Super-capacitor module

A technology of supercapacitor modules and capacitors, applied in multiple hybrid/electric double layer capacitors, protection/regulating hybrid/electric double layer capacitors, hybrid boxes/casings/packages, etc. Reliability, hidden dangers, fail-safe and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

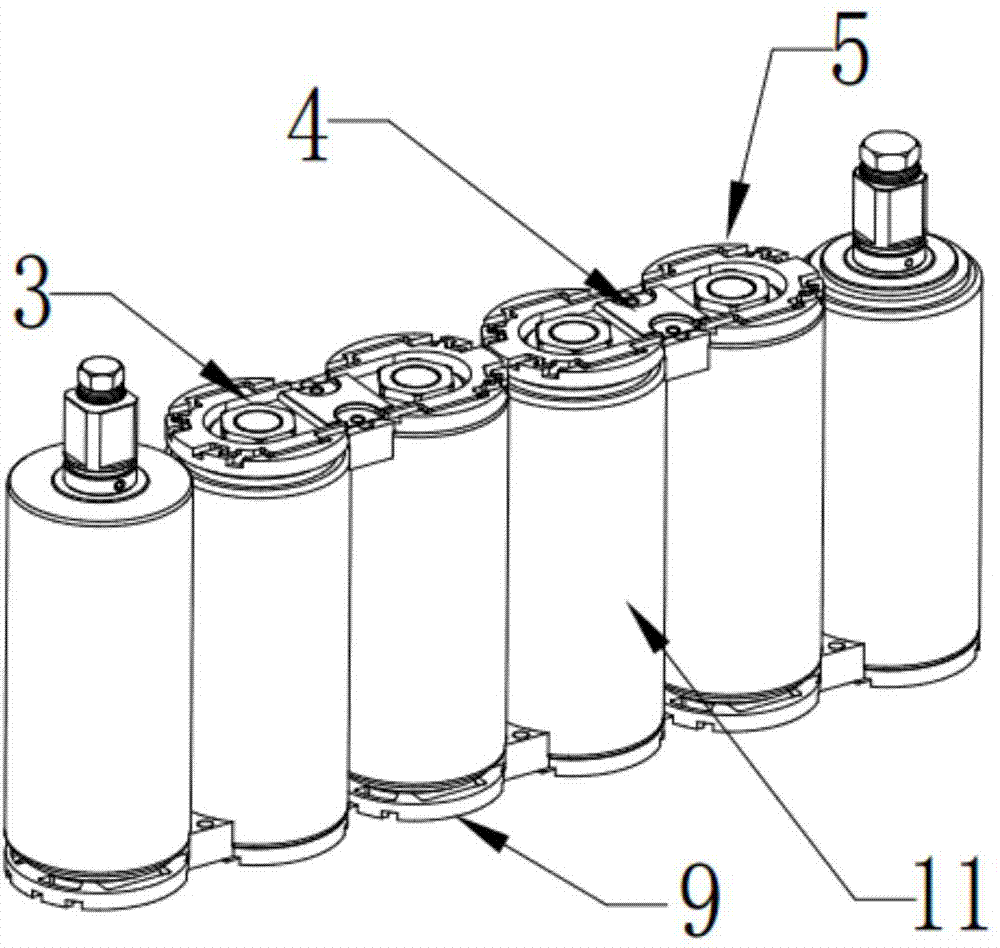

[0030] Such as Figure 1-2 As shown, the supercapacitor module of this embodiment includes:

[0031] 6 individual capacitors 11 arranged in rows and columns are connected in series through conductive connecting sheets 4, such as figure 1 shown.

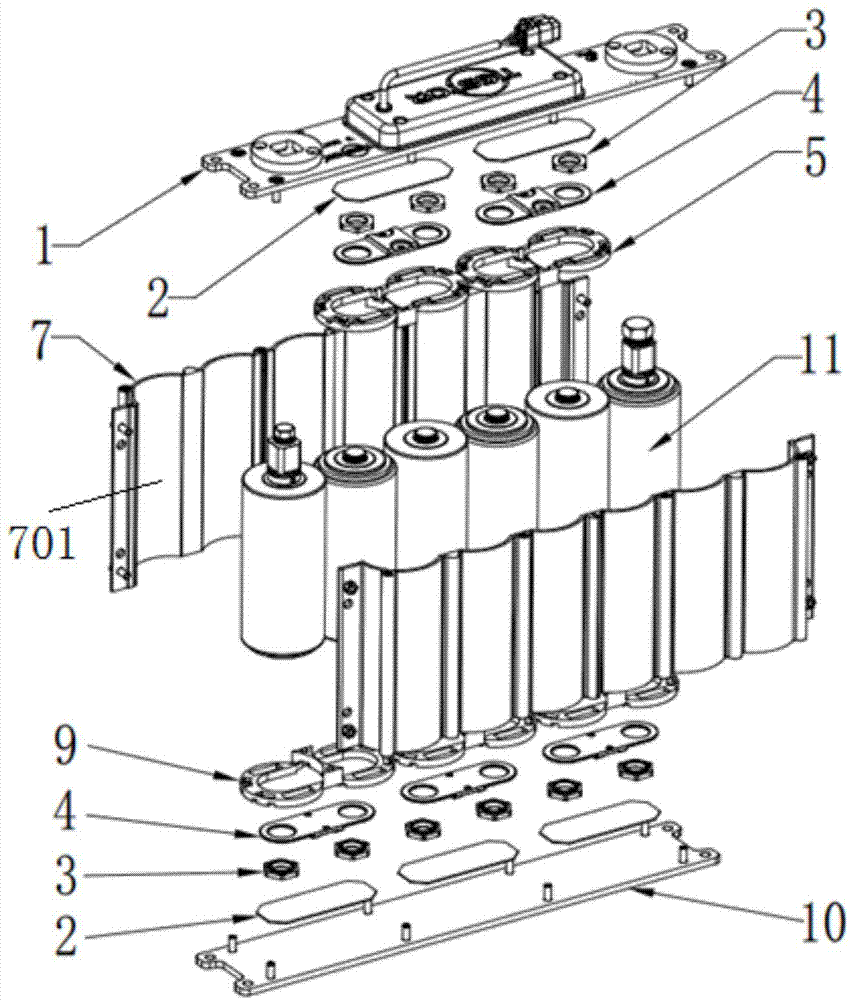

[0032] The upper cover plate 1 and the lower cover plate 10 with heat dissipation function: they are respectively arranged at the two ends of the six single capacitors.

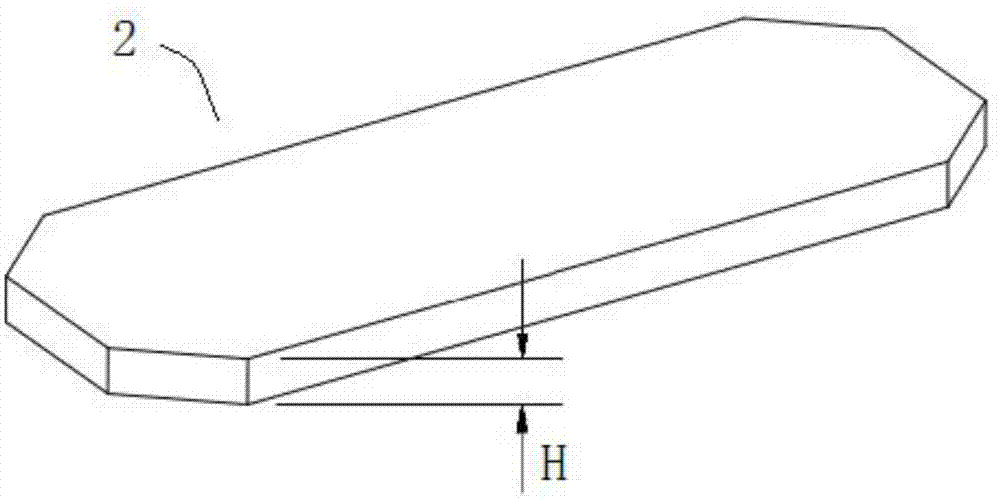

[0033] A plurality of insulating and heat-conducting sheets 2: used to electrically insulate between the upper cover plate 1 and the lower cover plate 10 and the conductive connecting sheet 4, and dissipate the heat on the conductive connecting sheet 4 (each single capacitor 11 generated) to the upper cover 1 and the lower cover 10 to dissipate heat.

[0034] The upper guard plate 5 and the lower guard plate 9 : are arranged at both ends of the six single capacitors 11 arranged in rows and columns, and are provided with a plurality of through holes that can expose...

Embodiment 2

[0039] Such as Figure 3-8 As shown, the difference between this embodiment and Embodiment 1 is mainly that there are 18 single capacitors 11 arranged in rows and columns in this embodiment, which are arranged in three rows and fixed by a pair of side fixing plates 7 and a pair of side fixing plates 7. Plates 8 are fastened together (as in image 3shown), two of the side fixing plates 7 are respectively in the shape of "[" and "]" that match each other, and two of the fixing plates 8 are also in the shape of "[" and "]" that match each other. ]” shape, a total of four side fixing plates are buckled on the four sides of the supercapacitor module respectively, and two side fixing plates 7 are connected to two adjacent side fixing plates 7 respectively.

[0040] In addition, in this embodiment, a plurality of supporting parts 6 are also included, which are used to connect the upper cover 1 and the lower cover 10, and limit the relative position between the upper cover 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com