A compound linear automatic printing machine

A linear and fully automatic technology, applied in the field of garment printing and dyeing, can solve problems such as large requirements for the workplace, low work efficiency, and unguaranteed construction period, and achieve the effects of strong factory adaptability, stable printing quality, and reduced work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

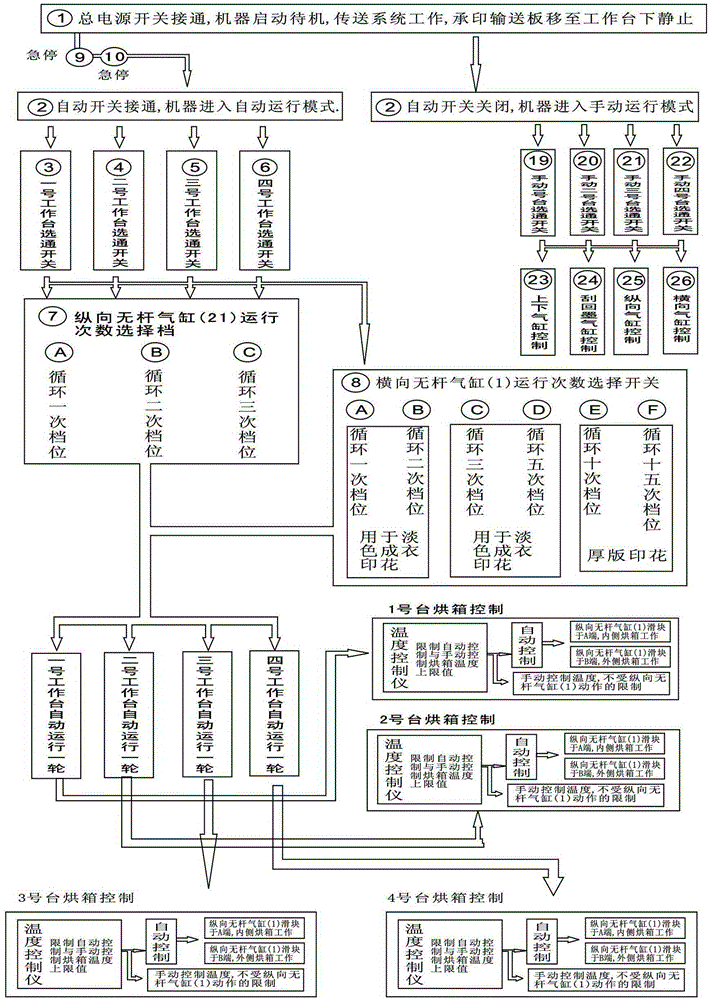

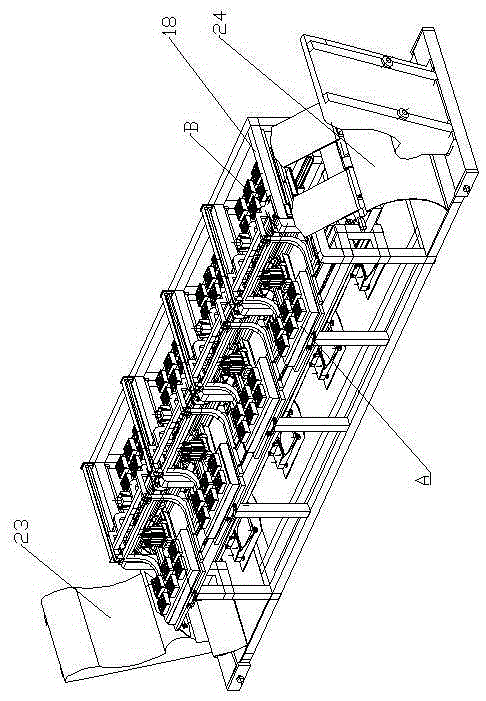

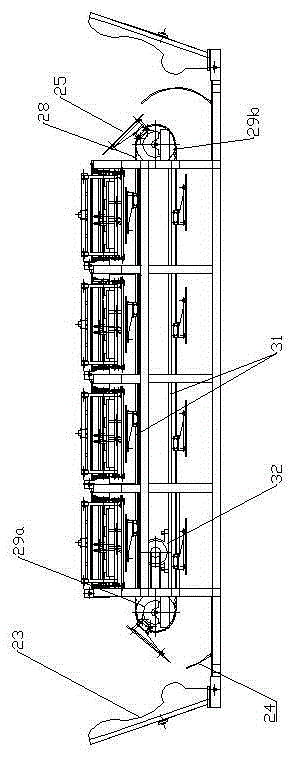

[0025] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 to attach Figure 5 ,

[0026] 1. The main power supply of the machine starts, the motor works, the motor drives the printing conveying table to the designated position, the printing table is in standby state, the up and down movement cylinder 16 is in the rising state, driving the printing component to be in the rising position, and the horizontal rodless cylinder 1 drives the printing component Put it at the near end position, and the vertical rodless cylinder 21 drives the ink scraper cylinder to be placed at the output end of the rack to stand by;

[0027] 2. The staff puts the clothes to be printed on the printing conveying table, and the automatic work starts. The printing conveying table is driven by the conveyor belt to move in a straight line. When the printing conveying table moves to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com