Pure electric vehicle remote power battery heating system and control method thereof

A pure electric vehicle and power battery technology, applied in the field of pure electric vehicle remote power battery heating system and its control, can solve the problems of poor safety and poor control logic, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

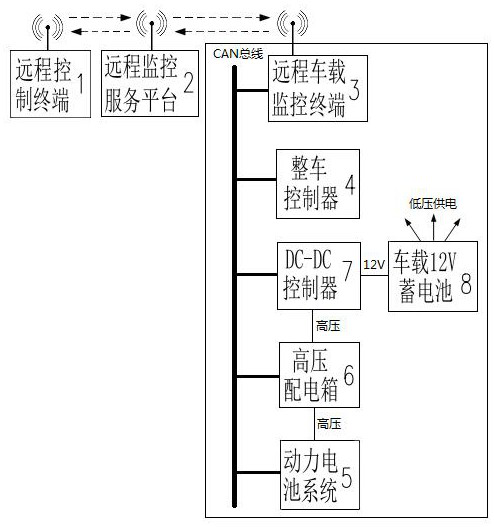

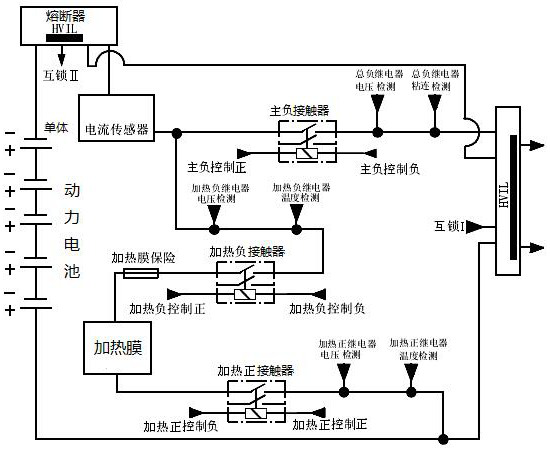

[0093] A remote power battery heating system for pure electric vehicles. The remote power battery heating system includes: a remote control terminal 1, a remote monitoring service platform 2, a remote vehicle monitoring terminal 3 and a vehicle controller 4. The remote control terminal 1 passes The telecom operator network is wirelessly connected to the remote monitoring service platform 2, the remote monitoring service platform 2 is wirelessly connected to the remote vehicle monitoring terminal 3 through the telecom operator network, the remote vehicle monitoring terminal 3, the vehicle controller 4, the power battery The system 5, the high-voltage distribution box 6, and the DC-DC controller 7 are all connected to the CAN bus signal, and the positive and negative poles of the power battery system 5 are connected to the positive and negative poles of the main power distribution interface of the high-voltage power distribution box 6 through high-voltage cables. The positive and...

Embodiment 2

[0118] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0119] The remote monitoring service platform 2 obtains and stores the remaining battery power SOC, cell temperature, cell voltage, total voltage, current, heating duration, and heating state data of the power battery system 5 on the vehicle through the remote vehicle monitoring terminal 3;

[0120] The remote control terminal 1 is a mobile phone with a remote heating program APP installed and a device with the function of connecting to the network of a telecom operator; the remote control terminal 1 can query the remote monitoring service platform 2 for the remaining battery power of the power battery system 5 on its corresponding vehicle , cell temperature, cell voltage, total voltage, current, heating duration, and heating state data information, the remote control terminal 1 can send instructions to the corresponding remote vehicle monitoring terminal 3 for battery heating to be turned on an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com