The preparation method of hand tearing machine pressed Fu brick tea

A Fuzhuan brick tea, hand-tearing technology, applied in the processing field of Fuzhuan tea, to achieve the effect of eliminating the growth of bacteria, preventing mold infection, and increasing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

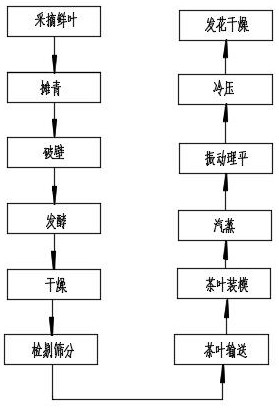

[0022] Embodiment: the preparation method of hand-tearing machine pressed Fu brick tea, including the preparation of hairy tea, tea transportation, steaming, pressing, flower drying,

[0023] The preparation of the hair tea: firstly spread the fresh leaves, spread the greens to a weight loss of 40-70%, preferably 50-65%, 55-60%, then put the green tea leaves into the squeeze container, and apply parallel The tea leaves are extruded into a translucent shape at least against the light, and then fermented and dried in a heap to make the black hair tea that maintains the original flat shape of the tea leaves.

[0024] After the steaming, the leaves are leveled and cooled, and the steamed tea leaves are put into the Fubrick tea mold box, and then placed on a vibrating table for vibration leveling, and the tea leaves that keep the original flat shape of the tea leaves are vibrated into a layer. Layer the tea leaves and cool to within 50°C.

[0025] The pressing is cold pressing, wh...

Embodiment 1

[0036] Example 1: The preparation method of Fu brick tea pressed by hand tearing machine, including the preparation of raw tea, tea transportation, steaming, pressing, and drying. %, and then put the green tea leaves into the squeeze container, and apply at least 250kg / cm 2 The parallel extrusion force is used to extrude the tea leaves to be at least translucent to the light, with a wall-breaking rate of 90%; and then fermented and dried in a heap to make black hair tea that maintains the original flat shape of the tea leaves; After the steaming, the leaves are leveled and cooled, and the steamed tea leaves are loaded into the Fuzhuan tea mold box, and then placed on a vibrating table for vibration leveling, and the tea leaves that keep the original flat shape of the tea leaves are vibrated into layers. The tea leaves are flattened and cooled to within 50 ° C; the pressing is cold pressing, which is to send the tea leaves after vibration, leveling and cooling together with the...

Embodiment 2

[0037] Example 2: The preparation method of pressed Fu brick tea by hand tearing machine, including the preparation of hairy tea, tea transportation, steaming, pressing, and drying. Green, spread the green tea until no tea juice flows out during the extrusion process, the weight loss rate of the tea leaves after spreading is 70%, and then put the green tea leaves into the extrusion container, and apply 320-400kg / cm 2Extrude with parallel extrusion force. When the extrusion reaches the required pressure, keep the pressure for 3-4 minutes, and squeeze the tea leaves into a transparent state at least against the light, with a wall-breaking rate of 96%. . Then enter the stacking fermentation, the stacking height is 60-80cm, the temperature is controlled within 45°C, and the stacking time is 24-48 hours before drying. The black hair tea keeps the original flat shape of the tea leaves; the dried tea leaves are removed from impurities and stalks, and then conveyed to steam by the vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com