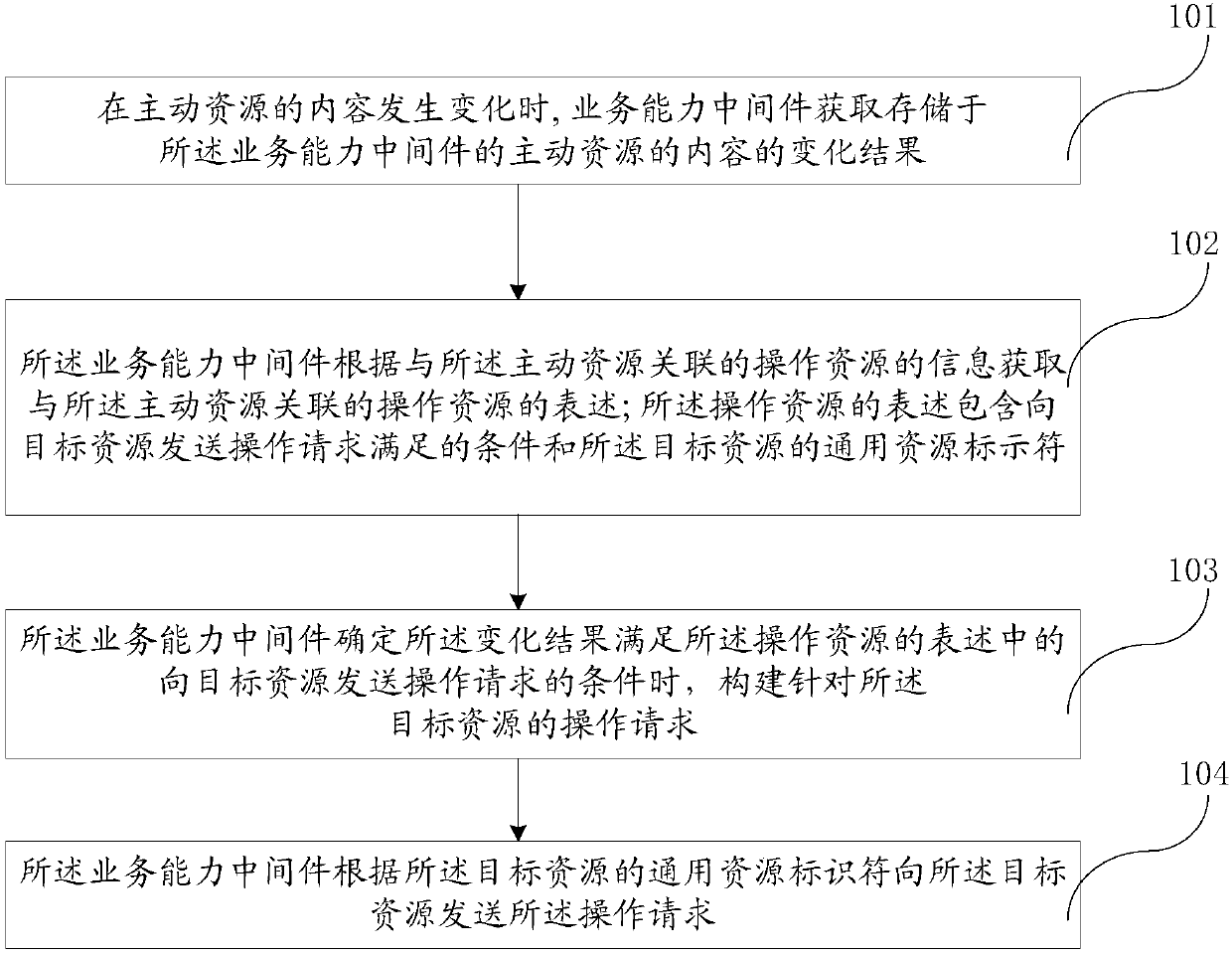

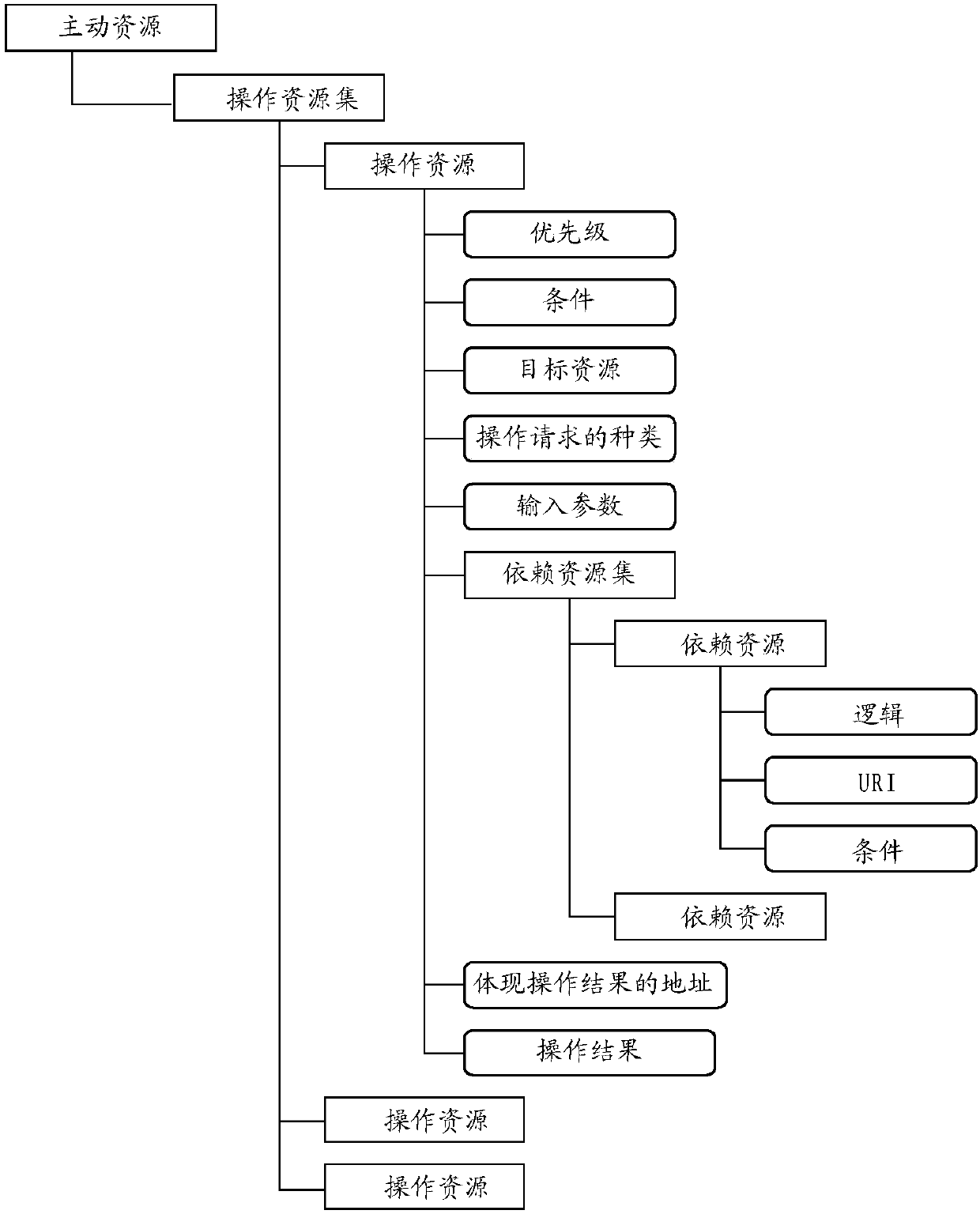

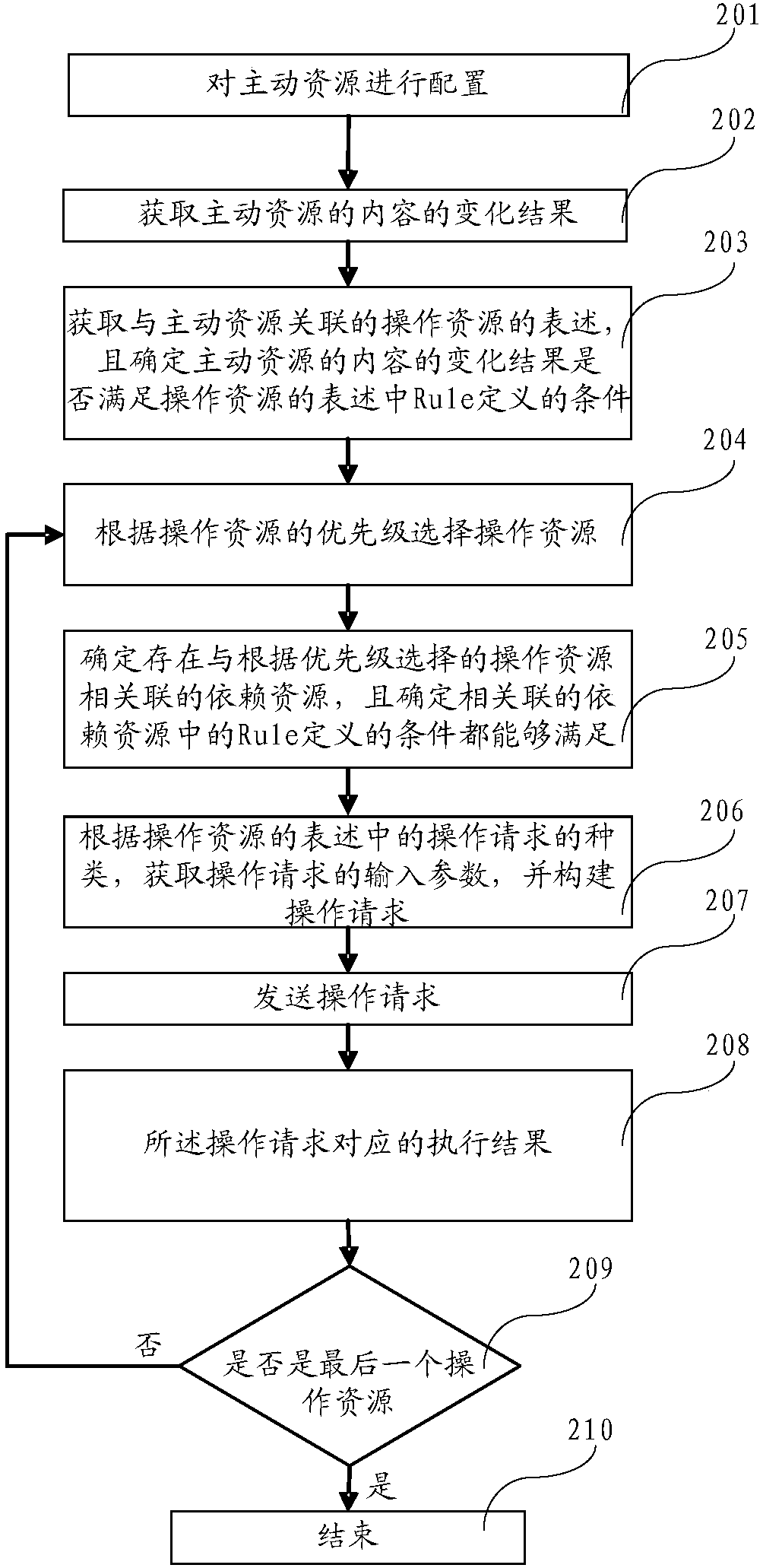

Machine communication operation triggering method and apparatus

InactiveCN107613011ASolve the impossibleAvoid complexityService provisioningInformation formatComputer scienceMiddleware

The invention provides a machine communication operation triggering method and apparatus. The method comprises the following steps: in the case of a change of contents of active resources, service ability middleware obtains a change result of the contents of the active resources stored in the service ability middleware; the service ability middleware obtains expression of operation resources associated with the active resources according to the information of the operation resources associated with the active resources, wherein the expression of the operation resources contains a condition ofsending an operation request to a target resource and a universal resource identifier of the target resource; the service ability middleware determines that the change result satisfies the condition of sending the operation request to the target resource in the expression of the operation resources, and constructs the operation request of the target resource; and the service ability middleware sends the operation request to the target resource according to the universal resource identifier of the target resource. The technical scheme of the invention can improve the stability of a triggering operation in an M2M system.

Owner:HUAWEI TECH CO LTD

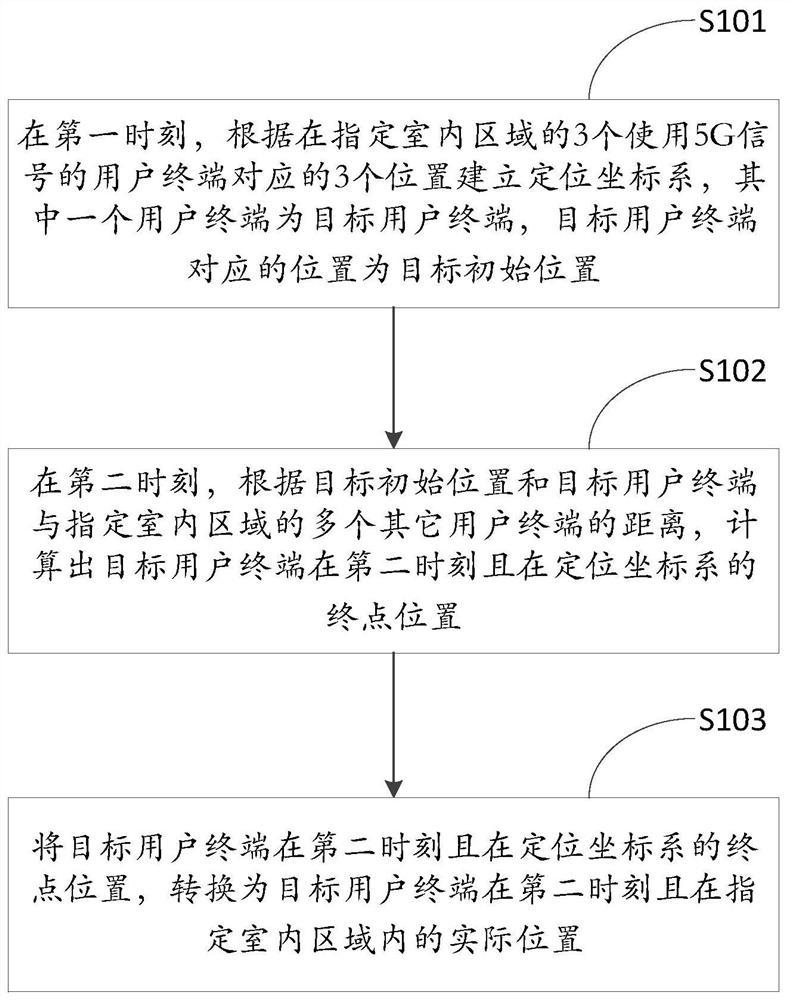

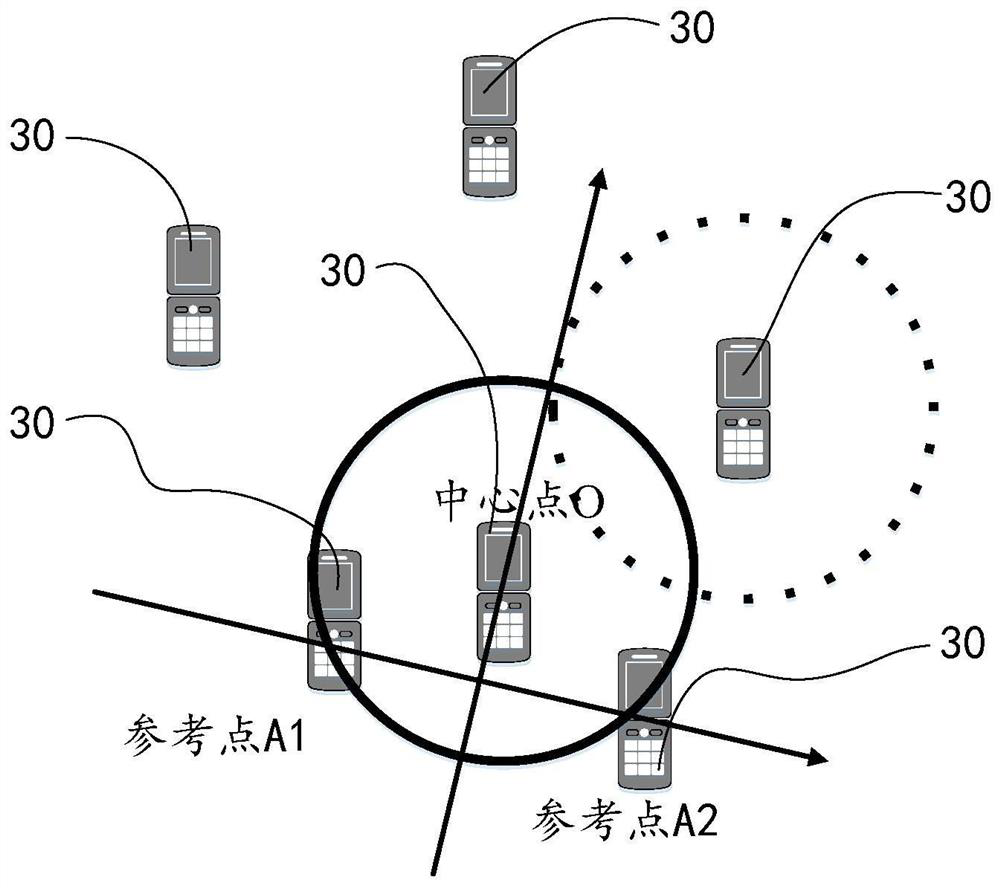

Multi-terminal indoor positioning method and device based on 5G signal

ActiveCN111263305BSolve the impossibleParticular environment based servicesPosition fixationComputer hardwareElectrical and Electronics engineering

The invention discloses a multi-terminal indoor positioning method and device based on 5G signals, wherein the positioning method includes: at the first moment, establishing positioning according to three positions corresponding to three user terminals using 5G signals in a designated indoor area A coordinate system, wherein one user terminal is a target user terminal, and the position corresponding to the target user terminal is the target initial position; at the second moment, according to the target initial position and the distance between the target user terminal and multiple other user terminals in the designated indoor area , calculate the end position of the target user terminal at the second moment and in the positioning coordinate system; convert the target user terminal at the second moment and the end position of the positioning coordinate system into the target user terminal at the second moment and at the specified Physical location within the indoor area. The present invention can realize high-precision positioning indoors without installing special positioning base stations and purchasing special positioning tags.

Owner:SHENZHEN SHUWEI MEDIA TECH CO LTD

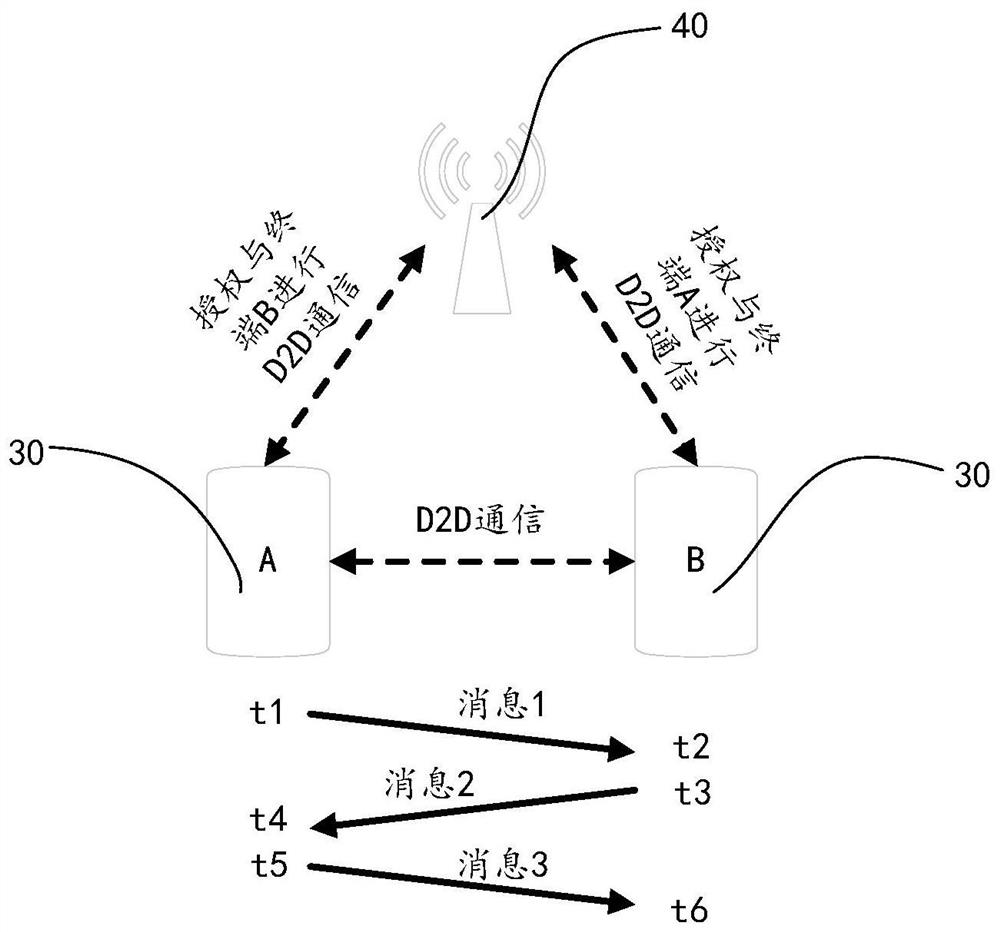

Distributed link aggregation method and device

ActiveCN103023814BAchieve aggregationSolve the problem that the aggregation cannot be realizedData switching networksComputer networkUniform system

The invention discloses a distributed link aggregation method and device. Wherein, the method includes: obtaining a unified distributed link aggregation system identification ID of multiple devices at the local end; sending the distributed link aggregation system ID to the opposite end, and distributing the distributed link aggregation system ID with the opposite end according to the distributed link aggregation system ID. type link aggregation negotiation. Through the present invention, the link aggregation of the distributed link aggregation system can be realized.

Owner:ZTE CORP

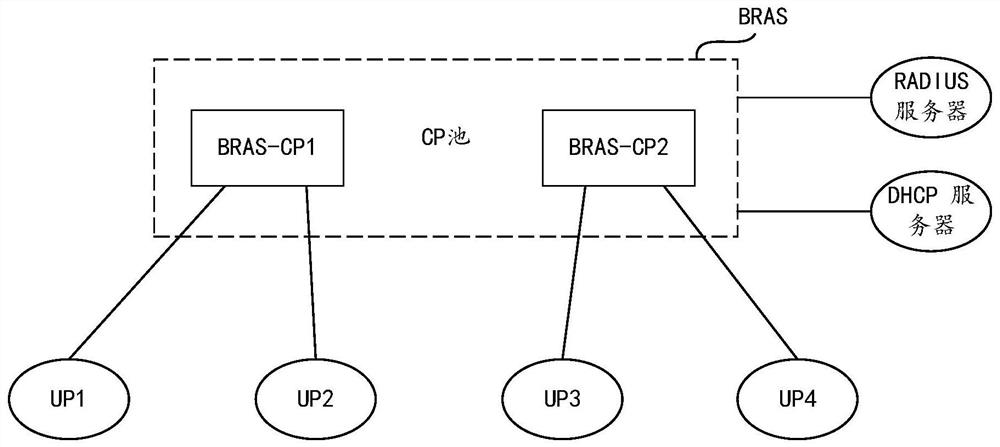

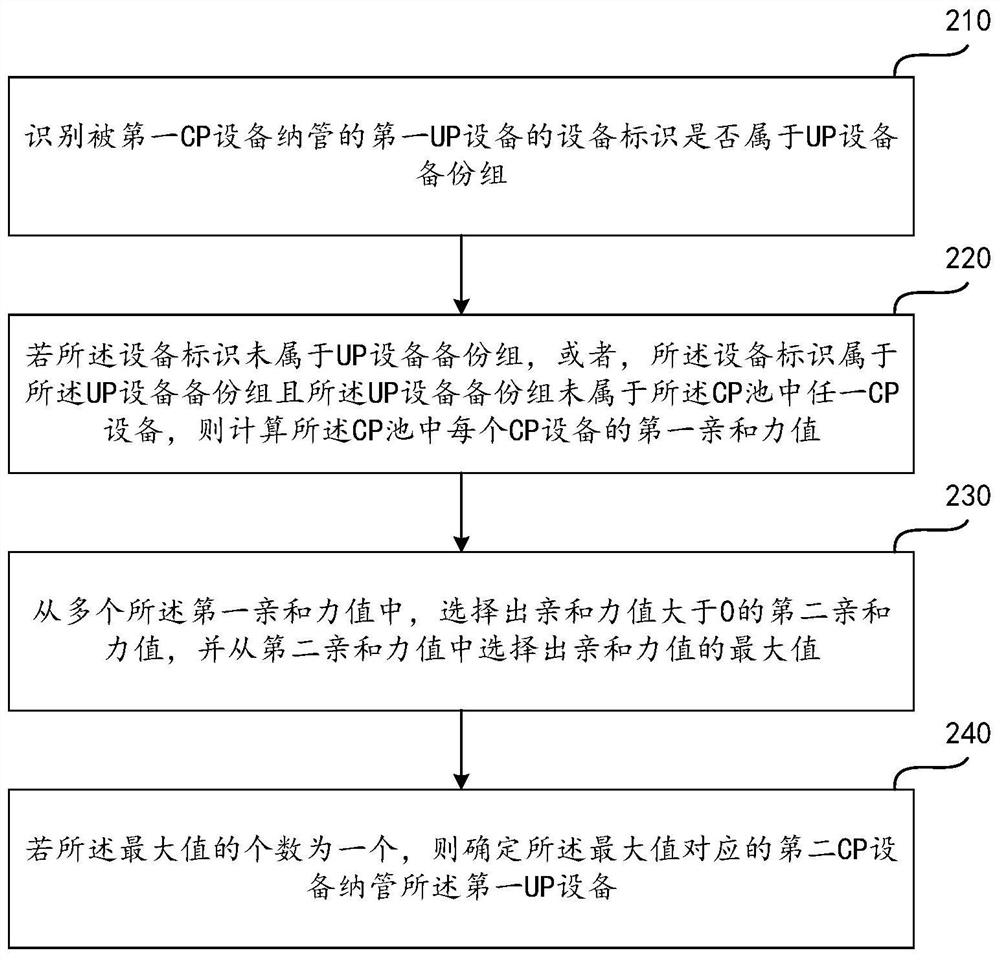

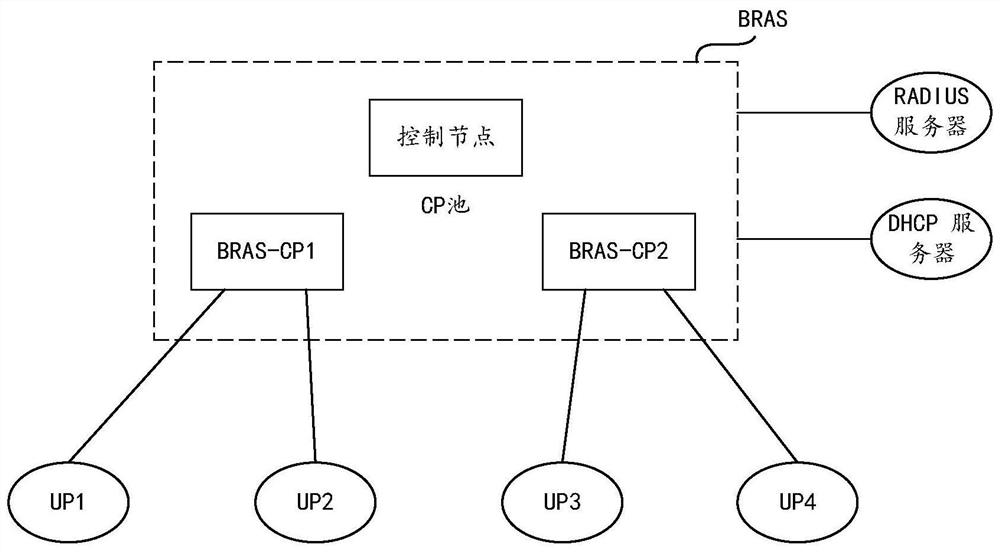

Network equipment migration method and device

ActiveCN112367197ASolve the impossibleImplement automatic migrationData switching networksComputer networkReal-time computing

The invention provides a network equipment migration method and device, the method is applied to a control node, the control node is located in a CP pool, the CP pool further comprises a plurality ofpieces of CP equipment, and the method comprises the following steps: identifying whether a device identifier of first UP equipment managed by the first CP equipment belongs to UP equipment backup group or not; if the equipment identifier does not belong to the UP equipment backup group, or the equipment identifier belongs to the UP equipment backup group and the UP equipment backup group does notbelong to any CP equipment in the CP pool, calculating a first affinity value of each CP equipment in the CP pool; selecting a second affinity value of which the affinity value is greater than 0 fromthe plurality of first affinity values, and selecting a maximum value of the affinity values from the second affinity values; and if the number of the maximum values is one, managing the first UP equipment through second CP equipment corresponding to the maximum value.

Owner:NEW H3C TECH CO LTD

A compound linear automatic printing machine

The invention provides a composite type linear full-automatic embossing machine. The composite-type linear full-automatic embossing machine is characterized by comprising an embossing system, a drying system, an upper clothing material taking auxiliary system and a ready-made clothing conveying system, wherein the ready-made clothing conveying system comprises two parallel linear guide rails which are arranged on a rack; an annular conveying belt is arranged between the guide rails, supported and unfolded by a driving synchronization wheel and a driven synchronization wheel which are respectively mounted at two ends of the rack; the driving synchronization wheel is connected with a motor by virtue of a transmission belt; a plurality of double-row embossing and conveying platens are uniformly arranged on the transmission belt; each double rows of embossing and conveying platens are taken as one group of embossing and conveying platens; two embossing and conveying table plates in each group are connected with each other by virtue of a connection bracket so as to form a whole body fixed at an equal interval; linear guide rail sliding blocks are respectively mounted under the two embossing and conveying platens in each group, so that each group of embossing and conveying platens stably and accurately run on the two parallel linear guide rails under the drive of the conveying belt.

Owner:李登峰

Self-cleaning mop sweeper

ActiveCN109998423BSolve the impossibleOvercome the disadvantage of mopping the floor more and more dirtyCarpet cleanersFloor cleanersRobotic armEngineering

Self-cleaning mopping sweeper, including body, yoke frame, yoke, mechanical arm, floor sweeper, mopping, mopping cleaning device, wiping pad cleaning device, garbage dumping mechanism, straightening device, and double-axis seat mechanism. The yoke frame is installed on the mast slideway in front of the body. The mopping cleaning device includes a mopping cleaning pool, a dehydration device, and a cleaning seat. The sweeper is controlled by the main engine and can climb from the pallet under the body to the ground, and sweep the floor in the low space under the sofa and counter. The fork arm lifts the chair and stool, and the jaws at the front end of the mechanical arm hold shoes and baskets, making it easier for the sweeper to sweep the floor below. The cleaning seat can pull out the dirty mop from under the sweeper, take it to the mop cleaning tank for cleaning and dehydration, and then insert the clean mop under the sweeper to make the mop cleaner. The handkerchief on the handkerchief seat can wipe tables, chairs, tea tables, and platens. The handkerchief seat takes the dirty handkerchief to the handkerchief washing pool for cleaning and dehydration. The cooperation of the fork arm and the clamping claw can dump the garbage in the dustbin in the floor sweeper. One machine with multiple functions.

Owner:SUINING CHANGFENG MECHANICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com