Discharging method for high-temperature carbonized material

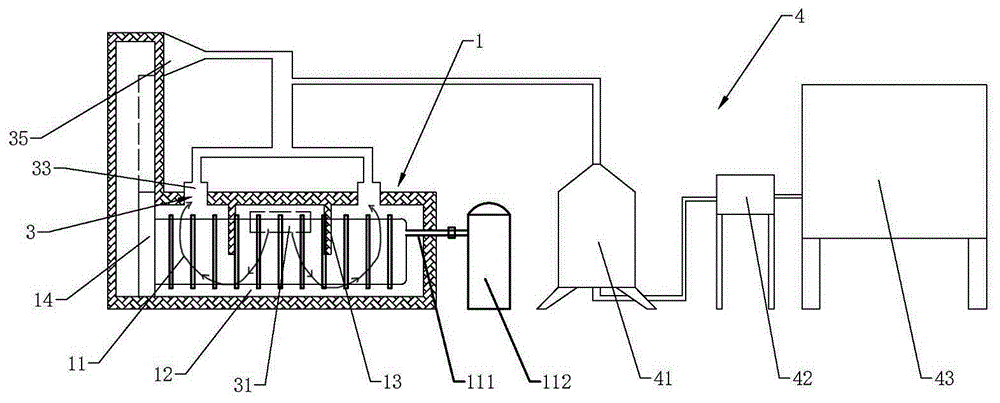

A high-temperature carbonization and carbonization technology, which is used in coke ovens, coke oven heating, combustible gas heating coke ovens, etc., can solve problems such as time-consuming, undisclosed high-temperature carbonization of animal carcasses, and difficulty in wastewater treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] The method for releasing the high-temperature carbide comprises the following steps:

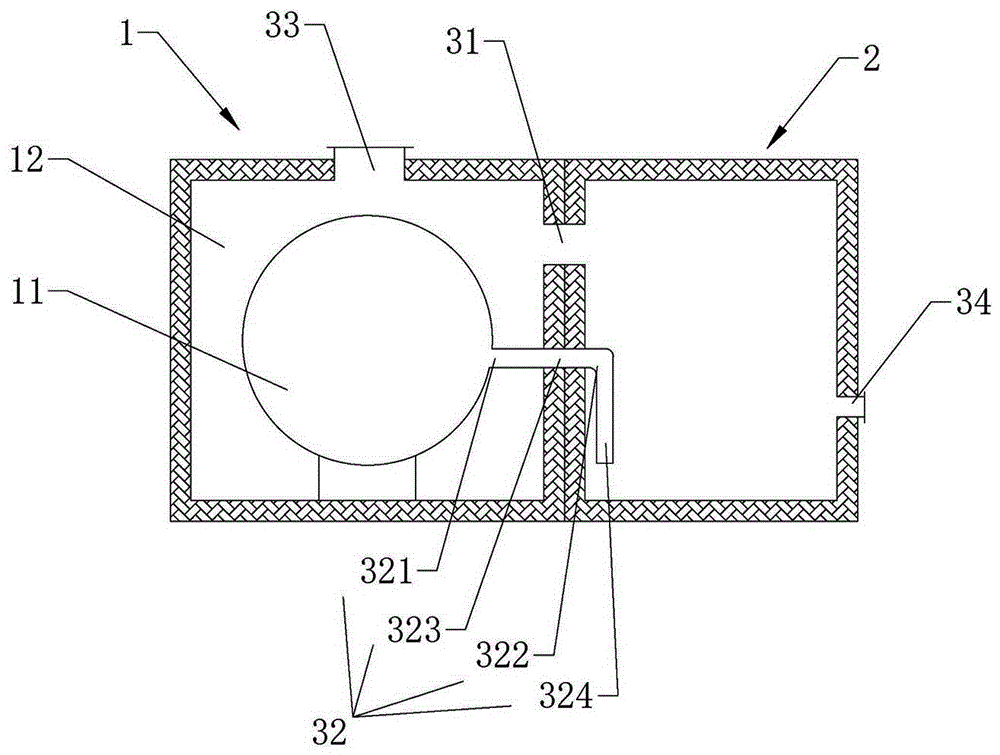

[0076] (1) Gas replacement: After the animal carcass carbonization process is completed, nitrogen gas is introduced into the carbonization tank 11 immediately, and the nitrogen gas with a purity of more than 99.5% is used to replace the flammable pyrolysis gas in the carbonization tank 11; the gas replacement is carried out through the gas Passage 3 is completed; taking the carbonization tank as an example of 8 cubic meters, the gas replacement is required to be completed within 10-20 minutes;

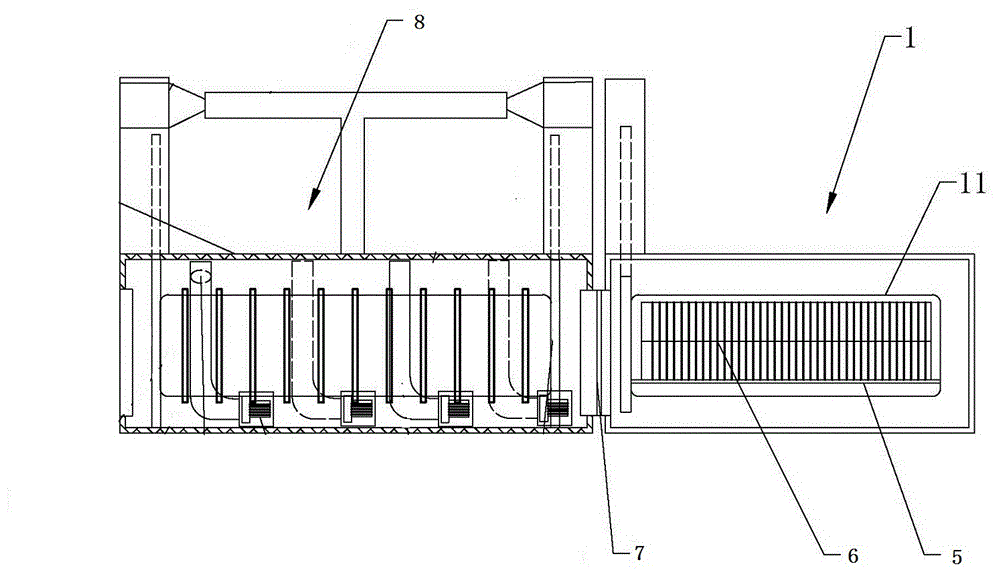

[0077] (2) Temperature-controlled start-up: After the temperature in the carbonization furnace 1 drops below 530°C, the carbonization furnace 1 is turned on, so that the high-temperature carbonized products in the carbonization tank 11 are released and sent to the cooling chamber 8 .

Embodiment 2

[0079] The pyrolysis and carbonization process is carried out in the carbonization furnace 1. The carbonization process includes pyrolysis and carbonization of dead animal corpses under the conditions of oxygen isolation, normal pressure and 600°C; The gas is automatically output to the combustion chamber 2 and burned at 1300°C for 2s. The high-temperature flue gas generated by the combustion provides energy to support pyrolysis and carbonization, and realizes the recovery and utilization of heat energy of the pyrolysis gas.

[0080] The method for releasing the high-temperature carbide comprises the following steps:

[0081] (1) Gas replacement: Immediately after the carbonization process of the animal corpse, helium gas is introduced into the carbonization tank 11, and the helium is used to replace the flammable pyrolysis gas in the carbonization tank 11; the gas replacement is completed through the gas passage 3;

[0082] (2) Temperature-controlled start-up: After the tempe...

Embodiment 3

[0084] The pyrolysis and carbonization process is carried out in the carbonization furnace 1. The carbonization process includes pyrolysis and carbonization of dead animal corpses under the conditions of oxygen isolation, normal pressure and 300°C; The gas is automatically output to the combustion chamber 2 and burned at 800°C for 2s. The high-temperature flue gas generated by the combustion provides energy to support pyrolysis and carbonization, and realizes the heat energy recovery and utilization of the pyrolysis gas.

[0085] The method for releasing the high-temperature carbide comprises the following steps:

[0086] (1) Gas replacement: Immediately after the carbonization process of the animal corpse, argon gas is introduced into the carbonization tank 11, and the argon gas is used to replace the flammable pyrolysis gas in the carbonization tank 11; the gas replacement is completed through the gas passage 3;

[0087] (2) Temperature-controlled start-up: After the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com