Miniature dehydrator

A dehydrator and micro technology, applied in the field of mechanical equipment, can solve the problems of unreasonable structure, large floor space and inconvenient maintenance of dehydrator, and achieve the effect of compact structure, small floor space and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

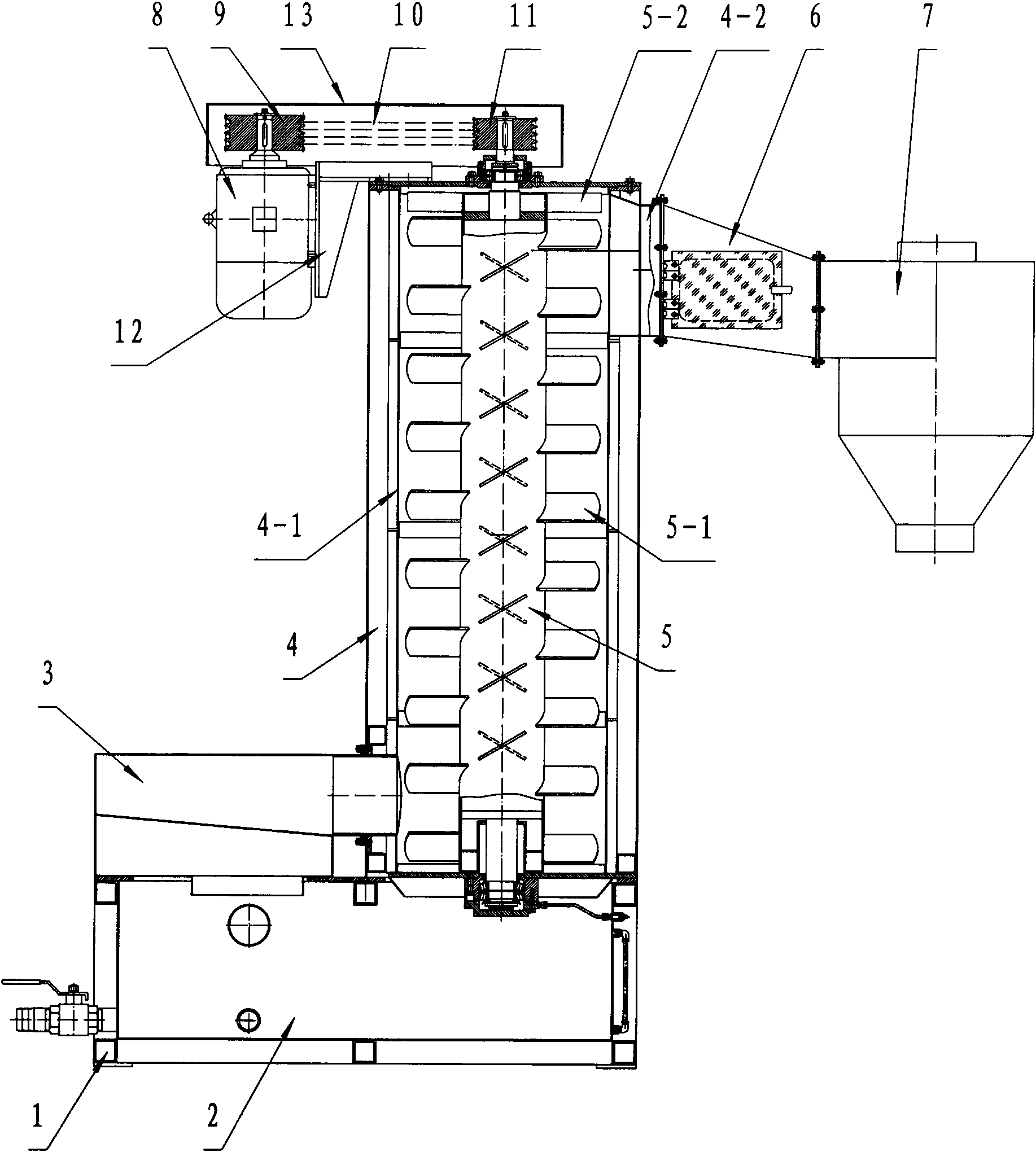

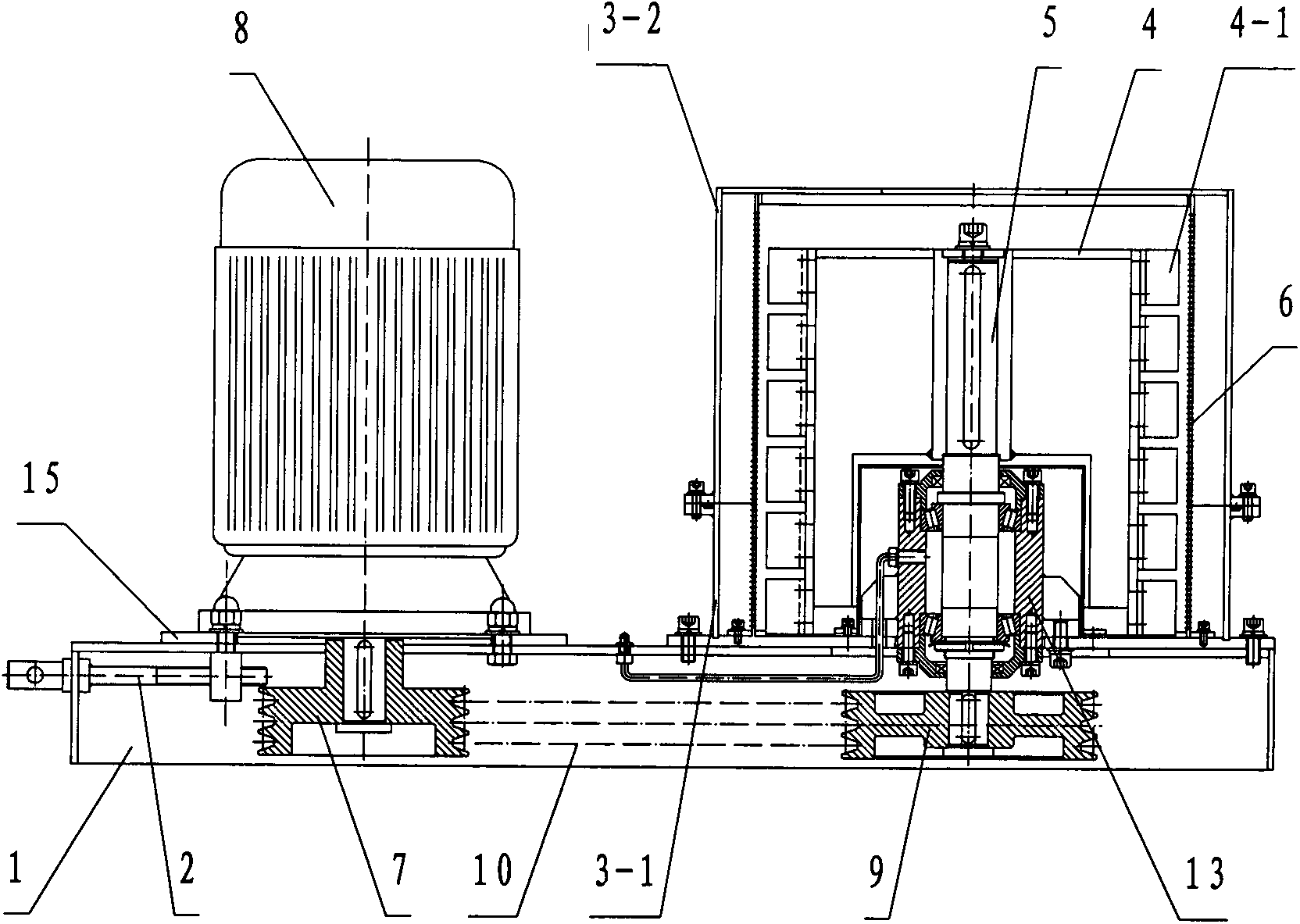

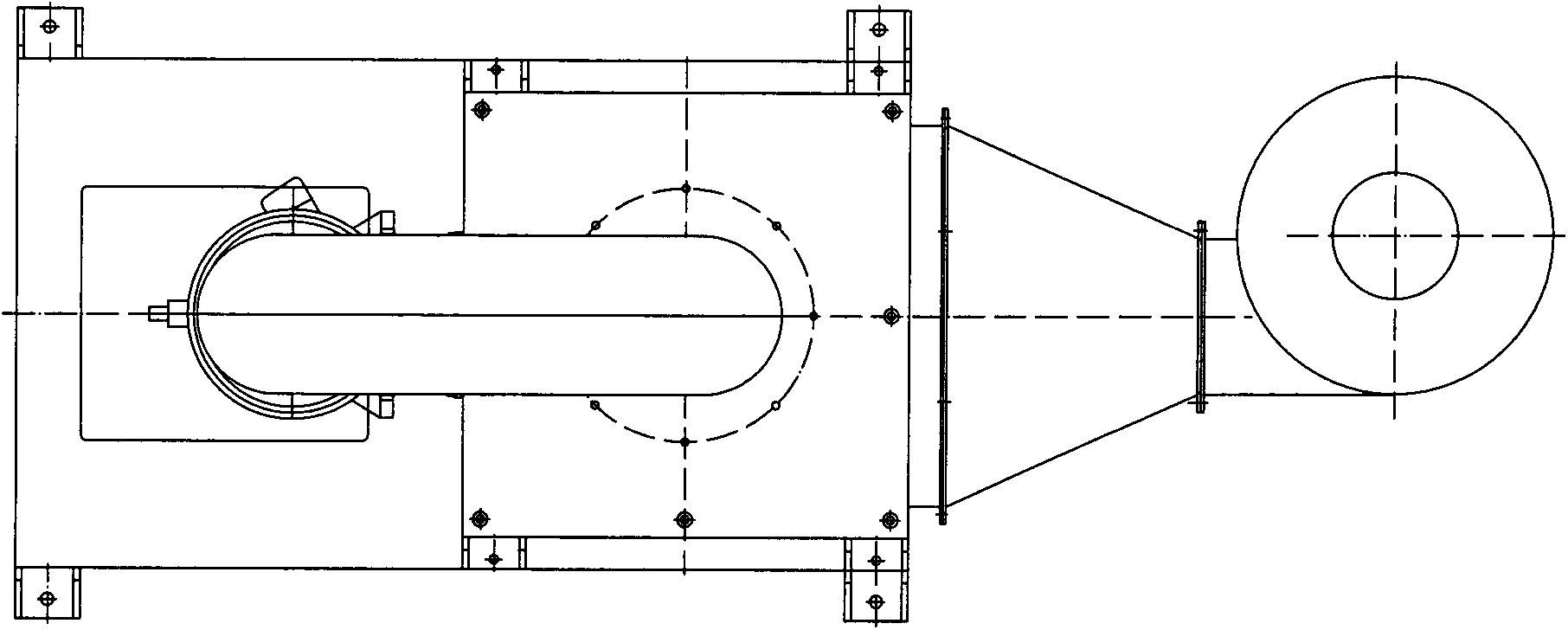

[0013] exist figure 2 Among them, a motor (8) and a cylinder (3) are installed on the base (1), and the cylinder (3) is divided into a lower cylinder fixing seat (3-1) and an upper cylinder (3-2), and the lower cylinder The fixed base (3-1) is fixed on the base (1) with bolts, and the upper cylinder (3-2) is connected with the lower cylinder fixed base (3-1) with bolts. The bottom of the mesh plate (6) is fixedly connected with the lower cylinder fixing seat (3-1) with bolts. The blades (4-1) are L-shaped and fixed to the rotating body (4) with bolts, and the blades (4-1) are arranged in a spiral shape on the rotating body (4). The rotating shaft (5) passes through the center of the rotating body (4), and its upper end is fixed with bolts. A rectangular hole is opened on the side of the mesh plate (6), and one end of the discharge port (11) is facing the square hole, and the other end is exposed outside the device. The lower cylinder holder (3-1) has a square aperture, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com