Method and device for judging emulsification generating position in long cementing tube

A technology of long cemented pipes and cemented pipes, which is applied in the direction of earthwork drilling, production fluid, wellbore/well parts, etc. It can solve the problems of large emulsification distance and the inability to judge the specific position of emulsification of oil and functional polymer solution, etc. To achieve a good guiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

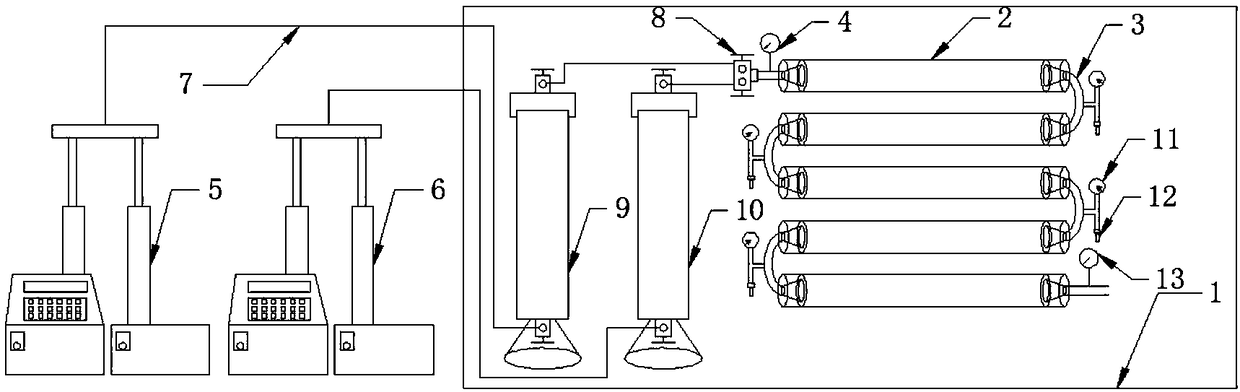

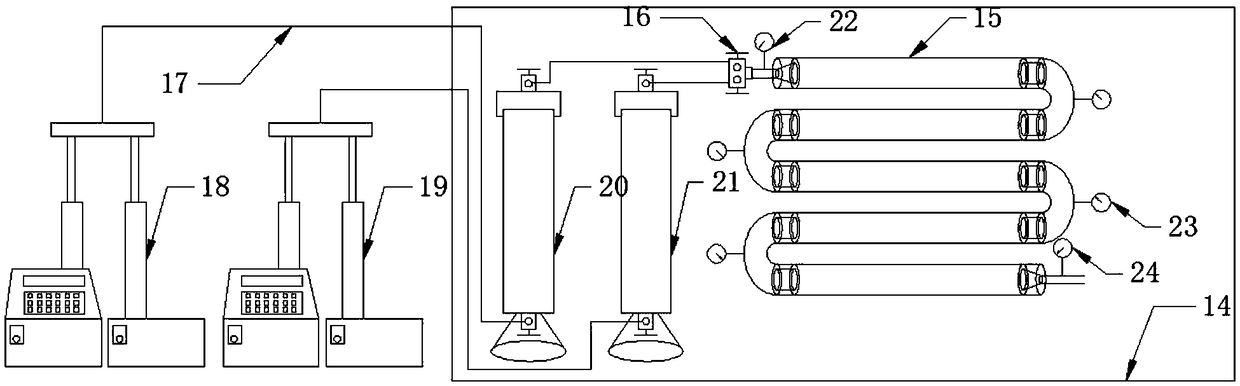

[0027] The device for realizing the present invention comprises a first constant temperature box 1, a second constant temperature box 14, a long cemented pipe simulation model 2 formed after a number of short cemented pipes are connected in series through curved connecting pipelines 3, a continuous curved long cemented pipe 15, The first injection end pressure gauge 4, the second injection end pressure gauge 22, the first displacement pump 5, the second displacement pump 6, the first oil injection piston container 9, the first functional polymer solution piston container 10, the second Three displacement pumps 18, a fourth displacement pump 19, a second oil injection piston container 20 and a second functional polymer solution injection piston container 21;

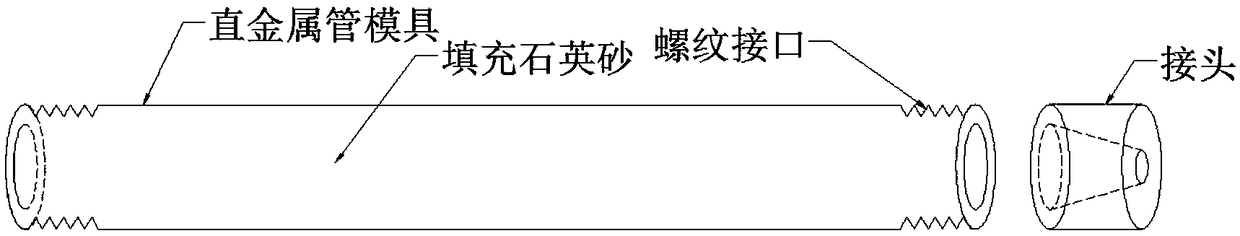

[0028] The short cemented pipe adopts a straight metal pipe mold with threaded joints at both ends, the straight met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com