A flexible variable absorbing layer of thickness and its preparation and use method

An absorbing layer and flexible technology, applied in the field of flexible and variable thickness absorbing layer, can solve the problems of peeling, weakening the surface performance of the workpiece, and the inability to achieve uniform strengthening, etc., and achieve the effect of simple manufacturing process, low cost and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited to the examples.

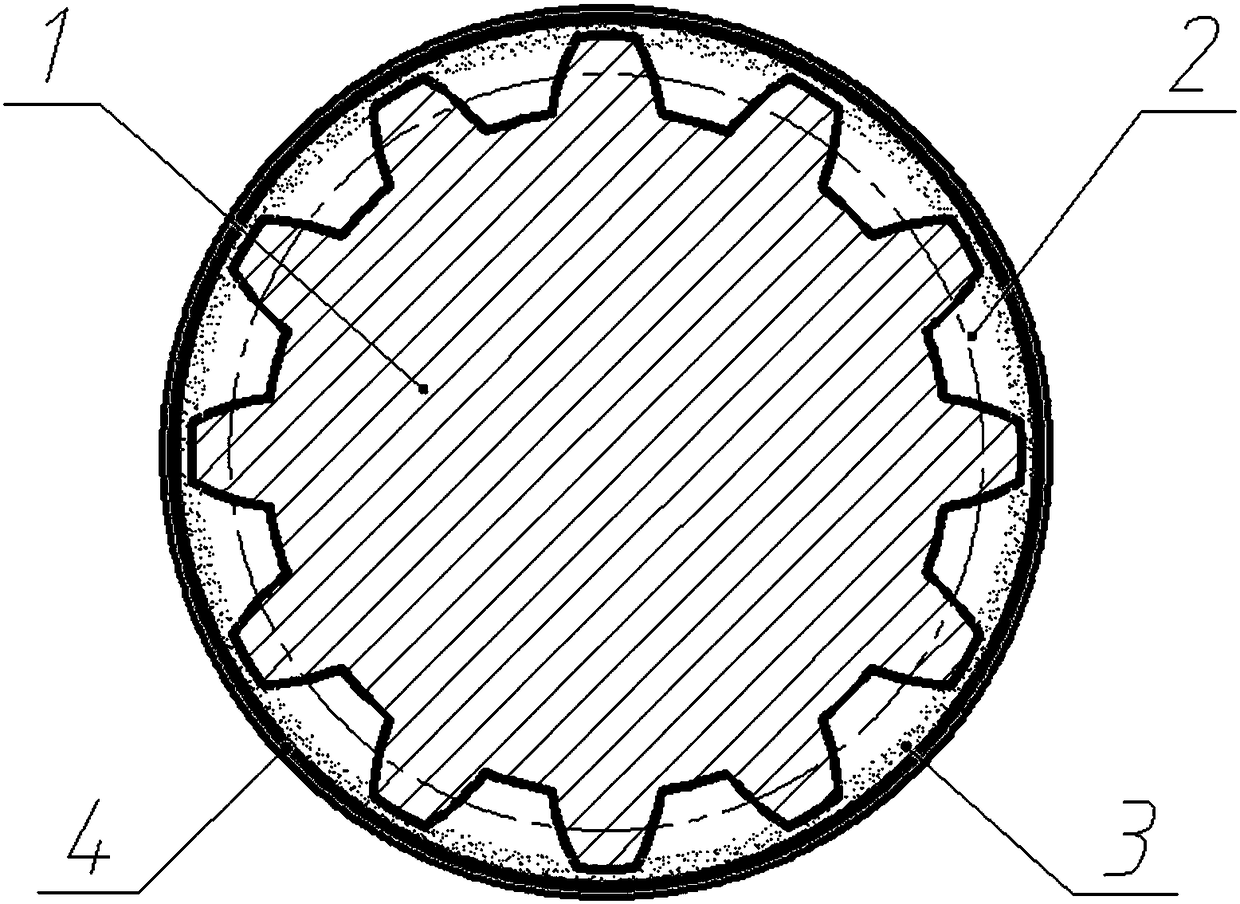

[0034] This embodiment adopts a small-pitch gear made of 304 stainless steel used at the engine end of an automobile, and its geometric dimensions are: number of teeth 50, modulus 1 mm, pitch 3 mm, and full tooth height 3 mm.

[0035] An example of using the above-mentioned workpiece for laser shock strengthening, the specific steps are:

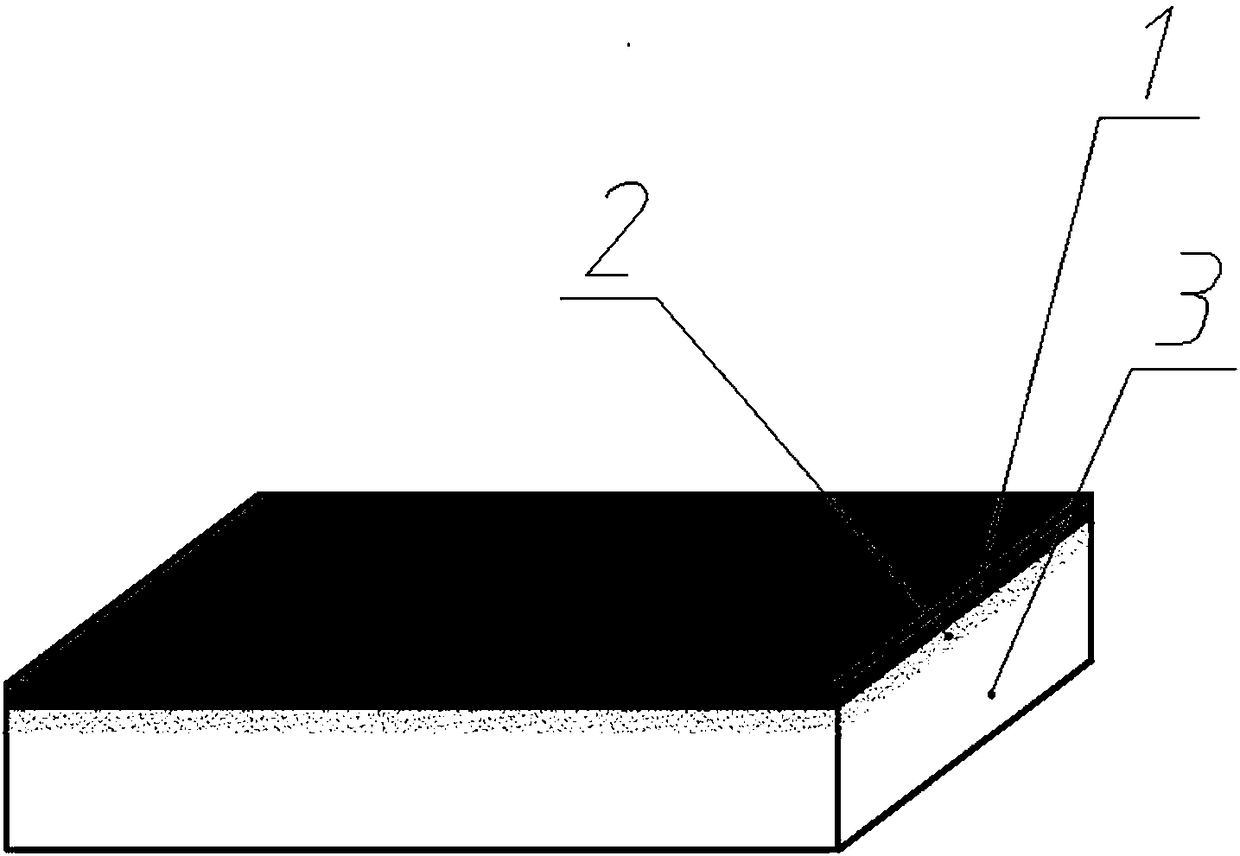

[0036] (1) Mix the M and N components of the GN-521D two-component silicone gel according to the volume ratio of 1:1, stir well, and then pour it into a mold made of plexiglass, with a thickness of 1.8mm .

[0037] (2) Spread the G-901 type PVC sol on the surface of the above-mentioned silicone gel, and its thickness is 0.3mm.

[0038] (3) Spread the ZJ-460 type acrylic resin mixed with black pigment on the surface of the above-mentioned PVC sol, and its thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com