Antistatic three-layer scratch resistant protective pasting film

An anti-static and protective sticker technology, applied in the field of mobile phone protective film and three-layer anti-scratch protective film, can solve the problems of non-anti-static, decreased bonding yield, affecting consumer use, etc., to achieve high transparency and improve good quality. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

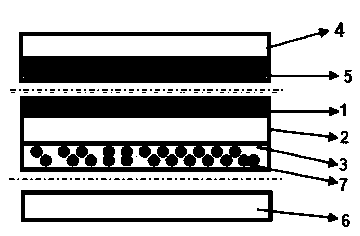

[0029] An antistatic three-layer anti-scratch protective film, the protective layer is the second optical PET film 4 of 50 μm and the second silicone pressure-sensitive adhesive 5 of 15 μm thickness, the viscosity is 1-2g / in; the use layer is the first layer of 100 μm On the optical PET film 1, a 3 μm thick hardened coating 2 is coated, and on the other side of the hardened coating 2, a 25 μm thick first organic silicon pressure-sensitive adhesive 3 is coated, and the viscosity is 5-7g / in; the release layer A third optical PET film 6 of 50 μm was used. Wherein, the first organosilicon pressure-sensitive adhesive 3 contains silver particles of 50-200 nanometers, so that the surface resistance of the adhesive surface is within 10 12 Ω, the static voltage of the use layer is lower than 250 V.

[0030] The anti-static three-layer anti-scratch protective film disclosed by the present invention is applied to the protective film of mobile phones. Nano-silver particles are added to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com