Marker

A scribing device and scribing wheel technology, applied to workshop equipment, manufacturing tools, etc., can solve the problems of wasting plates, prolonging working hours, and increasing costs, achieving high scribing accuracy, overcoming low accuracy, and improving The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution and structure of the present invention will be described below in conjunction with the accompanying drawings, so as to facilitate the understanding of those skilled in the art.

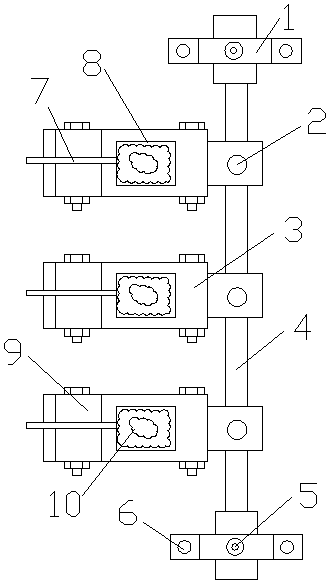

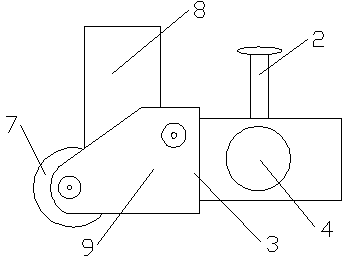

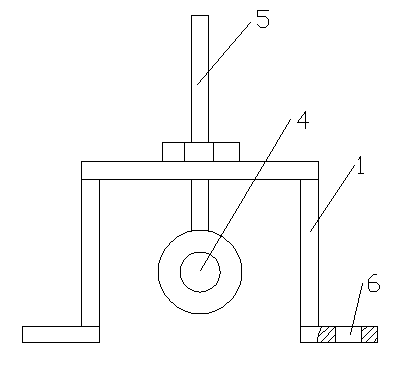

[0024] like figure 1 Shown, a kind of scribing device comprises mount 1 and scribing device 9, and described scribing device 9 comprises scribing wheel 7, and ink cartridge 8 is connected on the described scribing wheel 7, and described scribing wheel 7 and A fixing seat 3 is arranged outside the ink cartridge 8 , and a fixing rod 4 is connected to the fixing seat 3 , and mounting seats 1 are arranged at both ends of the fixing rod 4 .

[0025] like figure 1 and figure 2 As shown, the fixed rod 4 is sleeved with more than one fixed seat 3, the fixed seat 3 can move on the fixed rod 4, the connection between the fixed seat 3 and the fixed rod 4 is provided with a fastening screw 2, and the ink cartridge is provided with Be stained with the cotton cloth 10 of Chinese in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com