Staggered-tooth highlight milling cutter with chamfers and manufacturing method thereof

A manufacturing method and a technology of staggered teeth, applied to milling cutters, manufacturing tools, milling machine equipment, etc., can solve problems such as low processing efficiency, poor quality, and poor finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

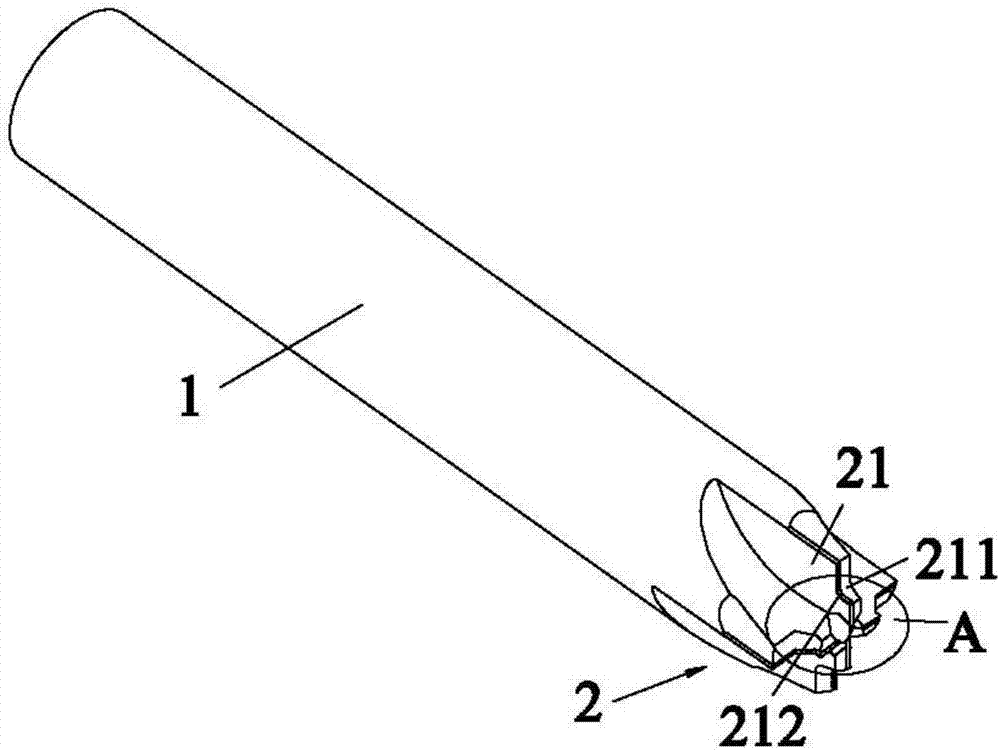

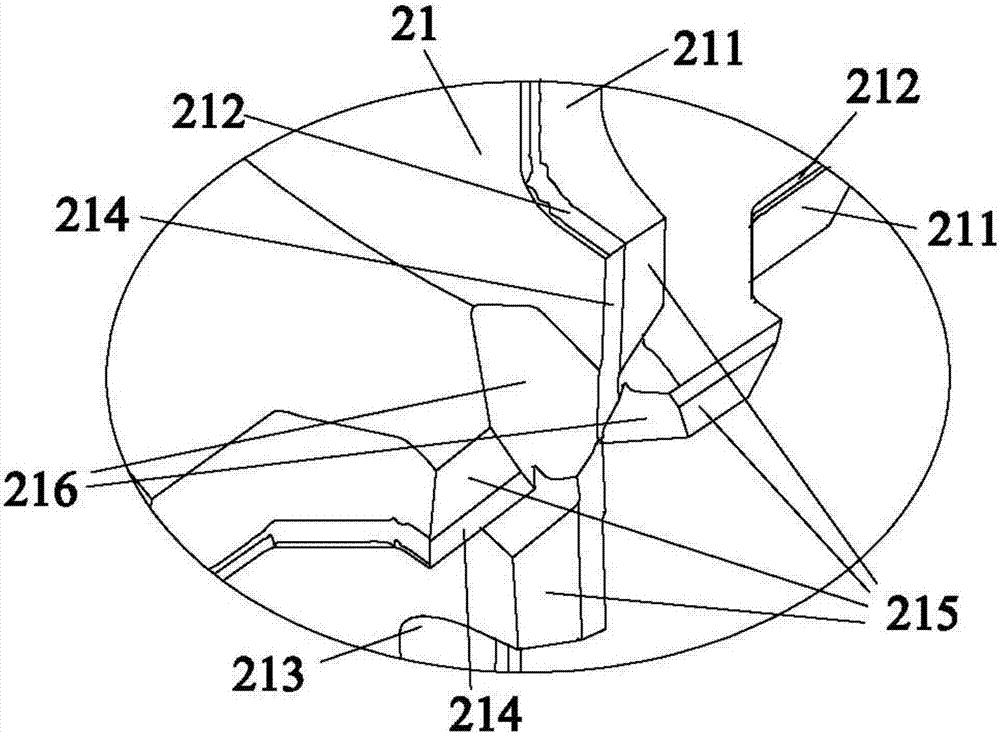

[0027] Such as Figure 1~2 As shown, a chamfered staggered-tooth high-gloss milling cutter includes a cutter bar 1 and a cutter head 2 integrally connected with the cutter bar 1. The cutter head 2 has several blades 21, and the number of blades 21 can be set as follows according to different requirements. Odd or even, each cutting edge 21 includes a step edge 211 and a wiper edge 212 connected to the step edge 211. The setting of the wiper edge 212 can enable the tool to meet the high finish requirements of the workpiece during use. The step edge 211 has Arc chamfering 213, arc chamfering 213 can be processed by the grinding wheel natural forming method and the contour trajectory method, the grinding wheel natural forming method: the contour is not programmed during edge cutting, and the required contour is obtained by interfering with the grinding wheel's own contour; Contour track method: the required contour can be achieved by program profiling during edge machining; the si...

Embodiment 2

[0032] A method for manufacturing a chamfered high-gloss milling cutter with staggered teeth in Embodiment 1, comprising the following steps:

[0033] Step 1. According to the processing requirements and effects of the above-mentioned staggered-tooth high-gloss milling cutter with chamfer, conduct design evaluation to determine whether the processing can be completed at one time, otherwise consider adopting the staggered-tooth structure;

[0034] Step 2. Complete the relevant drawing design and process documents;

[0035] Step 3. After receiving the material from the warehouse, use the manual step difference machine to carry out the step difference process of the above-mentioned high-gloss milling cutter with wrong teeth;

[0036] Step 4: After completing the step difference process, use a centerless grinder to control the outer diameter and process it to the required size;

[0037] Step 5. Use a laser laser machine to print a label on the outer diameter of the misaligned hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com